KBK Light Crane System for Sale, 1Ton KBK Crane for Philippines

KBK light crane system for sale Philippines. Custom 1 ton kbk crane system , with electric chain hoist, pendant control, columns, 54 m travelling length.

| Crane type | freestanding light kbk crane system |

| Crane specifications | 1T-9.5M H4M |

| Travelling length | 54 m |

| Power supply | 400V60HZ3P |

Category: Light KBK Crane

Your Trusted Overhead KBK Light Crane Manufacturer & Supplier

KBK Light Crane System for Sale, 1Ton KBK Crane for Philippines

KBK light crane system for sale Philippines. Custom 1 ton kbk crane system , with electric chain hoist, pendant control, columns, 54 m travelling length.

Overview of 1 ton crane for sale Philippines

- Crane type: 1 ton kbk light crane system

- Crane specifications: 1T-9.5M H4M,

- Crane travelling length: 54m

- Crane columns: provided

- Crane power: 400V60HZ3P

- Application: Workshop

- Project location: Philippines

Enhancing Workshop Efficiency with KBK Light Crane System in the Philippines

In the dynamic landscape of material handling equipment, the KBK Light Crane System has emerged as a revolutionary solution, particularly in the context of optimizing workshop operations. This case study delves into the successful implementation of a 1-ton KBK Light Crane System in a workshop setting in the Philippines, highlighting its benefits, specifications, and impact on efficiency.

Background and lifting requirements of material hanlding in Philippines

The client, a leading industrial workshop in the Philippines, sought to improve its material handling processes to enhance productivity, reduce downtime, and streamline operations. The company was focused on finding a reliable and efficient solution that would cater to its specific needs.

The existing manual material handling methods in the client's workshop were causing inefficiencies and operational delays. Heavy lifting was being done manually, leading to potential safety hazards for workers and slowing down production. The client required a modern material handling system that could seamlessly integrate into their existing setup, reducing human effort and improving overall operational efficiency.

Solution: KBK Light Crane System for sale Philippines

The solution proposed was the installation of a 1-ton KBK Light Crane System. This system featured an electric chain hoist, pendant control, columns, and an impressive 54 meters of travelling length. The crane's specifications included a 1-ton lifting capacity with a 9.5-meter height of lift, adhering to H4M standards. The power requirement for the system was 400V, 60Hz, 3-phase, perfectly suitable for the workshop's power infrastructure.

How to get custom kbk light crane system :

- Assessment and Customization:The KBK Light Crane System was customized to meet the specific needs of the workshop. The 1-ton lifting capacity was determined based on the average load requirements in the facility.

- Installation:Professional technicians oversaw the installation process. The columns were strategically placed to optimize the coverage area, ensuring smooth movement of the crane along its 54-meter travelling length.

- Testing and Training:Rigorous testing was conducted to ensure that the crane system operated flawlessly and safely. Additionally, comprehensive training was provided to the workshop staff to familiarize them with the operation of the KBK Light Crane System and its safety protocols.

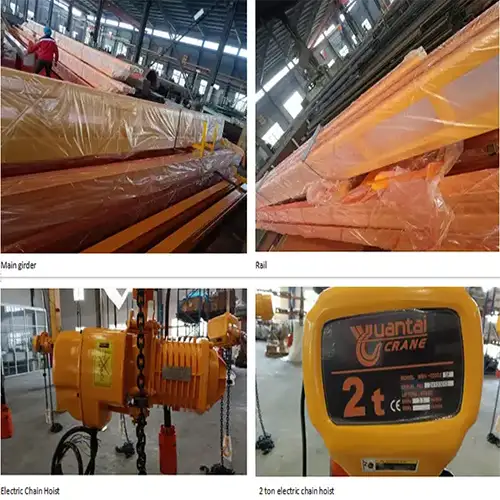

Main parts and components of 1 ton KBK Light Crane System

The 1-ton KBK Light Crane System comprises several main parts and components that work in harmony to facilitate efficient and safe material handling. These components are designed to provide flexibility, ease of operation, and customization options to cater to specific industrial needs. Here are the main parts and components of a typical 1-ton KBK Light Crane System:

Rails (KBK Profile Sections):

The rails, often referred to as KBK profile sections, are the foundational components of the system. These aluminum or steel profiles form the track along which the crane moves. They are available in various profiles and lengths, allowing customization to fit the layout of the facility.

Runway Systems:

The runway systems consist of the rails and supporting structures that provide the overhead track for the crane to move along. The rails are securely attached to the supporting structures, ensuring smooth and stable movement.

End Carriages:

End carriages are wheel assemblies that attach to the rails and support the entire crane system. These carriages house the wheels that run along the rails, allowing the crane to travel horizontally. The end carriages are often motorized to facilitate easy movement.

Bridge Girder:

The bridge girder is the horizontal beam that connects the end carriages. It supports the hoisting mechanism and spans the gap between the rails, enabling the crane to move back and forth along the track.

Hoisting Mechanism:

The hoisting mechanism is responsible for lifting and lowering loads. In the case of a 1-ton KBK Light Crane System, this mechanism typically consists of an electric chain hoist. The hoist is mounted on the bridge girder and has a hook or other lifting attachment for securing the load.

Trolley:

The trolley is a movable mechanism that travels along the bridge girder. It supports the hoisting mechanism and allows the load to move horizontally across the span of the crane. The trolley is controlled by the operator and is an essential component for precise positioning of the load.

Control System:

The control system includes the controls and switches that allow the operator to maneuver the crane and its various functions. It can include pendant controls, radio remote controls, or even automated control systems depending on the level of automation desired.

Electrification System:

The electrification system provides power to the crane and its various components as they move along the track. This system typically includes festooning or conductor bars that carry electrical power to the moving parts of the crane, ensuring continuous operation without interruption.

Column or Support Structures:

Column or support structures provide vertical support for the crane system. They are strategically positioned along the track and are responsible for carrying the weight of the rails, runway systems, and the loads being lifted.

Accessories and Attachments:

Various accessories and attachments can be added to the KBK Light Crane System based on the specific application. These might include load stabilizers, rotation devices, specialized lifting attachments, or even cameras for enhanced visibility.

The combination of these components creates a versatile and efficient material handling solution tailored to the needs of the industrial environment. The 1-ton KBK Light Crane System offers a balance of lifting capacity, mobility, and precision, making it suitable for a wide range of workshop and production scenarios.

1 ton electric chain hoist for 1 ton kbk light crane system for sale Philippines

1 ton light kbk crane system electric chain hoist

Light kbk crane system crane rail for sale

Crane columns of 1 ton light kbk crane system for 54 m travelling length

Crane power supply line for 54 m travelling 1 ton crane kbk system

Main parts and components of 1 ton light kbk crane system

1000kg light kbk crane system parts:pendant control

Main parts and components of 1 ton kbk crane system for sale Philippines

Benefits of using kbk light crane system :

The implementation of the KBK Light Crane System yielded significant benefits for the workshop:

- Enhanced Efficiency:The system's precision and ease of operation significantly reduced material handling time, leading to an increase in overall workshop efficiency.

- Safety:The electric chain hoist and pendant control eliminated the need for manual lifting, reducing the risk of workplace injuries and ensuring the safety of the workforce.

- Space Optimization:The design of the KBK Light Crane System allowed for maximum utilization of the workshop space, contributing to an organized and clutter-free environment.

- Flexibility:The crane's 54-meter travelling length ensured that it could cover a wide area within the workshop, accommodating diverse material handling needs.

- Customization:The ability to customize the system to the workshop's requirements highlighted its adaptability to specific operational demands.

The successful installation of the 1-ton KBK Light Crane System in the Philippines workshop exemplified the positive impact of modern material handling solutions on industrial operations. The client experienced heightened efficiency, improved safety standards, and optimized space utilization. This case study underscores the value of investing in advanced material handling systems to drive productivity and elevate workplace safety.

Related Products

Latest project

Workshop Overhead Crane 5 Ton & 10 Ton Buying Guide

Practical guide for selecting, installing, and maintaining 5 ton to10 ton workshop overhead cranes for safe, efficient, and reliable material handling.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch