Cantilever Gantry Crane- Single & Double Cantilever Gantry Design

Cantilever gantry crane designed with box girder/ truss girder, single / double beam, one cantilever / double cantilevers ? Better cantilever gantry crane design for you!

| Crane Type | Gantry crane with cantilever designs |

| Crane Capacity | 3 ton-15ton, 15ton -150ton |

| Crane Span | 18-35m, |

| Crane Lifting | 6-18m |

| Working Class | A3-A7 |

Category: Gantry Crane

Your Trusted European Style Gantry Crane Manufacturer & Supplier

Cantilever Gantry Crane for Sale Good Price

Single Cantilever & Double Cantilever Gantry Crane Design

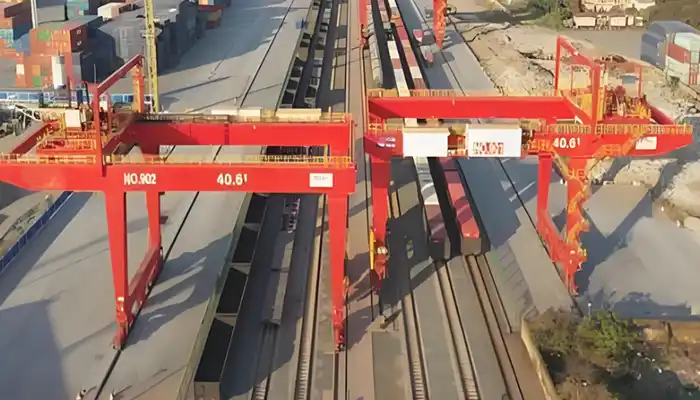

Cantilever gantry crane is one of the most frequently used overhead gantry crane equipment, widely used in variousopen air applications, such as railroad, freight yard, port and shipyard. The main girder beam of overhead gantry crane is outreached at one side or both sides to form cantilever, which extends the length of crane span andincreasesthe coverage of workspace.

Cantilevered Gantry Cranes

What is a Cantilever? A cantilever is a structural element that is supported at one end while the other end extends freely without support. In the context of gantry cranes, the cantilever refers to the horizontal arm that extends from the main frame of the crane, typically to one or both sides. This arm allows the crane to access areas beyond the main frame, providing greater reach and flexibility in its operations.

In simpler terms, a cantilever crane has an arm that sticks out beyond its support base, enabling it to lift and move loads from areas that would otherwise be out of reach. The cantilever structure is crucial in gantry crane design because it can dramatically improve a crane's ability to handle materials in confined spaces, tight corners, or over obstacles. The cantilever design makes the crane more adaptable and versatile, especially in environments where maneuverability is key.

Cantilevers come in different configurations, such as single cantilever (one arm extending from one side) or double cantilever (arms extending from both sides), and their design influences how the crane is used, the types of loads it can lift, and the working environments it is suitable for.

The gantry crane with cantilever gantry design offers the economical overhead travelling crane solution with capacity of up to 500 ton. And main parameters and specifications of the cantilever gantry cranes are presented for your reference and the custom designed cantilever gantry designs are available. Leave a message below to send your gantry crane inquiry.

Double Girder Cantilever Gantry Cranes

Main parameters of double girder cantilever gantry cranes

- Gantry crane types:A frame gantry crane with single cantilever or Double cantilever cranedesign

- Load capacity of cantilever gantry crane: 3 ton-15ton, 15ton -150ton, above150ton

- Span of cantilever gantry crane: 18-35m,

- Lifting height of cantilever gantry crane: 6-18m,

- Work duty of cantilever gantry crane: A3-A7

- Application of cantilever gantry crane:limited space but needs to realize long-distance transportation

Single Girder Cantilever Gantry Cranes

Main parameters of single girder cantilever gantry cranes

- Gantry crane types: Single girder A frame gantry crane with single cantilever or Double cantilever cranedesign

- Load capacity of cantilever gantry crane: 1 ton-20ton,

- Span of cantilever gantry crane: 18-35m,

- Lifting height of cantilever gantry crane: 6-18m,

- Work duty of cantilever gantry crane: A3-A5

- Application of cantilever gantry crane:limited space but needs to realize long-distance transportation

Applications of Cantilevered Gantry Crane

Single cantilever gantry crane is a variationof the regulargantry crane, whichis usually applied in applications where the space are limited such as in metro construction for the hoisting of tunnel muck, vertical transportation of materials and components, such as shield.

Double cantilever gantry cranewith the extensionsat both sides of the main gantry girder ismainly adopted in the placeswhere long-distance transportationis required in a limited working area, such as,road construction, railway, highway, steel mill,an shipbuilding, etc. If a wide range of horizontal operations is needed, a double cantilever gantry crane is recommended.

Why Use Cantilever Gantry Crane?

Large amount of overhead gantry cranes are designed with cantilever, but why to select the cantilever gantry design? Gantry The cantilever of overhead gantry crane is the extended part which outreaches the crane span at one side or both sides and increases the crane runway . The cantilever gantry design has the following advantages :

- Compared with gantry crane without cantilever, the extended crane span with single or double cantilevers makes the hoist trolley convenient to move loads on one side or both sides without affecting normal production within the span. The cantilever gantry designs offers very practical lifting equipment solutions for many applications.

- Little maintenance are needed which minimizes the equipment downtime and eventually improves crane efficiency.

- With optimized design, the gantry crane is light-weightedand has less wheel load pressure.

- Reasonable and compact structure design enables cantilever gantry crane capable of making the most of available workspace.

- Various safety devices are equipped on the cantilever type of gantry cranes to make sure the moving of overhead gantry stably and smoothly.

Gantry cranes can be designed with one or double cantilevers to lengthen the crane girder based on the crane capacity, lifting height and crane span in accordance with the standard ratio, to realized the needs of customers in different application site. Not only the cantilever gantry can meet the lifting requirement of customers, but also it can help to make full use of the material and to reduce the weight. The gantry crane can be designed with one cantilever or double cantilever , with equal or unequal length,all of which depends on the specific circumstances of the freight yard.Cantilever gantry cranes as a type of general purpose overhead travelling cranes commonly adopt a double cantilever gantry structure with equal length or nearly equal length for generally material handling.

Your Trusted Overhead Crane Manufacturer & Supplier

Cantilever Gantry Crane Design

Cantilever gantry cranes with various crane designs and configurations are applied in a variety of industrial applications to improve efficiency and productivity.Cantilever gantry cranes can be grouped into many types in terms of crane girder designs, cantilever designs, types of hoisting mechanism and mounting types, etc. As a reputable gantry crane manufacturerand supplier, we are devoted to provide cost-effective cantilever type gantry cranes solution for valuable customers and clients.

The cantilever in gantry crane design refers to a horizontal arm or structure that extends outward from the main frame, typically on one or both sides of the crane. The cantilever plays a critical role in determining the crane's reach, flexibility, and load-handling efficiency. Here's how the cantilever structure affects the crane's performance:

- Crane Efficiency: The cantilever allows the crane to extend its reach, enabling it to lift and move materials beyond the main span of the crane's frame. This is especially useful in tight or narrow spaces where the crane's main structure can't access the area directly. For example, in unloading cargo from a truck parked in the middle of a warehouse, a cantilever allows the crane to reach over the vehicle, improving the crane's overall operational efficiency.

- Stability and Load Distribution: The cantilever affects the overall stability of the crane, especially when lifting heavy loads. A well-designed cantilever helps distribute the weight more evenly, reducing the risk of tipping. In a double cantilever crane, for instance, both sides of the crane are balanced, providing greater stability when handling larger or unbalanced loads. On the other hand, a single cantilever design can provide greater flexibility but requires careful load management to avoid instability.

- Versatility in Different Environments: The cantilever design is particularly important in specialized environments. In tight, confined spaces where there is limited headroom or a need for lateral movement, a single cantilever crane provides more adaptability, allowing for efficient operation without the need for a large crane structure. For larger sites or outdoor projects, a double cantilever design may be preferred, offering the ability to span wider areas and carry heavier loads with added stability.

The choice of cantilever design impacts how the crane can be used in different operational conditions. It determines how well the crane can navigate through tight spaces, how much weight it can handle, and how much energy is required for operation. As such, understanding the cantilever design is essential for selecting the right crane for your specific application.

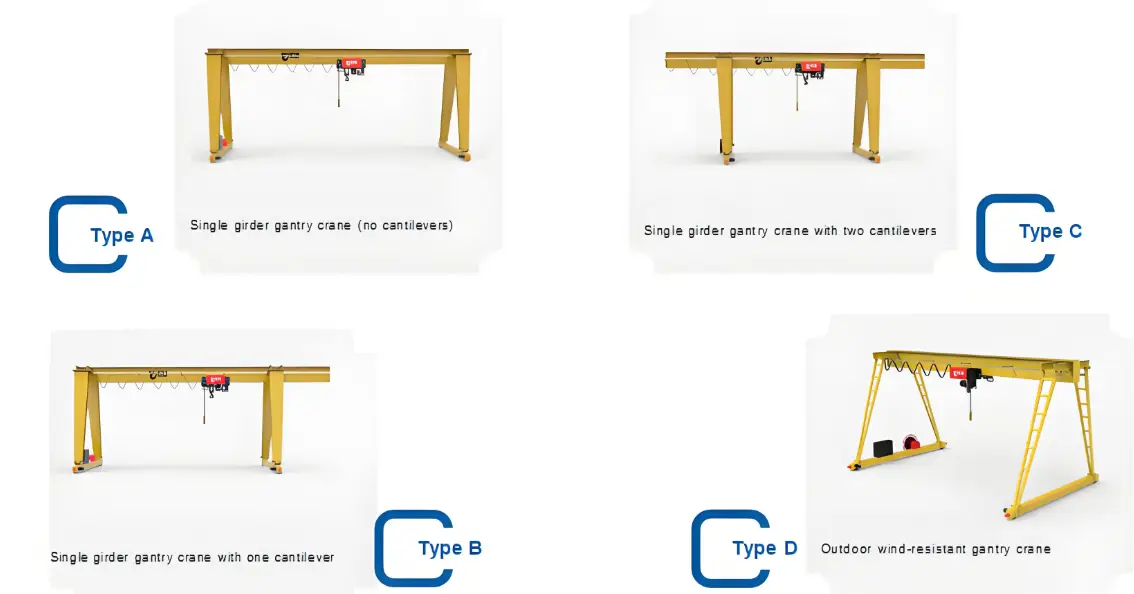

Single Cantilever or Double cantilever or No Cantilever

In terms of cantilever designof gantry frame, gantry crane can be grouped into

- Double cantilever gantry crane - most frequently used structure, which can take full use of the endurance capacity of crane structure and application space reasonably.

- Single cantilever gantry crane - used when the application space is limited.

- Gantry crane with no cantilever - the main girder has no cantilever with the hoisting trolley or winch trolley running within the crane span

Cantilever Design Options of Single Girder Gantry Cranes

Standard Double Girder Gantry Crane with No Cantilever

Standard Gantry Crane: A standard gantry crane does not have any cantilevered arms. The lifting mechanism is fixed within the span of the crane's main structure, meaning the crane operates only within the area directly beneath the bridge. This type of crane is typically used in open spaces or larger work areas where full access to both sides of the crane is available and no additional reach is required beyond the main frame.

Advantages:

- Simpler structure, often more cost-effective.

- Typically used in large, open areas with fewer space restrictions.

- High stability due to the absence of extended cantilevered parts.

Limitations:

- Restricted to moving loads within the span of the main crane frame.

- Less flexible for confined spaces or specific applications requiring reach over obstacles.

Cantilevered Gantry Crane: In contrast, a cantilevered gantry crane features one or more arms that extend outwards, increasing its operational range. This design allows the crane to access areas beyond the main support frame, making it ideal for more specialized applications where space is limited or additional reach is required.

Advantages:

- Increased reach and flexibility for lifting and moving materials from locations that a standard gantry crane might not be able to access.

- Perfect for operations where materials need to be moved over obstacles or around tight corners (e.g., loading trucks parked in the middle of a warehouse).

- More adaptable to smaller or irregularly shaped spaces.

Limitations:

- Typically more complex and costly than standard gantry cranes.

- May require additional structural reinforcement, especially for double cantilever cranes, to maintain stability when lifting heavy loads.

Common Applications of Cantilever Gantry Cranes

Cantilevered gantry cranes are especially useful in environments where the flexibility to reach different areas or maneuver around obstacles is essential. Here are some examples of where cantilever cranes are ideally used:

- Limited Space and Confined Work Areas: In narrow aisles or small workshops, a single cantilever crane can provide the ability to extend the reach of the crane beyond its main frame. This is helpful when the crane needs to operate in spaces where the available headroom is low or where access to only one side of the crane is possible.Example: In a warehouse where trucks park between the main structure and the unloading area, a cantilevered crane can reach over the parked vehicles to unload goods from the truck, making it more efficient than a standard crane that could only operate in the area beneath its frame.

- Loading and Unloading in Tight Spaces: A cantilever crane allows for loading and unloading operations where the crane cannot be positioned directly over the load. By using the cantilever arm, the crane can extend beyond its supports to lift or move materials from challenging positions, especially in areas where there are obstructions or limited clearance.Example: In shipyards or ports, where containers or large equipment must be moved from tight spaces, a cantilever crane can reach over obstacles or onto elevated platforms, allowing materials to be lifted and transported efficiently without the need for moving other equipment or materials.

- Increased Reach for Larger Work Areas: A double cantilever crane can be particularly useful in large-scale projects where a wider span is needed for lifting and moving heavy materials. The added reach allows for the handling of larger objects and longer spans, making the crane capable of covering more area with less repositioning.Example: In construction sites, a double cantilever crane could be used to move building materials, machinery, or structural components across vast areas, such as between construction zones or along the perimeter of a large building.

- Heavy Lifting in Challenging Environmental Conditions: In some industries, such as shipbuilding or petrochemical plants, there are often strict environmental conditions to consider. Cantilever cranes, especially those with double cantilevers, are ideal for handling heavy loads in these types of environments, as the design provides added stability and resilience against wind, vibrations, or other external forces.Example: In oil and gas facilities, cantilevered gantry cranes may be used to move heavy equipment and machinery over large distances, helping with maintenance, installation, or construction tasks in tight or hazardous areas where access is limited.

Overall, the cantilevered design in gantry cranes expands their versatility, making them suitable for specialized and space-constrained tasks where traditional gantry cranes would be less effective. Whether in manufacturing, construction, ports, or other industries, the ability to extend the crane's reach and maneuver around obstacles can significantly improve efficiency and reduce operational costs.

Single Cantilever Gantry Crane

The single cantilever gantry crane is characterized by its design in which a cantilever arm extends from only one side of the crane's main structure. This means that the crane has a structure with a bridge or girder supported by legs or tracks on one side, while the other side is free to extend beyond the frame. The cantilever arm adds extra reach to the crane, allowing it to access areas that would otherwise be out of its standard operating range.

Key design features of a single cantilever gantry crane include:

- Cantilever Arm: The crane features a single arm that extends outward from the main support frame, providing flexibility in accessing materials or areas that may be difficult to reach from the crane's main span.

- Compact and Lightweight Structure: The overall design of the crane is typically more compact and lightweight compared to other gantry cranes with double cantilevers. This makes the crane easier to install and relocate, which is especially important for operations in smaller spaces.

- Reduced Overhead: Because the cantilever extends only on one side, the overall height and span of the crane are usually reduced, allowing for easier integration into environments with limited headroom or space constraints.

Advantages

The single cantilever gantry crane offers several advantages, making it an ideal choice for specific applications:

- Best Suited for Confined Spaces: One of the main benefits of a single cantilever crane is its ability to operate in tight or confined spaces. Since the cantilever extends only on one side, it can be used in areas where there are obstructions or limited clearance, such as narrow aisles, workshops, or warehouse corners. This design allows the crane to reach over objects or barriers, providing flexibility in small environments.

- Simplified Installation and Maintenance: A single cantilever gantry crane is easier to install compared to cranes with more complex structures (such as double cantilever cranes). The simpler design means there are fewer components and moving parts, which can reduce both installation time and costs. Additionally, maintenance is more straightforward because there are fewer points of potential wear or failure, making it easier and less expensive to maintain the crane in good working order.

- Reduced Energy Consumption: Because the crane's structure is lighter, it consumes less energy during operation compared to heavier, more complex cranes. The reduced weight means that the crane's lifting system (including the motor and electrical components) doesn't need to work as hard to move the crane or lift loads, improving overall energy efficiency. This can result in lower operational costs and a more eco-friendly solution for material handling.

Applications

A single cantilever gantry crane is best suited for applications where work needs to be performed only on one side of the crane's span. Here are some examples of common uses:

- Small-Scale Operations: In smaller workshops or manufacturing plants, where space is limited, a single cantilever crane can be used to move materials or equipment within a confined area. For example, a small repair shop might use a cantilever crane to lift parts and machinery into place, allowing workers to operate efficiently without taking up too much floor space.

- Narrow Workshops: In a narrow workshop or factory where space is at a premium, a single cantilever crane is ideal for accessing the work area from only one side. It can also help with precise, localized lifting tasks without the need for additional space or crane movement.

- Unloading Vehicles: A classic application of a single cantilever gantry crane is in situations where the crane needs to load or unload materials from vehicles. For instance, if a truck is parked in the middle of a warehouse or workshop, a cantilever arm can extend over the truck to offload materials, making it possible to work without needing to reposition the vehicle.

- Material Handling in Small Workshops: In operations such as metalworking, assembly lines, or small-scale construction tasks, the single cantilever crane can serve as an efficient solution to move materials or equipment to the desired location without requiring an oversized crane system.

Considerations

While the single cantilever gantry crane offers many benefits, there are also certain considerations that must be taken into account before choosing this design:

- Limited Span and Lifting Capacity: Due to its lightweight design and single-arm configuration, a single cantilever crane typically has a smaller span and lower lifting capacity than cranes with double cantilevers or larger designs. This means that it may not be suitable for handling very large or heavy loads, or for applications that require extensive reach across a large area.Example: In a construction environment where heavy steel beams need to be lifted over a wide area, a single cantilever crane may struggle with both the weight and span requirements. A double cantilever or a standard gantry crane may be more appropriate in such cases.

- Structural Limitations in Windy or High-Load Environments: The structural design of the single cantilever crane may present challenges when operating in areas subject to high winds or heavy-duty lifting conditions. The cantilever arm creates additional leverage on the crane's frame, potentially making it more vulnerable to tipping or instability when lifting heavy or off-center loads. In such environments, additional structural reinforcement may be needed, or a more robust crane design (such as double cantilever or standard gantry cranes) may be more appropriate.Example: In outdoor environments such as ports or shipyards, where wind resistance is a factor and heavy loads are common, the single cantilever crane may not be the best option. The added flexibility of a double cantilever crane would provide better stability and load handling.

In summary, the single cantilever gantry crane is a highly efficient, flexible, and cost-effective solution for confined spaces and applications where the crane needs to operate on one side of the working area. Its compact design and simplified structure make it ideal for small-scale operations and specific tasks like unloading vehicles or working in narrow workshops. However, careful consideration of the crane's lifting capacity and environmental conditions is essential to ensure that it will meet the demands of the job without compromising stability or performance.

Double Cantilever Gantry Crane

The double cantilever gantry crane is a more robust and versatile design compared to the single cantilever crane. In this configuration, the crane features cantilever arms on both sides of the main support structure, providing a balanced load distribution. This design ensures that the crane's weight and lifting capacity are more evenly spread, which enhances its overall stability and lifting capabilities.

Key design features of a double cantilever gantry crane include:

- Dual Cantilever Arms: The crane is equipped with cantilever arms on both sides of the main bridge or girder. This allows for increased operational flexibility, as it can span larger areas and reach over obstacles from both sides.

- Larger, More Robust Structure: Compared to single cantilever cranes, double cantilever gantries have a heavier, sturdier design. The inclusion of two cantilevers adds structural integrity, allowing the crane to handle much larger loads and resist more significant stresses.

- Balanced Load Distribution: The dual cantilever arms ensure that the crane's load is evenly distributed, reducing the risk of tipping or instability. This is particularly beneficial when lifting heavy or off-center loads, as the design minimizes uneven force distribution.

Advantages

The double cantilever gantry crane offers numerous advantages, making it a preferred choice for demanding applications in large-scale industries:

- Enhanced Stability: One of the primary advantages of the double cantilever crane is its improved stability. With cantilever arms on both sides, the crane is better equipped to handle larger and heavier loads, especially in wide work areas. This design helps maintain a low center of gravity, reducing the risk of tipping even under challenging operational conditions.Example: In large manufacturing plants or construction sites, the enhanced stability of a double cantilever crane ensures that it can lift heavy beams or equipment safely without the risk of the crane swaying or tipping.

- Ability to Handle Larger Spans and Greater Lifting Capacities: The double cantilever design enables the crane to span wider areas, making it suitable for large-scale operations that require extensive reach. This crane can handle greater lifting capacities, making it ideal for industries that deal with large and heavy materials, such as shipping yards, steel mills, or construction sites.Example: A double cantilever crane would be perfect for unloading containers at a shipping port, where the need to lift heavy, oversized loads over large distances is common.

- Superior Resistance to Wind and Environmental Stressors: Because of its more robust structure and dual cantilevers, the double cantilever gantry crane offers superior resistance to environmental stressors, including high winds or harsh weather conditions. This makes it especially suitable for outdoor environments, where other crane designs might struggle to maintain stability.Example: In shipbuilding yards or coastal ports, where wind and environmental factors are often a concern, the double cantilever crane provides the necessary stability and durability to continue operations safely and efficiently.

Applications

The double cantilever gantry crane is best suited for large-scale projects and environments that require high efficiency, flexibility, and the ability to handle significant lifting capacities. Some of its common applications include:

- Large-Scale Projects: This type of crane is commonly used in industries like construction, heavy manufacturing, and shipbuilding, where heavy and oversized loads need to be moved over long distances. The crane's ability to span larger areas and handle heavy materials makes it ideal for such large-scale tasks.Example: A double cantilever crane could be used to transport massive structural components for building construction or infrastructure projects, where high load capacities and large spans are required.

- Open Yards and Shipping Yards: Due to its extended reach and ability to handle heavier loads, the double cantilever gantry crane is ideal for open yards or shipping yards, where large containers, materials, or goods need to be moved efficiently.Example: In a port facility, this crane can load and unload containers from ships with greater precision and stability, enabling quick turnaround times and maximizing operational efficiency.

- Industries Requiring High Efficiency and Wider Reach: The crane is also well-suited for assembly lines or production lines in industries that require precise material handling over large areas. Its ability to cover a greater distance and carry heavier loads makes it ideal for automotive plants, steel production facilities, or logistics operations.

Considerations

While the double cantilever gantry crane offers many benefits, there are certain factors to consider before choosing this design for your operation:

- Higher Construction and Maintenance Costs: Due to the more complex structure and larger size, double cantilever cranes come with higher initial construction costs compared to single cantilever cranes. Additionally, their maintenance requirements can be more demanding, as the crane's larger size and additional components mean more wear and tear over time. Regular maintenance checks, lubrication, and part replacements may be necessary to keep the crane operating efficiently.Example: In a large-scale steel mill, although the double cantilever crane is crucial for lifting large beams and equipment, the high maintenance costs may require careful budgeting for regular upkeep and repairs.

- Larger Footprint and More Complex Installation: The footprint of a double cantilever crane is significantly larger than that of a single cantilever crane. This means it requires more space for installation and operation. The crane's size also means that the installation process is more complex and may require specialized equipment and a longer setup time.Example: In tight or congested environments such as small industrial plants or narrow workshops, the large footprint of a double cantilever crane might not be feasible without significant adjustments to the site or the need for larger spaces.

- May Not Be Necessary in Spaces Where Only One Side Requires Operation: In some environments, the need for a double cantilever crane may be overkill. If only one side of the workspace needs crane operation, a single cantilever crane might provide sufficient reach and lifting capacity while saving on installation and operational costs.Example: In small warehouses or assembly areas where material handling is limited to one side of the crane, the more complex double cantilever design might not be necessary.

In conclusion, the double cantilever gantry crane is ideal for large-scale operations requiring high efficiency, significant lifting capacities, and the ability to span wide areas. Its enhanced stability, ability to handle larger loads, and superior resistance to environmental stressors make it an excellent choice for applications in open yards, ports, shipping facilities, and large industrial projects. However, the higher construction, maintenance costs, and space requirements mean it's most suitable for large-scale, high-demand operations where the benefits outweigh the added costs.

Your Trusted Cantilever Gantry Crane Manufacturer & Supplier

Hot Sale Cantilever Gantry Crane Types and Features

Various Designs of Cantilevered Gantry Cranes

Cantilevered Single girder vs. Double girder Gantry Cranes

In terms of crane girder construction,there are single girdercrane design&double girdercrane design for your selectionbased on thepractical lifting requirements and needs.

- Cantilever gantry crane with single girder crane design is featured as simple structure, easymanufacturingand installation, and light self-weight. Compared with doublebeam crane designs, the overall stiffness of single beam gantry crane is weakerand usually used when the loads Q≤50tonand the span S≤35m.

- Cantilever gantry craneswith double girder crane design is the most frequently used structure design, with the features of strong bearing capacity, large span, good overall stability, andcoming in many varieties, but the self-weight of the double beam gantry crane is larger and theirprocessingcost is higher compared with single beamgantry cranes

Cantilever gantry crane with box girder single beam gantry crane design

Load capacity: 3-50t

Span: 8-35m

Lifting height: 6-18m

Work duty: A3, A4

Cantilever gantry crane with box girder double beam gantry crane design

Load capacity: 5-500t

Span: 18-35m

Lifting height: 6-18m

Work duty: A3-A7

Box girder vs. Truss girder Gantry Crane with Cantilever Design

In terms of metal structure designs of crane girders, the cantilever type gantry crane can be designed in to box type and truss gantry crane :

- Box type cantilever gantry is welded withsteel plates , with featuresof high safety, stiffness and other, etc. . Box type cantilever gantry is usuallywith largeand super largetonnages.The box gantry girder designalso has the drawbacksof high production cost, heavy selfweightand poor wind resistance.

- Truss type cantilever gantry is welded with angle steel or I-beam, featured aslowmanufacturing cost, light self-weight, and good wind resistance. However, the truss gantry girder has the disadvantages of large deflection, low rigidity, low reliability, and frequent welding spots detection. Due to easy fabrication, the box type cantilever gantry crane accounts for the majority.

Cantilever gantry crane with truss girder single girder gantry crane design

Lifting capacity of:3.2-32tons

Span of truss crane :12-30m

Lifting height:6-9m

Working class:A3-A5

Cantilever gantry crane with truss girder double beam crane design

Lifting capacity:5-100tons

Span:22-40m

Lifting height:6-9m

Working class:A3-A5

Full Gantry vs. Semi Gantry Crane with Cantilever Design

In terms of structures of gantry frame, we supply full type gantry crane and semi gantry crane for your selection.

- Full gantry crane is adouble legged gantry crane with main girder supported on the two legs, which are in the same height.

- Semi gantry crane is asingle leg gantry crane, with the other end of the main girder supported on the building structure, widely applied in places where the space is an issue.

Full gantry crane with cantilever design

Semi gantry crane with cantilever design

Rail Mounted vs Rubber Tired Gantry Crane with Cantilevers

According to the mounted type of cantilever gantry cranes or the way it moves, the cantilever type gantry cranes can be grouped into rail mounted and rubber tiredgantry crane:

- Rail mounted cantilever gantry crane runs on and along the gantry rails fixed on ground, with the working area of rmg crane limited by the coverage of the gantry rail.

- Rubber tiredcantilever gantry crane is running on rubber tires,which enable the rtg cantilever craneable to move in 9 directions with more flexibility in lifting and transportation.

Cantilever gantry with rail mounted gantry crane design

Cantilever gantry with rubber tyred gantry crane design

Your Trusted Overhead Crane Manufacturer & Supplier

Pros and Cons of Different Cantilever Designs

No Cantilever, Single Cantilever & Double Cantilever Gantry Crane Design

When selecting the most suitable gantry crane for your needs, it's essential to weigh the benefits and drawbacks of each cantilever design. Below is a concise summary of the pros and cons of single cantilever, double cantilever, and no cantilever crane designs, helping you make an informed decision based on your specific operational requirements.

Single Cantilever Gantry Crane

Pros:

- Space-Saving: The single cantilever design allows for more efficient use of space, making it ideal for confined areas or where only one side of the crane needs to operate.

- Energy-Efficient: With a lighter structure, single cantilever cranes typically consume less energy compared to double cantilever cranes, making them cost-effective in long-term operation.

- Simple Maintenance: The simpler design makes the crane easier to maintain and service, reducing downtime and maintenance costs.

Cons:

- Limited Lifting Capacity and Span: The single cantilever design typically has smaller spans and lower lifting capacities, making it unsuitable for large-scale operations or when handling very heavy loads.

- Less Stability: Single cantilever cranes can be less stable, especially in windy conditions, due to the unbalanced load distribution created by the cantilever arm on only one side.

Double Cantilever Gantry Crane

Pros:

- Large Span: Double cantilever cranes offer a wider operational range, making them ideal for large workspaces, including open yards and shipping ports.

- High Stability: The presence of cantilever arms on both sides provides superior stability, reducing sway and improving safety, especially when lifting heavy loads or working in windy conditions.

- Better Wind Resistance: With two cantilever arms, the crane's structure can withstand greater wind forces, making it suitable for outdoor environments or areas with harsh weather conditions.

Cons:

- High Initial Cost: Double cantilever cranes tend to have higher upfront costs due to the larger, more complex structure and the additional components required.

- Complex Installation: The design's complexity results in more involved installation processes, requiring additional time and resources for setup.

No Cantilever Gantry Crane

Pros:

- Simple and Cost-Effective: The design of a no cantilever crane is simple, leading to lower initial costs and easier installation. It's a great choice when budget and straightforward functionality are priorities.

- Good for Large Symmetrical Spaces: These cranes are ideal for symmetrical and open spaces, where both sides of the crane need to be accessible for operations, such as in large industrial facilities or warehouses.

Cons:

- Less Versatile in Tight or Specialized Spaces: The lack of cantilevers reduces the crane's ability to operate in confined or asymmetrical spaces. It is not well-suited for situations where only one side of the workspace is accessible or when a crane needs to operate in narrow aisles.

In summary, each gantry crane design offers distinct advantages and challenges. Single cantilever cranes are best for tight spaces and energy-efficient operations but have limitations in span and lifting capacity. Double cantilever cranes are optimal for larger areas with high stability and greater load capacity but come with higher costs and more complex installation requirements. No cantilever cranes, while simpler and more cost-effective, are best suited for symmetrical spaces and may lack flexibility in more confined environments.

Choosing the right crane depends on your specific space constraints, lifting needs, environmental conditions, and budget considerations. By evaluating these factors, you can select the crane design that best fits your operational requirements.

Here's the revised table with the Single Cantilever Gantry Crane, Double Cantilever Gantry Crane, and No Cantilever Gantry Crane as the first line headers:

| Criteria | Single Cantilever Gantry Crane | Double Cantilever Gantry Crane | No Cantilever Gantry Crane |

|---|---|---|---|

| Pros | Space-saving: Ideal for confined areas where only one side operates. | Large span: Can cover wider work areas, ideal for large-scale projects. | Simple and cost-effective: Lower initial cost and easier installation. |

| Energy-efficient: Lighter structure reduces energy consumption. | High stability: Better load distribution, ideal for lifting heavy loads. | Good for large symmetrical spaces: Ideal for large, open, symmetrical environments. | |

| Simple maintenance: Easier to maintain and service. | Better wind resistance: Can withstand harsh environmental conditions. | ||

| Cons | Limited lifting capacity: Not suitable for large-scale operations or heavy loads. | High initial cost: More expensive due to the larger structure and components. | Less versatile: Not suitable for confined or asymmetrical spaces. |

| Limited span: Restricted operational range compared to double cantilever cranes. | Complex installation: Requires more time and resources to install. | Limited flexibility: Cannot operate in areas where only one side is accessible. | |

| Less stability: Unbalanced load distribution, especially in windy conditions. |

This layout provides a side-by-side comparison of the pros and cons for each crane design, helping you quickly identify the key benefits and limitations of each.

Factors to Consider When Choosing a Gantry Crane Cantilever Design

Selecting the right gantry crane cantilever design is a critical decision that impacts both operational efficiency and long-term reliability. Several factors should be considered to ensure the chosen design meets the specific needs of your business, facility, and environment. Below are the key factors to consider when choosing between single cantilever, double cantilever, or no cantilever gantry cranes:

Workspace Size and Shape

The size and layout of your workspace are some of the most significant factors influencing crane design. These factors directly affect the crane's reach, stability, and overall functionality.

- Narrow Spaces: In facilities where space is limited, a single cantilever crane may be the ideal choice. The crane's compact design allows it to operate efficiently in confined areas, such as small workshops or areas with obstacles along one side. It provides more flexibility to maneuver within the available space, making it easier to reach difficult-to-access areas.Example: A small factory floor with limited headroom or obstructions on one side of the workspace might benefit from a single cantilever design to ensure efficient operations within the tight space.

- Large Open Areas: For larger workspaces, such as shipping yards, construction sites, or large manufacturing plants, a double cantilever crane is often preferred. The crane's extended arms on both sides provide an increased range, allowing for broader coverage of the area and the ability to handle large spans or complex tasks.Example: A shipyard where materials need to be lifted across a wide space may benefit from the additional reach and stability offered by a double cantilever crane.

- Symmetry and Access: If the workspace is symmetrical, with equal access to both sides of the crane, a no cantilever crane might be sufficient. These cranes are ideal when operations need to span across a large open area and when both sides of the crane need to be accessible for lifting tasks.Example: A warehouse with wide aisles and no significant obstructions may benefit from a no cantilever gantry crane that offers full reach across the entire span of the workspace.

Load Capacity Requirements

Different cantilever designs have varying capacities and load-distribution characteristics, so it's essential to match the crane's design with your lifting needs.

- Single Cantilever Cranes: These cranes tend to have a lighter structure and are best suited for moderate load capacities. The cantilever arm adds some complexity to the load distribution, so the crane may not be able to handle heavy or uneven loads as efficiently as a double cantilever or no cantilever design.Example: A small machine shop requiring the lifting of lighter loads, such as tools or smaller components, could efficiently use a single cantilever crane without sacrificing performance.

- Double Cantilever Cranes: A double cantilever crane offers the advantage of better load distribution across the two cantilever arms. This design provides enhanced stability and can handle heavier loads over large spans. It is ideal for high-capacity operations, where load distribution and lifting power are crucial.Example: In a shipping yard or construction site, where heavy materials need to be lifted over a large span, a double cantilever crane offers the strength and capacity to handle the job without compromising safety.

- No Cantilever Cranes: These cranes offer strong load distribution due to the simple, robust structure, and they tend to have higher lifting capacities than cantilever cranes with similar design features. However, they are better suited for more balanced loads in symmetrical spaces.Example: Steel fabrication plants or large automotive manufacturing facilities, where heavy loads such as metal sheets or automobile parts need to be lifted, would benefit from the straightforward design of a no cantilever crane.

Environmental Conditions

The operational environment significantly influences the crane's design selection, particularly in terms of wind resistance, temperature extremes, and exposure to corrosive elements.

- Wind Resistance: A double cantilever crane provides better wind resistance and stability, especially in outdoor environments like ports or construction sites. The cantilever arms on both sides of the crane help balance the structure, reducing the risk of swaying and improving safety during lifting operations in windy conditions.Example: A shipping terminal located in a coastal area with frequent strong winds would benefit from the enhanced stability of a double cantilever crane to ensure safe lifting operations.

- Temperature Extremes and Corrosion: For cranes operating in areas with extreme temperatures or corrosive environments (such as chemical plants or oil refineries), it's essential to consider materials and coatings that prevent corrosion and ensure structural integrity. While the cantilever design itself may not impact the crane's performance directly in terms of temperature extremes, the overall design complexity and exposure to the environment will affect maintenance and durability.Example: A no cantilever crane designed with anti-corrosion materials and coatings would be ideal in a chemical plant where both the materials and the crane are exposed to harsh environmental factors.

Installation and Maintenance Considerations

The installation and ongoing maintenance of a gantry crane depend heavily on the design complexity and the specific needs of the workspace.

- Single Cantilever Cranes: These cranes offer a simple design that is relatively easy to install and maintain. With only one cantilever arm, the crane's structure is lighter, and the maintenance is typically less complex. This design is often a good choice for businesses with limited technical expertise or resources for crane installation.Example: A small workshop or production facility where ease of installation and minimal downtime is important may opt for a single cantilever crane to keep costs low and ensure smooth operation.

- Double Cantilever Cranes: While double cantilever cranes provide more extensive functionality, they also have a more complex installation process due to the additional components and the need for a larger structure. Maintenance costs can also be higher, as the more intricate design requires more detailed inspections and adjustments over time.Example: Large construction projects or industrial plants requiring high-capacity cranes may accept the higher installation and maintenance costs for the added efficiency and load-bearing capacity.

- No Cantilever Cranes: These cranes are generally the easiest to install due to their straightforward design. There are fewer parts to assemble, and the crane can be up and running quickly. Additionally, because of the absence of cantilevers, maintenance is relatively simple compared to more complex designs.Example: General industrial applications, such as warehouses or automotive assembly lines, can benefit from the ease of installation and low maintenance requirements of a no cantilever gantry crane.

Economic and Efficiency Factors

The final decision on gantry crane design often hinges on cost-effectiveness and energy efficiency. The crane design directly impacts both initial investment costs and long-term operating expenses.

- Initial Costs: The no cantilever crane generally has the lowest initial cost due to its simpler structure, making it an attractive option for budget-conscious businesses. Single cantilever cranes fall in the middle, while double cantilever cranes tend to have the highest upfront costs due to their larger, more complex design.Example: A small-scale business with limited budget and space may prioritize a no cantilever crane to reduce capital expenditure while still maintaining necessary lifting capacity.

- Energy Efficiency: Single cantilever cranes often consume less energy than larger double cantilever cranes due to their lighter design. However, double cantilever cranes offer greater lifting capacity, which could improve operational efficiency in large-scale operations, even if they consume more energy during operation.Example: A high-efficiency manufacturing plant requiring frequent, heavy lifting might invest in a double cantilever crane for long-term energy savings despite its higher energy consumption per operation.

Choosing the right gantry crane cantilever design requires balancing factors like workspace size, load capacity, environmental conditions, installation and maintenance complexity, and economic considerations. Each design offers unique benefits and limitations that must align with the specific needs of your operations. By thoroughly evaluating these factors, you can make a more informed decision and select the crane that optimally supports your business's lifting requirements.

FAQs about Cantilever Designs in Gantry Cranes

Choosing the right cantilever design for your gantry crane can raise several questions, especially when deciding between single cantilever, double cantilever, or no cantilever cranes. Below are some common questions and concerns about these designs, along with helpful tips for addressing specific technical challenges.

1. What is the primary difference between single, double, and no cantilever gantry cranes?

- Single Cantilever Crane: Has one cantilever arm on one side of the crane. It's ideal for confined spaces where operations are only needed on one side of the crane.

- Double Cantilever Crane: Features cantilever arms on both sides of the crane, allowing for better load distribution and increased stability. This design is suited for large, open spaces with heavy-duty lifting requirements.

- No Cantilever Crane: This design does not feature cantilever arms, offering a simple and straightforward design. It works best in symmetrical spaces and is often used in larger industrial facilities with balanced operations.

2. Which cantilever crane design is best for tight spaces or small workshops?

For tight spaces or small workshops, a single cantilever crane is usually the best choice. It allows operations on one side of the crane, making it ideal for areas with limited space. It's also easier to install and maintain due to its compact design.

Tip: Ensure that your space allows for the crane to operate efficiently within the limited span, as single cantilever cranes have a smaller lifting range compared to double cantilever cranes.

3. What is the lifting capacity difference between single, double, and no cantilever cranes?

- Single Cantilever Crane: Typically has a lower lifting capacity compared to double cantilever cranes due to its smaller structure and limited span.

- Double Cantilever Crane: Designed for higher lifting capacities, especially in areas requiring larger spans and greater stability. This design distributes the load evenly across both arms, making it more suited for heavy-duty lifting.

- No Cantilever Crane: The lifting capacity is generally consistent across the span and is typically sufficient for medium to large loads. However, it does not offer the same flexibility as cantilever cranes in terms of workspace usage.

Tip: If heavy lifting is required, consider a double cantilever crane to ensure safe handling and stability.

4. How do environmental conditions, such as wind or temperature, affect crane performance?

- Wind Resistance: Double cantilever cranes offer better wind resistance because the load is distributed evenly on both sides, providing added stability in open areas or exposed outdoor conditions.

- Temperature Extremes: All cranes, especially those with cantilevers, should be designed with materials that can withstand temperature extremes. However, cranes operating in cold or extreme environments might require additional anti-corrosion coatings and reinforced materials.

Tip: For outdoor use or environments with extreme weather, a double cantilever crane offers better resilience against these challenges.

5. How does crane design affect installation and maintenance?

- Single Cantilever Crane: Generally easier and quicker to install because of its simpler structure. Maintenance is also more straightforward due to fewer moving parts and components.

- Double Cantilever Crane: While offering superior lifting capabilities and stability, this design is more complex to install and maintain. The crane's structure needs careful alignment, and maintenance might require more time and specialized support.

- No Cantilever Crane: Easiest to install and maintain, as it is the simplest of the three designs. It requires less attention to detail during installation and has fewer parts that might wear out over time.

Tip: For easy maintenance and quicker installation, choose a single cantilever or no cantilever crane, depending on your operational needs.

6. Can I upgrade or modify my crane design later to add a cantilever?

Upgrading an existing crane to add a cantilever is typically not recommended, especially for no cantilever cranes, as the structural modifications required could be costly and complex. Adding a cantilever to a single cantilever crane or double cantilever crane would depend on the original design and load-bearing capacities.

Tip: It's better to choose the most suitable crane design upfront to avoid costly modifications down the line. If you anticipate changing needs, consult with the manufacturer about the possibility of future upgrades before purchasing.

7. What are the cost implications of each crane design?

- Single Cantilever Crane: Typically the most cost-effective design, offering lower initial costs and reduced installation complexity.

- Double Cantilever Crane: Higher initial cost due to the more complex design and higher materials needed. Installation and maintenance also tend to be more expensive.

- No Cantilever Crane: The cost is generally moderate, with lower initial expenses compared to double cantilever cranes but potentially higher than single cantilever cranes, depending on the span and load requirements.

Tip: Consider long-term costs, such as maintenance and energy efficiency, when deciding between crane designs.

8. What should I do if I'm unsure about which crane design to choose?

If you're uncertain about which design is best for your project, consulting with an expert is always a good idea. A crane manufacturer or engineer can assess your specific needs, including space requirements, load capacity, environmental factors, and operational efficiency.

Tip: Before making a decision, also conduct a site survey to better understand your facility's layout and future operational demands.

These FAQs should help guide your decision-making process when selecting a gantry crane with the right cantilever design. Keep in mind the specific needs of your operation and the unique challenges of your work environment to ensure the crane you choose is efficient, safe, and cost-effective for the long term.

Conclusion: Making the Right Choice for Your Needs

Choosing the right gantry crane design for your operation is critical to maximizing efficiency, ensuring safety, and controlling costs. Whether you need a single cantilever, double cantilever, or no cantilever crane, each design comes with its own set of advantages and considerations. Here's how you can make the best decision for your specific needs:

Final Recommendations: How to Assess Your Project's Requirements and Select the Ideal Cantilever Design

Evaluate the Space Available:

- For constrained spaces or when you only need to operate on one side of the load, a single cantilever crane can be the most efficient choice.

- In open, expansive work areas, especially where stability and large spans are needed (e.g., shipyards or construction sites), a double cantilever crane is ideal.

- If you're working in symmetrical, large facilities where the crane needs to cover the entire space evenly, a no cantilever crane offers a simple, cost-effective solution.

Consider Load Requirements:

- For lighter, more manageable loads, a single cantilever crane may be sufficient.

- For heavier, more dynamic loads, a double cantilever crane provides superior load handling capabilities and stability.

- No cantilever cranes are best for standard, balanced lifting tasks that don't require specialized flexibility but need to cover long distances.

Understand Environmental Conditions:

- Wind resistance and environmental stressors (e.g., outdoor operations) should be considered when selecting a design. Double cantilever cranes excel in environments prone to wind or heavy-duty work.

- In indoor environments or where space is limited, single cantilever or no cantilever cranes are usually more practical, cost-effective choices.

Project Scope:

- Small to medium-scale projects or narrow spaces benefit from the space-saving and lightweight design of a single cantilever crane.

- Large-scale operations with extensive lifting needs are better suited for a double cantilever design, offering larger spans and higher lifting capacities.

- Symmetrical layouts, like in large manufacturing plants, favor the simplicity and efficiency of no cantilever cranes.

Expert Advice: Consulting with a Crane Manufacturer or Engineer

Selecting the right crane design isn't just about choosing between different types based on specs. It's important to consult with a crane manufacturer or engineer who can assess your specific operational needs and the environmental factors affecting crane performance. Experts will help you:

- Design customization: Tailor the crane's design to your unique operational requirements, considering factors such as lifting capacity, span, and load distribution.

- Safety and compliance: Ensure that the crane adheres to local safety regulations and industrial standards.

- Operational efficiency: Help you choose a design that maximizes productivity while minimizing energy consumption, wear, and tear on components.

By involving professionals in the planning and decision-making process, you can ensure that the crane design will not only meet current needs but also be adaptable to future demands.

Long-term Considerations: Focus on Durability, Efficiency, and Maintenance Over Time

While initial costs and immediate operational requirements are important, long-term durability and maintenance should also be top priorities when selecting a crane design. Consider the following:

- Durability: A well-designed crane should have a long service life, even under demanding conditions. Choose materials and designs that resist wear, corrosion, and environmental stress.

- Efficiency: Evaluate the crane's energy consumption and operational costs. A more efficient design will reduce long-term operating costs and improve the overall economic benefit of your project.

- Maintenance: Consider the ease of maintenance for the selected crane design. Single cantilever cranes typically require less maintenance due to their simpler design, while double cantilever cranes may need more frequent checks due to the complexity of their structure. No cantilever cranes generally have the least amount of maintenance needs but may lack the flexibility offered by other designs.

- Parts availability: Ensure that you have access to replacement parts and support services over the crane's operational life. A reputable manufacturer should offer strong after-sales support to keep the crane running smoothly over the years.

The key to choosing the right gantry crane design is understanding your specific operational needs, workspace conditions, and future maintenance requirements. Take the time to assess your facility, load types, and environmental factors carefully. By consulting with industry experts and focusing on the long-term impact of your decision, you can ensure that your crane will provide reliable performance, operational efficiency, and cost savings for years to come.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch