Your Trusted Single Girder Overhead Crane Manufacturer & Supplier

0.5 Ton to 20 Ton Single Girder Overhead Crane

Top Running & Underhung Single Girder Crane Designs

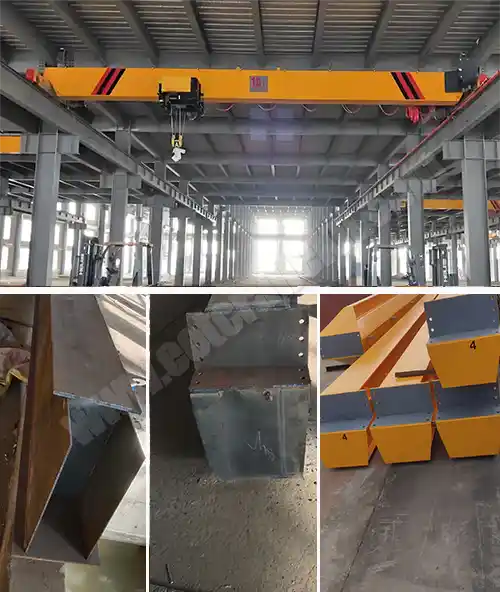

What is an single girder overhead crane? Single girder overhead cranes are an very important type of overhead cranes, an ideal solution for light duty and medium duty material handling. The single girder overhead cranes are mainly consisted of one main crane girder, supported on each side by an end truck, with monorail trolley hoist suspended on the beam girder. The single girder overhead cranes are usually designed either in top running single girder overhead crane configuration or under running single girder overhead crane configuration , equipped with manual or electric monorail hoists to meet various workshop or warehouse applications with the features of simple structure, light deadweight, lower shipping cost, and good crane price, etc.

Single girder overhead cranes are often the most cost-effective overhead bridge crane solution for various workshops and industrial applications.. Single girder overhead cranes use less steel material, with more compact crane structure and lighter dead weight than double girder overhead cranes, which results in a significant cost-savings in steel material purchasing , transportation, and crane installation. Also, due to the one girder design, these overhead cranes usually have less deadweight, which enable them to utilize lighter runway systems and attach to the existing support structure of the building .

Oveview of Single Girder Overhead Cranes

Single girder overhead cranes, also known as Single Girder EOT (Electric Overhead Traveling) cranes or Single Girder Bridge cranes, are essential lifting devices widely used in various industries. These cranes are designed with a single horizontal girder that supports the lifting mechanism and provides stability and efficiency in material handling.

Components of a Single Girder Overhead Crane

Single girder overhead cranes consist of several components that work together to lift and move heavy loads. These components include:

- Bridge: The bridge is the main component of the crane and consists of a single girder that spans the width of the workspace. The girder is supported by two end trucks that move along rails mounted on the building structure.

- Hoist: The hoist is the component that lifts and lowers the load. It consists of a motor, gearbox, brake, drum, wire rope, hook, and block. The hoist is mounted on the bridge girder and moves along it.

- Controls: The controls are used to operate the crane and include a pendant or radio remote control.

- Electrification: The electrification system provides power to the crane and includes a power cable or festoon system.

- End trucks: The end trucks support the bridge girder and move along rails mounted on the building structure.

Unlike double girder cranes, which utilize two girders for greater lifting capacity and stability, single girder cranes are typically more compact and cost-effective. This makes them an ideal choice for operations where space is limited and lighter loads are handled. Their design allows for easy installation and maintenance, making them a preferred option for many facilities.

Single Girder Overhead Cranes Specifications, Customized for Your Needs

With single girder overhead crane designs, the single girder overhead cranes are designed for light and medium duty material handling. The rated lifting capacity of single girder eot crane are from 1 ton, 2 ton, 3 ton, 5 ton, 10 ton, up to 20 ton . The single girder overhead crane specifications and parameters are mainly presented for your reference.Various single girder overhead crane designs are available. Contact us to get process single girder overhead crane designs and specific crane specifications and crane dimensions or to download free single girder overhead crane pdf brochure.

European Style Top Running Single Girder Overhead Crane Specifications

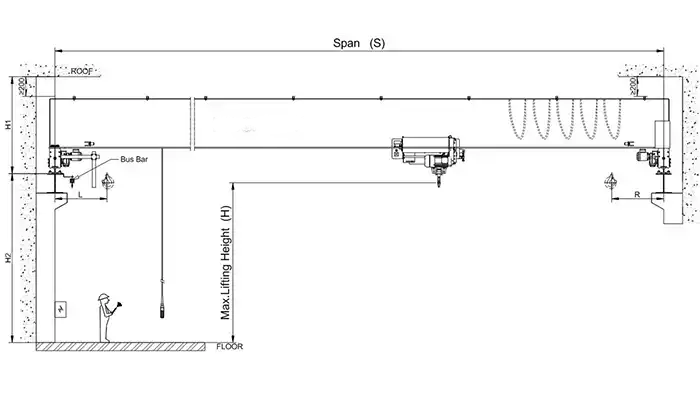

Top Running Crane -A top running single girder overhead crane is the most frequently used overhead bridge crane system for the top running crane configuration typically meets the needs of lifting requirements and facility space requirements for most customers.

- Lifting Capacity of Crane: 3.2 t to 20t

- Span of Crane: 7.5m to 28.5m

- Lifting Height of Crane:6m to 18m

- Working Class of : A3, A5

- Crane hoist Supply: Wire rope electric hoist or chain Electric hoist, European standard FEM hoists

- Customized single girder overhead crane can be up to 35 ton.

European style Under Running Single Girder Overhead Crane Specification

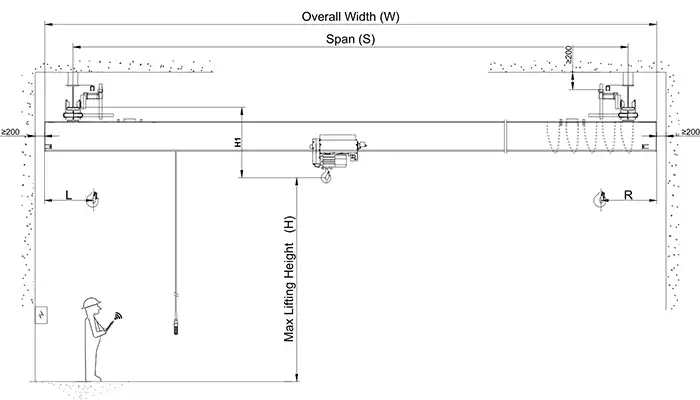

Under Running Cranes -Under running cranes are the suspension overhead crane system which are usually supported and attached to the existing structure in the facility,usually the building roof structure with no requirement of columns, free up floor space efficiently, a very cost-effective crane solution. Crane bridge of under running overhead crane travels along the bottom flange of the runway beam.

- Lifting capacity of overhead crane: 1 ton to 10 ton

- Span of single beam overhead crane: 3-15 m

- Lifting height of overhead crane: 3-100 m

- Working Class of Overhead Crane: A3

Customized Single Girder Overhead Crane Configurations with Required Specifications

Tailored single girder overhead cranes are designed to meet specific operational needs, offering flexibility in load capacity, span, lifting height, and other specifications. These customized configurations ensure optimal performance, safety, and efficiency in diverse industries, whether for light-duty handling in workshops or heavy-duty applications in factories and warehouses. Click to learn more on the single girder overhead eot crane specification tables.

Main Types of Single Girder Overhead Cranes

- European Style Single Girder Top Running Overhead Crane 1 Ton to 20 Ton

op running cranes: Top running cranes are designed to run on rails mounted on top of the building structure. They are ideal for facilities with high ceilings and heavy loads. - Single Girder Underslung Overhead Crane 0.5Ton to 10 Ton

Underhung cranes run on rails mounted underneath the building structure. They are ideal for facilities with low ceilings and limited space.Nlx single girder underhung bridge crane with European style is hot for sale, with capacity of 500kg, 1 ton, 2 ton, 3 ton, 5 ton, up to 10 ton. Smart features is optional for your design. - Freestanding Single Girder Top Running Overhead Crane 1 Ton to 20 Ton

Freestanding single girder overhead cranes for workshop or warehouse with floor mounted crane columns for loads handling.A self-supporting crane option that offers flexibility in large open areas, it features runway supporting columns for stable operation in manufacturing settings. - Single Girder Telescoping Overhead Bridge Crane 0.5 Ton to 3 Ton

This crane is equipped with an extendable cantilever, providing additional reach and versatility for loading and unloading tasks in tight spaces.Click to learn more on hot sale 1 ton, 2 ton telescopic overhead crane with single girder sliding beam. - Explosion Proof Single Girder Overhead Cranes 1 Ton to 20 Ton

LB series of single girder crane, designed specifically for hazardous environments, these cranes incorporate explosion-proof features to ensure safe operation in areas with flammable materials or conditions. - Low Headroom Single Girder Overhead Crane with Economical Electric Hoist 1 ton to 16 ton

This LDP crane features a compact design that maximizes vertical space, making it ideal for facilities with height limitations. The economical electric hoist provides efficient lifting capabilities while reducing overall operational costs, making it a practical choice for light to medium load handling in various industrial applications. - Metallurgical Use Electric Single Girder Crane1 Ton to 10 Ton

This types of single girder crane is specialized designed steel mill cranes. The top running single girder eot crane is designed for hot ladle handling for small steel mill with capacity form 1 ton to 10 ton. - Manual Single Beam Cranes 0.5 ton to 5 ton ,

The manual operated overhead crane is with capcacity of 500kg to 5 ton, which can be classed into SL— Manual Single Beam Crane Top Running Design & SLX—Manual Single Girder Suspension Crane design, which is designed for power limited area and applicaiton where explosion proof light duty material handling is required.

Hot Sale Capacity of Single Girder Overhead Cranes , Design Options for Your Selections

Single girder overhead cranes are available in a wide range of capacities, typically from 1 ton to 25 tons, with some customized models reaching up to 32 tons. These cranes are categorized into light, medium, and heavy duty based on lifting requirements, each serving specific industrial needs.

Light Duty Overhead Cranes (500 kg – 3 Ton)

Common Capacities: 500 kg, 1 ton, 2 ton, 3 ton

- 1 ton overhead crane single girder design options,

- 2 ton overhead crane single girder desgin options,

- 3 ton overhead crane single girder design options,

These cranes are ideal for lighter lifting tasks and are commonly used in:

- Workshops and small factories for tools and light machinery

- Maintenance and repair shops where frequent lifting is required

- Assembly lines for handling lightweight parts and materials

Advantages:

- Cost-effective with lower upfront and operating costs

- Easy to operate and suitable for a variety of users

- Options include straight or curved monorail hoist cranes, freestanding or ceiling-mounted

Medium Duty Overhead Crane (5 Ton – 15 Ton)

Common Capacities: 5 ton, 10 ton, 15 ton

- 5 ton overhead crane single girder design options,

- 10 ton overhead crane single girder design options,

- 15 ton overhead crane single girder design options

These cranes are a popular choice for general industrial applications where moderate loads are handled regularly, such as:

- Manufacturing plants for moving components and materials

- Construction sites for lifting equipment and building materials

- Warehousing operations for handling pallets and heavy goods

Advantages:

- Versatile and applicable in many industries

- Improves work efficiency and shortens handling time

Heavy Lifting Overhead (15 Ton – 32 Ton)

Common Capacities: 15 ton+, 20 ton, customized 25 ton, 32 ton

- 20 ton overhead crane single girder design options,

- Customized overhead crane single girder with double hoists for tandem lifting,

Built for heavy lifting operations, these cranes are suitable for:

- Heavy manufacturing industries such as automotive and aerospace

- Shipbuilding and marine repair for handling large equipment

- Infrastructure and construction projects requiring heavy material movement

Advantages:

- High load-bearing capacity for demanding lifting tasks

- Strong, durable construction for long service life in tough environments

- Customizable options such as single girder cranes with double hoists for tandem lifting

Each capacity range includes specific single girder design options to match your operational layout and lifting needs. Whether you need a compact 1-ton crane or a robust 32-ton system, tailored solutions are available to meet your application requirements.

Advantages and Limitations of Single Girder Overhead Cranes

Single girder overhead cranes offer several advantages over other types of cranes. These advantages include:

- Cost-effective: Single girder overhead cranes are less expensive than double girder overhead cranes.

- Easy to install: Single girder overhead cranes are easy to install and require less space than other types of cranes.

- Versatile: Single girder overhead cranes can be used in a variety of industries and applications.

However, there are also some disadvantages to using single girder overhead cranes, including:

- Limited lifting capacity: Single girder overhead cranes have a lower lifting capacity than double girder overhead cranes.

- Limited span: Single girder overhead cranes have a limited span compared to double girder overhead cranes.

If you are in the market for an overhead crane, you may be debating between a single girder crane and a double girder crane. Despite the fact that each style has advantages and disadvantages, you might want to consider a single girder overhead crane.

How single girder crane benifit your business? Here are just a few of the benefits they provide:

- A lower cost.It should go without saying that single girder overhead cranes are less expensive than double girder cranes. It makes sense when you think about it. After all, by removing one of the girders, the design requires far fewer materials. Furthermore, trolleys designed for single girder cranes are much simpler than those designed for double girder cranes. Again, this can help lower the overall purchase price, making these cranes a cost-effective option.

- Less weight. Single girder cranes are much lighter weight because they lack the second girder and much of the support structure required for a double girder crane. This can help to reduce your building's structural support requirements.

- Lower installation costs.Single girder cranes are far less expensive to install due to their light weight and minimalistic design. Adding additional structural support to the building to support the weight of the crane is not always necessary. The same cannot be said for double-girder cranes, which are often extremely heavy and require additional support. With a single girder crane, you not only save money on the crane itself, but also on the cost of installation. That is why these cranes are such an excellent choice for businesses with limited resources.

Applications of Single Girder Overhead Cranes

Industrial single girder overhead cranes are used in a variety of sectors, including manufacturing, construction, mining, transportation, and logistics. They are commonly used for lifting and moving heavy loads in industrial settings such as factories, warehouses, and assembly lines. These cranes are ideal for handling materials such as steel, concrete, and machinery components. They are also used in maintenance and repair operations, as well as in the construction of buildings and infrastructure. The specific type of single girder overhead crane used will depend on the requirements of the particular industry or sector.

General Use Single Girder Overhead Cranes for Indoor vs. Outdoor Use

Crane Design Features for Indoor Use:

- Environmental Control: Indoor environments allow for better control over temperature and humidity, which can lead to less wear and tear on the crane components. This environment is generally safer for operators, minimizing risks associated with external weather conditions.

- Space Optimization: Indoor cranes can be designed to maximize vertical lifting capabilities, allowing for efficient use of the facility's height. They can be customized to fit within the spatial constraints of the building.

- Enhanced Safety Features: Additional safety measures, such as collision detection systems and emergency stop buttons, can be more easily integrated into indoor setups.

- Featured single girder cranes for typical indoor uses; Workshop cranes , workstation cranes, and Garage cranes, etc. Indoor overhead crane single girder

Crane Design Features for Outdoor Use:

- Weather Resistance: Outdoor cranes must be designed to withstand harsh weather conditions, requiring robust materials and protective coatings to prevent rust and damage from elements such as rain, wind, and extreme temperatures.

- Structural Considerations: Outdoor installations often need reinforced structures to endure environmental stresses, including wind loads and uneven ground conditions.

- Mobility and Versatility: Outdoor cranes are frequently mobile or mounted on wheels, allowing for operation across large, open spaces like construction sites where flexibility is key. Outdoor overhead crane single girder

Hazardous Use Applications

All types of single girder explosion overhead cranes can be engineered with explosion-proof features, making them suitable for hazardous environments where flammable or explosive materials are handle

Hot Sale Hazardous Environment Cranes

- Explosion proof single girder overhead crane,

- Explosion proof underhung overhead crane single girder,

- Cleanroom use single girder overhead crane for dusty workshop or factory such as flower factory, etc.

Features:

- Explosion-Proof Design: These cranes incorporate materials and designs that minimize ignition risks in volatile atmospheres, ensuring safe operation.

- Enhanced Safety Measures: Built with additional safety controls such as overload protection systems and emergency stop features, they prioritize operator safety in hazardous settings.

- Specialized Applications: Ideal for industries such as oil and gas, chemical manufacturing, and pharmaceuticals, where safety standards are critical.

Your Trusted Overhead Crane Manufacturer & Supplier

0.5 to 32 ton Single Girder Overhead Cranes for Sale

Cost-effective Single Girder Overhead Cranes for Efficient Material Handling, Light Duty Indoor & Outdoor Overhead Crane Solutions & Projects

Single girder overhead cranes with capacities ranging from 0.5 tons to 32 tons offer versatile and cost-effective solutions for efficient material handling. Designed for both light-duty and medium-duty operations, these cranes are suitable for a variety of indoor and outdoor applications, making them a reliable choice for industrial projects.

- Wide Capacity Range:Handles loads from as small as 0.5 tons to robust 32-ton operations.Ideal for light-duty lifting in workshops and warehouses as well as medium-duty tasks in factories and construction sites. standard design is 1 ton to 20 ton, for smaller span, and customized design, the capacity can be up to 32 ton.

- Efficient Design:Lightweight single girder construction minimizes structural load while maximizing strength.Compact design ensures space efficiency, with options for low headroom models for facilities with height limitations.

- Adaptability for Indoor and Outdoor Use:Corrosion-resistant components for outdoor applications.Weatherproof features ensure reliable performance in various environments.

- Cost-Effective Operation:Affordable purchase and maintenance costs compared to double girder cranes.Incorporates economical electric hoists for smooth and efficient lifting.

- Customizable Solutions:Available in various configurations, including top-running, underhung, and freestanding models.Smart features such as remote control, anti-sway technology, and automation available for enhanced productivity.

These 0.5 to 32-ton single girder overhead cranes are ideal for businesses seeking reliable and budget-friendly lifting solutions, ensuring safety, efficiency, and productivity in a wide range of applications.If you have any need, please feel free to contact us to get your cusotmized single girder overhead cranes