Blade pneumatic winch, explosion proof pneumatic winch

Blade pneumatic winch, powered by a vane pneumatic motor,manual control, efficient, small pneumatic winch & portable pneumatic winch. Blade pneumatic winch for sale.

| Winch Type | Blade pneumatic winch |

| Winch Capacity | 0.75t to 6t |

| Rope Capacity | 80m to 100m |

| Air Preasure | :0.6-0.69Mpa |

Category: Winch

Your Trusted Pneumatic Winch Manufacturer & Supplier

Small, Portable & Explosion Proof

Blade Pneumatic Winch

The blade pneumatic winch one type of pneumatic winch which is made of aluminium alloy and powered by compressed air. Usually, the blade pneumatic winch is with manual control operation and driven by a vane pneumatic motor. The blade pneumatic winch is widely used in fire resistant situations such as oil fields, drilling platforms, mining, workshops, cargo handling, engineering sites, etc.

Main parameters of blade pneumatic winch

- Model :AW

- Lifting capacity of blade pneumatic winch: 0.75t to 6t

- Rope capacity of blade pneumatic winch:80m to 100m

- Rope speed of blade pneumatic winch:7~45m/min

- Air pressure of blade pneumatic winch:0.6-0.69Mpa

- Tailored blade air pneumatic winch are available.

Blade pneumatic winch/Pneumatic Winch

Blade pneumatic winch/Pneumatic Winch

Blade pneumatic winch/Pneumatic Winch

Blade pneumatic winch for sale.Tailored blade pneumatic winch are available. Contact us to get your blade pneumatic winch design & specific blade pneumatic winch price.

Main Features of blade pneumatic winch

- High safety and reliable - With air powered motor, the blade pneumatic winch is explosion proof, spark proof and insulated in wet and damp application.

- Automatic braking -The pneumatic winch will stop automatically when air power is off to prevent the happening of error operation to ensure safety.

- Easy operation, high efficiency -With the control valve and air motor combined together, the control of pneumatic winch can be operated by one control handle which can be operated to change the speed of air motor, direction of rotation and the braking of air chamber.

- Small size & light weight -The main parts of the blade pneumatic winch is made of aluminum alloy, with adequate strength and rigid but lighter dead weight which make transportation and installation of air winch convenient.

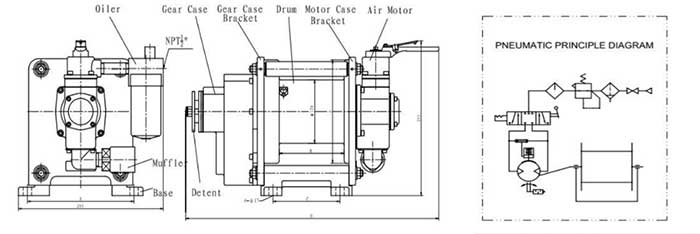

Main components & features of blade pneumatic winch

Air motor

Vane air motor of blade pneumatic winch is made of motor case , cylinder, rotor, rotor vane , top bearing case ,and bottom bearing case, etc. After compressed air enter motor, the blade air winch will start to work. The controlling of compressed air inlet may change the revolving direction of air motor and the changing of current and pressure of compressed air will manage to get the suitable revolving speed and output torque.

Gear box

Gear box of blade pneumatic winch is made up gear case , deceleration gears, and gear bracket etc. Four levels of deceleration includes the first level of 22:70, second level of 26:62, third level of 16:100, the last internal gear , the internal gear key connect with drum .

Braking system

The braking system of blade pneumatic winch is made up bearing plate, brake plate, rubber diaphragm, and brake spring etc. When the air pipe is in "open" position, the blade pneumatic winch release brake plate, and the winch drum start to rotate . When the air line is closed, the brake systems of the blade pneumatic winch brakes the drum tightly and efficiently.

Industries and applications of an pneumatic winch

Due to the unique features,the air operated pneumatic winches are widely used in various industrial sectors and especially suitable for applications of oilfields, geological drilling, natural gas, coal mine, metal mine, ocean exploration, shipbuilding, and many other occasions with potential existence of inflammable and explosive elements, etc.

Metal Processing Industrial

Iron, steel, aluminum & basic metal processing industry cranes. Industry cranes for metal process- EAF charging & ladle crane, forging crane, finished product crane & scrap crane - for metallurgy harsh conditions, safe overhead travelling crane.

General Manufacturing

Types of industrial hoist & cranes for general manufacturing- Various types of industrial overhead crane systems for multiple sectors of manufacturing, integrated solution, maximum productivity, cost-effective price.

Mining Industry

Mining industry cranes, Coal mine crane systems - Safe industrial overhead crane & industrial gantry crane system for ore, limestone, coke, coal, slag, loose clay handling, explosion proof and durable.

Energy Industry

Energy generation|Industrial cranes for types of power plants - Industrial cranes & hoists systematic solutions for various power plants,i.e, traditional fuel power & waste renewable energy, wind power, hydroelectric, biomass energy, etc.

Machinery and Equipment

Industrial material handling cranes for mechanical engineering- Material handling cranes for mechanical engineering industry - overhead industrial crane solution for manufacturing of light & heavy machinery & equipment.

Pulp & Paper Industry

Pulp & paper| Industrial crane systems for paper making - Industrial overhead crane system for pulp & paper industry , full overhead travelling crane services, cost-effective paper making cranes for your paper mills.

Waste Management Industry

Waste management|Waste recycle & sorting industry cranes - Industrial overhead cranes for waste sorting&recycling. Types of industrial cranes in incinerator for mixing, stacking, handling and stirring of the waste materials, etc.

Wood , Timber & Furniture

Industrial cranes and hoists systems for timber & wood processing. Diverse overhead crane & hoists designs for material handling in sawmills or furniture plants, etc.

Shipbuilding & Boat Making

Industry crane systems for shipyard material handling, i.e, components assembly, boats & yachts lifting, etc. Reliable & safety industry crane system.

Plastic & Rubber

Industrial hoist and crane solution for plastic & rubber industry- Injection mould installation & Die exchanging- Efficient & Accurate heavy lifting systems.

Construction and Infrastructure

Industrial material lift for construction & infrastructure- types of industry overhead travelling cranes, gantry & hoist crane system- Reliable & cost-effective.

Chemical Industry

Industry cranes for chemical & petrochemical material handling, explosion proof overhead crane & hoist system for hazardous environment.

Automobile Industry

Automotive | Industrial overhead crane & hoist for automobile - Industrial cranes for automotive industry from press & assembly lines to workstations & warehouses, i.e., open winch crane & Light kbk, jib crane & chain hoists,etc.

Due to the excellent explosion proof feature, the pneumatic winch is among the best explosion-proof equipment which is an ideal selection when an explosion-proof pulling winch or explosion proof hoisting winch is needed. Based on your requirements and applications conditions, pneumatic winches with process winch designs are available to meet your needs satisfactorily.

Get your customized pneumatic winch, cost-effective crane winch solution

To meet the various industrial needs and your particular application, the tailored pneumatic winch design and fabrication services are available. To provide your the specific pneumatic winch, please help us to confirm the following information of the pneumatic winch you need, which including the following;- Loading capacity of pneumatic winch: _____________?(Ton/kN)

- Working speed of pneumatic winch: _____________?(m/min)

- Wire rope length of pneumatic winch: _____________?(m)

- Functions or usages of pneumatic winch: _____________? For horizontally pulling or vertically hoisting?

- Specialized requirements to get tailored pneumatic winch design.

Send us a inquiry to get your tailored pneumatic winch design and pneumatic winch price.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch