Electromagnetic cranes & Electromagnets - Electromagnetic overhead crane

Electromagnetic overhead cranes with types of electromagnetic chucks & magnetic carrier beams for steel scraps, billet, slab,wire, coil, pipe, plate, etc., handling with efficiency and safety.

| Crane Type | Overhead crane with electromagnetics |

| Crane Capacity | 5 ton ~32 ton |

| Crane Span | 10.5~31.5m |

| Working Class | A5, A6 |

Category: Overhead Crane

Your Trusted Overhead Travelling Crane Manufacturer & Supplier

Electromagnetic Overhead Crane,

Electromagnetic Cranes & Electromagnets

Overhead Travelling Cranes with Electromagnetic Chucks & Magnetic Beam Spreader

Electromagnetic overhead cranes with types of electromagnetic chucks& magnetic carrier beams for steel industrial material handling, such as, steel scraps, billet, girder, slab, wire ( coiled bar),bundled rebar, round steel pipe, heavy rail , steel plate , coiled steel, etc.Complete electromagnetic overhead crane system solutions for the steelindustry, which will improve the efficiency and flexibility of your processing and manufacturing, transporting and storage and eventually improve your profitability in steel business.

Electromagnetic overhead cranes for efficient material handlingin steel industries. Types of electromagnetic overhead cranesare available for you such as, overhead travelling magnetic cranes with round chucks, overhead bridge crane with hanging magnetic carrier beams, and rotatory beam spreader magnetic cranes, etc.

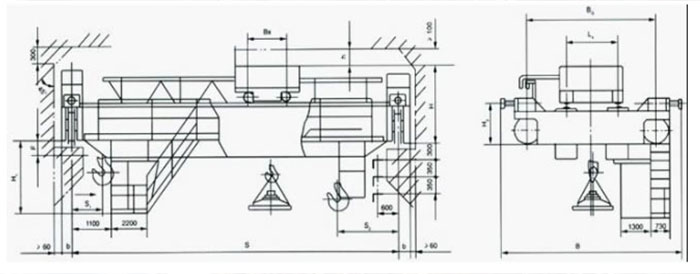

QC type of overhead electromagnetic cranes

QC type of Electromagnetic Overhead Crane is a kind ofelectromagnetic cranes with double girder overhead crane designs, equipped with detachable electromagnetic chucks & corresponding crane operating system to lift and transporting all the magnet-ableobjects such as steel scraps and various types of steel products such as billet, girder, slab, wire ( coiled bar),bundled rebar, round steel pipe, heavy rail , steel plate , coiled steel, etc

Overhead electromagnetic crane with round chucks:Capacity: 5 ton ~32 ton , Span: 10.5~31.5m, Working duty:A5, A6. The basic structure of the magnetic overhead crane with round chucks is same as that of a bridge overhead travelling hook crane, except that a DC lifting crane electromagnetic chuck is hung on the crane hook, for the handling of ferromagnetic ferrous metal and related products.

Overhead magnetic crane with carrier beam spreaders: The basic structure of magnetic beam cranes is double girderoverhead cranes, equipped with spreadersof electromagnetic carrier beam, which can be grouped into upper rotating electromagnetic cranes & lower rotating electromagneticcranes. The electromagnetic carrier beam overhead crane is designed for handling long steel billets, plates, bars, discs and other itemswith long liftingpoints.

Main crane parameters & crane specifications

The lifting capacity of overhead electromagnetic crane included the weight of electromagneticchucks is ranging from 5 to 32 ton. The working class of electromagnetic overhead cranesis A5 and A6. The retentive timeof crane magnetis 10 to 30 minutes.

Mainparameters of electromagnetic overhead crane is for your reference shown in the following table:

- Crane Type:QC type double girder overhead crane with electromagnetic chucks

- Lifting Capacity of Electromagnetic Crane:5 ton ~32 ton

- Span Lengthof Electromagnetic Crane:10.5~31.5m

- Working Class of Electromagnetic Crane:A5, A6

- Ambient Temperature ofElectromagnetic Crane:-20~40℃

- Retentive Time ofElectromagneticCrane:10 to 30 minutes

The electromagnetic overhead travelling crane is developedon the base of QD types ofoverhead hookcrane and the main structure is the same as that of overheadhook crane, but with an electromagnetic chuck for the material handling of steel scrapes, steel plate, steel pipe, steel bars, steel coil, steel slab, steel roll, etc.

Electromagnetic overhead crane is mainly consisted of overhead travelling crane bridge, crane trolley, crane traveling mechanism, crane operator's cab/ cabin, electrical system, and crane electromagnetic system, including electromagnetic chuck, rectification control equipment, cable connectors and othersparts and safety devices, etc.

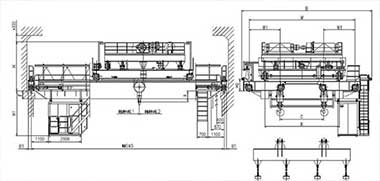

QL magnetic overhead crane with beam spreader

Magnetic cranes with customized electro- magnetic beam spreader, the cost-effective overhead travelling cranes solution for long and larger steel loads handling which enable the crane operator to handle loads remotely with high efficiency and safety.

The magnetic crane is a Double Girder Overhead Crane with rotary crane design, equipped with electro- magnetic beam spreader widely used for long and larger steel loads handling such as, steel rebar, steel billet slab, steel plate, steel sheet,steel pipe and other steel products in the steel mill and steel plants.

The magnetic crane is a high-efficiency rotary overhead crane for Metallurgy Industrial applications which is used used for stacking, transshipment and loading and unloading task of the steel warehouse. If your steel mill needs any overhead travelling crane system, please feel free to contact us to get the customized steel mill cranes,giving us a chance to save your money and increase your material handling safety.

Main parameters of magnetic cranes with beam spreader

- Load capacity of magnetic overhead crane : 7.5+7.5t -20+20t

- Span of magnetic overhead crane: 10.5-34.5 m

- Lifting height of magnetic overhead crane: 6-16m

- Lifting speed of magnetic overhead crane: 11.7-13.2m/min

- Trolley running speed of magnetic overhead crane: 31.3-37m/min

- Crane running speed of magnetic overhead crane: 58.5-74.3m/min

- Work duty of magnetic overhead crane: A5-A7

- Customized electro- magnet cranes are available.

The carrier beam electro- magnet crane is mainly consisted of box-shaped bridges, double girder trolleys, cart operation mechanisms, crane operators cabin and electrical control system, installed with power failure protection system. The lifting mechanism of magnetic crane with double lifting points beam spreader usually adopts single motor, double speed reducer and double reel arrangement. And the electro- magnet beam spreader can be installed to the main girder either perpendicularly or parallel. And the other forms of the magnetic overhead crane are the same with the general use double girder overhead crane with hook.

Advantages of electromagnetic overhead cranes

- The unique coil designmakesthe suction fore of the electromagnetic chuck strongand capable of high loading capacity and heavy duty working class application.

- Fine selection, standard steel with carbon content lessthanthat 0.12% carbon steeland together with delicate crane design makes the magnetic crane featured as light dead weight, lower wheel load and low noise.

- Precision manufacturing, high rigidity, stableperformance, very small heat change, low power consumption andlow crane maintenance.

- Ergonomic design for easyand ease crane operation , Good usability and durability, High safety and reliability.

- CE certificated hoist and crane, Factory direct sale, Competitiveoverhead cranepricewithout any compromise ofquality.

Features of electromagnetic overhead crane

- High quality materials and standards ensure high quality, safety, stability and durability of magnetic overhead cranes. In accordance to the nation regulations and standards, all compression structural part of electromagnetic overhead crane's components are made of high quality materials, and theinspection report is available when required.

- High quality welding is under supervision strictlyand closely. The welding ofcranesteel structures are strictly checked and inspected and theinspection reports and photos of every each processing procedure also can be informed to clients on requirement.

- High quality motors with high safety and stability are installed with Class F insulation and IP54 protective class to ensure the good performance of your magnetic cranes

- Easy operation is ensured for all the mechanismis operated under PLC control. Any speed requirement is achievable.

- Flexible crane control methods at you your selection, Cabin with joystick panel, wireless radio control and pendant control.

- Protective and durable crane painting. 3 layers crane painting isrequired to protectthe steel from rusting.

- Various protective devices and measurements are used to secure overhead crane safety, such as overload limiter, height limiter, rail end stop, andshort circuit protection, lose phase protection, low-voltage protection, power failure protection, over current protection, and others , etc.

Electromagnets

A lifting electromagnet is a lifting devicewith an iron core, which can be easy magnetizableby current througha current-carrying coil. The electromagnetic crane chuckis magnetic when energized, and disappears when the currentis turned off. Lifting electromagnets have anextraordinarywide applications inmaterial handlingwith the following advantages:

- Electromagnet magnetism can be easily controlled by switching on-off current;

- The strength of the electromagnetic is controllable by adjustingthe strength of the current or the number of coil turns;

- Magnetic sizeis controllable by adjusting the size of the resistance control current.;

- Magnetic pole is controllable by changing the direction of the current, and so on.

Types of magnetics

Round magnetics for overhead crane and gantry crane

Oval magnetics beam spreaders for types of cranes

Electromagnet for overhead crane for high speed wire ( coiled bar), steel bundles handling cranes

- Round magnetic chunks-Due to the compact dimensions and high load capacity, our round magnets can work together with your electromagnetic crane for large pieces of sheet and plate metal handling with outstanding performance

- Single magnets chucks: Single round magnetic chuck is supposed to hold / suck and transport small metal plate / sheet, broken castings, screws, nuts and bolts or other small parts, etc.

- Carrier beam spreader magnets: Electromagnetic carrier beam spreader is aimed to handle larger sheet and plate or long objects with many lifting points, which can eliminate the sag which usually occurs during the lifting of sheet metal at many points. The carrier beam magnetic crane has a wide application.

- Excavator electromagnetic chuck: Developed from scrap electromagnet, the excavator electromagnetic chuck is installed on the excavator, featured asconvenient, quick and flexiblebut with relatively high generator oil- consumption.

- Automatic electromagnet: With the features of strong and reliable suction, high security within full voltage, the automatic electromagnetic sucker can ensure continuous work for 24 hours.

- Permanent magnet lifter: The magnetic crane chucks is for all magnetizable loads, ageneral material handling attachments, especially offering reliable suction and hold for flat and round objects or loads. The crane magnetic sucker has a wide application for indooror outdoors in the manufacturing and assembly areas with high safety, high reliability, low operation costs and low maintenance.

Advantages of electromagnetic chucks

Types ofelectromagnetic crane chuckswith different capacity, sizes and shapes are available to work with your electromagnetic overhead cranes for efficient handling of steel scraps, billet, girder, slab, wire ( coiled bar), bundled rebar, round steel pipe, heavy rail, steel plate, coiled steel, etc.

The main advantages of electromagnetic crane chucks are as following for your reference.

- With fully sealed structure design, the electromagnetic crane chucks has good moisture resistance.

- With optimized design,the electric crane magnet is with the features of reasonable structure, light weight, strongsuctionforce, butlow energy consumption.

- The electrical and mechanical properties of excitation coils are improved by special treatment.

- The thermal rating of the insulation materials is Class C, ensuringa long service life.

- The use efficiency of electromagnetsis largely improved by the incrementof the rated electrification continuation rate of ordinary electromagnets.

- Adopting special heat insulation , theultra-high temperature electromagnet is able to handle objects with the temperature up to 700°C and the application of electromagnetis expanded.

Tailored electromagnetic cranes and magnetic chucks are available at good price. Leave your message below to get consultation from our magnetic crane engineers for free.

Application of overhead electromagnetic crane

The overhead bridge electromagnetic cranes are specially designed overhead cranes forindustrial steel mill applications, for indoor and outdoor black metal materials and products, handling, transporting,and storing,etc.

Electromagnetic overhead cranes has a wide applications, which can be used in various industries, such as, steel industry, foundry, metallurgy, iron and steel, metal mines, construction and building materials, petrochemicals, shipbuilding, port transportation, brick ceramics,paper-making, oil, food, and railway logistics, and others, etc.

Get your electromagnetic crane and magnets

To offering customized magnetic overhead crane solution to satisfy your specific needs and industrial requirements are always what we are devoted to. If you have any need of hoist or crane, or have any questions or doubt related to overhead travelling cranes and hoists, please feel free to contact us. If you have any inquiry about the electromagnetic overhead cranes or electromagnetic suckers, please kindly offering the following information for quick and specific quotation. The information needed for electromagnetic crane quotation are including:

- Type of electromagnetic overhead crane: Round magnetic crane or carrier beam magnetic crane?

- Whats is the capacity? lifting height? Crane span? Travelling length?

- What is the loads for the needed electromagnetic crane?Weight ? Size? Temperature?

- Do you have any drawing about your workshop, or about the electric magnet?

- Do you have any special requirements about the electromagnetic overhead crane?

- Could you please leave us your good name and contact email for efficient communication?

With specific informationand parameters, our engineers can send you quotation as soon as possible and our reply will be given within 24 working hours. Leave your requirements for the electromagnetic overhead crane below now to get free consultation and free overhead crane brochure and customized overhead electromagnetic crane solution.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch