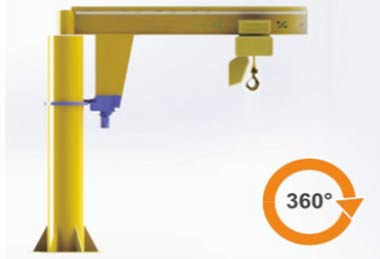

Rotating jib crane : Rotary crane design with slewing jib arm

Rotating jib cranes -floor & wall jib cranes- flexible swing or rotating jib arm & rotary crane design, 180, 270 &360 degree rotating jib crane for sale.

| Crane Type | Slewing jib crane |

| Crane Capacity | 0.5 ton -16 ton |

| Crane Span | 8 m |

| Crane Lifting | 3-8m |

| Degree of Rotating | 180 degree, 270 degree & 360 degree |

Category: Jib Crane

Your Trusted Rotating Jib Crane Manufacturer & Supplier

Rotating Jib Cranes

Floor & Wall Jib Cranes with 180, 270 &360 Degree Rotating Design

Swing Jib Cranes and Rotating Cantilever Cranes

Swing jib cranes are versatile lifting devices used for handling materials in various industrial and commercial settings. They consist of a horizontal jib that swings around a vertical pillar, allowing for efficient movement of loads within a specified range. These swing cranes are popular in environments where space is limited or where precise material handling is required.

Swing jib cranes come in two main designs: full rotation and limited rotation. Full rotation jib cranes can turn a full 360 degrees, providing complete access around their base. Limited rotation jib cranes, on the other hand, typically offer a rotation range of between 180 and 270 degrees. Each design offers unique advantages tailored to different operational needs.

Importance of Understanding Rotation Capabilities in Crane Design

Understanding the rotation capabilities of swing jib cranes is crucial for selecting the right crane for your specific application. The rotation degree directly impacts how the crane performs in your workspace, affecting both its efficiency and effectiveness.

- Full Rotation Cranes: Ideal for large or open areas where the ability to handle materials from any direction around the base is beneficial. These swing cranes enhance flexibility and productivity, allowing operators to access and move loads without repositioning the crane.

- Limited Rotation Cranes: Better suited for confined or specific areas where a full 360-degree rotation is unnecessary. They offer space-saving benefits and are generally more cost-effective, but require careful planning to ensure they meet the handling needs within their rotation limits.

Choosing the right rotation design ensures that the crane fits well within your space, enhances operational efficiency, and meets your material handling requirements effectively.

Rotating Systems- Manual & Electric Motor Driven Rotating

rotating jib cranes are optional with manual rotating & electric motor driven rotating with the rotating degree of 90, 180, 270 ,360 degree according to your requirements.With motor driven design, the rotation of the rotating jib crane can be controlled by a pendant control with all motion buttons which is hard wired in to the electric hoist/ jib crane with a low voltage to ensure safety, and a remote radio control is also an option which enable the crane operator to operate the crane in a safety distance from the loads and crane.

Manual rotating jib crane

floor mounted type:

Capacity up to 2 ton,

Length: up to 4 m,

Jib rotating: 180/ 270 degree

Hosting: manual or electric

Electric column type jib crane

Floor mounted type :

Capacity up to 16 ton,

Length: up to 7 m,

Jib rotating: 180/270 / 360 degree

Hosting: manual or electric

Manual rotating jib crane

wall mounted type:

Capacity up to 2 ton,

length up to 4 m,

Jib rotating: , 180 degree

Hosting: manual or electric

Tie Rod rotating jib crane wall mounted on type

Capacity up to 2 ton,

Length up to 6 m,

Jib rotating:1 80 degree

Hosting: manual or electric

Your Trusted Rotating Jib Crane Manufacturer & Supplier

Rotating Jib Crane for Sale

Full Rotation Swing Jib Cranes (360°)

Full rotation jib cranes are equipped with a mechanism that allows the jib to rotate a complete 360 degrees around the base. This design includes a rotating column or base that supports the horizontal jib arm, which can swing fully around the central pillar. The rotation is typically powered by a combination of electrical motors and gear systems that enable smooth and continuous movement. This design ensures that the crane can access and handle materials from any direction without requiring the crane itself to be repositioned.

Full rotation jib cranes (360°) can be either manual swing or electric swing, depending on the specific design and application requirements:

- Manual Swing: This type of crane requires the operator to manually push or pull the jib arm to rotate it. Manual swing is typically used for lighter loads and in situations where precise positioning is less critical or where electric power might not be readily available.

- Electric Swing: An electric motor powers the rotation of the jib arm, allowing for smoother and more precise movement. Electric swing is generally used for heavier loads, high-frequency operations, or when precision and ease of movement are important.

The choice between manual and electric swing will depend on the load capacity, frequency of use, required precision, and available power sources.

Typical Applications and Environments of 360° Swing Jib Cranes

Full rotation jib cranes (360°) are designed for environments where extensive flexibility and complete coverage are crucial. These swing cranes are capable of rotating a full circle around their base, allowing for the efficient handling of materials in all directions. This makes them particularly valuable in several key applications:

- Manufacturing Plants: In manufacturing settings, full rotation jib cranes are ideal for managing large or heavy materials throughout assembly lines and production areas. They offer comprehensive reach, enabling operators to maneuver items seamlessly from one workstation to another without needing to reposition the crane base. This is especially beneficial in facilities with complex production processes where different stages require materials to be moved frequently and accurately.

- Warehouses: In large storage environments, such as warehouses, These swing cranes enhance efficiency by enabling the swift movement of goods and materials. The full 360-degree rotation allows operators to access inventory from any angle, facilitating quicker loading and unloading. This flexibility minimizes the need for additional equipment or manual labor, optimizing the use of space and improving overall workflow.

- Ports and Shipping Yards: Full rotation jib cranes are crucial in ports and shipping yards, where they assist in loading and unloading cargo. The ability to handle materials from multiple directions is invaluable when positioning heavy or bulky items onto ships or trucks. This versatility reduces turnaround time and enhances operational efficiency in these high-traffic environments.

These swing cranes are best suited for large, open areas where their full rotation capability can be fully exploited. The unrestricted movement provided by 360-degree swing jib cranes makes them indispensable for industries that require versatile, robust solutions for handling diverse loads and materials efficiently.

Benefits of 360° Swing Jib Cranes

- Complete Coverage: The ability to handle materials in all directions around the base offers unparalleled flexibility. With 360° rotation, operators can move and position loads without needing to relocate the crane, which significantly enhances operational efficiency. This feature is especially useful in environments where the handling of materials needs to be performed quickly and smoothly across a wide area. By allowing full access to all parts of the workspace, the crane minimizes downtime and ensures that materials are always within reach, thereby improving overall workflow.

- Enhanced Flexibility: Full rotation capability means the crane can easily maneuver around obstacles and operate in tight spaces without frequent repositioning. This is particularly advantageous in environments with complex layouts or where space is at a premium. The ability to rotate completely allows for precise load placement, which reduces the time spent adjusting the crane's position and minimizes the risk of accidents or damage to nearby equipment. This flexibility ensures that the crane can adapt to various tasks and environments, making it a versatile tool in diverse applications.

- Increased Productivity: By eliminating the need for constant crane repositioning, 360° swing jib cranes streamline material handling processes. This leads to faster operation cycles, as operators can handle multiple tasks in succession without pausing to adjust the crane's location. The result is increased throughput and higher overall productivity. In high-demand settings, such as manufacturing plants, warehouses, and shipping yards, this efficiency boost can significantly impact the bottom line by reducing labor costs and improving turnaround times.

Overall, the benefits of 360° swing jib cranes make them an excellent choice for industries that require a versatile, efficient, and adaptable material handling solution.

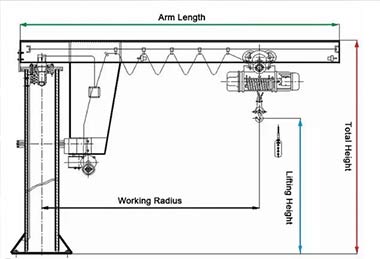

Floor Mounted Swing Jib & Free Standing Rotating Jib Crane

The floor mounted or free standing jib crane is a swing crane or rotating jib crane which can be designed with full rotation of 360 ° with maximum coverage in 360°areas and also can be provided with 180 degree's rotation and 270 degree's rotation.The swing jib arms and loads are supported by the column or pillar which is functioned as a fulcrum, centered by the cantilever to rotate around which has the hoist and loads running along.Under loading, the torque mainly works on the column and cantilever which requires the foundation of the column must be strong enough to support them, therefore customized design is needed. Contact us to get your customized rotating jib crane drawing now. The floor mounted swivel cranes can be your ideal choice for short distance material handling with intense of handling work.

Main Parameters of Floor Mounted Rotating Jib:

rotating crane type: floor mounted jib crane or free standing jib crane

- Lifting capacity of rotating jib:0.5-16 ton

- Cantilever design: full cantilever, drop cantilever, i beam, box girder, enclosed track beam cantilever

- Rotation type of swing jib cantilever: Manual or motor driven

- Degree of rotating jib crane : 180 degree, 270 degree & 360 degree

- Lifting height of rotating jib:3-8m

- Maximum rotating radius of rotating jib crane : 8 m

- Optional jib hoists: electric , manual, chain hoist or wire rope hoist

- Working class of rotating jib:A3 A4

- Ambient temperature of rotating jib: -20-40℃

- Customized free standing jib crane with specific crane parameters and specifications are available.

360 degree rotating jib crane design

Full cantilever jib crane with rotating jib

360 degree rotating jib crane design

Box girder free standing crane with gear rotating jib

360 degree rotating jib crane design

Drop cantilever tie rod jib crane with H beam girder

Portable 360 ° Rotating Jib Crane

The portable rotating jib crane is a movable jib crane or rotating jib cranewith 360°rotating jib arms, which has a manual jib hoist or electrical jib hoist with capacity of 0.08 ton, 0.125 ton, 0.25 ton, 0.5 ton and 1 ton, 110 volt single phase or 240-480 volts, 3 phase. For the portable crane design, the portable rotating jib crane offers a very flexible lifting crane solution for small and light duty material handling , due to the unique jib structure design, safe &reliable operation, time & energy saving , high efficiency and flexibility, cost-effective.

Main Parameters of Portable Jib Crane

- Slewing crane types: Portable jib cranes on wheels, equipped with manual jib hoist or electric jib hoists

- Rated load of portable rotating crane : 0.08t, 0.125, 0.25t, 0.5t, 1 ton

- Lifting height of portable rotating crane : 1.5m, 2m, 3m

- Turning radius of portable rotating crane : 2m, 3m

- Rotation angle of portable rotating crane : 360°

- Rotary way of portable swing jib crane : electric or manual

360 degree rotating portable jib crane design

Full cantilever rotating jib crane with H beam girder

360 degree full rotating portable jib crane on roller design

Fall cantilever rotating jib crane with electric chain jib hoist

Full rotation tie rod drop cantilever portable jib crane

Tie rod drop cantilever jib with rotating arms

Considerations of 360° Swing Jib Cranes

When choosing a 360° swing jib crane, there are several important factors to consider to ensure that it is the right fit for your operational needs.

- Space Requirements: Full rotation jib cranes require ample space around the base to perform their full range of motion effectively. This unrestricted movement allows the crane to access materials from any angle but also necessitates a clear, obstacle-free area around its base. In smaller or more confined work environments, such as compact workshops or densely packed manufacturing floors, accommodating the full rotation can be challenging. There needs to be sufficient clearance not only for the crane's arm to rotate without interference but also for safe operation and movement of personnel and other equipment. Before selecting a full rotation jib crane, it's crucial to evaluate the spatial layout of the installation site to ensure that there is adequate room for the crane to operate safely and efficiently.

- Cost Factors: The advanced design and rotation mechanisms of 360° swing jib cranes generally require a higher initial investment compared to limited rotation models. The increased cost is due to several factors, including the complexity of the mechanical components needed to facilitate full rotation, such as additional bearings, motors, and structural reinforcements. Moreover, These swing cranes often incorporate more sophisticated control systems to handle the enhanced maneuverability, adding to the overall cost. Maintenance costs can also be higher over the lifespan of the crane due to the additional wear and tear on these components. Regular maintenance and potential repairs for the rotational mechanisms, bearings, and motors can contribute to increased operational expenses. Therefore, it's important to weigh the benefits of full rotation against these higher costs. In applications where full coverage and flexibility significantly enhance productivity and efficiency, the investment may be justified. However, in environments where such extensive maneuverability is not crucial, a limited rotation jib crane might provide a more cost-effective solution without compromising performance.

In summary, while 360° swing jib cranes offer numerous operational advantages, careful consideration of space and cost requirements is essential to determine whether they are the best choice for your specific application. Analyzing these factors in the context of your operational needs and constraints will help ensure that you select a crane that optimizes both functionality and investment.

Your Trusted Overhead Crane Manufacturer & Supplier

Rotating Jib Crane for Sale

Limited Rotation Jib Cranes (180°-270°)

Limited rotation jib cranes are designed to rotate within a restricted range, typically between 180 and 270 degrees. This rotation is controlled by a pivot mechanism that allows the jib arm to swing back and forth within this specific angle. Unlike full rotation cranes, these models are built with a stationary or semi-stationary base, meaning the arm does not complete a full circle around the central pillar. The mechanism usually involves a combination of gears and bearings that ensure smooth and precise movement within the limited range.

Limited rotation jib cranes (180°-270°) can also be either manual swing or electric swing, similar to full rotation jib cranes:

- Manual Swing: These swing cranes are manually operated by the user to rotate the jib arm within the specified range. Manual swing is common for lighter loads or applications where power supply is limited or not necessary. It is also suitable for environments where the crane does not need to move frequently or rapidly.

- Electric Swing: Electric swing jib cranes use an electric motor to control the rotation of the jib arm within the limited range (180°-270°). This type is preferred for heavier loads, high-frequency use, or applications requiring more precise control and ease of movement.

The decision between manual and electric swing for limited rotation jib cranes depends on factors such as the weight of the loads, the frequency of crane use, the desired level of control and precision, and the availability of electric power.

Typical Applications and Environments of 180°-270° Swing Jib Cranes

Swing jib cranes with limited rotation, typically between 180° to 270°, are ideal for environments where full rotation is impractical due to space limitations or specific operational needs. These swing cranes provide focused coverage and are best suited for a range of applications:

- Small Workshops: In compact workshop environments, where space is limited, a swing jib crane with a full 360-degree rotation could be too cumbersome, potentially interfering with other equipment or nearby obstacles. Limited rotation swing jib cranes are perfect for these settings, offering just the right amount of movement to handle tasks efficiently without requiring extensive space. This setup ensures effective material handling and load positioning within a confined area, optimizing both safety and space utilization.

- Assembly Stations: In assembly lines, where work is often focused within a specific area, swing jib cranes with limited rotation are particularly advantageous. These swing cranes allow for precise handling of parts and tools necessary for repetitive tasks, minimizing unnecessary movements and enhancing operational efficiency. By focusing on a set area, swing jib cranes reduce the need for constant repositioning, making them ideal for streamlined workflows in assembly operations.

- Material Handling in Confined Spaces: Swing jib cranes are also well-suited for environments where space is tight, and the crane needs to operate alongside other machinery or equipment. The limited rotation capability ensures that the crane can move materials and perform tasks within a restricted range without causing interference with surrounding operations. This makes swing jib cranes an excellent choice for warehouses, workshops, or manufacturing facilities where space efficiency and careful maneuvering are crucial.

These applications highlight how swing jib cranes with limited rotation are particularly useful in environments where tasks are repetitive and confined to a specific workspace. Their focused rotation capability makes them a practical choice for efficient material handling and operational precision.

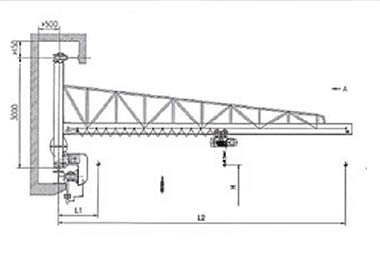

Wall Mounted Rotating Jib Cranes

Wall mounted jib cranes with rotating jibs is an economical overhead travelling crane solutions for light duty loads handling in workshops. The wall mounted rotating jib cranes can be mounted on the walls, columns or other supporting structures existing in the workshop which will save your crane cost and building investment. The wall crane with rotating jib arm does not need to take your floor space or a concrete floor foundation due to the simple structure and light self-weight, which is a good alternative and a economical lifting crane of free standing jib cranes.

Main Parameters of Wall Mounted Rotating Jib Cranes

- rotating crane type: wall mounted jib crane with rotating jibs

- Beam design of the swing crane: H type beam / kbk beam/ enclosed track beam (1-7 meter )

- rotating degree of swing crane:180 / 270 degree

- Jib hoist design of swing crane: chain jib hoist or wire rope jib hoist

- Load capacity design of swing crane: 1 ton - 5 tons

- lifting height design of swing crane: 3-9 meter

- Mounting type of swing crane: H beam, column beam or wall

- Contact Supplier Get latest price

180°-270° rotating wall jib crane design

Wall mounted rotating jib crane with H beam

180°-270° rotating wall jib crane design

Wall mounted rotating jib crane with enclosed track cantilever

180°-270° rotating wall jib crane design

Tie rod jib crane embraced on H beam column

Benefits of 180°-270° Swing Jib Cranes

- Space Efficiency: Swing jib cranes with limited rotation, typically between 180° and 270°, are specifically designed for use in confined or clearly defined workspace areas. The reduced swing range allows These swing cranes to operate effectively without the need for a large operating radius. This makes them ideal for tight or crowded environments, such as small workshops, manufacturing stations, or areas with numerous pieces of equipment. Their compact design ensures that they can maneuver efficiently without interfering with nearby operations or requiring significant space clearance.

- Cost-Effectiveness: Limited rotation swing jib cranes are generally more affordable than their full rotation counterparts. The simpler design of These swing cranes, which includes fewer mechanical components, results in a lower initial investment. Additionally, their reduced complexity often translates to lower maintenance and operational costs over time. These swing cranes offer a cost-effective solution for businesses that need reliable material handling within a specific range, without the higher expenses associated with full rotation models.

- Focused Coverage: With a rotation range that is specifically confined to a certain degree, swing jib cranes with limited rotation are highly efficient for tasks that are concentrated within a defined area. This focused operation makes them perfect for applications where material handling needs are localized, such as assembly lines or dedicated workstations. By limiting the crane's movement to a particular zone, These swing cranes minimize unnecessary repositioning, thereby enhancing task efficiency and reducing operational downtime. This targeted approach ensures that materials are handled swiftly and precisely, optimizing workflow in environments with specific handling requirements.

Considerations of 180°-270° Swing Jib Cranes

- Rotation Limitations: The main limitation of swing jib cranes with a 180° to 270° rotation range is their restricted motion. These swing cranes cannot handle materials beyond their specified swing range, which can pose challenges in operations requiring extensive reach. For tasks that involve moving items outside of this rotation range, operators may need to reposition the crane or employ additional equipment, such as forklifts or conveyors, to access areas that the crane cannot reach directly. This limitation necessitates careful planning to ensure that the crane's operational range aligns with the specific handling requirements of the workspace.

- Operational Adjustments: To address the constraints of limited rotation, it may be necessary to make operational adjustments based on the layout and requirements of the workspace. This could involve strategically positioning the crane to maximize its effective range or incorporating supplementary tools and equipment to extend its functionality. For example, in a tightly packed workshop, arranging the crane to cover the most critical areas or using additional lifting devices can help compensate for its restricted rotation. Ensuring that the crane's capabilities align with the operational needs will require thoughtful planning and coordination to maintain efficiency and productivity in the workspace.

Practical Applications and Space Considerations

Freestanding Jib Crane with rotating design for sale : 500kg to 20 ton freestanding jib crane & cantilever jib crane designs

Full Rotation Jib Cranes

Best Suited For: Full rotation jib cranes are ideal for large production facilities, expansive warehouses, and other environments where there is ample space for unrestricted crane movement. These swing cranes thrive in open areas where their 360-degree rotation can be fully utilized to maximize operational efficiency.

Examples of Applications:

- Large-Scale Material Handling: In extensive warehouses or distribution centers, full rotation jib cranes can handle and move bulk materials with ease, providing complete access around the base to streamline loading and unloading processes.

- Comprehensive Assembly Lines: In manufacturing plants with complex assembly lines, These swing cranes offer flexibility by allowing workers to position materials from any direction, enhancing workflow and reducing downtime.

- Extensive Storage Areas: Full rotation jib cranes are beneficial in large storage facilities where they can efficiently access and manage stored goods across a wide area, minimizing the need for crane repositioning and improving overall storage management.

Limited Rotation Jib Cranes

Ideal For: Limited rotation jib cranes are best suited for smaller or more constrained spaces where full rotation is not practical or necessary. They are designed to operate effectively within a defined swing range, making them a good fit for environments where space is limited or where tasks are concentrated in specific areas.

Examples of Applications:

- Compact Workshops: In smaller workshops or manufacturing spaces, limited rotation jib cranes provide efficient material handling within the available area, allowing for precise and focused operations without requiring a full rotation.

- Specific Task Stations: These swing cranes excel in environments where tasks are performed in designated zones, such as assembly or maintenance stations, where the crane's limited swing range aligns well with the operational needs.

- Tight Manufacturing Environments: In tight manufacturing settings where space is at a premium, limited rotation jib cranes offer a practical solution for handling materials efficiently within a confined footprint, improving workflow without necessitating extensive space for crane movement.

Wall Mounted Electric Jib Crane With Electric Wire Rop Hoist - Wall Mounted Rotating Jib Crane with 180 degree limited rotation design

Your Trusted Jib Crane Manufacturer & Supplier

Rotating Jib Crane for Sale

How to Get Your Swing Crane Design: Analysis for Clients

Operational Efficiency

Comparing How Each Crane Design Impacts Material Handling Speed, Flexibility, and Overall Productivity

When selecting a swing crane, it's crucial to evaluate how each design influences operational efficiency:

Full Rotation Cranes:

- Material Handling Speed: Full rotation cranes enhance material handling speed by allowing operators to move and position loads from any direction without needing to reposition the crane. This results in faster completion of tasks and reduced downtime.

- Flexibility: These swing cranes provide maximum flexibility, adapting easily to various handling tasks and layouts. They are ideal for environments with high variability in material handling needs.

- Overall Productivity: Increased flexibility and reduced need for repositioning translate into higher productivity. Full rotation cranes can handle complex tasks more efficiently, leading to streamlined operations and higher throughput.

Limited Rotation Cranes:

- Material Handling Speed: While limited rotation cranes may not match the speed of full rotation models in some applications, they still offer efficient handling within their designated swing range. The need for repositioning might impact overall speed.

- Flexibility: The flexibility is constrained to the rotation range, making These swing cranes suitable for specific tasks or confined spaces where full rotation is unnecessary. They are effective in focused operational scenarios.

- Overall Productivity: Productivity is optimized within the defined rotation range. For tasks concentrated in specific areas, These swing cranes provide effective solutions without the need for more complex systems.

Cost vs. Benefit

Weighing the Trade-offs Between the Higher Cost and Greater Flexibility of Full Rotation Cranes Against the Cost-Effectiveness and Space-Saving Benefits of Limited Rotation Cranes

Full Rotation Cranes:

- Higher Costs: The complexity of the design and the advanced rotation mechanism result in a higher initial investment and potentially higher maintenance costs.

- Greater Flexibility: The benefits include superior flexibility and reduced need for crane repositioning, which can justify the higher cost in applications requiring versatile and high-volume material handling.

Limited Rotation Cranes:

- Cost-Effectiveness: Generally more affordable due to their simpler design and fewer moving parts. Lower initial and maintenance costs make them a budget-friendly choice for specific applications.

- Space-Saving Benefits: These swing cranes are ideal for constrained spaces, offering efficient material handling without requiring extensive operational space. The lower cost combined with space-saving advantages provides practical benefits for smaller or specialized environments.

Space Optimization

Evaluating How Each Crane Design Fits Within the Spatial Constraints of Your Facility

Full Rotation Cranes:

- Space Requirements: These swing cranes need sufficient space around the base to accommodate the full 360-degree swing. Ensure your facility has the necessary clearance to allow for unobstructed rotation and optimal crane performance.

- Impact on Layout: Consider how the crane's rotation might influence the layout and organization of your workspace. Full rotation cranes require careful planning to integrate effectively into the facility without causing congestion.

Limited Rotation Cranes:

- Space Efficiency: Designed for environments where space is limited, These swing cranes operate efficiently within a restricted swing range. They are well-suited for confined areas where full rotation is impractical.

- Integration into Layout: Evaluate how the crane's limited rotation range fits within your existing layout. Limited rotation cranes can be integrated into tighter spaces, allowing for more efficient use of available area without compromising operational needs.

Application Suitability

Aligning Crane Design Features with Specific Operational Needs

Full Rotation Cranes:

- Load Handling Requirements: Ideal for applications that involve handling large or diverse loads from various directions. Ensure the crane's capacity and range align with your specific load requirements.

- Frequency of Use: Suitable for high-frequency operations where flexibility and quick access are essential. Assess the expected usage to determine if the investment in a full rotation crane provides a significant advantage.

Limited Rotation Cranes:

- Load Handling Requirements: Effective for handling loads within a specific range and within defined zones. Match the crane's rotation range and capacity with the typical load handling needs of your operation.

- Frequency of Use: Best for scenarios with lower frequency or specialized tasks within a confined area. Evaluate the crane's performance in relation to the frequency and nature of use to ensure it meets your operational needs effectively.

By thoroughly analyzing these factors, you can select the swing crane design that best aligns with your operational requirements, space constraints, and budget considerations, ensuring optimal performance and value for your facility.

Recommendations for Selecting the Right Crane

Based on Specific Application Conditions:

- High Flexibility Needs: If your operations require handling materials from multiple directions or involve complex workflows, a full rotation jib crane may be the best choice. Its versatility will enhance material handling speed and productivity.

- Defined Task Zones: For operations focused on specific tasks within a restricted area, a limited rotation jib crane offers an efficient solution. It provides targeted coverage while minimizing costs and fitting well within confined spaces.

Space Availability:

- Ample Space: In facilities with sufficient space for a full range of motion, a full rotation crane can optimize handling processes and improve efficiency. Ensure that there is enough clearance around the crane to accommodate its full rotation.

- Constrained Spaces: In smaller or more confined environments, a limited rotation crane is ideal. It maximizes space utilization while providing effective material handling within its designated range.

Budget Considerations:

- Higher Budget: If your budget allows for a higher initial investment and you require advanced flexibility, a full rotation crane will provide significant benefits in terms of operational efficiency and productivity.

- Cost Constraints: For a more cost-effective solution, especially in smaller or specialized environments, a limited rotation crane offers a practical choice with lower initial and operational costs.

Case Studies: Examples of Successful Crane Installations

We offer a comprehensive collection of case studies that highlight successful installations of both full rotation (360°) and limited rotation (180°-270°) jib cranes across various industries. These case studies provide detailed insights into how different crane designs have been strategically implemented to enhance operational efficiency, boost productivity, and optimize space utilization.

Full Rotation Jib Cranes (360°):

- Automotive Manufacturing: A leading car manufacturer installed a full rotation jib crane to streamline the assembly process. The 360° rotation capability allowed workers to handle parts and components from any angle, reducing the need for repositioning and significantly speeding up the workflow. The case study details how this improved operational efficiency by 30%, reduced labor costs, and minimized production downtime.

- Large-Scale Warehousing: In a large distribution center, a full rotation jib crane was installed to handle heavy pallets and containers. The crane's ability to rotate fully around its base allowed for seamless movement of goods across multiple loading zones, enhancing space utilization and reducing the time required to move inventory. The study outlines how the installation led to a 40% increase in throughput and a 20% reduction in handling time.

Limited Rotation Jib Cranes (180°-270°):

- Compact Workshops: A precision machining company with limited floor space opted for a limited rotation jib crane with a 180° swing. This setup provided efficient coverage for their specific machining area without obstructing other equipment. The crane's focused range of motion ensured precise material handling within a confined space, boosting productivity and reducing the risk of accidents. The case study highlights a 25% increase in efficiency and a notable reduction in equipment wear and tear.

- Specific Task Stations: In a small-scale manufacturing plant, a 270° jib crane was deployed to manage tasks at dedicated workstations. This crane's restricted range was ideal for loading and unloading materials at the station without affecting adjacent areas. The case study illustrates how this targeted application led to more efficient use of space and a 15% cost saving on crane operations.

Process Rotating Jib Crane Design, Economical Jib Crane Price

Customized jib cranes with process crane design and particular jib crane specifications for your specific applications are the most cost-effective jib crane solutions.

In order to give your specific quotation quickly, could you please send us the inquiry with the details of the jib crane for us to quote of wall mounted jib crane:

- The type of the jib crane : Free standing jib , Wall mounted jib, or Wall travelling jib?

- Lifting capacity of jib crane: 0.08 ton ,0.25 ton, 0.5 ton, 1 ton, 2 ton, 3 ton , 4 ton, 5 ton , 10 ton , 16 ton?

- Lifting height of jib crane: ____m?

- Valid Radius (the jib length)of jib crane: ____m?

- The rotating angle of jib crane: Manual or electric rotating? 180, 270, 360 or other degree?

- Hoisting trolley: Electric or manual? Chain or wire rope hoist?

- The power voltage of jib crane:____?

If you do not know about how to select the jib crane, please feel free to leave us a message or email to us. The reply of our jib crane engineer will be given within 24 hours. Contact us to get the free jib crane design drawing and specific pillar jib crane price .

Conclusion: Contact Us to Get Your Customized Rotating Jib Cranes

Key Differences Between Full Rotation and Limited Rotation Jib Cranes

- Full Rotation Jib Cranes: These swing cranes offer 360-degree rotation, providing maximum flexibility and efficiency for handling materials from any direction. They are best suited for large production facilities, extensive warehouses, and environments with ample space where their full rotation can be fully utilized. They offer benefits in speed, flexibility, and overall productivity but come with higher costs and space requirements.

- Limited Rotation Jib Cranes: With rotation typically restricted to 180° or 270°, These swing cranes are ideal for smaller or constrained spaces. They provide effective material handling within a defined range, making them cost-effective and space-efficient. They are suitable for compact workshops, specific task stations, and tight manufacturing environments. While they offer lower initial and operational costs, they may require repositioning for tasks outside their swing range.

Consultation Services

Choosing the right swing jib crane for your facility is a critical decision that impacts your operational efficiency, safety, and budget. To ensure you select the most suitable crane for your needs, we offer personalized consultation services:

- Tailored Needs Assessment: Our expert consultants will work closely with you to understand your specific operational requirements, including the types of materials handled, frequency of use, load capacities, and spatial constraints. This detailed assessment allows us to recommend the most appropriate crane design that aligns with your needs.

- Space Utilization Analysis: We will conduct a thorough evaluation of your facility's layout to determine the optimal crane configuration. This includes assessing the available space, potential obstacles, and workflow patterns to recommend a crane design that maximizes efficiency and minimizes interference with other operations.

- Cost-Benefit Analysis: Understanding your budget constraints, we provide a cost-benefit analysis of different crane options, weighing the initial investment against long-term operational savings, maintenance costs, and productivity gains. This helps you make an informed decision that balances performance and affordability.

- Customized Solutions and Recommendations: Based on our assessment, we will offer customized solutions tailored to your specific needs. Whether you require a full rotation crane for comprehensive coverage or a limited rotation crane for focused tasks, our team will guide you through the selection process, ensuring the chosen crane enhances your operational capabilities.

- Post-Installation Support: Our service doesn't end with the purchase. We provide ongoing support, including installation assistance, operator training, and maintenance services to ensure your crane operates efficiently and safely for years to come.

Contact Us Today to schedule a consultation and discover how the right swing jib crane can transform your operations. Let our expertise help you find the best solution for your unique needs.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch