22/5 Ton Overhead Crane Double Hook for Phipppines Good Price

22/5 Ton Overhead Crane Double Hook System for Sale Phipppines, Double GirderCrane with 2 Hooks ,Robust double girder crane with 22-ton main and 5-ton auxiliary hooks for heavy lifting.Advanced Dual-Hook Overhead Crane Solutions for Heavy Lifting in the Philippines

Introduction

This project involves a 22/5 ton double hook overhead crane system, specially designed for heavy lifting tasks where precision matters. It's not just about lifting heavy loads; it's about doing it smoothly and safely every time. This crane is built to handle tough jobs in factories or workshops where both strength and accuracy are required.

The key feature here is the double hook setup. Having two hooks—one main hook with a 22-ton capacity and a smaller auxiliary hook rated at 5 tons—means you can lift different loads without stopping to switch gear. It gives operators the flexibility to handle big, heavy items and smaller, lighter loads with ease. This setup boosts productivity by reducing downtime and allowing more work to get done in less time.

Another important part of the design is the double girder structure. Compared to single girder cranes, double girders are stronger and more stable, especially for heavier loads like 22 tons. This means less sway, better balance, and longer service life for the crane. The double girder frame also spreads the weight evenly, which protects both the crane and the building it's installed in.

Key points:

- Heavy and precise lifting with two hooks of different capacities (22t main + 5t auxiliary).

- Dual hook system allows faster switching between loads, saving time.

- Double girder design improves load capacity, stability, and reduces crane sway.

- Suitable for factories or workshops handling heavy steel, machinery, or other bulky items.

What Is an Overhead Crane with Two Hooks?

An overhead crane with two hooks—often called a double hook overhead crane—is a lifting system designed for operations that require both power and precision. It features two separate hoists, usually mounted on a shared trolley, also known as a doublehook hoist trolley. One is the main hook, responsible for handling the heavy lifting, while the auxiliary hook is used for lighter loads, balancing tasks, or helping to position items with greater accuracy.

These cranes are commonly built on a double girder structure, offering greater load capacity and structural stability. The two-hook setup allows both hoists to operate independently or together, giving operators more flexibility in managing complex lifting scenarios.

Typical Use Cases:

- Steel mills: For lifting large slabs, molds, or handling billets with tilt or rotation assistance.

- Fabrication workshops: Where oversized components need positioning, welding, or fitting.

- Heavy warehouses: Where mixed load sizes are common and rapid switching between hoists is needed.

Main advantages of a double hook crane setup:

- Two hooks on one trolley save time and space during operation.

- Improved load control, especially during lift-and-rotate or dual-point lifting.

- The electric hoist reel double hook setup ensures smooth speed control and safety.

- More efficient than switching between different cranes or lifting gear for varying loads.

Technical Specs at a Glance: 22/5 Ton Double Hook Overhead Crane for the Philippines

Crane Overview

- Type: European-style double girder overhead crane

- Design: Compact structure with dual-hook hoist trolley

- Use Case: Heavy-duty lifting + precise load positioning

Load Capacities

- Main Hoist: 22 tons — for large machinery, steel parts, dies

- Auxiliary Hoist: 5 tons — for small loads or fine load adjustment

- Trolley: Electric hoist reel double hook type, capable of both synchronized and independent lifts

Dimensions & Coverage

- Span: 10.9 m — tailored to fit client's existing column grid

- Lifting Height: 15 m — accommodates tall equipment, stacked loads

Power & Duty

- Power Supply: 400V / 60Hz / 3-phase — standard for Philippine industrial sites

- Duty Class: FEM 2m / ISO M5 — supports regular daily use under moderate impact loads

Drive & Controls

- Hoisting & Travel: VFD-controlled — smooth acceleration, reduced wear

- Control Mode: Remote control + pendant backup

Key Feature: Twin Hook Hoist Trolley

- Single trolley carries both hoists

- Supports dual-hook lifting for balanced loads, tilting, or tandem operations

- Compact, efficient, and ideal for mixed-load facilities

Double Hook Crane Design Focus

This crane wasn't just built to lift — it was engineered to handle real-world demands in industrial workshops, fabrication plants, and logistics yards across the Philippines. The double hook design was chosen with purpose, not as an add-on, but as a core part of the crane's working capability.

Why a Double Girder with Two Hooks?

- A double girder structure offers stronger support, less deflection, and more even load distribution than a single girder crane — especially important for 22-ton rated lifting.

- The crane with two hooks setup expands flexibility: heavy loads on the main hook, light tools or materials on the auxiliary — or both working together.

Doublehook Hoist Trolley Design

- Both hooks are mounted on a shared trolley frame, known as a twin hook hoist or doublehook hoist trolley.

- This allows synchronized or independent operation — a key benefit when lifting irregular or long loads requiring two-point support.

Versatility in Real Operations

- From machinery installation to steel plate handling, the double hook crane setup gives operators more control with fewer manual adjustments.

- It's particularly useful in tight production lines where a separate crane for lighter tools isn't practical.

Structural Engineering & Build Quality

- Built to a deflection limit of L/800 — ensures stable lifting with minimal beam flex.

- All welds are carried out under qualified procedures; joints are fatigue-resistant and stress-checked.

Coating & Environmental Protection

- Finished with corrosion-resistant paint, the crane is well prepared for humid and salty air — common in coastal regions like Cebu, Batangas, or Subic Bay.

- Internal electrical components are sealed and shielded to reduce maintenance in these environments.

In short, this double hook overhead crane isn't just a lifting tool. It's a multi-function, heavy-duty workhorse designed to stay reliable in real industrial conditions. Would you like to move on to the section covering load testing and validation?

Key Advantages of the Overhead Crane Double Hook System

A crane with two hooks—also known as a double hook crane—offers more than just extra lifting points. For many facilities in the Philippines, especially those handling both heavy and precision loads, it solves several common lifting challenges in one system. Here's how:

- Dual Lifting = Higher Efficiency

Lift heavy and light loads without switching equipment. Main and auxiliary hooks work together or separately—ideal for fast-paced workflows. - Safer, Balanced Handling

Two-point lifting keeps loads stable. Built-in overload protection on both hooks reduces strain on the crane and risk to operators. - Versatile for Mixed Loads

Switch between bulky items and smaller parts seamlessly—no second crane or manual rehandling needed. - Precision-Friendly

VFD-controlled hoists allow fine movement. Use the auxiliary hook to tilt or align while the main hook holds the load steady. - Fits Tight Spaces

Compact design suits narrow bays and low headrooms common in many Philippine workshops—no need for structural changes.

This system isn't just a feature—it's a practical solution for improving workflow, safety, and adaptability in real-world lifting operations.

Production and Quality Assurance for the Double Hook Crane

Building a double girder overhead crane with two hooks requires more than just putting two hoists on a frame. From materials to testing, each step ensures that the doublehook hoist trolley and structural parts are ready for safe, long-term use—especially in demanding industrial environments like those in the Philippines.

- Certified Steel with Full Traceability

All load-bearing materials meet strict quality standards and can be traced back to their source. - Welds Focused on Strength & Safety

Key joints—especially around the two-hook setup—are welded by certified procedures and thoroughly reviewed. - Precision-Cut, Machine-Finished Components

CNC processes ensure the twin hook hoist runs smoothly, reducing vibration and wear during daily operation. - Thorough Weld Testing (UT & MT)

Non-destructive methods confirm internal weld quality at high-stress areas before paint or assembly. - Real-Condition Simulation on Test Bench

Before dispatch, both the main and auxiliary hoists go through function tests under simulated loads to verify lifting, travel, and braking.

main girder of 22 / 5 ton overhead crane for sale the Phillipines , more projects for the Phillipines

main girder of 22 / 5 ton overhead crane for sale the Phillipines , more projects for the Phillipines

end carriages of double girder overhead bridge crane

end carriages of double girder overhead bridge crane

main hook and axuliary hook hoist trolley for your reference

main hook and axuliary hook hoist trolley for your reference

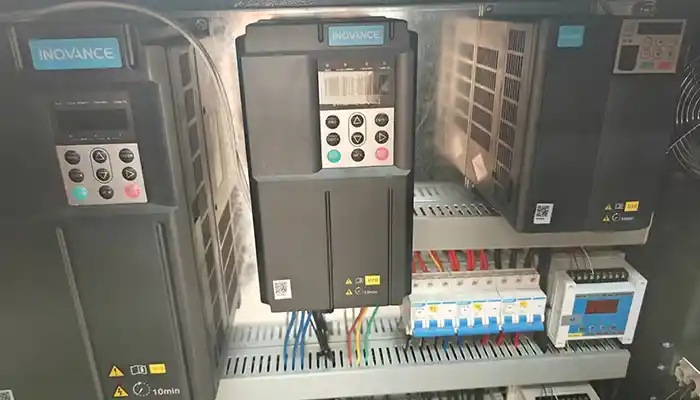

Variable speed overhead crane control

Variable speed overhead crane control

Factory Load Testing & Verification

Before delivery, every double hook overhead crane undergoes thorough testing to prove its strength, reliability, and smooth operation. These tests ensure that both the 22-ton main hook and the 5-ton auxiliary hook perform safely under real working conditions.

- Static Load Test at 125% Capacity

The main hook is loaded beyond its rated 22 tons (up to 27.5 tons) and held to verify the crane's structural integrity and brake system under maximum stress. - Dynamic Load Test at 110% Capacity

Hoisting, lowering, and travel motions are tested with both hooks working at full load plus an extra safety margin to check motor performance and control stability. - Auxiliary Hook Overload Test

The 5-ton secondary hook is similarly tested at 125% of its rating to confirm its safety and durability. - Smooth Operation Checks

The doublehook hoist trolley is tested for both synchronized and independent hook movements, ensuring precise control whether lifting loads separately or together. - Testing Videos Provided

Clients receive full video documentation of the load testing for review before the crane is shipped to the Philippines.

Smart Features & Control Systems

Modern overhead cranes need more than just raw lifting power—they require smooth, safe, and efficient operation. This double hook crane comes packed with smart technology to make handling heavy loads easier and safer while reducing wear and maintenance.

- VFD Drives for Smooth, Efficient Motion

Variable frequency drives control both the hoists and travel motors, allowing precise speed adjustments and energy savings during lifting and moving. - Anti-Sway & Load Stabilization for Both Hooks

Advanced systems minimize load swing whether lifting heavy materials or moving between points, improving safety and accuracy. - Flexible Control Options

Operators can choose between remote wireless control or pendant control, offering convenience and improved ergonomics for different work environments. - Condition Monitoring Sensors

Built into the doublehook hoist trolley, these sensors track operational data to predict maintenance needs before failures occur, reducing downtime. - Robust Safety Systems

Dual brakes, overload protection, and limit switches ensure the crane meets CE and ISO safety standards, protecting both operators and equipment.

Application & Benefits for Philippine Industries

This dual hook overhead crane is designed to meet the varied demands of industries across the Philippines. It's especially useful where space is tight, loads vary in size and weight, and safety is a top priority.

- Versatile for Multiple Sectors

Perfect for steel fabrication, manufacturing plants, shipping yards, and warehouses that handle mixed types of loads daily. - Simplifies Complex Lifting Tasks

Filipino operators can manage both heavy and delicate lifts with one crane—no need to switch equipment or bring in extra cranes. - Boosts Productivity

Fewer lifting cycles and reduced manual handling mean faster operations and less downtime. - Improves Safety & Compliance

Designed to fit busy, space-constrained industrial sites common in the Philippines, helping meet local safety regulations. - Optimizes Space & Workflow

The compact double hook design maximizes operational flow without needing major facility modifications.

This crane offers a practical, reliable solution for Philippine industries looking to increase lifting efficiency while maintaining safety and flexibility.

Packing, Delivery & After-Sales Support

Ensuring your crane arrives in perfect condition and is ready to work smoothly is just as important as its design and manufacture. This section covers how the crane is prepared for shipment, installed, and supported after delivery.

- Secure Packing for Overseas Transport

All crane components are carefully packed with seaworthy wrapping and arranged in containers optimized to prevent damage during the long journey to the Philippines. - Coordinated Delivery and Installation

Shipment timing is planned closely with the client's site readiness and customs processes to avoid delays and ensure smooth unloading and setup. - Optional On-Site Technical Assistance

Expert technicians can be dispatched to help with installation, commissioning, and operator training—especially focusing on the specifics of handling a double hook crane safely and efficiently. - Comprehensive Documentation Package

Clients receive all necessary manuals, electrical diagrams, detailed test reports, plus digital videos of the crane's load testing—giving full transparency and confidence before handover.

This thorough approach to packing, delivery, and support ensures the crane performs reliably from day one and that clients in the Philippines have expert help whenever needed.

Conclusion

To wrap things up, the 22/5 ton double hook overhead crane is a solid, reliable solution designed to meet the complex lifting demands of today's industries, especially in the Philippines. Here's why this crane stands out:

- Versatility and Efficiency

With two hooks working independently or together, this crane lets operators handle a wide range of loads—from heavy steel plates to lighter, precise positioning tasks—without slowing down operations. - Robust Double Girder Structure

The strong double girder frame combined with a doublehook hoist trolley provides excellent load distribution, safety, and minimal deflection—giving confidence for demanding lifting jobs. - Proven Quality and Safety

The crane is thoroughly tested, certified, and equipped with smart control features that improve performance and help protect both workers and equipment, even in the humid, coastal climate common across the Philippines. - Tailored Support from Yuantai Crane

Beyond the crane itself, Yuantai Crane offers customized design, expert advice, and reliable after-sales service to ensure each client's specific needs are met from start to finish.

This project highlights how a well-designed double hook crane can boost productivity, improve safety, and adapt to the unique challenges of heavy lifting in Philippine industries.