Your Trusted Overhead Crane Manufacturer & Supplier

Underhung Bridge Crane & Underhung Overhead Crane Runways

Single & Double Girder, Electric & Manual Underhung Bridge Cranes

Underhung bridge crane for sale. Types of underhung bridge crane designs 500kg -10 ton, Single & double girder, electric & manual underhung bridge cranes,etc.

The underhung bridge crane is also called undehrung overhead crane. Or suspension crane. Under hung bridge crane runways are typically lighter than top running systems, allowing for more versatile application.

These underhung bridge cranes, which are usually suspended from roof trusses, are mostly used for maintenance tasks inside small spaces such as pumping stations and small workshops. They are ideal for low-ceiling buildings that require a high hook height due to their compact design and construction.

We are one of China's leading manufacturers and suppliers of overhead cranes, offering modular component packages that can handle any load up to 500 tons. Any factory workshops or application can be quickly and easily adapted to fit our product line.

Main types of underhung bridge cranes

Electric chain hoist single girder underslung bridge crane

Telescopic underhung bridge crane - Telescopic overhead crane serices

Hot sale underhung bridge cranes capacity

1 ton under slung bridge crane

2 ton under slung bridge crane

3 ton under slung bridge crane

5 ton under slung bridge crane

5 ton under slung bridge crane

Custom under slung bridge crane can be up to 10 ton

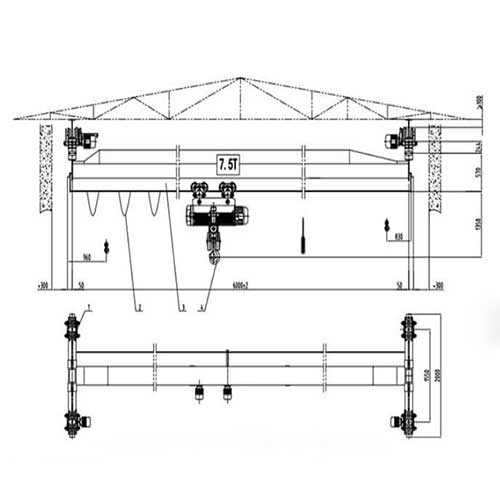

Main Specifications of underhung bridge cranes

Technical Parameter of LX Single Girder Under Running Overhead Crane 0.5 Ton - 10 Ton | |||||||

Item | Capacity | 0.5 ton | 1 ton | 2 ton | 3 ton | 5 ton | 10 ton |

Span | S(m) | 3~22.5 | 3~22.5 | 3~22.5 | 3~22.5 | 3~22.5 | 3~22.5 |

Lifting height | m | 6~30 | 6~30 | 6~30 | 6~30 | 6~30 | 9~30 |

Lifting speed | m/min | 8(0.8/8) | 8(0.8/8) | 8(0.8/8) | 8(0.8/8) | 8(0.8/8) | 7(0.7/7) |

Trolley speed | m/min | 20(30) | 20(30) | 20(30) | 20(30) | 20(30) | 20(30) |

Crane speed | m/min | 20(30) | 20(30) | 20(30) | 20(30) | 20(30) | 20(30) |

Work duty | A3~A4 | A3~A4 | A3~A4 | A3~A4 | A3~A4 | A3~A4 | |

Standard underhung bridge crane specifications are presented for your reference. Custom ceiling mounted underhung bridge cranes system are available for your particular applications. Contact us to get your custom underhung bridge crane nows.

Structural features of underhung bridge crane

When the top running bridge crane operation structure cannot be constructed, the underhung bridge crane is adopted. The suspension crane from our company can make good use of the lifting height thanks to its standard design.

- Optimal design of end carriages and end trucks.

- Loads can be handled near the building wall with beam ends suited to application conditions.

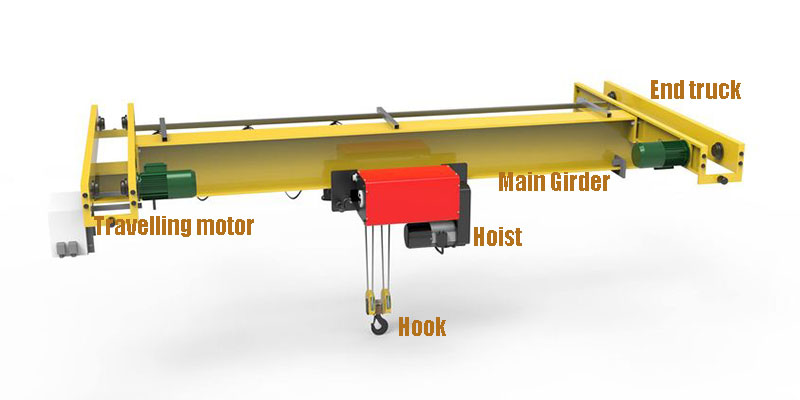

main parts and components of underhung bridge crane

Underhung bridge crane crane configurations & runway structrues

Under-hung bridge cranes are typically attached to the building structure itself; if the building structure is capable of supporting the overhead crane, column support systems are not needed. This kind of configuration makes it possible to cover a larger area with fewer support columns. The absence of any columns from the work area below the crane is useful in facilities with constrained floor space or intricate procedures.

An under-running overhead crane, also known as a "under-hung" bridge crane, moves the bridge up and down the runway using wheels supported by the bottom flange of the runway beam. Under-hung overhead cranes are typically designed with a single girder for lighter service and lower-capacity applications. They can also be built with two girders for increased capacity or hook height where needed.

An under running single girder crane will use an under running hoist and trolley that moves across the bridge beam's bottom flange. A double girder under running crane can run its hoist and trolley along the bridge beams' top or bottom.

When supported by roof or ceiling structures, under-hung overhead cranes also provide excellent side approach and maximize utilization of the building's width and height. They are ideal for facilities that do not have enough vertical clearance to install a top-running overhead crane system.

Freestanding underhung bridge cranes

The underhung bridge cranes can be supported by the free standing supporting columns. The Freestanding is usually used for workshop or applications where the ceiling structure is not strong enough to support the loads and overhead crane weight. With the freestanding overhead crane supporting structures, the underhung bridge cranes can be used to meet your facility conditions and lifting requirements.

Underhung Ceiling-Mounted Bridge Crane Runway

Ceiling mounted underhung bridge crane have overhead crane runways that attach directly to a building's ceiling or roof structure. Ceiling-mounted underhung bridge cranes are bolted directly to the ceiling frame or trusses, or they are suspended from suspension rods or tube brackets. For sloped and pitched ceilings, custom support brackets are available. The underhung bridge crane's traveling bridge is suspended beneath the runway track system.

Underhung bridge crane runways are generally lighter than top running systems, allowing for greater versatility and usability. Underhung runways can be ceiling-mounted because they are significantly lighter. They can also run side by side without interfering with one another. Another mechanical benefit of underhung bridge crane systems is their ability to interlock multiple systems, allowing operators to transfer loads between them.They can also interlock with monorails to transfer material along a fixed path. Ceiling-mounted underhung bridge crane runways have overhead crane runways that attach directly to a building's ceiling or roof structure. Ceiling-mounted, underhung systems are extremely versatile, and transfer switches can be used to easily transfer loads from one bay to another. Ceiling-mounted underhung bridge crane runways allow for the use of the entire floor space beneath the crane runway. More on underhung bridge crane runway.

Features of underhung bridge crane runways

- Maximized the use of valuable floor space.

- Material flow is unhindered because the crane runway is column-free.

- Multiple overhead cranes can operate on the same runway to maximize production space utilization and flexibility.

- Load transfer from one building bay to the next is uninterrupted.

- The hoist and trolley can move from crane to crane or from a crane to a monorail spur using transfer switches.

- There are unlimited runway lengths available.

- The runway electrification, assembly manual, and hardware are all included.

- The system drawings are provided in CAD format.

- A professional engineer inspects all runways.

- There are both motorized and manual cranes available.

Applications of underhung bridge cranes

Underhung overhead or bridge cranes are a good choice for factories and warehouse facilities that want to free up floor space while improving safety and productivity. Underhung bridge cranes, also known as under-running overhead cranes, do not require supporting floor columns. This is due to the fact that they typically ride on the lower flange of a runway beam suspended from the roof or rafters of the facility.

Underhung overhead cranes maximize facility space by optimizing end approaches. In other words, they allow the hoist to get closer to the end truck or end of the runway than a top-running crane can. The underhung configuration also improves the bridge end approach, or how close the bridge girder can get to the wall or runway end.

Undehrung bridge cranes are widely used in various warehouses and factory workshops, either in steel structure facility and concrete workshops, in various industries such as Aerospace production,Aircraft maintenance,Glass manufacturing,Automotive,Food production,Bottling,Dipping operations,Injection molding,Explosion proof,Air powered motor,Electric motor, and so on.

Underhung overhead crane for steel structrue workshops

Underhung overhead crane with free standing structure for low headroom workshop and facility

Underhung bridge crane for concrete workshops

Underhung bridge crane for flat roof concrete workshops

Why choose a underhung bridge crane design?

- The underslung bridge crane design is distinctive in that it can make full use of the available height and narrow space. It can ensure efficient material handling even in factory areas with limited space.

- Under running bridge cranes are typically single girder configurations with capacities ranging from one to ten tons. They use an under running hoist and trolley that run across the bottom flange of the bridge girder.

- The underhung bridge crane can also be designed in accordance with European standards, providing higher performance, longer service life, a more attractive appearance, a compact structure, and minimal maintenance.

We can also design and build an underhung bridge crane system with a double girder for greater capacity, but this is both impractical and costly.

Customized single girder under-slung crane configurations for your application

Underhung bridge cranes are typically attached to the building structure itself and don't need column support structures if the building structure can support the bridge crane. This kind of arrangement makes it possible to cover a larger area with fewer support columns. The absence of any columns from the work area below the crane is advantageous in facilities with constrained floor space or intricate processes. The distance of the hook from the floor is typically shorter in underslung bridge crane configurations. Your lifting requirements and the building itself will ultimately dictate your top priorities for crane configuration.

Underhung bridge crane Vs. top running bridge crane system: which one is right for you?

Several factors can help you decide whether a top running or underhung bridge crane system is best for your facility and lifting requirements:

- Will you build new engineering columns or use existing support columns in your facility?

- Are there any existing runways on which the crane could be installed?

- Your crane specifications, such as rated load capacity, lifting height, and hook approach.

- Your facility's overhead room

You are welcome to contact one of our experts and discuss this information with them. They will help you choose a crane system that strikes the right balance of efficiency, suitability, durability, and cost effectiveness. More information about Top running overhead crane and Underhung bridge crane for your reference.

Attentions on underhung bridge crane buying

The building roof structure must be able to withstand the weight exerted by the crane and the load in order to install the underhung crane. As a result, before making the final decision to purchase the single girder underhung crane, you must consult with our engineers to ensure that every detail of the overhead crane is met.

The underhung bridge crane is simply attached to the existing roof structure and does not require runway support columns. As a result, the entire floor area of the building is available for use, and the workshop's surrounding area can be fully utilized by using the suspended beam extension.

Please contact the underslung crane manufacturer for more information.

After-sales service of underhung bridge crane

We provide our clients with a comprehensive range of after-sales services, including:

- Installation and commissioning of the equipment - We send experienced after-sales service engineers to the job site to assist our clients with the installation and commissioning of the equipment.

- Staff training and instruction - We can train employees to use the machine correctly.

- Warranty period of 12 months.

- Free technical assistance.

- Our service is available 24 hours a day, seven days a week.

- If you have any further questions, please contact the after-sales service center.

Single girder underslung bridge crane configurations are most commonly used for lower capacity and lighter service applications. They can also be built with two girders for additional capacity or hook height as needed. Contact us today to get your customized underhung bridge cranes.

Standard single girder underhung bridge crane up to 10 ton for sale

Custom underhung bridge crane, European style underslung bridge crane