Crab Crane Trolley & Hoist Trolley for Bridge Crane& Gantry Crane

Electirc hoist trolley & heavy duty open winch crane trolley, ie., chain, wire rope & builtup open winch types for double girder bridge & gantry cranes.

Category: Hoist

Your Trusted Overhead Crane Manufacturer & Supplier

Double Girder Crane Trolley for Sale

Electric Chain Hoist Trolley, Wire Rope Hoist Trolley, Open Winch Trolley for Double Girder Overhead Bridge Cranes & Gantry Cranes

Introduction: Double Girder Crane Trolleys

Why the Right Crane Trolley Matters

A crane is only as good as its lifting mechanism—and in double girder overhead or gantry cranes, that mechanism sits in the trolley. The crane trolley moves back and forth along the two girders, while the hoist raises and lowers your load. It's simple in concept, but the details make a big difference.

You'll see a wide range of trolley options in the market, from compact chain hoist trolleys to large open winch trolleys designed for serious lifting power. Picking the right one isn't just about capacity. It's also about how often the crane runs, how much space you have above the girders, and what kind of hoist system you're pairing with it.

- The trolley affects how much headroom you'll need in your workshop or facility.

- It determines how stable your load stays during travel—especially on long spans or rough movement paths.

- It directly impacts maintenance needs, wear-and-tear, and even operator fatigue over time.

Some trolleys come with an integrated hoist and are built to save space. Others are large, heavy-duty machines that can handle multiple shifts and high-cycle operations.

In short, it's not a part you want to overlook. The right crane trolley ensures that your crane performs safely and efficiently—and keeps doing so without costly breakdowns. Let's break down your options based on hoist type, so you can find the right fit for your crane setup and working conditions.

Classification of Crane Trolleys by Hoist Type

The hoist system defines how your crane lifts, how much it can carry, and how it fits into your workspace. Whether you're dealing with light maintenance tasks or heavy industrial handling, choosing the right hoist type is the starting point for a reliable crane trolley.

Let's look at the three most common types of hoist trolleys used in double girder crane systems—and what each one brings to the table.

Electric Chain Hoist Crane Trolley

If you're handling lighter loads and need something compact and easy to set up, the electric chain hoist trolley might be exactly what you need. It's a straightforward option and works well in places where space is tight and precision matters more than speed.

- Lifting Capacity: Generally supports loads up to 10 tons, though most common models are in the 1 to 5-ton range.

- Installation: Simple and fast to mount—makes it ideal for smaller facilities or workshops that can't afford long downtime.

- Applications: Used in light-duty operations like tool handling, mold positioning, repair bays, and light equipment movement.

Advantages:

- Compact size fits in workshops with low headroom.

- Fewer moving parts mean lower maintenance costs.

- Chain hoists offer smooth vertical positioning, which is useful when you're aligning delicate parts or components.

This type of crane trolley isn't built for high-speed operation or round-the-clock lifting. But when it comes to small-scale work that needs accuracy and minimal fuss, it gets the job done—and keeps the cost down.

Electric Wire Rope Hoist Crane Trolley

This is the most widely used trolley type for double girder overhead and gantry cranes. It's a solid, dependable choice when you're dealing with heavier loads or frequent lifting cycles. Wire rope hoists offer higher speeds, greater capacity, and smoother operation compared to chain hoists.

Electric wire rope hoist trolleys are typically divided into two categories: economical models, often used in standard industrial settings, and European-style trolleys, which are designed to meet higher performance and efficiency standards.

Economical Wire Rope Hoist Trolleys

These are well-suited for everyday lifting tasks—where performance, reliability, and budget need to balance out. Many factories, warehouses, and fabrication plants choose these models for their simplicity and cost-effectiveness.

CD/MD Wire Rope Hoist Trolley

This is a traditional Chinese-style setup where the hoist is mounted on a separate trolley frame. It's one of the most common and reliable options in the market.

- Lifting Capacity: From 5 tons up to 32 tons

- Design: Wire rope hoist (CD for single speed, MD for dual speed) paired with a steel trolley frame

- Usage: Ideal for general-duty applications in manufacturing plants, metal workshops, warehouses, and machinery assembly lines

Benefits:

- Easy to install and maintain

- Readily available spare parts

- Proven design that works well for moderate duty cycles

Integrated Hoist Crane Trolley

Unlike the CD/MD setup, this design combines the hoist and trolley frame into a compact, unified unit. It's a smart choice when the building has limited vertical clearance.

- Lifting Capacity: Also ranges from 5 to 32 tons

- Design Advantage: Integrated structure saves overhead space and simplifies installation

- Common Use: Frequently installed in older buildings or production workshops with low roof height

Key Points:

- Maximizes lifting height under restricted headroom

- Still retains the reliability of wire rope hoisting

- Good solution when modifying building height isn't practical

These economical trolleys aren't fancy, but they're dependable. And in most routine factory settings, that's exactly what matters. In the next section, we'll look at the European-style wire rope hoist trolleys—designed for users who need higher lifting performance, efficiency, and quieter operation.

B. European Style Wire Rope Hoist Trolley

If you're working in a high-demand environment—where every inch of space and every second of downtime matters—the European-style wire rope hoist trolley is worth your attention. These trolleys are built to meet FEM and DIN standards, which means they're designed with performance, efficiency, and longevity in mind.

They have a low-profile, modular design, making them suitable for installations where headroom is limited but high capacity and smooth operation are still required.

- Lifting Capacity: Typically from 5 tons, with models available up to 80 tons

- Design Standards: Conforms to European FEM/DIN classifications for structure and duty cycle

- Explosion proof Crane Trolley: Designed for hazardrous environment to ensure safety.

Use Cases:

- Automated production lines

- Precision part assembly

- Aerospace equipment handling

- Energy plant maintenance

Key Advantages:

- Compact dimensions allow for a higher lifting height under the same roof

- Dual-speed or variable-frequency drive (VFD) offers smoother speed transitions

- Quiet motor and gearbox operation—ideal for clean, controlled environments

- Reduced wear on components, meaning fewer breakdowns and longer service life

This type of crane trolley is often chosen for custom-engineered cranes, where reliability and performance aren't optional—they're required. While the upfront investment may be higher than economical models, the reduced maintenance and extended durability make it a smart long-term choice.

If you're building or upgrading a high-tech production facility, or need a lifting system that integrates with automation and control systems, this is the trolley to consider before all others.

Hot Sale Hoist Trolley and Crane Trolley for Double Girder Overhead Cranes

Crane hoist trolleys are designed for double girder overhead crane and are widely used for heavy duty lifting operations with higher safety and stability. The hoist trolley are runs on along the top of edge of two girders and the wire rope with hook will descend between the two girders to handle the load, which enables the maximum possible height of lift under the beam girder, however, on the hand more roof space will be required above the crane beams or girder, due to it sits on the top of crane beam girders.

Double girder hoist trolley

Double girder hoist trolley for double girder overhead crane and gantry cranes

Double girder hoist trolley

Double girder hoist trolley for double girder overhead cranes and gantry cranes with double hoists for hoisting and lifting .

Electric chain hoist trolley

Electric chain hoist trolley for double girder overhead cranes and gantry cranes

Electric wire rope hosist trolley

Electric wire rope hosist trolley for double girder overhead cranes and double girder gantry cranes

Chinese style hoist trolley -The Chinese style hoist trolley adopts the CD/MD wire rope electric hoist trolley or electric chain hoist with frame as the lifting mechanism and lifting capacity is from 5 ton 32 ton,

European style hoist trolley -European standard FEM/ DIN standard low profile hoist trolley with lifting capacity are up to 80 ton. The European low profile hoists trolleys are used on double girder overhead cranes configurations, such as, types of overhead crane & A frame gantry cranes, etc.

Open Winch Crane Trolley

Open winch trolleys are used for heavy-duty lifting tasks on double girder bridge and gantry cranes. They offer a wide range of lifting capacities and customization.

A. European Style Open Winch Crane Trolley

- These are high-precision winch trolleys designed to meet FEM or DIN standards.

- Lifting capacity can go up to 500 tons.

- Commonly used in high-demand sectors such as steel production, hydropower, and custom-engineered crane systems.

- They provide precise control, modular construction, and smooth operation.

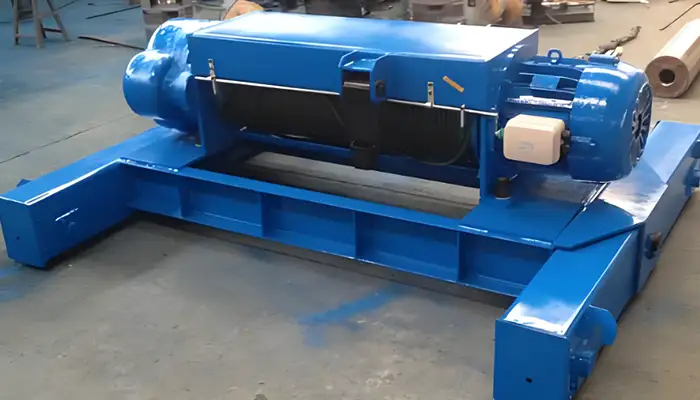

B. Traditional Chinese Style Open Winch Crane Trolley

- These winches are based on proven Chinese design standards and are CE-certified.

- Lifting capacity ranges from 5 to 500 tons.

- They are widely used in shipbuilding, steel plants, cement yards, and other heavy industrial applications.

- Known for reliable operation, strong structure, and cost-effective performance in heavy-duty environments.

Open Winch Trolley for Double Girder Overhead Cranes

Build up open winch and electric winch trolleys are adopted on double girder overhead cranes as the lifting system for handling heavy loads with capacity from 5 ton 500 ton. According to different design style and features, the overhead open winch crane can be grouped in the following types:

Open winch with European style design

European style open winch for double girder overhead cranes with capacity up to 500 tons.

Open winch with European style design

European style open winch for FEM / DIN standard double girder overhead crane

Open winch with Chinese traditional design with CE certificate

Chinese style open winch trolley for double girder overhead cranes system

Open winch with Chinese traditional design with CE certificate

Chinese style double girder overhead crane with open winch hoisting system

Open winch with Chinese traditional design -These types of open winch and electric crane winch trolley are frequently adopted on the Chinese traditional heavy duty double girder overhead cranes with capacity from 5 ton to 500 ton,with the features of safe, flexible, powerful, reliable & stable.

European open winch crane design-European crane winch is a custom crane components for heavy duty double girder overhead cranes and overhead gantry cranes. The European winch trolleys are tailored to meet the specific requirements of your application and custom cranes. The process winch trolleys are vary versatile and applicable to a variety of industrial applications.

Quick Reference Table of Double Girder Crane Trolley Types and Their Applications

Before choosing a crane trolley for your double girder overhead or gantry crane, it helps to understand the main types available and what each is best suited for. The table below breaks down the common categories, their typical lifting capacities, and where you're most likely to see them used in industry. This overview will help you match the right trolley to your specific lifting needs and working conditions.

| Category | Sub-Type | Lifting Capacity | Typical Use |

|---|---|---|---|

| Electric Chain Hoist Trolley | — | Up to around 10 tons | Light-duty, compact areas |

| Electric Wire Rope Hoist Trolley | CD/MD Hoist Trolley | 5 to 32 tons | General lifting |

| Integrated Hoist Trolley | 5 to 32 tons | Low headroom applications | |

| European Style Hoist Trolley | Up to 80 tons | High-end precision industries | |

| Open Winch Crane Trolley | European Style Open Winch | Up to 500 tons | Custom heavy-duty processes |

| Traditional Chinese Style Open Winch | 5 to 500 tons | Heavy industrial sectors (steel, energy) |

This summary gives you a quick snapshot of the key trolley types for double girder cranes and their typical roles. By understanding these distinctions, you can narrow down your options and focus on the crane trolley that fits your load, space, and operational demands—helping to ensure safer, more efficient lifting performance.

How to Choose the Right Double Girder Crane Trolley

Choosing the right crane trolley isn't just about picking the one with the biggest lifting capacity. There are several important factors to consider that will affect how well your crane performs, how safe it is, and how long it lasts. Here's a practical checklist to help you make the best choice for your specific needs.

1. Type of Crane: Overhead Bridge or Gantry Crane

Start by identifying the type of crane you have or plan to install.

- Overhead bridge cranes are fixed inside buildings, usually running on runway beams attached to the building's structure.

- Gantry cranes have legs and often run on rails outdoors or in large open spaces.

The trolley design and requirements can differ between these two types. For example, gantry cranes often need more robust trolleys because they might operate outdoors with variable weather conditions and uneven surfaces.

2. Required Lifting Capacity

Knowing your exact lifting needs is critical. Trolleys are made to handle specific load ranges—choosing a trolley with too low capacity risks equipment failure and safety hazards. On the other hand, oversized trolleys can increase cost unnecessarily.

- Calculate the maximum weight of your heaviest load, including any rigging or fixtures.

- Consider whether you might lift bundled or multiple loads at once.

- Remember to factor in a safety margin—usually 10 to 20 percent above the heaviest expected load.

3. Space and Headroom Limitations

Your facility's vertical and horizontal space will influence the trolley type.

- If headroom is tight, you'll want a compact or integrated hoist trolley that minimizes the distance from the beam to the hook.

- For taller buildings or outdoor setups, open winch trolleys or traditional wire rope hoist trolleys can be a better fit.

- Also, consider the length and height of the crane span, which affects trolley design and drive requirements.

4. Duty Cycle and Working Frequency

Duty cycle refers to how often and how hard the trolley will work over time. It's classified from M3 (light use) to M8 (heavy industrial use).

- Light duty (M3) might be occasional lifting in workshops or storage yards.

- Medium to heavy duty (M5 to M8) covers manufacturing plants, steel mills, or ports where the crane runs multiple shifts daily.

Selecting a trolley designed for the proper duty cycle will extend equipment life and reduce maintenance.

5. Hoist Type: Electric Chain, Wire Rope, or Open Winch

Each hoist type brings strengths and limitations:

- Electric Chain Hoists are compact and good for precise, lighter loads but aren't built for continuous heavy use.

- Electric Wire Rope Hoists are versatile, suitable for a broad range of capacities and frequencies, and come in economical and high-performance versions.

- Open Winches handle the heaviest loads and are ideal for harsh environments, but require more space and maintenance.

Your choice will depend on load, duty cycle, space, and budget.

6. Industry Standards and Certifications

To ensure safety and compliance, always check the applicable standards and certifications.

- CE certification confirms compliance with European safety standards.

- FEM and DIN standards apply to crane design and performance, common in Europe and many international markets.

- Other regional certifications or quality marks may apply depending on your location.

Choosing trolleys that meet recognized standards means better quality, safer operation, and easier insurance or audit approvals.

7. Application-Specific Requirements

Finally, consider the details of your operation:

- How frequently will the crane run each day?

- What is the operating environment—indoor, outdoor, dusty, corrosive?

- Are your loads uniform in shape or irregular and bulky?

- Do you need special attachments like electromagnetic lifters or clamps?

- Is noise level a concern in your facility?

Answering these questions helps narrow down the trolley options that will work best for your unique situation.

Choosing the right double girder crane trolley takes some thought, but it pays off. The right match improves safety, reduces downtime, and ensures smooth operation for years. Before making a purchase, carefully review these factors and work closely with your supplier or crane manufacturer to get a trolley built for your needs—not just the biggest or cheapest model available.

From compact electric chain hoist trolleys to heavy-duty open winch systems, a wide selection of crane trolleys is available for both overhead and gantry double girder cranes. Whether you need an economical CD/MD wire rope hoist trolley or a European-standard crane trolley for a process crane, selecting the right system ensures safe, efficient, and reliable lifting performance tailored to your project.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch