Explosion proof electric wire rope hoists

Wire rope hoists with explosion proof, flame proof & spark resistant hoist designs to secure your electric hoist crane. Check wire rope explosion proof hoists now.

| Wire Rope Hoist Type | BCD wire rope hoists with features of explosion proof , spark resistance and flame proof |

| Loading Capacity | 500kg-50 ton |

| Lifting Height | 3 m to 100 m |

| Working Class | M3, M4 |

Category: Hoist

Your Trusted Overhead Electric Hoist Manufacturer & Supplier

Exproof Wire Rope Hoist | Explosion Proof Hoist & Flame Proof Hoist

With explosion proof, flame proof & spark resistant hoist design, the electric wire rope hoist are able to provide safety overhead hoist crane solution for hazard application wherever explosive gases or dusts exists, such as, in oil rigs, in gas factory and plants, in mines industries or in the chemical industry, or other explosion proof & spark resistant workshops such as in the plants or factories of industrial petrochemical , power generation,pharmaceuticals & food industries, etc.The proof electric hoist are designed and manufactured with the the advantages of stable & reliable performance, high & durable quality, reasonable & affordable hoist price and excellent before & after sale service to free your trouble all over the lift time of the explosion proof hoist & cranes.

Main parameters of explosion proof

With special explosion protection, the explosion proof hoists are able to prevent potentially explosions occurring during hoisting operation in hazardous situations. The lifting capacity of standard explosion proof electric hoist is ranged from 0.5 to 16 tons with working class of M3. The main parameters of standard explosion proof wire rope hoists are for reference. For detailed specifications and parameters, please fee free to contact us.

Main parameters of the explosion proof wire rope hoists:

- Wire Rope Hoist Type: BCD wire rope hoists with features of explosion proof , spark resistance and flame proof

- Lifting capacity of electric wire rope hoist :0.5 ton, 1 ton, 2 ton, 3 ton, 5 ton, 7.5 ton, 10 ton, 15 ton, 16 ton up to 50 ton

- Lifting height of electric wire rope hoist:3~100 m

- Working class of electric wire rope hoist:M3, M4,

- Ambient temperature of electric wire rope hoist:-25~40℃

- Customized explosion proof hoists are available ahead of standard electric wire rope hoists.

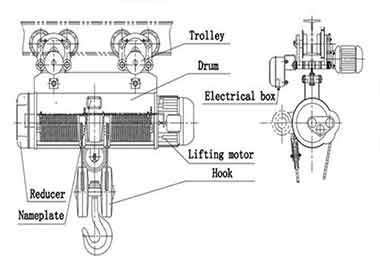

Structure & Components

The wire rope explosion proof hoists is equipped with specialized components to remove the potential sources of ignition during hoisting and with ongoing monitoring of potentially hazardous environment to ensure the safety of hoisting operation .The explosion proof wire rope hoists are designed and developed on the bases of standard CD/ MD wire rope hoists, which is consisted of the engine, transmission mechanism, rolling drum, hooks, and wire ropes, etc. With two separately speeds of8 m/min and 0.8 m/min, the proof electric hoists can be used to hoist the fragile objects slowly and carefully and to handle loads required high precision in the hazardous working environments.

Explosion proof wire rope hoist

Explosion proof wire rope hoist drawing

As a third-party certificated explosion-proof equipment ,the explosion proof hoist is consisted of explosion proof and flame proof electric hoist parts and components such as, explosion-proof motor, explosion-proof switch box, explosion-proof flashlight door, explosion-proof journey switch, explosion-proof overload limiter and explosion-proof junction box, etc.

Features of explosion proof hoists

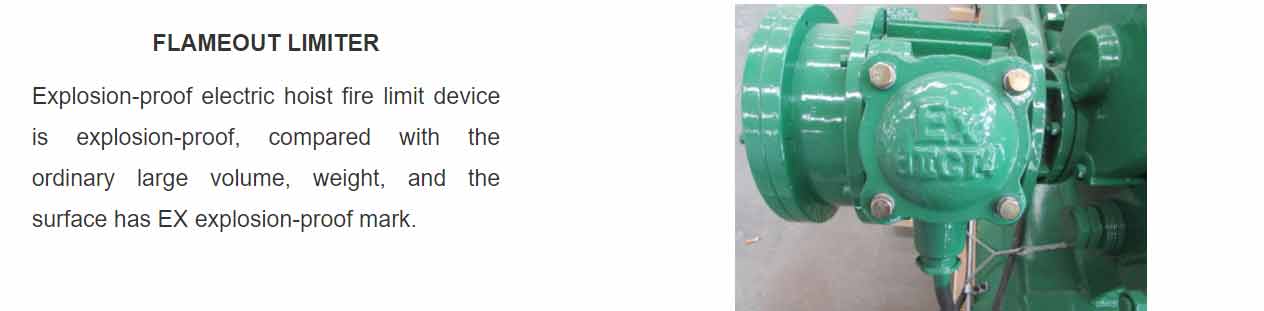

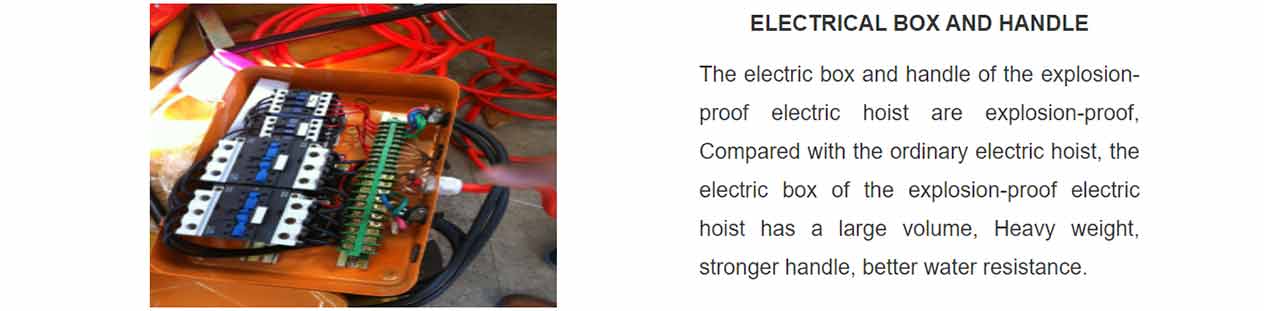

The main features of explosion-proof electric hoist are explosion proof, spark resistant and flame proof by using the explosion proof hoist components and parts such as explosion-proof motor, the control box adopts explosion-proof electronic control box, the operation handle adopts explosion-proof operation handle, anti-collision mark, etc.

- Ex-proof Motor -The lifting motor and travelling motor of the electric wire rope hoists are all explosion-proof with good, strong & durable explosion-proof ability.

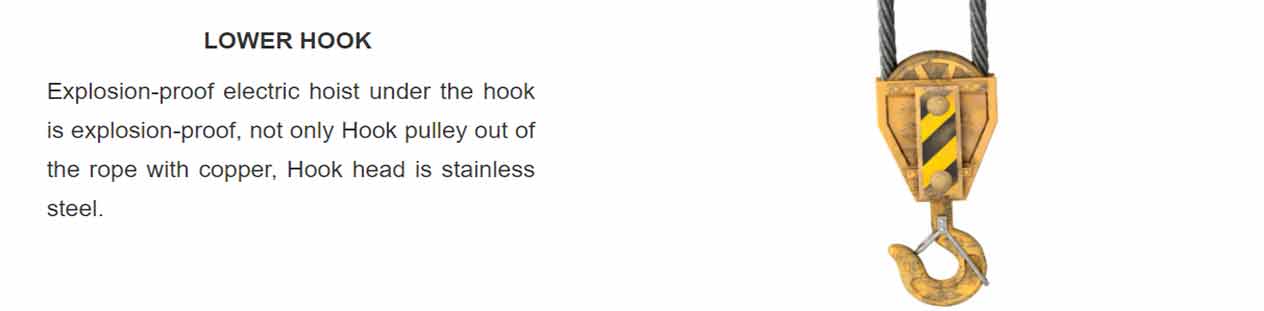

- Explosion-proof hook- The explosion proof hoist hook is designed with normal design but with a special copper sheet and if necessary the hook material will be changed into into stainless steel to get a higher degree of explosion proof ability and performance.

- Ex-proof electrics - The electric box and the handle of the hoists are all explosion proof which can be customized based requirements and application conditions. Comparing with ordinary wire rope hoists, the explosion proof hoists have a larger and heavier box and a stronger and more water-proof handle.

- Ex-proof limiter - Good performance ex-proof limiter, with "EX" mark printed on the explosion proof hoists.

- Ex-proof Rope guide -The rope guide of three degree explosion proof wire rope hoists is same as the ordinary types but the four degree ex-proof electric hoists adopts the explosion proof rope guide with copper.

- Wireless remote - Wireless remote control is optional for standard electric wire rope hoists but for the explosion proof hoists, the wireless remote control is usually adopted and, of course, the non wireless remote control is also available to offer the most-effective electric hoist solution for customers.

Explosion proof protection

How to avoid explosion ? To avoid the creation of an explosive environment or atmosphere is naturally the first option and the most easiest way with high safety. For example, to provide the adequate and effective ventilation or confine the work processes to prevent the appearance of dangerous gases or dusts in the closed system.

Secondly, to prevent the explosive atmosphere from ignition is also an effective to prevent explosion . To justify this aim, the surface temperature of the explosion proof equipment must be limited and the creation of sparks or sources of ignition must be avoided,

-Lastly, the effects of an explosion must be controlled and reduced to a negligible level. Usually, it is conducted by isolating the ignition source, e.g. by mounting explosion proof equipment in flameproof enclosures, etc.

Explosion proof electric hoists use the explosion protection of removal of potential sources of ignition to prevent explosion by adopting specialized hoist parts & components and together with ongoing monitoring of potentially hazardous environments. What's more, the explosion proof hoists are also used in explosion proof and flame proof workshops.

Scope of Use of explosion proof hoists

Explosion-proof electric wire rope hoists are a series of lifting equipment, designed and processed in accordance with the National Standard of GB3836-2000 (Electrical Apparatus for Explosive Gas Atmospheres). And all of the hoist parts and components either self-made or complemented factory-made, such as, motors and electrical apparatuses are designed, manufactured, inspected and accepted according to the National Standard GB3836.1-2000 (General Requirements of Electrical Apparatus for Explosive Gas Atmospheres) and GB3836.2-2000 (Electrical Apparatus for Explosive Gas Atmospheres Flame-proof Enclosure "d").

- 1. The explosion proof hoists marked as dⅡBT4,dⅡCT4 are applicable to the application environment whereⅡA,ⅡB,ⅡC & T1-T4 Combustible Gas or vapor and air form an area of explosive mixtures , Zone 1 & Zone 2

- 2. The ex- proof electric hoist marked as dⅡBT4 are applicable to applications where the Combustible Gas, water vapor and air formed as explosive mixture .

- 3.Operational conditions of explosion proof hoist - Relatively air humidity:85%( 20℃±5℃), Temperature:0℃- +40℃, Height above sea level:<1000m

Advantages of explosion proof electric hoist

Besides strong explosion proof ability, the BCD electric wire rope hoists has the general advantages of compact structure, light deadweight, small sizes and large lifting capacity. The explosion proof electric hoists are widely used to improve working efficiency and safety in the potentially hazardous & explosive workshops and workstations.

Advantages of wire rope explosion proof hoist:

- Compact structure, small size, light weight, large capacity,

- Strong explosion proof ability, high safety and reliability.

- The exposed parts of the electric rope hoists adopts no-spark materials to explosion-proof performance good and reliable.

- All the spare parts of explosion proof hoists are generalized and changeable,making the hoist maintenance easy and simple.

- Various hoist configurations and wide specifications, applicable to a wide application.

Applications of explosion-proof electric hoist

The explosion proof electric wire rope hoists are widely used in potentially hazardous applications where explosive gases or dusts exist such as the industrial workshops & plants of mines, chemical, gasoline l petrochemical , power generation,pharmaceuticals and food industries, etc.

The series of explosion proof hoists and cranes can be designed based on your service requirements, there are explosion proof wire rope hoist & explosion proof chain hoist, explosion proof electric hoist & explosion proof manual hoist, single girder explosion proof crane explosion-proof suspension crane or explosion-proof single-beam bridge crane & double girder explosion proof hoist cranes with various hoist crane configurations and wide specifications and applications to meet your particular requirements and needs.

Fixed Type Wire Rope Hoist

- Lifting Capacity:0.25t to 50t

- Lifting Height: 3m to 100m

- Lifting Speed: 0.33~8,Single or Dual Speed

- Working Class: M3, M4

- Ambient Temperature: -20℃ to 40℃

Travelling Wire Rope Hoist

- Lifting Capacity:0.25t to 50t

- Lifting Height: 3m to 100m

- Lifting Speed: 0.33~8,Single or Dual Speed

- Working Class: M3, M4

- Ambient Temperature: -20℃ to 40℃

Double girder hoist crane

- Lifting Capacity:0.25t to 50 ton

- Lifting Height: 3m to 100m

- Lifting Speed: 0.33~8,Single or Dual Speed

- Working Class: M3, M4

- Ambient Temperature: -20℃ to 40℃

Single girder hoist crane

- Lifting Capacity:0.25 ton to 32 ton

- Lifting Height: 3m to 100m

- Lifting Speed: 0.33~8,Single or Dual Speed

- Working Class: M3, M4

- Ambient Temperature: -20℃ to 40℃

With decades of study and development,our explosion proof & flame proof series of electric wire rope hoists has takes a prominent place in the field and our explosion proof hoists & spark resistant hoists has been popular around world and regions such as, United Arab Emirates, Australia, Philippines, United States, Singapore, Canada, Malaysia, South Africa, United Kingdom, Indonesia, Thailand, Vietnam, Mexico, and Brazil,etc.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch