Single Girder Gantry Crane

Single girder gantry cranes & single beam gantry cranes overview on single girder gantry crane specifications, gantry crane designs, crane types, features & usage, etc.

| Crane Type | Single girder gantry crane |

| Crane Capacity | 3-20 ton |

| Crane Span | 7.5-31.5 m |

| Lifting Height | 6/9/12/18 m |

| Working Class | A5 |

Category: Gantry Crane

Your Trusted Overhead Gantry Crane Manufacturer & Supplier

Economical Overhead Gantry Crane Solutions

Single Girder Gantry Cranes for Sale 3 Ton, 5 Ton, 10 Ton, 15 Ton to 20 Ton

Single beam gantry cranes as one of the most economical overhead travelling crane solutions offer a various of gantry girder designs and configurations. Single girder gantry crane is a light duty Single girder gantry crane with Single gantry girder design, featured as simple structure, easy manufacturing and installation, and light self-weight.

Single Girder Gantry Cranes for Efficient Material Handling Needs

Single Girder Gantry Cranes provide a robust and flexible solution for managing the movement of materials. Their versatility enables them to handle a variety of tasks, from lifting and positioning heavy components to organizing inventory in confined spaces. By integrating these cranes into their operations, businesses can enhance their efficiency, reduce operational downtime, and maintain a steady flow of production.

Main Crane Parameters & Crane Specifications

The main crane parameters and crane specifications of the standard single girder gantry cranes are as following for your reference. And process design gantry crane are available. Please contact us to confirm detailed crane specifications and parameters.

- Lifting capacity of single beam gantry crane: 3-20 ton

- Gantry hoists : wire rope hoists, chain hoists, manual hoist or FEM hoists,

- Span of single beam gantry crane: 7.5-35 m

- Lifting height of single beam gantry crane: 6/9/12/18 m

- Working class of single beam gantry crane: A5

Advantages of Buying a Single Girder Gantry Crane

Why to buy single girder gantry crane? What is the advantages of buying a single girder gantry crane?

- Single girder gantry cranes are able to offering material handling solution without making large investments.Single girder gantry cranes with the runway located on the floor, which need no supporting steel structure, saving building construction cost, which are more cost-effective comparing with the overhead crane system.

- Single girder gantry crane s have a wide application indoors and outdoors.Single girder gantry cranes can be used when the existing steel or concrete structure of factory workshop cannot support the wheel loads of the overhead crane, or when the handling objects need to be lifted outside the crane span and when the crane relocation is required after finishing tasks at a certain site.

- Single girder gantry cranes offers more flexible material handling solutions.With adjustable design, the single girder gantry crane can adjust the heights, spans, and treads , which makes loads go through doorways or around obstacles flexibly and easily. With portable or movable design, the portable Single girder gantry cranes offers a completely mobile solution with capacity up to 10 tons, a great alternative to large and permanent crane system.

If the single girder gantry crane will travel on the same path, the fixed rail gantry cranes make the travelling of single girder gantry crane simple and fast. If space is limited, a single leg gantry crane can provide a lifting solution with a wall-mounted semi-gantry, or A-frame gantry cranes with single or no cantilever design may offer satisfied solutions. With different wheel options, single girder gantry cranes are able to provide the right wheels for the particular applications.

The single girder gantry crane is more economical, much easier for installation and commissioning, and gantry crane cost for maintenance is extremely low. More on monorail single beam gantry crane specifications and gantry crane price, please contact us.

Hot Sale Single Girder Gantry Cranes Types and Comparison

Comparative Analysis of Single Girder Gantry Cranes

Single girder gantry cranes are pivotal in various industries for their versatility, efficiency, and cost-effectiveness in material handling. As the name suggests, these cranes feature a single main beam (or girder) supported by end trucks and running on rails, allowing them to perform lifting tasks with precision. However, not all single girder gantry cranes are created equal. They come in different configurations, designs, and capacities, each suited to specific operational needs and environments. This comparative analysis delves into the key variations among single girder gantry cranes, including differences in design, capacity, and application. By examining factors such as European-style versus traditional designs, A-frame versus L-frame structures, and standard versus simple gantry configurations, we aim to provide a comprehensive understanding of how these cranes can best meet diverse industrial requirements. This guide will help you make an informed decision by highlighting the strengths and limitations of each crane type, ultimately aiding in selecting the most suitable single girder gantry crane for your operational needs.

Single girder gantry cranes can be grouped into different types in terms of cantilever design of gantry frame , numbers and shapes of gantry girder, and applications, etc. According to your applications, we are able to provide your single beam gantry crane with process crane design. Contact us to get your tailored gantry crane and get good gantry crane price.

Single Girder Gantry Crane Design: European Style vs Traditional Style

Single girder gantry cranes come in two main design styles: European and traditional. The European-style single girder gantry crane features a compact structure, low headroom, and efficient operation, often equipped with a frequency inverter and modular electric hoist. It emphasizes lightweight design and energy efficiency. In contrast, the traditional style typically uses heavier steel structures, standard control systems, and offers a more rugged, cost-effective solution for basic material handling. The choice between them depends on factors like operational frequency, workspace constraints, and performance requirements.

European Style Single Girder Gantry Crane

European Style Single Girder Gantry Crane

Overview: European Style Single Girder Gantry Cranes are known for their high-quality construction, modern design, and advanced safety features. These cranes are widely used in various industries across Europe and are becoming increasingly popular globally.

Key Features:

- Design: Compact and robust design with a high degree of modularity.

- Lifting Capacity: Typically ranges from 1 ton to 20 tons.

- Configuration: Often features a top-running configuration for efficient space utilization.

- Safety Features: Includes advanced safety systems such as limit switches, overload protection, and emergency stop buttons.

- Performance: High lifting precision and smooth operation due to sophisticated control systems.

Applications:

- Manufacturing: Suitable for precise lifting tasks in manufacturing environments.

- Warehousing: Ideal for efficient material handling in warehouses.

- Light Industry: Used in various light industrial applications requiring high safety standards.

Traditional Design Single Girder Gantry Crane

Traditional Design Single Girder Gantry Crane

Overview: Traditional Design Single Girder Gantry Cranes are characterized by their classic design and straightforward functionality. They offer a cost-effective solution for many standard lifting applications.

Key Features:

- Design: Conventional design with a simple girder structure.

- Lifting Capacity: Typically ranges from 1 ton to 10 tons.

- Configuration: Commonly features a top-running or underhung configuration.

- Safety Features: Basic safety features including limit switches and emergency stops.

- Performance: Reliable for general material handling with moderate precision requirements.

Applications:

- Construction: Suitable for construction sites requiring durable and straightforward lifting solutions.

- Maintenance: Ideal for maintenance tasks in various industrial settings.

- Small to Medium Warehousing: Used in facilities with standard lifting requirements.

Comparison: European Style vs. Traditional Design

Comparison: European Style vs. Traditional Design

Load Capacity:

- Both European and traditional designs can handle capacities of 3 tons, 5 tons, 10 tons, and 20 tons, but the design may influence the efficiency and operational characteristics.

Design and Aesthetics:

- European Style: Sleek, modern, and compact, with an emphasis on efficiency and advanced features.

- Traditional Design: Heavier and more straightforward, with a focus on durability and simplicity.

Construction Materials:

- European Style: Uses high-strength, lightweight materials to enhance performance.

- Traditional Design: Employs standard steel components, which are more robust but heavier.

Cost:

- European Style: Higher initial cost due to advanced technology and materials.

- Traditional Design: Lower initial cost, more budget-friendly.

Maintenance and Operation:

- European Style: May require specialized maintenance due to advanced features.

- Traditional Design: Easier and more cost-effective maintenance.

Applications:

- European Style: Best for modern, high-tech environments where space efficiency and advanced features are critical.

- Traditional Design: Suitable for general industrial use, especially where robustness and cost-effectiveness are prioritized.

Choosing between a European style and a traditional design Single Girder Gantry Crane depends on your specific needs regarding space, technology, budget, and operational requirements.

Single Girder Gantry Crane: Box Girder Design vs. I Beam Girder Design

When selecting a Single Girder Gantry Crane, choosing between a box girder design and an I beam girder design is a crucial decision. Each design offers distinct advantages and is suited to different operational needs. Here's a detailed comparison to help you determine the best option for your application:

Box style single girder gantry crane

Box Girder Design

Box Girder Design

A box girder design features a girder that is shaped like a hollow box, offering a closed cross-sectional profile. This design is known for its strength and rigidity.

Key Features:

- Shape: The girder is a hollow box, which can be made from various materials, including steel or aluminum.

- Strength: Provides high strength-to-weight ratio due to its closed shape, allowing it to handle larger loads and span longer distances.

- Stability: The box girder design enhances stability and reduces deflection under load.

Advantages:

- Higher Load Capacity: The enclosed box shape can handle greater loads and distribute stress more evenly, making it suitable for heavy-duty applications.

- Reduced Deflection: Box girders are less prone to bending and deflection compared to I beams, ensuring more precise load handling.

- Durability: Offers better durability and resistance to deformation, enhancing the crane's longevity.

- Aesthetic and Safety: The design can provide a cleaner appearance and reduce the risk of injuries from protruding parts.

Disadvantages:

- Cost: Generally more expensive due to the complex fabrication and material costs.

- Weight: Heavier than I beam designs, which may require more robust support structures.

Applications:

- Heavy Industry: Ideal for applications requiring high load capacities and long spans, such as steel mills, shipyards, and large manufacturing facilities.

- Long Spans: Suitable for environments where long spans are required without intermediate supports.

I Beam Girder Design

The I beam girder design features a girder with a cross-section resembling the letter "I". This traditional design is widely used due to its simplicity and cost-effectiveness.

Key Features:

- Shape: The girder has a vertical web and two horizontal flanges, forming an "I" shape.

- Strength: Provides a good balance of strength and weight, suitable for many general applications.

- Flexibility: Often used for standard applications with moderate load requirements.

Advantages:

- Cost-Effective: Typically less expensive to manufacture and install compared to box girders, due to simpler design and fabrication processes.

- Simplicity: Easier to design and integrate into various crane systems, making it suitable for standard applications.

- Lightweight: Lighter than box girders, which can reduce the cost of supporting structures and installation.

Disadvantages:

- Load Capacity: May not handle as large loads or long spans as effectively as box girders.

- Deflection: More prone to deflection under heavy loads, which can affect precision and stability.

- Durability: Less resistant to deformation compared to box girders, potentially impacting long-term performance.

Applications:

- General Industry: Well-suited for moderate load applications and environments where cost-effectiveness and ease of installation are priorities.

- Standard Facilities: Ideal for facilities with typical load and span requirements, such as warehouses, workshops, and light manufacturing plants.

Comparison and Selection:

Comparison and Selection:

Load Capacity and Span:

- Box Girder: Handles larger loads and longer spans with reduced deflection, making it ideal for heavy-duty applications.

- I Beam: Suitable for moderate loads and shorter spans, offering cost advantages for standard applications.

Cost:

- Box Girder: Higher initial cost due to complex design and materials but offers greater strength and durability.

- I Beam: More cost-effective and simpler to fabricate, ideal for budget-conscious projects.

Durability and Maintenance:

- Box Girder: Provides enhanced durability and reduced maintenance needs due to its robust design.

- I Beam: May require more frequent maintenance and inspection due to susceptibility to deflection and deformation.

Installation:

- Box Girder: Heavier and may require more robust support structures and complex installation procedures.

- I Beam: Easier to install with fewer structural modifications required.

Aesthetic and Safety:

- Box Girder: Offers a cleaner appearance and increased safety by minimizing protruding parts.

- I Beam: More exposed components that may require additional safety measures.

The choice between a box girder and an I beam girder design for your Single Girder Gantry Crane should be based on your specific load requirements, span needs, budget, and operational environment. Box girders are ideal for heavy-duty applications with high load and span requirements, while I beams offer a cost-effective solution for general applications with moderate demands. Evaluating these factors will help you select the design that best meets your operational needs and ensures optimal performance.

Single Girder Gantry Crane : Truss Gantry vs. Box Gantry

In terms of the structure of gantry girder designs , single girder gantry cranes can be grouped into

- Truss single girder gantry crane- The truss gantry girder is welded with angle steel or I-beam, featured as low manufacturing cost, light self-weight, and good wind resistance. However, due to the large amount of welding points and the inborn defects of the trusses structure,, the truss gantry girder has the disadvantages of large deflection, low rigidity, low reliability, and frequent welding spots detection. Truss cranes are suitable for application with low requirements on safety and lifting capacity.

- Box structure single girder gantry crane- The box shaped gantry girder is welded with steel plates , with features of high safety, stiffness and other, etc. Box gantry girder design is usually used for Single girder gantry cranes with large and super large tonnages. The box gantry girder design also has the drawbacks of high production cost, heavy self weight and poor wind resistance.

Truss type single girder gantry crane with capacity of 3 ton to 20 ton

Box girder single girder gantry crane with capacity of 3 ton to 20 ton

European style full gantry crane with capacity of 1 ton to 20 ton

Girder Design Comparison: Truss Gantry vs. Box Gantry Crane

Single girder gantry cranes are versatile and widely used across various industries, including construction, manufacturing, and logistics. The two primary types of single girder gantry cranes are truss gantry cranes and box gantry cranes. Both types have distinct structural features, advantages, and applications. Below is a detailed comparison to help you understand which one might be best suited for your needs.

Structural Design

Structural Design

- Truss Gantry Crane: The truss gantry crane features a framework of connected triangular structures, resembling a lattice or web. The truss design allows the crane to be lighter while maintaining structural integrity. Truss cranes are typically made of steel or aluminum and have a lot of open spaces in their construction, which contributes to their lightweight nature.

- Box Gantry Crane: The box gantry crane has a solid, enclosed girder resembling a box-shaped beam. This design makes the crane more rigid and capable of handling heavier loads compared to truss cranes. The box-shaped girder is usually made of welded steel plates, making it heavier and bulkier than the truss gantry crane.

Weight and Mobility

Weight and Mobility

- Truss Gantry Crane: The truss design is inherently lighter, which allows for easier transportation and installation. This makes the truss gantry crane an excellent option for situations requiring frequent mobility or for temporary work sites where the crane needs to be relocated often. Its light weight also puts less stress on the wheels and rail systems.

- Box Gantry Crane: Box gantry cranes are heavier due to their solid beam structure, which makes them more challenging to move. However, the heavier weight contributes to their increased stability and ability to lift heavier loads. These cranes are typically used in permanent or semi-permanent installations where mobility is not a primary concern.

Load Capacity and Applications

Load Capacity and Applications

Truss Gantry Crane: Truss gantry cranes are generally used for lighter to moderate load applications. Their open-frame design allows them to handle loads up to a certain limit (typically around 5 to 10 tons for single girder configurations). They are best suited for environments where wind resistance is a factor, such as outdoor sites, as the open truss design minimizes wind load impact.

Applications:Construction sites,Open-air workshops,Temporary loading zones,Small to medium-scale material handling

Box Gantry Crane: The box gantry crane is designed to handle much heavier loads, often exceeding 10 tons. Due to the enclosed, solid beam structure, it is better suited for high-capacity lifting in heavy-duty industries. Box cranes are less affected by weather conditions and provide greater stability under load, making them ideal for indoor operations or high-capacity outdoor applications.

Applications:Heavy manufacturing,Steel mills and foundries,Warehouse and logistics operations,Long-term projects requiring high-capacity lifting

Wind Resistance and Environmental Considerations

Wind Resistance and Environmental Considerations

- Truss Gantry Crane: Truss gantry cranes are ideal for environments with strong winds because their open-frame structure reduces wind resistance. This makes them particularly suited for outdoor applications, including construction and ports, where high winds could otherwise cause instability.

- Box Gantry Crane: Box gantry cranes have a solid beam structure, which means they face more wind resistance. For outdoor use, especially in high-wind environments, additional measures may be necessary to ensure stability. They are, however, more resistant to adverse environmental conditions such as rain or snow due to their solid construction.

Cost and Maintenance

Cost and Maintenance

- Truss Gantry Crane: Truss gantry cranes are generally less expensive than box gantry cranes due to their lighter materials and simpler design. However, due to the open-frame nature, they may require more frequent maintenance, especially if used in areas prone to debris buildup within the truss structure. Inspection and cleaning can be more time-consuming compared to box cranes.

- Box Gantry Crane: Box gantry cranes are more expensive due to the use of more material and the need for additional structural integrity. However, their enclosed design requires less frequent maintenance compared to truss cranes, as there are fewer exposed elements. The solid beam is less likely to suffer from environmental wear and tear, making it more durable over the long term.

Flexibility and Customization

Flexibility and Customization

- Truss Gantry Crane: Truss gantry cranes are more flexible when it comes to custom configurations. Their modular structure allows for easier alterations and extensions, making them adaptable to different workspace sizes and project needs. The truss design can also accommodate various attachments and components without adding much weight to the overall structure.

- Box Gantry Crane: Box gantry cranes, while highly stable, are less flexible when it comes to customization. Their solid beam structure is more difficult to modify, and any alterations often involve significant reengineering. These cranes are better suited for specific, high-capacity applications where flexibility is less of a concern.

Choosing Between Truss and Box Gantry Cranes

Choosing Between Truss and Box Gantry Cranes

When choosing between a single girder truss gantry crane and a single girder box gantry crane, the decision largely depends on the application and environmental factors:

- Truss Gantry Cranes are ideal for lighter loads, outdoor use, and environments with high wind speeds. They are also a more economical and mobile option, suitable for temporary or semi-permanent setups.

- Box Gantry Cranes are better suited for heavy-duty applications where higher lifting capacities, stability, and durability are required. They are typically used in industrial settings where the crane will remain in place for long periods and wind resistance is not a primary concern.

For industries like construction or temporary material handling, truss gantry cranes are often the best choice. In contrast, for manufacturing or logistics where heavier loads and stability are crucial, a box gantry crane will likely be more appropriate.

Single Girder Gantry Crane: Full Gantry vs. Semi Gantry Crane

In terms of structures of gantry frame , Single girder gantry crane can be grouped into

- Full single girder gantry crane - Single girder gantry crane with full gantry design is a double leg single girder gantry crane, with main beam girder supported on the two legs, which are in the same height.

- Semi single girder gantry crane - Single girder gantry crane with semi gantry design is a Single leg single girder gantry crane, with the other end of the main girder supported on the building structure.

Comparison of Full and Semi Gantry Cranes

Single girder gantry cranes are highly effective for a variety of industrial tasks, offering cost-efficient lifting solutions where overhead crane systems may not be feasible. Within the category of single girder gantry cranes, the two primary configurations are full gantry cranes and semi-gantry cranes. Each type has unique advantages depending on the operational requirements, workspace layout, and specific lifting tasks.

Structural Design

- Full Gantry Crane: A full gantry crane consists of two legs that span the entire width of the workspace. These legs travel on rails embedded in the floor on both sides, providing a freestanding system that covers a wide area. The bridge (girder) spans across the legs, allowing the hoist to move horizontally across the span.

- Semi-Gantry Crane: A semi-gantry crane has only one leg that travels on a floor rail, while the opposite end of the crane is mounted on a wall or runs along a supporting structure, such as a building column. This means the crane has an asymmetrical design, where one side is supported by a leg and the other is anchored to an elevated rail or runway attached to the building structure.

Space Requirements

- Full Gantry Crane: Full gantry cranes require more open floor space, as both legs need to travel on rails embedded into the ground. This setup works best in large areas such as factories, shipping yards, or warehouses with no restrictions on floor space. The entire crane system operates independently, making it ideal for covering vast operational areas.

- Semi-Gantry Crane: Semi-gantry cranes are better suited for facilities with limited floor space, as only one side of the crane uses a floor rail. The other side is supported by an existing structure, which reduces the amount of ground space needed. This setup is ideal for facilities where part of the floor space is constrained, but there is adequate structural support on one side of the workspace.

Load Capacity and Applications

Full Gantry Crane: Full gantry cranes are designed for higher load capacities, making them suitable for heavy-duty industrial applications. Depending on the size and configuration, single girder full gantry cranes can handle loads ranging from a few tons to tens of tons. They are typically used in industries like shipbuilding, steel fabrication, construction, and outdoor material handling where large items such as containers, steel beams, or heavy machinery need to be moved.

Applications:Shipping container yards,Steel yards and warehouses,Large-scale construction sites,Manufacturing plants.

Semi-Gantry Crane: Semi-gantry cranes are often used for medium to heavy loads but generally have lower load capacities compared to full gantry cranes. Since they are anchored to a wall or a support structure, semi-gantry cranes provide a compact lifting solution for workshops or facilities with limited space but do not require the same floor area as a full gantry crane.

Applications:Small to medium-sized workshops,Warehouses with limited floor space,Facilities where one side is open to ground traffic,Indoor and outdoor operations,

Flexibility and Mobility

- Full Gantry Crane: Full gantry cranes offer full mobility and flexibility within their workspace, as they can move freely on rails that span the entire operational area. This makes them ideal for operations that need complete coverage of a large space. Full gantry cranes can also be customized with different span lengths, heights, and capacities to suit various lifting needs.

- Semi-Gantry Crane: Semi-gantry cranes are more restricted in movement, as one side of the crane is attached to a fixed structure. However, they still offer excellent mobility within the workspace. This design is particularly useful when floor space is limited, but flexibility is needed to move loads in and out of confined areas.

Cost and Installation

- Full Gantry Crane: Full gantry cranes are generally more expensive than semi-gantry cranes due to the need for additional materials, such as dual support legs and floor rails on both sides. Installation can be more complex, as it requires precise alignment of the rails and legs. Additionally, the costs of rail maintenance and the potential need for a larger foundation should be considered.

- Semi-Gantry Crane: Semi-gantry cranes are usually more cost-effective, as they require only one supporting leg and floor rail, with the other side mounted on an existing wall or structure. Installation is often simpler because there are fewer rails to install and align. In facilities where a wall or support structure is already available, a semi-gantry crane can be a more economical choice.

Ease of Maintenance

- Full Gantry Crane: Full gantry cranes typically require more maintenance because both legs are moving on rails embedded in the ground. Over time, debris, weather, and other environmental factors can affect the rail system. Regular inspection and cleaning of both rails, as well as the crane's legs, is necessary to ensure smooth operation.

- Semi-Gantry Crane: Semi-gantry cranes have fewer moving parts since only one side is supported by a leg. This can make maintenance easier, as there is only one rail to maintain on the floor. The overhead runway or support structure also tends to experience less wear compared to a full gantry crane, reducing the overall maintenance burden.

Wind Resistance and Outdoor Use

- Full Gantry Crane: Full gantry cranes are commonly used outdoors, making them susceptible to wind loads. Their dual-leg structure provides more stability in windy conditions, making them suitable for use in environments such as shipyards or open-air industrial sites where high winds are common. However, they may require additional wind bracing or other safety features in extreme weather conditions.

- Semi-Gantry Crane: Semi-gantry cranes are generally used in more sheltered environments or indoors because their asymmetrical design can make them less stable in high wind conditions. However, in indoor settings or environments where one side is protected by a wall or structure, they offer excellent performance and stability.

Customization and Use Case Flexibility

- Full Gantry Crane: Full gantry cranes are highly customizable. Their span, height, and capacity can be adjusted to meet specific operational needs. They can also be outfitted with special attachments or features, such as rotating hooks, magnet systems, or grab buckets, to handle various types of loads.

- Semi-Gantry Crane: Semi-gantry cranes are also customizable but typically less so than full gantry cranes because of their reliance on a fixed support structure. However, they are still flexible enough to be adapted for different load capacities, heights, and span lengths, making them suitable for many industrial environments.

Conclusion: Choosing Between Full Gantry and Semi-Gantry Cranes

When choosing between a full gantry crane and a semi-gantry crane, consider the specific needs of your workspace and the type of lifting you will be performing:

- Full Gantry Cranes are best for applications requiring maximum flexibility, full workspace coverage, and heavy-duty lifting. They are more suitable for large, open areas where space is not a concern and high-capacity loads need to be moved over long distances.

- Semi-Gantry Cranes are ideal for facilities with limited floor space or where one side of the crane can be anchored to an existing structure. They are a cost-effective solution for medium-duty lifting in confined spaces where full gantry cranes might not be practical.

Both crane types offer unique advantages, and the best choice depends on your specific operational and space requirements.

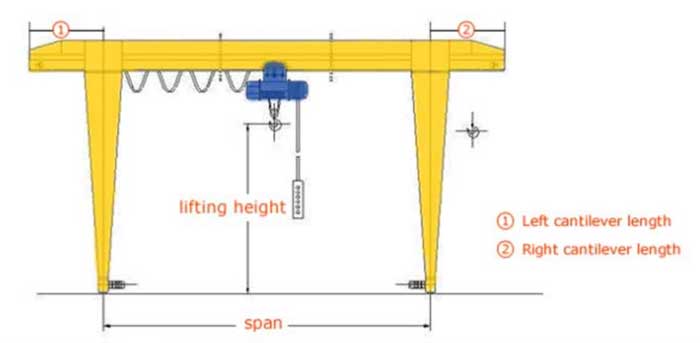

Double Cantilever, Single Cantilever & No Cantilever

In terms of cantilever design of gantry frame , single girder gantry crane can be grouped into

- Double cantilever Single girder gantry crane -Single girder gantry crane with double cantilevers are the most frequently used structure, which can take full use of the endurance capacity of crane structure and application space reasonably.

- Single cantilever Single girder gantry crane - Single girder gantry crane with Single cantilever is usually used when the application space is limited.

- Single girder gantry crane with no cantilever - Single girder gantry crane with no cantilever makes the hoisting trolley or winch trolley running within the crane span.

Box type single girder gantry crane with single cantilever

Single girder gantry crane with no cantilever

Single girder gantry cranes are versatile and efficient lifting systems used in various industrial environments. One of the key features that differentiates these cranes is the cantilever design, which affects the crane's overall workspace coverage, load handling, and structural balance. Let's explore the three main cantilever configurations—double cantilever, single cantilever, and no cantilever—and how each impacts crane performance and application.

Double Cantilever Single Girder Gantry Crane

Double Cantilever Single Girder Gantry Crane

In a double cantilever configuration, the single girder of the crane extends beyond the legs on both sides. This extra length beyond the supporting legs allows the hoist to cover a larger working area, making it possible to move loads beyond the track width of the gantry. The cantilevered ends also allow the hoist to service areas that are outside the main structure, providing more flexibility in load handling.

Key Features:

- Increased Span Coverage: The double cantilever design allows the crane to handle loads across a broader area, extending beyond the legs, which increases the operational range.

- Enhanced Flexibility: With both ends extending, loads can be picked up or placed outside the boundaries of the gantry legs, making it ideal for tasks that require access to peripheral areas.

- Improved Load Handling: The extended girder can accommodate oversized or longer loads, offering more flexibility for moving materials that exceed the main span.

Applications:

- Warehouses and factories where goods need to be lifted or stored outside the main crane runway area.

- Shipping yards where containers or materials are moved from the crane area to adjacent storage.

- Construction sites where materials must be transferred over large distances, including beyond the support legs.

Pros:

- Greater working area and flexibility.

- Ability to handle loads outside the main runway.

- Efficient for long-span applications and handling oversized materials.

Cons:

- Increased weight on the crane structure due to extended cantilever.

- More complex structural design, often requiring additional bracing or support.

Single Cantilever Single Girder Gantry Crane

Single Cantilever Single Girder Gantry Crane

A single cantilever configuration involves the crane's girder extending beyond the legs on only one side, creating an asymmetrical structure. This design is a compromise between the full coverage of a double cantilever and the simpler structure of a no cantilever system. It provides partial flexibility while keeping the crane's overall design lighter and simpler than a double cantilever system.

Key Features:

- Partial Extension: The girder extends beyond one set of legs, allowing the hoist to reach areas outside the crane's primary track on just one side.

- Balanced Flexibility and Simplicity: This design offers some flexibility in load handling beyond the legs while maintaining a simpler structure than a double cantilever crane.

- Optimized for Smaller Spaces: Single cantilever cranes are ideal for operations where space is limited on one side but more coverage is needed on the other.

Applications:

- Warehouses or workshops where storage or workspace is available on one side of the crane.

- Operations where some peripheral access is required, but not as extensive as what a double cantilever would provide.

- Factories with limited floor space on one side but needing extra reach on the other side for loading or unloading.

Pros:

- Lighter and simpler than double cantilever cranes.

- Provides additional coverage on one side without overcomplicating the design.

- Ideal for spaces with asymmetrical storage or operation needs.

Cons:

- Limited coverage compared to double cantilever systems.

- Asymmetrical design can cause unbalanced load distribution if not carefully managed.

No Cantilever Single Girder Gantry Crane

No Cantilever Single Girder Gantry Crane

Design Overview

In a no cantilever design, the girder does not extend beyond the supporting legs. The load handling area is entirely within the space between the legs, which means the hoist can only operate directly above the crane's footprint. This configuration offers a compact, stable, and balanced design, making it ideal for environments where space is limited or precision handling within the crane's track area is required.

Key Features:

- Compact Design: The girder ends directly at the legs, so there is no overhanging structure. This compact design reduces the crane's footprint and is suitable for indoor operations.

- Stability: No cantilever designs are more stable and balanced, with evenly distributed loads, making them suitable for operations where high precision and safety are needed.

- Lower Cost: This design is simpler and less costly than cantilevered configurations since fewer materials and structural reinforcements are needed.

Applications:

- Indoor factories and workshops where space is limited, and all work is confined within the crane's track area.

- Facilities where precise, confined movements are required.

- Small to medium-sized warehouses where the load is lifted and transported within the crane's legs.

Pros:

- More stable and balanced load distribution.

- Lower cost and simpler design.

- Ideal for confined spaces or smaller operational areas.

Cons:

- Limited workspace coverage, as the hoist is confined to the area within the crane's legs.

- Not suitable for moving loads outside the crane's main footprint.

Single Girder Gantry Crane: A-Frame Design vs. L-Frame Design

According to the leg design , the Single girder gantry cranes have L-shaped leg single girder gantry crane and C-shaped leg single girder gantry crane,and A frame single girder gantry crane.

- L shape leg single girder gantry crane - The L-shape leg single girder gantry crane is easy to manufacture and install, , good endurance capacity and light self-weighted. However, the space for lifting cargo through the legs is relatively small.

- C shape leg single girder gantry crane -The C-shaped legs are made to be inclined or curved so as to have a large lateral space for the cargo to pass through the legs.

- A frame single girder gantry crane - The A frame single girder gantry crane is a variation of general use single girder gantry crane, which shape of side profile, which is used for light and medium material handling.

A-Frame Design (up to 20 Ton)

A-Frame Design (up to 20 Ton)

Features:

- Structural Design: The A-Frame design features legs shaped like an "A," providing a stable and balanced support for the main girder. This configuration is typically used for lighter to medium-duty applications.

- Load Capacity: Designed to handle loads up to 20 tons. It is ideal for moderate lifting tasks.

- Construction Materials: Often constructed from high-strength steel or other durable materials to ensure stability and safety.

- Configuration: Usually features a fixed height and width, but some models may offer limited adjustability.

- Space Efficiency: The A-Frame design is generally more compact compared to other designs, making it suitable for environments with space constraints.

Applications:

- Medium-Duty Environments: Common in workshops, small to medium-sized warehouses, and manufacturing facilities where moderate lifting capacity is required.

- Material Handling: Suitable for handling components, machinery, and other loads up to 20 tons.

Advantages:

- Stability: The A-Frame design provides a stable base and balanced support for the crane.

- Cost-Effective: Generally less expensive compared to more complex designs due to its simpler structure.

- Space-Saving: Compact design makes it suitable for facilities with limited space.

Disadvantages:

- Limited Capacity: Restricted to handling up to 20 tons, which may not be sufficient for heavier applications.

- Fixed Configuration: Limited adjustability in height and width compared to other designs.

L-Frame Design (up to 32 Ton)

L-Frame Design (up to 32 Ton)

Features:

- Structural Design: The L-Frame design features legs shaped like an "L," providing enhanced stability and support for heavier loads. This design is ideal for heavier-duty applications.

- Load Capacity: Capable of handling loads up to 32 tons, making it suitable for more demanding material handling tasks.

- Construction Materials: Typically built with high-strength materials to support the increased load capacity and ensure long-term durability.

- Configuration: Often includes adjustable height and width options, allowing for greater flexibility in different operational environments.

- Footprint: The L-Frame design usually has a larger footprint compared to the A-Frame design, which may require more space.

Applications:

- Heavy-Duty Environments: Ideal for large warehouses, manufacturing plants, and construction sites where high lifting capacities are necessary.

- Material Handling: Suitable for lifting and transporting heavy machinery, large components, and bulk materials up to 32 tons.

Advantages:

- Higher Capacity: Can handle up to 32 tons, making it suitable for heavier and more demanding applications.

- Flexibility: Adjustable features allow for customization to meet specific operational needs.

- Enhanced Stability: The L-Frame design provides robust support for heavy loads, ensuring safe and reliable operation.

Disadvantages:

- Higher Cost: Generally more expensive due to the increased load capacity and more complex design.

- Larger Footprint: Requires more space, which may not be suitable for facilities with limited space constraints.

Comparison of A Frame and L Frame Gantry Crane Single Girder

Comparison of A Frame and L Frame Gantry Crane Single Girder

Load Capacity:

- A-Frame Design: Up to 20 tons, suitable for lighter to medium-duty tasks.

- L-Frame Design: Up to 32 tons, ideal for heavy-duty applications.

Structural Complexity:

- A-Frame Design: Simpler structure with a stable but fixed design.

- L-Frame Design: More complex with enhanced stability and adjustable features.

Cost:

- A-Frame Design: Typically less expensive due to its simpler design and lower load capacity.

- L-Frame Design: Higher cost due to increased capacity and more complex design.

Space Requirements:

- A-Frame Design: More compact, suitable for space-constrained environments.

- L-Frame Design: Larger footprint, requiring more space for operation.

Applications:

- A-Frame Design: Best for moderate material handling needs in smaller or medium-sized facilities.

- L-Frame Design: Best for heavy-duty material handling in larger facilities or construction sites.

Choosing between the A-Frame and L-Frame designs for your Single Girder Gantry Crane depends on your specific load capacity requirements, available space, and budget considerations.

Underhung vs. Top-Running Semi Gantry Crane: Selecting the Optimal Configuration

When choosing between an underhung and a top-running semi gantry crane, understanding their differences and how each configuration aligns with your specific operational needs is crucial. Here's a detailed comparison to help guide your decision:

top running semi gantry crane

Underhung semi gantry crane

Underhung Semi Gantry Cranes

Underhung Semi Gantry Cranes

Underhung semi gantry cranes are characterized by their rail systems being mounted on top of the supporting structure, with the crane's wheels running on these rails. This design allows for a more compact setup where the crane is suspended from the structure rather than running on the floor.

Key Features:

- Mounting: Rails are mounted on the top of the support structure, which can be existing building structures or dedicated supports.

- Design: The crane travels along the upper rail, which can be advantageous in facilities with limited floor space.

- Height: Typically offers greater hook height as the crane's travel mechanism is above the floor.

Advantages:

- Space Efficiency: Ideal for facilities with limited floor space since the rails are mounted above, leaving the floor clear for other uses.

- Higher Hook Height: Provides more headroom and hook height compared to floor-mounted systems.

- Less Floor Obstruction: Reduced need for floor space support structures minimizes potential obstructions on the shop floor.

Disadvantages:

- Structural Requirements: Requires strong building structures or dedicated support to mount the rails, which can impact installation and cost.

- Complex Installation: Installation might be more complex and require precise alignment and structural modifications.

Applications:

- Industrial Facilities: Suitable for environments where floor space is at a premium or where high hook heights are needed.

- Existing Structures: Ideal for retrofitting into existing buildings with sufficient overhead support.

Top-Running Semi Gantry Cranes

Top-Running Semi Gantry Cranes

Top-running semi gantry cranes feature a rail system mounted on the top of the crane's supporting structure or columns. The crane's wheels run on these top-mounted rails, which allows it to move along the gantry's length.

Key Features:

- Mounting: Rails are mounted on the top of the crane's support columns or gantry, with the crane traveling along these top rails.

- Design: The crane structure supports itself on the top rails, making it more traditional in terms of design.

Advantages:

- Robust Design: Generally more robust and straightforward in design, offering a stable and reliable operation.

- Cost-Effective: Often less expensive to install compared to underhung systems, with simpler structural requirements.

- Ease of Installation: Typically easier to install with fewer structural modifications required.

Disadvantages:

- Floor Space Usage: May require more floor space for the crane's support structure, which could limit available workspace.

- Lower Hook Height: Might offer less hook height compared to underhung systems, depending on the crane's design and support structure.

Applications:

- General Industrial Use: Well-suited for manufacturing and warehouses where floor space is less of a concern.

- New Facilities: Ideal for new construction projects where design flexibility can accommodate the crane's structural requirements.

Comparison and Selection:

Comparison and Selection:

Space Utilization:

- Underhung: Maximizes floor space and offers higher hook height, making it ideal for facilities with limited ground space.

- Top-Running: Utilizes more floor space but may be more suitable for environments where floor space is not as constrained.

Installation and Cost:

- Underhung: Requires more complex installation and structural modifications, potentially leading to higher costs.

- Top-Running: Generally easier and more cost-effective to install with fewer structural modifications.

Structural Requirements:

- Underhung: Depends on strong existing structures or dedicated supports for mounting rails.

- Top-Running: Requires support columns or a gantry structure, which can be more straightforward to install.

Headroom and Hook Height:

- Underhung: Provides greater hook height and headroom, which can be crucial for certain lifting applications.

- Top-Running: May offer less headroom compared to underhung systems.

Maintenance:

- Underhung: Maintenance may require access to the top rail system, which can be more challenging.

- Top-Running: Maintenance is typically more accessible due to the crane's design.

Selecting between an underhung and a top-running semi gantry crane depends on your specific operational needs, space constraints, and budget considerations. If maximizing floor space and hook height is critical, and you have suitable overhead support, an underhung crane may be the better option. Conversely, if you seek a robust, cost-effective solution with simpler installation requirements, a top-running semi gantry crane may be more appropriate.

Mobile Gantry vs. Rail Mounted Gantry Crane

A frame single girder gantry crane has the two types, mobile single girder gantry crane / portable single girder gantry crane and fixed single girder gantry crane for indoor or outdoor applications:

- Mobile single girder gantry cranes–Mobile A-frame single girder gantry cranes can be wheeled between locations with high flexibility , suitable for light duty material handling.

- Rail mounted rail travelling single girder gantry cranes – Fixed A-frame single girder gantry crane offers higher strength for heavier capacities but with lower mobility comparing with the portable Single girder gantry crane.

Simple Gantry Design Non Rail Roller Travelling Portable Gantry Cranes (up to 10 Ton)

Features:

- Structural Design: Simple gantry cranes have a more basic structure, often with a single beam supported by L-shaped or A-shaped legs. They are designed for lighter loads, up to 10 tons.

- Load Capacity: Suitable for light to medium-duty applications where loads do not exceed 10 tons.

- Construction Materials: Constructed from standard steel or aluminum, focusing on cost-effectiveness while still ensuring structural integrity.

- Configurations: Typically feature fewer customization options and are more straightforward in design compared to standard cranes.

- Maintenance: Simpler design often results in lower maintenance requirements and costs.

Applications:

- Ideal for smaller workshops, light manufacturing environments, and smaller warehouses.

- Suitable for handling lighter loads, such as small machinery, components, or materials.

Advantages:

- Cost-Effective: Generally less expensive than standard designs due to simpler construction and lower load capacity.

- Compact Footprint: Requires less space, making it suitable for environments with space constraints.

- Ease of Installation: Simpler design often leads to quicker and easier installation.

Disadvantages:

- Lower Load Capacity: Limited to handling up to 10 tons, which may not be suitable for heavier applications.

- Fewer Features: Less customization and fewer advanced features compared to standard designs.

Standard Single Girder Rail Travelling Gantry Crane Design (up to 20 Ton)

Standard Single Girder Rail Travelling Gantry Crane Design (up to 20 Ton)

Features:

- Structural Design: Standard design single girder gantry cranes are engineered to handle higher lifting capacities, typically up to 20 tons. They feature a robust and durable structure with a single main beam supported by legs or A-frames.

- Load Capacity: Designed to manage heavier loads, making them suitable for medium to heavy-duty applications.

- Construction Materials: Made from high-strength steel or other durable materials to support the increased load capacity and ensure stability.

- Configurations: Often available in various configurations, such as top-running or underhung, to accommodate different space and operational needs.

- Customization: Standard design cranes often come with options for customization, including adjustable heights, widths, and additional features like hoist travel limit switches and advanced control systems.

Applications:

- Ideal for environments requiring higher lifting capacities, such as manufacturing facilities, automotive assembly lines, and large warehouses.

- Suitable for operations involving heavy machinery, large components, or significant material handling tasks.

Advantages:

- Higher Load Capacity: Can handle up to 20 tons, providing versatility for heavy-duty applications.

- Durability: Designed to withstand significant stress and wear, ensuring a long service life.

- Customization Options: Offers flexibility to tailor the crane to specific operational needs.

Disadvantages:

- Cost: Generally more expensive due to the higher load capacity and additional features.

- Footprint: Larger footprint compared to simpler designs, which might require more space.

Comparison:

Comparison:

Load Capacity:

- Standard Design: Up to 20 tons, suitable for heavier and more demanding applications.

- Simple Gantry Design: Up to 10 tons, ideal for lighter loads.

Structural Complexity:

- Standard Design: More complex, with additional features and customization options.

- Simple Gantry Design: Basic structure with fewer features, focusing on cost-effectiveness.

Cost:

- Standard Design: Higher cost due to advanced features and higher capacity.

- Simple Gantry Design: More affordable due to its simpler design and lower capacity.

Applications:

- Standard Design: Best for environments with heavy-duty material handling needs.

- Simple Gantry Design: Suitable for lighter, less demanding tasks.

Single Girder Gantry Crane: Indoor Design vs. Outdoor Design

Indoor Gantry Crane

Features:

- Structural Design: Indoor single girder gantry cranes are typically designed with a focus on compactness and efficiency. They often have a more streamlined structure to fit within the confined spaces of indoor facilities.

- Construction Materials: Made from materials suited for indoor environments, such as coated steel to prevent rust in non-corrosive conditions.

- Footprint: Designed to maximize the use of available indoor space. They usually have a lower height and narrower base to accommodate limited overhead clearance and floor space.

- Environmental Protection: Indoor cranes are generally not equipped with extensive weatherproofing or anti-corrosion features since they are not exposed to harsh outdoor conditions.

- Operation: Operates in controlled environments, which means it can include features that prioritize precision and smooth operation, such as advanced control systems.

Applications:

- Ideal for use in factories, warehouses, and workshops where space is limited and precise material handling is required.

- Suitable for environments where exposure to outdoor elements is minimal, and there is no need for weather protection.

Outdoor Gantry

Features:

- Structural Design: Outdoor single girder gantry cranes are designed to withstand various weather conditions and environmental factors. They usually have a more robust and weather-resistant construction.

- Construction Materials: Made from weather-resistant materials, such as galvanized steel or specially coated steel, to protect against rust and corrosion due to exposure to rain, sun, and other environmental factors.

- Footprint: Typically designed with a larger base and higher clearance to accommodate outdoor use and uneven terrain. They often include features to ensure stability in varying ground conditions.

- Environmental Protection: Equipped with features to protect against weather conditions, such as sealed bearings and corrosion-resistant components.

- Operation: Designed to handle outdoor conditions, including temperature variations, high humidity, and exposure to dust or debris.

Applications:

- Ideal for construction sites, outdoor manufacturing facilities, and storage yards where cranes are exposed to the elements.

- Suitable for environments where durability and resistance to environmental factors are crucial.

Comparison:

Comparison:

Design Considerations:

- Indoor Cranes: Focus on space efficiency, precision, and a compact footprint. Less emphasis on weatherproofing.

- Outdoor Cranes: Prioritize durability, weather resistance, and stability on various terrains.

Material Selection:

- Indoor Cranes: Use standard materials suitable for indoor conditions.

- Outdoor Cranes: Use weather-resistant materials and coatings to withstand environmental exposure.

Operational Environment:

- Indoor Cranes: Operate in controlled, climate-regulated environments.

- Outdoor Cranes: Designed to handle a range of weather conditions and environmental challenges.

Maintenance and Longevity:

- Indoor Cranes: Generally require less maintenance related to environmental wear.

- Outdoor Cranes: May need more frequent maintenance and inspections due to exposure to outdoor elements.

Typical Capacities of Single Girder Gantry Cranes

Single Girder Gantry Cranes are available in a variety of capacities to cater to different material handling needs. Here's a detailed breakdown of the typical lifting capacities and their common applications:

3 Ton Single Girder Gantry Crane:

- Usage: Ideal for light-duty applications.

- Typical Applications: Used for tasks involving relatively small loads, such as part assembly, maintenance operations, and handling lightweight materials in workshops or small industrial settings.

- Advantages: Provides precise control for small to medium-sized tasks and is suitable for facilities with limited space.

5 Ton Single Girder Gantry Crane:

5 Ton Single Girder Gantry Crane:

- Usage: Versatile for light to medium-duty operations.

- Typical Applications: Commonly found in warehouses, fabrication shops, and construction sites. It handles moderate loads, including moving steel, machinery, and components.

- Advantages: Balances capacity and cost, making it a popular choice for a range of industries requiring moderate lifting capabilities.

10 Ton Single Girder Gantry Crane:

10 Ton Single Girder Gantry Crane:

- Usage: Designed for medium-duty tasks.

- Typical Applications: Suitable for manufacturing facilities, industrial operations, and construction sites where heavier loads need to be managed. It is effective for handling substantial materials and equipment.

- Advantages: Offers increased load-bearing capacity, making it ideal for more demanding tasks and environments.

15 Ton Single Girder Gantry Crane:

15 Ton Single Girder Gantry Crane:

- Usage: Also classified as a medium-duty crane but with a higher lifting capacity.

- Typical Applications: Used in scenarios where lifting requirements exceed those handled by a 10-ton crane but are still within the medium-duty range. Common in various industries for lifting larger and heavier materials.

- Advantages: Provides additional capacity for heavier loads while maintaining the efficiency and versatility of a single girder design.

Capacity Matters: Determining Load Limits for Single Girder Gantry Cranes

Determining the appropriate capacity for your Single Girder Gantry Crane is crucial for ensuring both safety and operational efficiency. The crane's capacity—the maximum weight it can safely lift and transport—must match your specific material handling needs. Here's an in-depth look at how to assess the right capacity for your Single Girder Gantry Crane:

- Assessing Regular Loads: Start by evaluating the heaviest loads your Single Girder Gantry Crane will need to handle on a regular basis. This involves considering not only the maximum weight but also the type and distribution of these loads. Understanding the typical load profiles ensures that the crane can manage these weights effectively and without strain.

- Planning for Future Needs: Factor in potential future increases in load requirements or changes in your material handling processes. Choosing a Single Girder Gantry Crane with a slightly higher capacity than currently needed provides flexibility for growth and adaptation. This proactive approach prevents the need for premature equipment upgrades as your operations expand.

- Safety and Equipment Longevity: Operating your Single Girder Gantry Crane within its rated capacity is essential for maintaining safety and extending the crane's operational life. Overloading can pose significant safety risks, including structural failure or accidents, and can lead to increased wear and tear, resulting in costly repairs and downtime. Adhering to the crane's capacity limits ensures safe operation and minimizes maintenance issues.

- Consulting Experts: To accurately determine the right capacity for your Single Girder Gantry Crane, consult with a qualified engineer or crane specialist. They can assess your specific operational needs, analyze load data, and recommend an appropriate crane capacity that aligns with your material handling requirements while adhering to safety standards. Expert advice helps in making informed decisions and ensures your crane's capacity is well-suited to your operational demands.

By carefully evaluating these factors and seeking professional guidance, you can select a Single Girder Gantry Crane with the optimal capacity for your material handling tasks. This approach enhances operational efficiency, ensures safety, and extends the lifespan of your crane, making it a valuable asset for your facility.

While these capacities cover many typical needs, Single Girder Gantry Cranes can be customized to meet specific requirements. For industries with even heavier lifting needs, cranes with capacities exceeding 15 tons are available. Conversely, for lighter applications, cranes with capacities less than 3 tons can also be tailored. When selecting a crane, always base the choice on the actual weight and nature of the loads to ensure safety and efficiency in your operations.

Gantry hoist

For various types of single girder gantry cranes, there are various types of gantry hoists available to meet industrial applications.

Features and Benefits of Single Girder Gantry Cranes

Single Girder Gantry Cranes are celebrated for their versatility, efficiency, and cost-effective performance. Here's an in-depth look at the features and benefits that make them an excellent choice for various material handling applications.

Lightweight and Agile: Efficiency Without Compromising Strength

Single Girder Gantry Cranes are designed to be lightweight while maintaining robust strength, offering several distinct advantages:

- Enhanced Efficiency: Their streamlined design allows for agile and precise movements, making these cranes ideal for tasks requiring accuracy and quick material transport. Whether it's positioning loads with precision or moving materials swiftly across a workspace, these cranes excel in efficiency.

- Reduced Structural Load: The lightweight nature of Single Girder Gantry Cranes places less strain on the building or support structures. This is particularly beneficial in facilities with lighter structural capacities, allowing for installation without the need for extensive reinforcement.

- Cost Savings: With reduced weight comes lower wear and tear on crane components, which translates to less frequent maintenance and repair needs. Additionally, the lower energy consumption of these cranes contributes to overall cost savings, making them a budget-friendly choice for long-term operations.

Space-Efficient Design: Maximizing Your Facility's Layout

Single Girder Gantry Cranes are designed with space efficiency in mind:

- Compact Footprint: Their design typically requires less floor space compared to other crane configurations, optimizing the use of your facility's layout. This can lead to more effective use of available space, allowing for better organization and workflow within the facility.

- Flexible Installation: Their space-saving design makes them suitable for both large and small facilities, as they can be installed in various configurations to fit the specific layout and operational needs.

Versatility and Adaptability: Meeting Diverse Needs

Single Girder Gantry Cranes are highly versatile and can be adapted to a variety of material handling needs:

- Adjustable Span and Height: Many models offer adjustable span and lifting height options, allowing you to tailor the crane's capabilities to the specific dimensions and requirements of your workspace.

- Customizable Features: These cranes can be equipped with various accessories and features, such as different types of hoists, controls, and safety systems, to enhance their functionality and fit specific applications.

- Wide Range of Applications: From manufacturing and construction to warehouses and workshops, Single Girder Gantry Cranes are suitable for handling a diverse array of materials and tasks, making them a versatile solution for many industries.

Typical Applications of Single Girder Gantry Cranes

Single Girder Gantry Cranes are celebrated for their adaptability and versatility, making them an ideal choice across various industries and applications. Here's a closer look at some typical scenarios where these cranes excel:

Typical Uses of Single girder gantry cranes

Single girder Single girder gantry crane is a light duty single girder gantry crane which is generally used when the loads Q≤50 ton and the span S≤35m. Single girder gantry cranes have a very wide application, which can be adopted when overhead crane or bridge crane is not practical such as, the following conditions:

- when the existing workshop structure cannot support the wheel loads of the overhead crane,

- When the material handling solution is need outdoors without the cost of a building or support steel work,

- when objects needs to be hoisted outside the crane span

- when the relocation of the hoisting Single girder gantry crane is needed after the completion of work at a certain site..

The single girder gantry cranes can be used indoors or outdoors, for material handling in various industrial applications such as in steel stock yards, pre-cast segment yards, construction sites , open-air storage yard, freight yards, docks, power plants, ports and railway stations and other places for cargo handling and installation operations.

Monorail Gantry Crane: Precision Meets Efficiency in Assembly Lines

Monorail Gantry Crane: Precision Meets Efficiency in Assembly Lines

Monorail Gantry Cranes are a hallmark of precision and efficiency, particularly suited for assembly line operations. Here's why they stand out:

- Streamlined Assembly: Monorail Gantry Cranes are designed to move materials and components with exceptional accuracy. This precision is crucial for assembly lines where exact alignment and positioning of parts are essential for maintaining production quality.

- Reduced Handling Time: By swiftly delivering components to designated workstations, Monorail Gantry Cranes significantly cut down handling time. This efficiency leads to faster production cycles and improved overall throughput.

- Enhanced Worker Safety: These cranes can be equipped with advanced safety features, such as collision avoidance systems and operator training modules. Such features ensure a safer working environment, reducing the risk of accidents and enhancing overall workplace safety.

Semi-Gantry Crane: Ideal for Space-Constrained Work Environments

Semi-Gantry Crane: Ideal for Space-Constrained Work Environments

Semi-Gantry Cranes are particularly effective in environments with limited space or where maximizing vertical storage is a priority. Their key benefits include:

- Space Optimization: Semi-Gantry Cranes are designed to straddle a workspace, with one side operating underhung and the other running on top of the runway beams. This configuration allows for optimal use of vertical and horizontal space, making it ideal for facilities with headroom restrictions.

- Versatility in Confined Spaces: These cranes are highly adaptable, enabling efficient material handling in areas where space constraints might otherwise limit operational options. They are perfect for tight or irregularly shaped work areas.

- Quick Installation: The compact design of Semi-Gantry Cranes often leads to a quicker and more straightforward installation process, minimizing disruptions to ongoing operations and allowing for faster operational readiness.

Cost-Effective Solutions for Small and Medium Enterprises

Cost-Effective Solutions for Small and Medium Enterprises

Single Girder Gantry Cranes provide a cost-effective material handling solution, making them an attractive option for small and medium-sized enterprises (SMEs). Here's why they are favored:

- Affordable Investment: These cranes offer efficient lifting capabilities at a fraction of the cost of larger, more complex crane systems. This affordability makes them a practical investment for SMEs looking to enhance their material handling operations without breaking the bank.

- Versatile Use: SMEs can leverage Single Girder Gantry Cranes for a wide range of tasks, including loading and unloading goods in warehouses and supporting various manufacturing processes. Their versatility ensures they can meet diverse operational needs.

- Reduced Operating Costs: The lightweight design of Single Girder Gantry Cranes translates to lower energy consumption and reduced maintenance costs. This efficiency helps SMEs optimize their budgets and improve their bottom line.

Single Girder Gantry Cranes, including Monorail and Semi-Gantry configurations, offer tailored solutions for assembly lines, space-constrained environments, and budget-conscious SMEs. Their adaptability, efficiency, and cost-effectiveness make them invaluable assets in a variety of applications, enhancing productivity and streamlining material handling processes.

Industrial Uses in Automotive Industry

Industrial Applications of Single Girder Gantry Cranes

Single Girder Gantry Cranes are integral to numerous industrial sectors, offering efficient and precise material handling solutions. Their versatility makes them invaluable in a wide range of applications. Below are some key industries where these cranes play a critical role:

Automotive Industry: Enhancing Assembly Lines with Efficiency

In the automotive industry, Single Girder Gantry Cranes are crucial for optimizing assembly lines and ensuring smooth production processes:

- Precise Component Handling: These cranes excel in the accurate positioning and handling of heavy automotive components, including engines and chassis parts. This precision helps maintain the high quality and consistency required in automotive manufacturing.

- Efficient Movement: Single Girder Gantry Cranes streamline the movement of parts and materials along the assembly line, reducing downtime and improving overall workflow efficiency. This leads to faster production cycles and enhanced operational throughput.

- Worker Safety: Modern Single Girder Gantry Cranes come equipped with advanced safety features, such as collision avoidance systems, overload protection, and ergonomic control interfaces. These features ensure a safe working environment, minimizing the risk of accidents and injuries.

Warehouses and Logistics: Streamlining Material Handling

Warehouses and Logistics: Streamlining Material Handling

In warehouse and logistics operations, Single Girder Gantry Cranes are pivotal for managing inventory and optimizing material flow:

- Efficient Pallet Handling: These cranes are designed to handle pallets of goods with ease, facilitating quick loading and unloading processes. This capability is essential for maintaining efficient warehouse operations and meeting delivery schedules.

- Space Optimization: The compact design of Single Girder Gantry Cranes is particularly advantageous in warehouses with limited space. By maximizing vertical and horizontal space, these cranes enable more effective storage and retrieval of inventory.

- Inventory Accuracy: The precise control provided by Single Girder Gantry Cranes reduces the likelihood of product damage during handling, which helps ensure accurate inventory management and reduces losses.

Construction Sites: Lifting Heavy Loads with Precision

Construction Sites: Lifting Heavy Loads with Precision

On construction sites, Single Girder Gantry Cranes are essential for managing the heavy lifting and positioning of construction materials:

- Heavy Load Lifting: These cranes are robust enough to handle substantial loads, including steel beams, concrete blocks, and construction machinery. Their lifting capacity is crucial for various construction tasks, from assembling structural elements to setting up large equipment.

- On-Site Mobility: The mobile nature of Single Girder Gantry Cranes allows them to be repositioned easily around construction sites. This flexibility ensures that materials can be lifted and placed exactly where needed, enhancing efficiency and precision in site operations.

- Time and Cost Savings: By improving the speed and accuracy of material handling, Single Girder Gantry Cranes contribute to significant time and cost savings on construction projects. This efficiency helps keep projects on schedule and within budget.

Single Girder Gantry Cranes are versatile and effective tools across diverse industrial applications, including automotive manufacturing, warehousing and logistics, and construction. Their ability to enhance efficiency, precision, and safety underscores their importance and adaptability in various operational contexts.

Costs, Prices, and Manufacturers

When evaluating the acquisition of a Single Girder Gantry Crane, it's crucial to understand the full scope of costs involved, the factors that influence pricing, and the importance of selecting a reputable manufacturer. Here's an in-depth look at these critical aspects:

Total Cost of Ownership for Single Girder Gantry Cranes

The Total Cost of Ownership (TCO) for a Single Girder Gantry Crane extends beyond its initial purchase price and encompasses all expenses incurred throughout the crane's operational lifespan. Key components of TCO include:

- Initial Purchase Price: This is the upfront cost of the crane, influenced by factors such as lifting capacity, configuration (e.g., underhung vs. top-running), and any customizations.

- Installation and Commissioning: Costs associated with the assembly and setup of the crane in your facility. This includes site preparation, installation labor, and any necessary adjustments.

- Operating Costs: Regular expenses related to the crane's operation, such as energy consumption for powering the crane and ongoing maintenance to keep it in optimal working condition.

- Training and Operator Certification: Investment in training programs for crane operators to ensure safe and efficient use. This may include certification courses and safety training.

- Repairs and Upgrades: Budget for unexpected repairs and potential upgrades to extend the crane's operational life and adapt to changing needs.

- Downtime and Productivity Loss: Consider the potential cost of production downtime if the crane is out of service for maintenance or repairs. This can impact overall productivity and revenue.

By thoroughly evaluating these factors, you can gain a clearer picture of the true cost of owning a Single Girder Gantry Crane and make a more informed investment decision.

Pricing Factors: What Affects the Price of Single Girder Gantry Cranes

Several factors can influence the pricing of a Single Girder Gantry Crane. Understanding these can help you better assess the final cost:

- Capacity: The lifting capacity of the crane is a primary determinant of price. Higher capacity cranes, capable of lifting heavier loads, typically come with a higher price tag.

- Configuration: The choice of crane configuration—such as underhung, top-running, or semi-gantry—affects the price. Top-running cranes, for instance, generally cost more due to their higher load capacity and enhanced structural design.

- Customization: Additional features, such as specialized hoists, advanced controls, or bespoke modifications, can increase the overall cost. Customization allows for tailored solutions to specific operational needs.

- Manufacturer: Different manufacturers offer varying price structures and levels of quality. It's important to consider the reputation and reliability of the manufacturer when evaluating costs.

- Geographic Location: Local factors such as regulations, taxes, and labor costs can affect the overall price. Prices may vary depending on your location and regional market conditions.

- Market Conditions: Economic conditions and market demand can influence crane pricing. Staying informed about market trends can help you make a well-timed purchase.

Choosing the Right Manufacturer: Quality and Reliability Matter

Selecting the right manufacturer is crucial to ensuring the quality and reliability of your Single Girder Gantry Crane. Key considerations include:

- Reputation: Investigate the manufacturer's reputation within the industry. Look for customer reviews, case studies, and feedback from previous clients to gauge their track record.

- Quality Standards: Ensure the manufacturer adheres to industry quality standards and certifications, such as ISO 9001 or CE marking. This ensures that the crane meets high standards of safety and performance.

- Customization Capabilities: Choose a manufacturer that offers customization options to tailor the crane to your specific requirements. This can include modifications to fit unique operational needs or facility constraints.

- Customer Support: Evaluate the level of customer support provided by the manufacturer. Consider factors such as after-sales service, technical support, and responsiveness to inquiries.

- Warranty: A comprehensive warranty can offer peace of mind and financial protection. Verify the terms and coverage of the warranty to ensure it adequately addresses potential issues.