2000KG Aluminum KBK Crane System

2000Kg aluminum kbk crane for sale. Aluminum kbk crane systems,i.e. double & single girder kbk , suspension kbk, telescopic kbk, kbk part & kbk rail,etc.

| Type of kbk Crrane | Aluminum kbk crane system |

| Cpacity of kbk crane | 2000kg |

| Track type | Aluminum |

Category: Light KBK Crane

Your Trusted Overhead Crane Manufacturer & Supplier

2000KG Aluminum KBK Crane System,Custom for Your Needs

Aluminum KBK Crane, KBK Trolley, KBK Component & KBK Rail System

2000Kg aluminum kbk crane for sale. Types of aluminum kbk crane systems,i.e. double girder kbk system & single girder kbk system, suspension kbk system, telescopic kbk system & all types of kbk components and parts , kbk rails & kbk track for your selection.

KBK crane systems, renowned for their modularity and adaptability, have become essential tools in various sectors, from automotive to aerospace. These systems are designed to offer customizable solutions tailored to specific operational needs, enhancing productivity and streamlining processes.

Among the various KBK crane systems available, aluminum KBK cranes stand out due to their unique benefits. Leveraging the inherent properties of aluminum—such as its lightweight nature and resistance to corrosion—these cranes offer significant advantages over traditional steel options. The lightweight design of aluminum KBK cranes not only facilitates easier installation and modification but also reduces the overall load on supporting structures, leading to cost savings and improved operational efficiency.

The Aluminum KBK Crane System represents a cutting-edge solution for industries seeking both customization and performance. Its design allows for a range of configurations, ensuring that each system can be tailored to meet the specific demands of different applications. This flexibility is crucial in today's fast-paced industrial environments, where the ability to adapt to changing needs can provide a competitive edge.

Key benefits of the Aluminum KBK Crane System include enhanced load capacities, reduced maintenance requirements, and improved durability in diverse environmental conditions. By choosing aluminum KBK cranes, industries can achieve a balance between strength and weight, optimizing their operational workflows while maintaining high standards of safety and efficiency.

Advantages of aluminum alloy kbk rail (A type kbk rail )

- Low resistance: Low resistance

- Load capacity: The maximum orbital load is 2000KG, Hot Sale, 500KG, 1000KG, 2000KG

- Material: high strength anodized aluminum alloy kbk rail , surface anodized

- Light dead weight: the smallest product with light kbk rail dead weight, 2.7Kg/m

Basics of Aluminum KBK Crane Systems

Lightweight Design

Material Benefits of Aluminum

Aluminum is a highly favored material for KBK crane systems due to its remarkable properties. Its lightweight nature significantly reduces the overall weight of the crane system compared to traditional steel options. This reduction in weight translates to several advantages:

- Easier Installation: The lighter weight of aluminum components simplifies the installation process, reducing labor costs and time required for assembly.

- Lower Structural Load: The reduced weight decreases the load on supporting structures and foundations, which can lead to cost savings in structural reinforcements and support systems.

- Enhanced Maneuverability: Lightweight cranes are easier to maneuver, allowing for more precise movements and reduced strain on the operational environment.

Comparison with Traditional Steel Cranes

When compared to traditional steel cranes, aluminum KBK systems offer several distinct benefits:

- Corrosion Resistance: Aluminum naturally resists corrosion, making it ideal for use in harsh or corrosive environments where steel would require additional protective coatings or treatments.

- Strength-to-Weight Ratio: Aluminum has a high strength-to-weight ratio, providing comparable strength to steel while being lighter. This allows for effective load handling without compromising on performance.

- Energy Efficiency: The lighter weight of aluminum reduces energy consumption during crane operation, contributing to lower operational costs and enhanced energy efficiency.

Customizability

Modular Design and Flexibility

One of the key features of aluminum KBK crane systems is their modular design, which allows for exceptional flexibility:

- Easy Reconfiguration: The modular nature of aluminum KBK systems enables easy reconfiguration to adapt to changing operational needs or workspace layouts. Modules can be added, removed, or rearranged with minimal effort.

- Scalability: Systems can be scaled up or down depending on the requirements of the application, making them suitable for both small and large-scale operations.

- Adaptability: The modular design also facilitates integration with existing infrastructure, ensuring that the crane system can be customized to fit within various facility layouts.

Customization Options for Different Industries and Applications

Aluminum KBK crane systems offer a range of customization options to cater to diverse industrial needs:

- Load Capacity: Cranes can be designed to handle specific load capacities, from light to heavy loads, ensuring optimal performance for various applications.

- Reach and Span: Customizable reach and span options allow the crane to cover specific areas within a workspace, maximizing efficiency and coverage.

- Operational Features: Additional features such as specialized hoists, trolleys, or control systems can be integrated based on the unique requirements of different industries, including automotive, aerospace, and manufacturing.

Performance Characteristics

Load Capacities and Performance Metrics

Aluminum KBK crane systems are designed to deliver reliable performance across a range of load capacities:

- Load Handling: Depending on the design, aluminum KBK cranes can handle various load capacities, from lightweight items to heavier industrial materials. The performance metrics are optimized to ensure safe and efficient lifting and transportation.

- Speed and Precision: The lightweight nature of aluminum contributes to smoother and more precise crane operations, enhancing overall performance and productivity.

Suitability for Various Operational Environments

Aluminum KBK crane systems are well-suited for a variety of operational environments:

- Indoor and Outdoor Use: Due to their corrosion resistance and lightweight design, aluminum KBK cranes are effective in both indoor and outdoor settings, including environments with high humidity or exposure to chemicals.

- Clean Rooms and Sensitive Areas: The non-corrosive nature of aluminum makes these cranes ideal for clean rooms or other environments where contamination needs to be minimized.

Overall, the aluminum KBK crane system offers a combination of lightweight design, customizability, and performance characteristics that make it a versatile and efficient solution for diverse industrial applications.

Design and Engineering of Aluminum KBK Cranes

Structural Design Considerations

Key Design Elements for Aluminum KBK Systems

The design of aluminum KBK crane systems involves several critical elements to ensure optimal performance and safety:

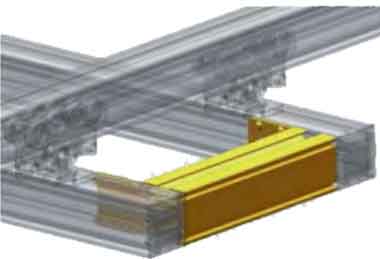

- Beam Design: The beams in aluminum KBK cranes are designed with a focus on strength and rigidity while maintaining lightweight properties. They often feature an I-beam or box-section profile to provide the necessary support for load-bearing and structural stability.

- Rail System: The crane rails are precision-engineered to ensure smooth and stable movement of the crane carriage. The design includes considerations for load distribution and alignment to prevent wear and ensure reliable operation.

- Connection Points: Connections between different crane components are designed to accommodate the stresses encountered during operation. High-strength fasteners and joints are used to ensure durability and minimize maintenance needs.

Structural Integrity and Safety Features

Maintaining structural integrity and safety is paramount in aluminum KBK crane design:

- Load Distribution: The crane's design ensures even load distribution across the rails and support structures, reducing the risk of deformation or failure under heavy loads.

- Safety Mechanisms: Safety features such as limit switches, emergency stops, and overload protection are integrated into the design to prevent accidents and ensure safe operation.

- Corrosion Resistance: Aluminum's natural resistance to corrosion enhances the longevity of the crane, especially in environments exposed to moisture or chemicals. Additionally, anodized or coated finishes can be applied for added protection.

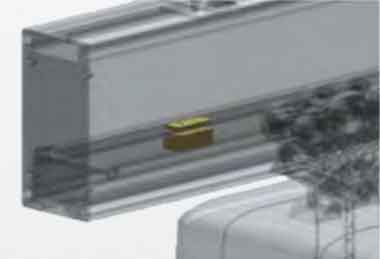

Aluminum Alloy Kbk Rail System Combination Options

Double track telescopic KBK crane type

Double girder and track rail-mounted KBK crane type

Double girder and track KBK crane type

Monorail suspension KBK crane type

Single girder double rail telescopic KBK crane type

Single girder and double track KBK crane type

Engineering Solutions for Customization

Tailoring Designs to Specific Needs

Customization is a key advantage of aluminum KBK crane systems, allowing them to be tailored to meet the specific requirements of different applications:

- Load Capacity Customization: Engineering solutions include adjusting beam sizes and rail specifications to handle specific load capacities, ensuring the crane system meets the demands of the intended application.

- Reach and Span Adjustments: The design can be customized to achieve the required reach and span, accommodating various workspace configurations and operational needs.

- Operational Features: Custom features such as specialized hoists, variable speed drives, or automated control systems can be incorporated to enhance functionality and efficiency.

Integration with Existing Infrastructure

Aluminum KBK cranes are designed to integrate seamlessly with existing infrastructure, providing a flexible solution for various facilities:

- Compatibility with Existing Systems: The modular design allows for easy integration with pre-existing crane systems or production lines, minimizing disruption during installation and ensuring compatibility with existing equipment.

- Custom Mounting Solutions: Custom mounting options and support structures can be engineered to align with the facility's layout and structural requirements, ensuring a stable and secure installation.

- Future Expansion: The modular nature of aluminum KBK systems facilitates future expansion or reconfiguration, allowing the crane system to adapt to changing operational needs without requiring a complete overhaul.

In summary, the design and engineering of aluminum KBK cranes focus on key structural elements and safety features, while offering flexible customization and integration solutions to meet diverse industrial needs. This ensures that the cranes not only perform efficiently but also adapt seamlessly to various operational environments and requirements.

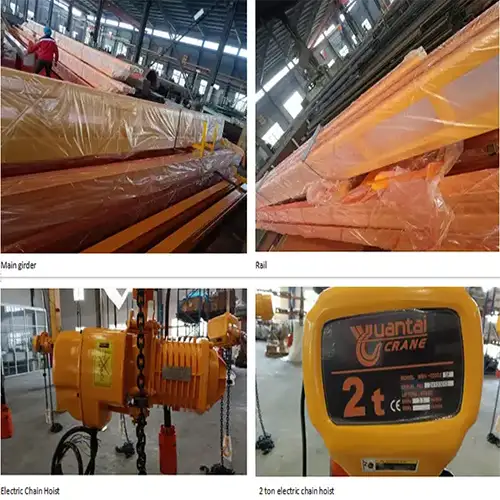

Reliable and efficient aluminum alloy kbk rail system

aluminum alloy kbk rail system

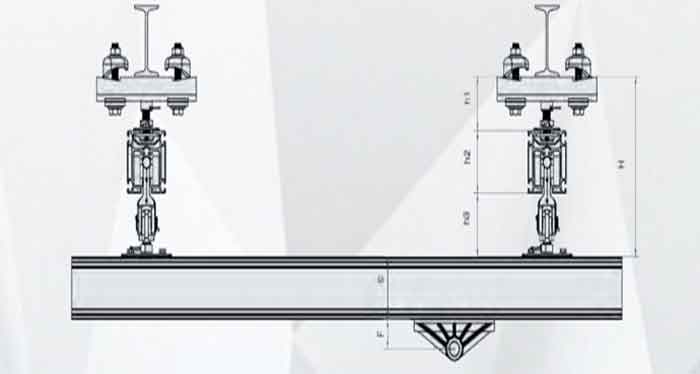

aluminum alloy kbk rail mounting systme drawing

Advantages of aluminum alloy kbk rail system

- The aluminum alloy kbk rail system is lightweight, has a high bearing capacity, and is ergonomic.

- With a sliding coefficient as low as 0.3 percent, the kbk rail system runs smoothly.

- Rated load: Various versions are available to satisfy a variety of load requirements.

- Safer with multiple layers of protection. Hanging pieces have a safety factor of more than 5 times.

- Secondary protection devices are included in the entire line of goods.

- Optional: Flat cable, sliding wire, pneumatic/electric moving unit, origin conveying unit (spring pipe, engineered tow chain).

Aluminum profile kbk rail serialized components

C type aluminum alloy light load conveying system

HCL06 aluminum alloy kbk rail

- Materials: natural aluminum, anodized

- Weight: 6.2 Kg/m

- kbk rail accuracy: 0.02mm/m

- The lifting distance is 3 meters and the load is 300Kg

- Mechanical properties of aluminum alloy

- Tensile yield strength pa2.8e +008

- Tensile strength limit Pa3.1e+008

Flexible suspension components

A maintenance-free ball structure with a built-in copper pad connects the lower flange plate. The structure is flexible and usually bears downward pressure.

Rigid suspension components

Manipulators, hoisting devices, and telescopic beams can all be precisely positioned when upward force is required. Install stiff lifting parts with changeable height; the lifting parts' height adjustment range can compensate for the steel structure's height discrepancy.

Materials

Low noise: wear-resistant nylon wheel with high strength, easy and smooth operation.

Each die casting mold is made of aluminum alloy and weighs 1.25 kilograms. The maximum load is 600 kilograms.

Anti-roller device: This one-of-a-kind anti-roller device can bear both ways and has good anti-eccentricity capabilities, ensuring precise lifting device alignment. The method of operation is more stable, the operation is more agile, and the safety factor is exceedingly high.

Tandem trolley

Two tandem aluminum alloy trolleys can safely raise a load under 1200kg. The double girder trolley frame's purpose is to hang a chain hoist from two kbk rails or two double girders.

Double girder trolley frame

The hanging trolley connects the double beam trolley to the corresponding kbk rail.

Motorized trolley

A motorized trolley is a gadget that allows you to create a light load conveyance system based on your specific lifting needs.

0° hanger and 90° Hanger

A girder hanger is used to connect the girder to the rail. Precision integration and the use of aluminum alloy trolleys ensure that the system runs smoothly and quietly. The maximum load capacity is 600 kg. The girder hanging sections are separated into two types: 0° hanger and 90° hanger, to accommodate various kbk rail installation methods.

0° hanger

90° Hanger

Joint bar

Joint bar

kbk rail end cap

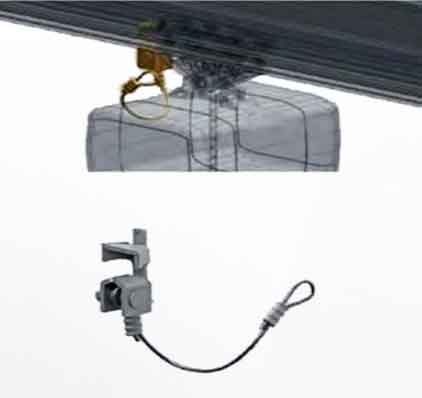

To keep the end cover from falling off and dust from entering the inner track, all end caps are made of metal structure.

Secondary protection device

The company offers three types of safety systems, depending on the features of the rail connection:

- rail protection device kbk (connection from kbk rail to upper steel structure)

- Girder protection (from kbk rail to girder connection)

- Load-strengthening device (to prevent the load from falling off the trolley axle)

Track protection devices

Girder protection

Load protection devices

kbk rail connector components

There are four different types of kbk rail connector components that are fixed in the grooves on the side of the kbk rail and can be used to increase the length of the kbk rail as needed. Lightweight design, simple installation, and precise kbk rail connection.

kbk rail connector components

kbk rail connector components

kbk rail connector components

kbk rail connector components

End stoper of aluminum kbk crane system

End stoper of aluminum kbk crane system

End stoper of aluminum kbk crane system

End stoper instllation drawing for aluminum kbk crane

End stoper instllation drawng for alluminum kbk crane

End stoper instllation drawing for kbk crane system

Middle stopper for aluninum kbk crane

Our middle stopper is the conventional solution when two or more girders are mounted on the kbk rail. The center stopper we give is 300-3000mm in length. If necessary, non-standard sizes can be offered.

Rigid suspension components

Suitable for hanging on I-beams, H-beams, and other similar structures. To assure safety, it is built of a high-strength forged alloy. The rigid kbk rail system has a suspension point adjustment range of up to 20mm, which effectively compensates for the height error of the steel structure. There are primarily two distinct sizes from which to pick.

Trolley

To provide the highest level of safety, it is built of a high-strength wrought aluminum alloy. Horizontal thrust for 0.5 percent to 0.8 percent of deadweight, super silent operation, smooth and smooth. There are a range of trolleys to choose from, with a maximum weight capacity of 1200kg. The trolley may be modified to a variety of kbk rail models for a precise fit.

KBK crane trolley for aluminum kbk crane system

KBK crane trolley for aluminum kbk crane system

KBK crane trolley for aluminum kbk crane system

Connection components

The connection components are mostly used to join two aluminum alloy kbk rail sections together. To ensure the safety of the connection, the forged aluminum alloy joints can bite the rails in the unique grooves of the aluminum rails. It's comprised of an anodized aluminum alloy with a high strength. Install the connecting components 1/10 of the distance between the suspension points, with a minimum of 200mm and a maximum of 500mm.

End cap for lightweith aluminum kbk

Cast aluminum design, high strength; Own buffer block; End cable clamps can be set on the end cap and secured with a group of eight bolts. It's comprised of an anodized aluminum alloy with a high strength.

Lifting lugs for aluminum lightweight kbk

The main beam can be suspended on a light load transit kbk rail or on a moveable beam using lugs and trolleys. In various directions, there are two sorts of lifting lugs.The main girder and the kbk rail are connected with 90° lifting lugs, while the telescopic girder is connected with 0° lifting lugs.

Connection components

The connection components are mostly used to join two aluminum alloy kbk rail sections together. To ensure the safety of the connection, the forged aluminum alloy joints can bite the rails in the unique grooves of the aluminum rails. Install the connecting components 1/10 of the distance between the suspension points, with a minimum of 200mm and a maximum of 500mm.

Cable trolley for kbk crane system

The trolley's body is made of high-strength aluminum alloy, and the wheels are molded to the mold's specifications. In addition, sealed bearings, smooth movement, low noise, low start inertia, and a special clip designed to preserve the wire are all included.

Limit buffer for kbk crane system

The end cap's front protection, which may be mounted on the kbk rail of the corresponding model, with a buffer block and the ability to form a limit.

Secondary protection devices

Protect the girder and the kbk rail, the kbk rail and the I-beam, and the hoist and the girder.

Applications and Industry Use Cases

Food Processing Industry

The food processing industry benefits from aluminum KBK crane systems due to their hygienic properties and efficiency in handling materials:

- Hygienic Material Handling: Aluminum KBK cranes are ideal for moving food products, packaging materials, and processing equipment. Their corrosion-resistant and easy-to-clean surfaces ensure that the cranes meet the strict hygiene standards required in food processing, preventing contamination and maintaining product safety.

- Efficient Operations: The lightweight design of aluminum KBK cranes facilitates smooth and precise handling of materials, reducing wear and tear on equipment and minimizing the risk of damage to food products during transport. This efficiency is crucial in maintaining the high throughput required in food processing facilities.

- Custom Solutions for Food Processing: The modular and customizable nature of aluminum KBK crane systems allows them to be tailored to the specific needs of food processing plants. Whether it's integrating with existing production lines or adapting to unique facility layouts, these cranes provide flexible and reliable solutions that enhance operational efficiency.

Overall, aluminum KBK crane systems offer tailored solutions that meet the specific requirements of the food processing industry, improving hygiene, safety, and productivity across various applications. Their successful implementation highlights their suitability and effectiveness in addressing the unique challenges of this sector.

Automotive Manufacturing

In the automotive industry, aluminum KBK crane systems play a crucial role in enhancing production efficiency and flexibility:

- Assembly Lines: These cranes are used to handle parts and components along assembly lines, streamlining the assembly process and reducing manual handling. Their modularity allows for easy reconfiguration as production needs change.

- Material Handling: Aluminum KBK cranes are employed for the precise handling of automotive components such as engines, chassis parts, and body panels. Their lightweight design minimizes the load on supporting structures, making them ideal for use in confined spaces or on elevated tracks.

- Maintenance and Repair: In automotive maintenance and repair facilities, these cranes facilitate the lifting and positioning of heavy components, improving safety and efficiency during servicing operations.

Aerospace and Marine Industries

The aerospace and marine industries benefit from aluminum KBK crane systems due to their adaptability and high performance in specialized environments:

- Aerospace Manufacturing: Aluminum KBK cranes are used to handle delicate and high-value aerospace components, including aircraft wings, fuselage sections, and engine parts. Their precision and flexibility are essential for meeting the stringent requirements of aerospace manufacturing.

- Marine Applications: In shipbuilding and marine maintenance, these cranes are utilized for lifting and moving heavy marine equipment and parts. Their resistance to corrosion makes them suitable for use in environments with high humidity and exposure to seawater.

Overall, aluminum KBK crane systems provide tailored solutions that address specific industry needs, enhancing efficiency, safety, and flexibility in various applications. The successful implementation of these custom solutions highlights their versatility and effectiveness in meeting diverse operational challenges.

Benefits of Aluminum KBK Crane Systems

Efficiency and Cost Savings

Energy Efficiency and Operational Costs

Aluminum KBK crane systems offer several efficiency benefits that translate into significant cost savings:

- Reduced Power Consumption: The lightweight design of aluminum cranes results in lower power requirements for operation. The decreased load on the supporting structures and mechanisms means less energy is needed to lift and move materials.

- Lower Operational Costs: The energy savings from operating a lighter crane can lead to reduced utility bills. Additionally, the ease of installation and minimal maintenance requirements of aluminum KBK systems further contribute to cost savings over the crane's lifecycle.

- Enhanced Productivity: The efficiency of aluminum KBK cranes, including their smooth operation and reduced manual handling, can lead to increased productivity and faster turnaround times in various industrial processes.

Longevity and Durability

How Aluminum's Properties Contribute to a Longer Lifespan

Aluminum's inherent properties make it an ideal material for crane systems, contributing to their longevity and durability:

- Corrosion Resistance: Aluminum's natural resistance to corrosion ensures that the crane system remains functional and aesthetically pleasing even in harsh environments. This reduces the need for frequent repairs or replacements.

- Lightweight Strength: Despite its light weight, aluminum provides excellent strength and load-bearing capacity. This combination of attributes contributes to the crane's overall durability and resistance to wear and tear.

- Minimal Maintenance: The low maintenance requirements of aluminum cranes are due to their resistance to environmental factors such as rust and deterioration. This means fewer maintenance interventions and lower associated costs.

Environmental Impact

Benefits of Using Aluminum in Terms of Sustainability

The use of aluminum KBK crane systems offers several environmental advantages:

- Recyclability: Aluminum is highly recyclable and can be reused indefinitely without losing its properties. This reduces the environmental impact associated with mining and processing new materials.

- Reduced Carbon Footprint: The lighter weight of aluminum reduces the energy required for transportation and installation, which can contribute to a lower overall carbon footprint.

- Sustainable Production: Many aluminum manufacturers employ sustainable practices in their production processes, such as using renewable energy sources and minimizing waste, further enhancing the environmental benefits of aluminum crane systems.

In summary, aluminum KBK crane systems offer a range of benefits including increased efficiency, cost savings, extended longevity, and positive environmental impact. These advantages make aluminum cranes a valuable investment for various industries, contributing to operational excellence and sustainability.

Choosing the Right Aluminum KBK Crane System

Factors to Consider

Load Capacity, Reach, and Operational Needs

When selecting an aluminum KBK crane system, several key factors must be considered to ensure it meets your specific requirements:

- Load Capacity: Determine the maximum load the crane will need to handle. This includes not only the weight of the materials but also any dynamic forces that may be applied during operation. Ensure the crane system is rated for the required load capacity to maintain safety and efficiency.

- Reach and Span: Assess the necessary reach and span of the crane. This involves evaluating the distance the crane needs to cover and the height at which it must operate. Proper reach and span are essential for efficient material handling and to avoid operational limitations.

- Operational Needs: Consider the specific operational requirements of your facility, including the type of materials being handled, the frequency of use, and any special handling needs. This will help determine the appropriate design features and customization options for the crane system.

Working with a Custom Crane Provider

Selecting the Right Supplier and Service Provider

Choosing the right supplier and service provider is crucial for obtaining a high-quality aluminum KBK crane system that meets your needs:

- Experience and Expertise: Look for a provider with extensive experience and expertise in designing and manufacturing aluminum KBK crane systems. An experienced supplier will be able to offer valuable insights and recommendations based on industry best practices.

- Customization Capabilities: Ensure the supplier can provide customized solutions tailored to your specific requirements. This includes offering a range of options for load capacities, reach, and operational features, as well as the ability to integrate with existing infrastructure.

- Support and Services: Evaluate the support and services offered by the provider, including installation, maintenance, and technical support. A reliable provider should offer comprehensive support throughout the lifecycle of the crane system to ensure optimal performance and longevity.

- Reputation and References: Research the provider's reputation and seek references from other clients who have used their products and services. Positive feedback and successful case studies can indicate the reliability and quality of the supplier.

In summary, choosing the right aluminum KBK crane system involves carefully considering factors such as load capacity, reach, and operational needs. Working with a reputable and experienced custom crane provider ensures that you receive a high-quality, tailored solution that meets your specific requirements and supports your operational goals.

Custom Aluminum KBK Crane for Your Needs

Aluminum KBK crane systems offer numerous advantages, including lightweight design, customization flexibility, and efficiency. Their structural design focuses on strength and safety while leveraging aluminum's benefits such as corrosion resistance and low maintenance. These cranes are highly adaptable to various industries, including automotive manufacturing, aerospace, and marine applications. Custom solutions and careful consideration of factors like load capacity, reach, and operational needs ensure that these systems meet specific requirements effectively. Working with an experienced and reputable provider further enhances the benefits of aluminum KBK cranes by ensuring high-quality design, installation, and support.

In conclusion, aluminum KBK crane systems represent a robust and flexible solution for various industrial applications. As technology progresses, these systems are expected to become even more efficient, customizable, and environmentally friendly, continuing to support the evolving needs of modern industries.

Types of kbk crane systems for your selection. If you have any doubt about kbk crane system selection, please feel free to contact us.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch