Ladle crane: 5 ton -74 ton steel mill ladle crane & 5 ton up 320 ton ladle crane

Ladle cranes for 5 ton -320 ton ladle or liquid metal lifting, heavy duty ladle crane for steel mill, foundry, furnace, and casting factory. Good priced ladle crane, charging crane, casting crane & foundry crane !

| Crane Type | Overhead crane with ladle hook for steel mill |

| Crane Capacity | 5 ~ 75t |

| Crane Span | 10.5 ~ 31.5 m |

| Protection Class | IP54 IP55 IP65 |

Category: Overhead Crane

Your Trusted Overhead Travelling Crane Manufacturer & Supplier

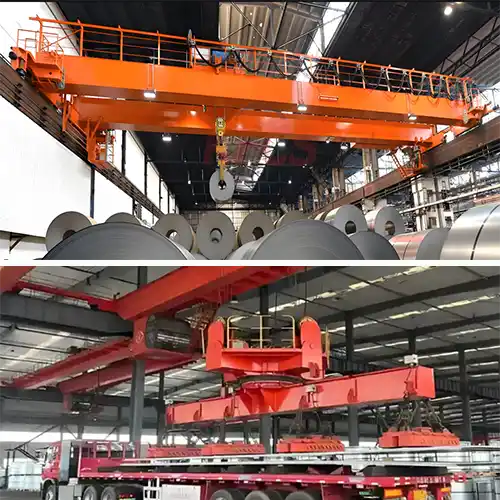

Ladle crane, Casting crane, Charging Crane & Foundry Crane

5 Ton -74 Ton Steel Mill Ladle crane & 5 Ton up 320 Ton Ladle Crane

Competitive Ladle Cranes, One-stop Ladle Handling Solutions

Ladle crane is one of the main material handling equipment in the continuous casting technology of steel manufacturing and processing, which is designed for pouring and charging the ladle to the pointed place, etc. he ladle crane is a heavy duty crane which can work continuously for 20 - 24 hours working. With supreme crane designs and technological superiors, our ladle cranes and charging cranes win satisfactions at many steel plants around world and a strong reputation is established among clients and customers as preferred crane supplier. Our customized crane solution and one-stop crane services will make you one of them.

Ladle cranes for 5 ton -320 ton ladle or liquid metal lifting, heavy duty ladle crane for steel mill, foundry, arc furnace, and casting factory. Good priced 5 ton -74 ton ladle crane & 75 ton -320 ton casting crane, charging crane, foundry crane, metallurgical crane for sale now.

With supreme crane designs and technological superiors, we are able to provide ladle handling solutions for various applications. Typically, QDY series of 5 ton -74 ton ladle cranes &YZ series of 75 ton -320 ton ladle casting cranes are the competitive ladle handling solution for charging and casting workshops in small and large scale steel mills, foundry or other metallurgical applications.

QDY series of 5 ton -74 ton ladle crane

QDY series of ladle crane is applied to transport the molten iron ladles to the basic oxygen furnace or to transfer the molten steel from the basic oxygen furnace and electric arc furnace to the casting machine continuously. The ladle crane also can be applied for teeming and casting. Due to the high temperature of molten steel, the safety and reliability always comes to the first for the ladle charging crane. The design and manufacturing of the Ladle Cranes are strictly in according to the notification requirements of JB/T7688-1 and JB/T7688 and the National Quality Supervision Bureau: Quality Inspection Office Special [2007]-375 document on the relevant opinions of the overall work of metallurgy lifting machinery.

QDY type of ladle cranes generally adopts the structure of two girder beams & single trolley . The main beam of the ladle crane is box shaped beam girder, covered by walkways and maintenance platforms.For the inspection of ladle cranes, there is a diagonal ladder from the crane operator's cabin to the main beam girders, and a heat insulation layer is added right beneath the main girder to prevent it from deformation due to the high temperature. When a driver's cab is used, a heat insulation layer is also added at the bottom of the driver's cab and an air conditioner can be equipped if necessary.

QDY series of ladle cranes is with the lifting capacity of 5 ton to 74 ton, span from 10.5m to 31.5m, Temperature range: -10℃~+50℃ and working class A7. The main parameters of the ladle handling cranes are for your reference to get your ladle crane solution. Any need, please leave us a message below.

Ladle crane main parameters:

- Crane Type of Ladle Crane:QDY series of double girder ladle crane

- Lifting Capacity of Ladle Crane: 5 ton ~74 ton

- Span Length of Ladle Crane: 10.5 ~ 31.5m

- Working Class of Ladle Crane: A7

- Ambient Temperature of Ladle Crane: -10 ~50℃

Due to a high risk level, casting are designed with special safety features to ensure the efficiency and safety of crane system. The features of Ladle Cranes are as follow:

- Double sets of independent crane brakes are used for the lifting mechanism of ladle crane to ensure high safety.

- Heavy hammer and rotary lifting position limiters and down position limiter will be installed when the hoisting height of the ladle crane is more than 20 m.

- Insulating layer is installed beneath the main girders of ladle crane to prevent deformation and long working life. Thermal insulation layer and air conditioner are installed to the cabin of Ladle Crane.

- Specialized crane parts and components are used to ensure the safety and long working life of the ladle cranes such as metallurgy motor, Cast steel pulley, Steel core wire rope, and High temperature resistant cable and others, etc.

- Metallurgy motor with H level insulation class and IP54 protection grade are used to ensure the performance and safety.

- High level protection devices and measurements are installed such as Over speed protection equipment and Fault protection devices including positive and negative contactor and others, etc.

YZ series of 75 ton - 320 ton ladle casting crane

Normally the YZ casting crane adopts the structure of four beam girders and two trolleys , with laminated ladle hook equipped on the main trolley for hoisting the ladle, and Aux trolley is used for overturning the ladle and other assistant works. Due to the hot and dusty conditions, the electrical appliance with heat insulation device and cooling device is installed inside of the main girder which makes the casting crane can work under harsh conditions continuously for 20 -24 hours.

The casting crane is widely used for metallurgical material handling with capacity from 75 ton to 320 ton. Usually, the double girder casting cranes is for hoisting loads under 125 ton and four girder ladle casting crane is for loads above 125 ton. The application ambient temperature of metallurgical crane is from - 10 ℃ to + 50 ℃, the relative humidity is not more than 50 ℃ at 40 ℃, and the radiation temperature of the liquid metal lifted to the forged hook and plate hook is not more than 300 ℃. As heavy duty cranes, the working level of metallurgical casting cranes are A7 and A8 , which are used in relatively busy casting workshops of metallurgical industry.

YZ series of ladle casting crane is mainly used in smelting workshop of BOF bay, EAF bay and CCP bay in metallurgical industry.

Main parameters of metallurgical ladle casting crane

- Ladle Crane type: YZ series ladle casting crane

- Lifting Capacity of Casting Crane: 75 ton ~ 320 ton

- Span Length of Casting Crane: 10.5~31.5m

- Lifting Height of Casting Crane: 6~18m

- Working Class of Casting Crane: A6, A7

- Ambient Temperature of Casting Crane: -10~50℃

Metallurgical casting cranes are mainly are used in metal smelting, binding and hot processing line, cooperated with other special cranes, such as, open hearth charging crane, ground charging crane, charging box crane, stripping crane, whole mold crane, uncovering crane, clamp crane, slab turnover crane, forging crane, heating furnace charging and reclaiming crane, charging box electromagnetic crane, charging box grab crane. More information for the casting crane, please leave a message below.

Advantages & Features of YZ Casting Crane

- As a heavy duty crane, the casting crane is able to handle loads with capacity of 75/20 ton, 100/30 ton , 125/50 ton, 140/40 ton, 160/40 ton, 200/80 ton, 280/75 ton, and up to 320 ton continuously for 20 - 24 hours with high safety and stability.

- High safety and reliability is guaranteed by advanced technology, strict quality control, scientific management and systematic supervision.

- Cost-effective crane price is achieved by technology innovation and resources development.

- Easy operation and maintenance is realized based on designing concept ofHuman oriented and Safety oriented of ladle crane.

Specifications Table of QDY & YZ Ladle Cranes

Crane type | QDY | YZ |

Loading capacity | 5 ~ 75t | 75 ~ 350t |

Lifting height | customized | |

Lifting speed | Varies with lifting capacity | |

Span | 10.5 ~ 31.5 m | 15 ~ 38 m |

Lifting mechanism | Winch trolley | |

Working class | A7/A8 | |

Working temperature | -20 ~ +60 ℃ | |

Power supply | AC-3Phase-220//230380/400/415/440V-50/60Hz | |

Control voltage | DC-36 / 48V | |

Motor protection class | IP54 IP55 IP65 | |

Control way | Cabin, wireless remote, pendant push button | |

Safety device | Buffer,current overload protection,overload device,power failure protection | |

Application area | Factory,workshop,warehouse,power station,logstic,etc. | |

Painting color | Yellow,Red or Customzied | |

Steel mill ladle crane vs. General use overhead crane

For ladles or other molten metals handling, the ladle casting cranes or metallurgical cranes must be used and the general use overhead cranes are not allowed in the high temperature and hazardous application conditions. In the following the comparison of the steel mill ladle crane and general use overhead cranes are presented for your reference.

Major difference of the ladle crane and general use overhead cranes:

- On working duty - The working duty of the casting crane is generally higher, usually above the A6 level.

- Superior components and parts- The loads of the metallurgical use crane is high temperature molten metal.The high temperature application requires the ladle crane adopting high-temperature resistant crane parts and components such as high-temperature resistant motors and cables, cast steel or rolling steel pulley, steel cored wire rope and so on.

- Heat insulation layer - To protect the crane beam from deformation due to the high temperature, heat insulation layers should be added beneath of the main beam of the steel structure.

- On wire rope - Steel cored wire rope is used on ladle crane for the fiber core wire rope may cause direct combustion and fail because of the high temperature application condition.

- Electric cabinet - The heat dissipation ability of the electric cabinet of the ladle crane must be good and air conditioner should be equipped when necessary, which is a important feature of the ladle casting crane. Explosion proof feature may be needed under special conditions.

- Crane Brake -Double braking systems are required for the main lifting system of the casting cranes, which are more than 2 brakes.

- On price - The casting overhead cranes are much more expensive than that of the general use overhead bridge crane. The overhead casting cranes are different from the overhead cranes in general, such as the selected electric cabinet, cable, crane motor, the reducer, , the crane brakes, hook off the hook, pulley, and others, etc.

Send a quotation on your ladle handling crane

- 1.the crane lifting weight is__________ton. A.0-10t B.10-25t C.25-100t D.80-120t

- 2.the crane lifting height is __________ m. A.0-5m B.5-10m C.10m-20m D.20m-30m

- 3.the voltage is V__________ HZ__________ 3phase. A.208/240V B.220V C.380/460V D.400V

- 4. the crane work duty is __________ (normal A3). A.Manufacturing B.Metals Production C.Shipyards D.Power

- 5.the span of crane is __________ m. A.5fpm B.10fpm C.15fpm D.30fpm

- 6.What material will be lifted?

- 7.the control model is__________. A.pendent control B.remote control C.cabin control

- 8.If you need rail and bus bar,please supply the travelling length is__________ m.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch