Cleanroom Crane & Hoists Equipment for Clean Room

Cleanroom cranes & hygiene cranes for cleanroom environment for pharmaceutical, food industry, aerospace and semiconductor. Check cleanroom crane & hoists now.

Clean Room Environments

When a clean room is your top priority, cleanroom cranes and hoists helps your material handling and also helps to make your environments stay hygienic.

Hygiene rooms are environments that are kept free of dust, airborne microbes, chemical vapors, and other environmental contaminants. The clean room environment are required to the production and operation of products which are consisted of sensitive components.

Cleanroom crane and hoist lifting equipment: enhancer of workplace comfort

Cleanroom lifting equipment boosts productivity and improves workplace comfort because it is hygienic, precise, ergonomic, and functional. Additionally, cleanroom lifting tools let us move heavy objects with even more accuracy.

Choosing the proper cleanroom lifting equipment is primarily determined by:

- the needs of the people who work in the cleanroom.

- The product or items that will be produced in the cleanroom

- the standards established by the industry

- Furthermore, the material from which the equipment is made and treated plays an important role.

Applications of cleanroom crane and hoisting equipment

Pharmaceutical & Medical technology:

- Clean room crane and hoisting equipment for the pharmaceutical industry require extremely stringent contamination controls.

- A clean room is essential in the manufacturing and research processes of a pharmaceutical company because it works to control microorganisms.

Food and beverage:

- Food grade cleanroom cranes and hoists are intended for use in clean environments such as commercial kitchens and mass manufacturing plants.

The cranes and hoists require stainless steel components, corrosion-resistant surfaces, and are designed for use in a room that is regularly sprayed with water and chemically sanitized.

Aerospace:

Clean room processing is essential for the delivery of safe and reliable components in the aerospace industry. Sensitive components can fail completely if even a small amount of contamination or particulate is present.

Electronics & Semiconductor:

- The semiconductor industry is one of the world's fastest growing manufacturing environments.

- Cleanrooms are required in semiconductor operations because the smallest speck of dust can destroy an entire chip's functionality.

Overhead cleanroom crane

When compared to general-purpose overhead cranes, the cleanroom cranes have high standards. The overhead cleanroom crane is used in high-demand applications such as electronics, pharmaceutical, biotechnology, medical, laboratory, and other areas with high environmental demands. The special clean room environment is known as the clean room , and the hoisting crane used is known as the clean crane or cleanroom crane.

In contrast to general-purpose overhead cranes, cleanroom overhead cranes or clean room hoists must be wear-resistant, broad clean, have a low failure rate, a wide speed range, precise positioning, and other characteristics. The overhead cleanroom crane must not only be dust-proof, not produce dust, and not absorb dust, but it must also have a beautiful appearance, a long maintenance cycle, and other features.

Taking environmental factors into account, the overhead cleanroom crane is typically designed with a double girder and a chain electric hoist as the lifting equipment. When choosing the above components, general wear-resistant materials should be used, and some parts should not accumulate dust. Furthermore, the appropriate access platform for routine cleaning should be considered.

The following areas are dust-free and are shown for your convenience:

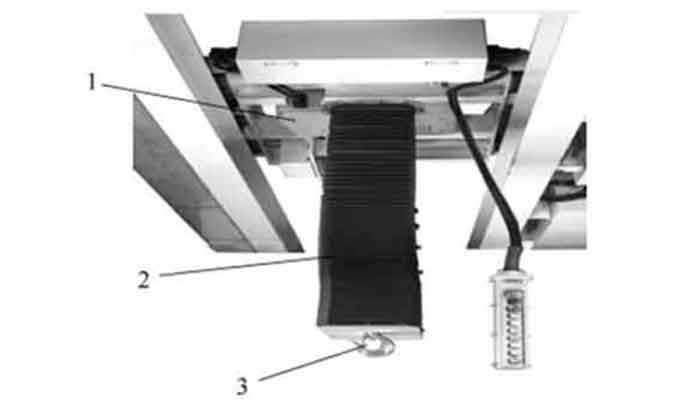

cleanroom overhead crane hoist diagram

1. Main body of cleanroom crane, 2. Anti-dust cover 3. Anti-dust hook

With the impact of the electronics, photovoltaic, pharmaceutical, and other industries gradually standardizing, we seize this opportunity to promote the rapid development of clean crane.

Cleanroom Crane - Portable Gantry Crane for Clean Room

Cleanroom lifting solutions are frequently tailored systems to meet both operational and hygienic standards, so we offer a wide range of equipment such as electric chain hoists, wire rope hoists, manual chain hoists , jib cranes, gantry crane, and overhead crane systems, all of which are cleanroom crane hoisting equippment and suitable for use in a hygienic environment.

Portable gantry cranes are extremely versatile cranes that can be used in a wide range of cleanrooms. Gantry cranes can be moved manually or electrically around a cleanroom due to their portable wheels design.

The client requested a 1 ton portable gantry crane for his cleanroom. Due to the low cleanliness requirement, our design: only the main beam is cold-galvanized, and all other parts are standard materials, equipped with a European chain hoist. Given the cost, the main beam can be galvanized; alternatively, the main beam can be coated with a layer of stainless steel, which can also help with dust prevention.

1 Ton -10 Ton Mobile Gantry Crane for Cleanroom, Lab & Pharmacy, Portable Gantry Crane Manufacturer

Features of cleanroom portable gantry crane

A manual a-frame gantry crane are avaible for cleanroom material handling that can be re-positioned within the clean room facility to suit your application conditions. The cleanroom gantry crane is simple to disassemble and reassemble as needed. A manual or electrically powered chain hoist is also available.

A portable gantry crane is also a more flexible and cost-effective option than a permanent crane. One significant disadvantage of this crane is that it takes up more space than, say, an overhead crane.

We are delighted to assist you in selecting the best handling solutions for your cleanroom material handling.

Cleanroom Crane- Jib Cranes for Clean Room

Cleanroom Jib Crane is a type of lightweight pillar/column jib crane that is easy to operate, flexible in its slewing, large in its working area, and equipped with high-efficiency material handling tools.

Jib cranes for clean rooms are constructed with stainless steel parts and a heavy nickel coating.

2 ton cleanroom jib crane for sale

Lifting capacity: 2 tons

Lifting height: 3.5 meters

Arm length: 5 meters

Application scenario: clean room of Pakistan machinery factory

Features of cleanroom jib cranes

- Light weight and reasonable design.

- Optional H-beam and KBK-beam.

- High energy efficiency, small floor area.

- Optional controls include a radio remote and a pendant.

- Used for frequent, short, and dense material handling with low and easy maintenance.

- Manual trolley is used for loads handling <500kg , electric trolley is used for loads handing >1000kg

Dust Free Kbk Crane for Food Industry

Dust Free Kbk Crane should be sterile, high temperature resistant, and corrosion-resistant. It is simple to clean with a powerful corrosive detergent.

KBK Crane & Clean Crane for Clean Food Industry - Light kbk crane series

The new type of kbk crane is especially suitable for the food industry. Its main advantages include maintenance-freeness, lack of greasiness, and lack of wear. The hoist can be controlled by a cable-connected manual control device, automatic control, or radio remote control. The new electric belt hoist is suitable for three shift operation in production facilities for quick processing of perishable foods like milk because fully enclosed components with smooth surfaces are particularly time-saving to clean. parts made of stainless steel, such as pulleys, hooks, and push wheels.

Cleanroom stainless steel hoist equipment

In controlled environments, particularly in wet industries, hoists with a stainless steel chain or complete stainless steel hoists are very common. It protects the surface and keeps materials from deteriorating quickly.

Equipment made of cleanroom stainless steel is also common in dry industries, though this option is less obvious. It's important to remember that stainless steel equipment is more brittle but also stronger than steel. Additionally, it can cost up to five times as much as painted steel. We would always recommend seeking professional advice for your unique cleanroom requirements.

Stainless Steel Electric Chain Hoist for Sale | Anti -corrosion - Stainless steel electric chain hoists for sale, anti- corrosion electric hoist for oil & gas field, clean room, chemical industry, farming, & sewage, etc.

Stainless Steel Lever Hoist & Aluminum Alloy Lever Hoist - Stainless steel lever hoist & aluminum alloy lever hoist, corrosion resistant, dust-proof, anti-static & anti-magnetic. Corrosion resistant chain hoist.

Low Headroom Stainless Steel Chain Hoist for Better Hook Height - Low headroom stainless steel chain hoist- low headroom chain block & low headroom trolley conbination, compact hoist design for better hook height.Click!

Stainless Steel Chain Hoist & Stainless Steel Chain Block - Stainless steel chain hoist & chain block with high safety,reliability, easy maintenance, high mechanical efficiency, light weight & easy manual handling.

What are cleanroom cranes?

Cleanroom cranes lift and move heavy or delicate components or objects within a cleanroom or other controlled environment while preventing accidents. Cleanroom cranes are frequently manufactured and used for cleanrooms to maintain cleanliness standards from start to finish.

We have designed and built cleanroom cranes for a variety of industries. For turnkey cleanroom crane design and construction, we build custom crane designs based on individual setup. We get to know you and your goals, and we can help you decide if a cleanroom crane is right for you.

What factors do I need to consider when choosing cleanroom lifting equipment for my facility?

Classification levels, room sizes, lighting needs, and material handling requirements vary among clean rooms. To fully satisfy the requirements of a particular facility, an individual cleanroom crane solution is frequently required.

Some important factors to consider are:

- Clean room layout (available space, headroom, material and process flow etc.)

- Material handling needs and requirements (such as the need for flexibility and/or mobility, the need to turn or tilt items, the frequency of handling, etc.)

- What kind of material needs to be handled (size, weight, shape, surface etc.)

Considerations on cleanroom cranes

- 1. Make a plan. -Understanding how you want your cleanroom crane to work and perform within your controlled environment is essential before installation. Take into account the size of your cleanroom, the equipment and components that will be sharing space with your cleanroom crane, and the workflow of your intended operation.

- 2. Reliability -Whatever your use, you want your cleanroom crane to perform precise material handling operation. In order to transport materials safely, they must be free from the threat of mishaps like crushing or dropping. To produce high-quality, contaminant-free products, you will need precise operation cleanroom cranes.

- 3. Cleanliness -Everything you put in your cleanroom must be clean. Cranes used in cleanrooms should be built and engineered to be easily sanitized and cleaned in order to avoid contamination in your carefully regulated environment. To produce the highest-quality items for your application, your cleanroom must be completely controlled and hygienic whether you're producing medicines, performing injection molding, or making medical equipment.

- 4. Portability -Customized cleanroom crane solution can be designed based on your cleanroom layout and lifting requirements to meet the demands of your expanding business. Several of our customers, we've discovered, also want portable and flexible cleanroom crane solutions. We collaborate with you to design and build a cleanroom setup and crane that meets your application requirements because cleanroom cranes can be positioned in a variety of ways, including ceiling mounting, standing on casters, or using other configurations.

How do cleanroom and cleanroom crane design affect each other?

Air is the primary cause of pollutants in all industries. Production procedures are transferred to a cleanroom to reduce the amount of particles floating around.

A cleanroom's layout is specifically intended to limit these airborne contaminants. Using particle counters that adhere to ISO 21501-4 standards and fulfill the criteria of both 21 CFR part 11 and ISO14644 et GMP Annex 1, the particles are periodically measured.

A fundamental cleanroom layout includes the following features:

- Filters remove fibers, dust, and other particles from the outside air.

- The air inside is continuously purified and moved about. Contaminants that grew inside the cleanroom are removed using filters.

- It is always closely controlled how humid and warm the air is.

- The air pollution of cleanroom lifting equipment, like a cleanroom crane, is kept to a minimum.

- Staff members wearing specialized cleanroom suits enter and depart a cleanroom using airlocks or gray rooms.

Making a clean room design? Have a cleanroom crane in mind

In many ways, building a cleanroom is comparable to building a house: both involve laying out goals, options, and solutions on a table in a cleanroom design. Every cleanroom is unique and needs a solution that is created specifically for it. Several cleanrooms include cleanroom cranes as a crucial component. Products and materials that would otherwise be too heavy to move manually can be lifted by them. If necessary, do so with considerable accuracy. However when constructing a cleanroom, a cleanroom crane is frequently forgotten during the design stage.

Since it is always advantageous to take into account your lifting and hoisting equipment during the first stages of designing and building your cleanroom, regardless of the size of your cleanroom or the product you are manufacturing. Effective in terms of money, time, and space.

Want to gain insights about the use of cranes in cleanrooms?

- Make the most of your manufacturing process. -A cleanroom or controlled environment is established to minimize contamination during labor or product operations. These could include cleanrooms in industries like the semiconductor industry, regulated spaces in the food processing or pharmaceutical industries. Contamination may take the shape of dust, fibers, bacteria, particle matter (caused, for example, by metals rubbing against one another and wearing down), or material evaporation.

- Fundamental rules for your industry -Many businesses, including the production of semiconductors, employ cleanrooms. Controlled environments are installed in the pharmaceutical sector to safeguard products or processes. Better manufacturing process control, for instance, helps in extending expiration dates in the food processing business.

- Learn the foundational principles for your industry -Are you trying to establish a regulated workplace and production environment? Are you looking into the best options for cleanroom cranes? Then you'll unavoidably run into a startling number of possibilities and things to think about. It's crucial to be planned.

Is it required to apply smart designs to your cleanroom crane?

Technology is continuously developing. Equipment is continuously being upgraded, including appliances. There is no reason for your cleanroom crane to remain in place. Your business operations can be improved with the help of clever solutions.

Even a seemingly basic overhead crane can be transformed into a cutting-edge solution. There are numerous options and clever ideas to consider. You can see a few examples below.

- Overhead and software systems - Lifting and hoisting equipment can operate simultaneously. Even using existing hardware and software. This is particularly beneficial in settings where people are not permitted for safety or security reasons. This not only improves your cleanroom's efficiency, but it also means fewer people are involved in the process. As a result, you have a cleaner and more sanitary cleanroom.

- Weight calculation - Assume you have to lift ten thousand kilograms. It's helpful to know exactly what you're going to lift. A heavier load, in particular, could cause damage to your equipment and/or cranes, costing you a lot of money. You can determine the weight of your load before lifting it by using the weight determination function. Assuring that you will not overload or reach beyond the indicated level, in accordance with the FEM Hoist Duty classification (European Materials Handling Federation).

- Balanced automatically - Because they require such high precision, fragile products like microchips must be lifted several times. If the load on each hook is equal, they will lift at the same time. This will always be the case thanks to the automatic balancing solution. A load is precisely aligned against the lifting eyes using sensors and measuring points with up to 1mRAD/m accuracy. This is equivalent to a one-millimetre difference in height per meter.

How to ensure precise lifting of clearnroom crane ?

One or more cranes. Electrically or manually powered. The possibilities are limitless, but our cranes all have one thing in common: they precisely lift your product. Precise lifting is more than just having a high-quality crane, though that is essential. Cleanroom Cranes provides custom solutions to help you find the ideal crane for your cleanroom. These solutions include techniques that allow the crane to lift your load as precisely as possible.

- Automatic balancing -A very useful technique primarily employed in the high-tech industry. Assume you need to lift a load at multiple points at the same time. This must be done with extreme precision. When the weight on each hook is the same, the load will be raised synchronously by each hook. This is where automatic balancing comes in handy. A load can be precisely aligned against the lifting eyes by using sensors and measuring points. This is accurate to 1mRAD/m! This is equivalent to a one-millimetre difference in height in a meter.

- Use preload - A useful technique for shock-sensitive products. Consider this: your product weighs 10,000 kilos. Before you begin lifting, tension the webbing sling chain until it reaches 9900 kilos while the product remains stable on the ground. If all points are equally tense, begin lifting with restraint. That is, slowly. Because if the product and crane are not restrained, they will receive a massive shock that could be fatal to both.

- Coordinated positioning - You could integrate software into your cleanroom crane system if this was predetermined. You can upgrade your cleanroom crane system to operate semi-automatically and lift and lower your product with extreme precision. This is extremely helpful in fields like nuclear waste storage where no living thing is allowed to enter.

How to ensure ergonomic lifting and hoisting crane operation in cleanrooms?

Lifting capacities in cleanrooms can range from less than fifty kilograms to well over twenty tons. To move these heavy weights, you can use a single cleanroom crane or multiple cranes that can be powered either electrically or manually.

In a cleanroom, almost anything is possible as long as the specially designed cleanroom cranes follow industry laws and regulations. Jib cranes and overhead cranes are two examples of ergonomic lifting equipment that improve workplace comfort and efficiency. In contrast, cutting-edge hygienic systems aid in moving products from "dirty" zones to "clean" zones.

How does cleanroom crane help to ensure sterile manufacturing

Sterile manufacturing is critical when producing pharmaceuticals or other medical devices. A sterile manufacturing process is especially important in the pharmaceutical and food industries.Manufacturing that is completely sterile implies that no potentially harmful organisms, like bacteria, can develop while being produced. Because of their contaminant-free nature, cleanrooms are the only place where sterility can be maintained during this process.

Sterile pharmaceutical manufacturing is subject to stringent laws and regulations, so the pharmaceutical business places a special emphasis on maintaining sterility. If a crane is needed in a pharmaceutical cleanroom, it should also be one that is specifically made for cleanrooms. Any other kind of crane could result in unwanted contamination and ultimately harm the finished product.

Which material should you select for your cleanroom crane?

It can be challenging to select the best material for your crane. Every cleanroom is unique. Moreover, laws vary by nation and industry. What functions the best for your business? And what option is both economical and sanitary? Find out by reading on.

Different materials are best suited for your lifting and hoisting equipment depending on your product and industry. Your business can be categorized into one of around three different groups. Let's look more closely.

- 1. The wet industry- It makes sense that the wet business deals with liquids. These fluids can occasionally be aggressive. Consider chemical cleaning agents or the juices found in meat, such as brine and blood. Your equipment may deteriorate or age quickly if these come into contact with the ingredients in your machines. Your machinery will be safeguarded by a substance like stainless steel. Stainless steel equipment can also have a variety of surface treatments.

- 2. The dry industry - The choice of material is less evident in the dry industry. Everything is depending on the raw materials you use. A steel crane is great if you process pharmaceutical materials, for instance. You can frequently pick between steel and stainless steel. Steel is lighter and less expensive than stainless steel, which is heavier and more expensive. Both have benefits and drawbacks. Steel that has been properly surfaced can be sufficient in some situations.

- 3. Intrinsically safe system - It may sound complex, but it's not. When there is a possibility of a gas or chemical exploding, ATEX is used. Production facilities that work with these compounds can be found in the food processing and pharmaceutical industries, for instance. For instance, coated nuts. Many particles are released as a result of abrasive movements. The air is filled with the discharged particles. When you combine this with a spark brought on by static electricity, an explosion hazard results.

- 4. Surface treatments - Surface treatments have been addressed on this site a few times. There are high possibilities and uses. Which one should you pick? That largely depends on your needs and the product you use.

What are the benefits of using cleanroom crane?

Each cleanroom has unique specifications. To satisfy these needs and subsequently turn them into business advantages, you can pick from a wide selection of options and solutions.

Consider adding ergonomic lifting solutions to your workspace to assist reduce the growth of microbes. As contamination presents a problem for many businesses, the latter is especially important for cleanrooms. Cleanliness and hygiene should prevail in your controlled environment. As a result, we provide a range of options and top-notch cleanroom cranes that help your sterile production process by lowering the danger of contamination in your cleanroom. In other words, a good crane doesn't leave behind a lot of waste.

- Perfect process -Choosing the appropriate hoisting and lifting equipment selections can significantly impact your production process. Your production speed and efficiency greatly enhance with the proper cleanroom crane.

- TCO optimization -The ergonomic design, the location of hoists, switches, and curves are only a few of the aspects that affect the lifespan of your cleanroom crane. In every one of these areas, Cleanroom Cranes is an expert. Bring us along for the ride, and we'll help you choose the ideal crane for your cleanroom.

- Improved capacity - Your production procedures will operate more quickly, smoothly, and efficiently. Our cranes can save your workload and boost your capacity with creative, clever solutions.

What are the applications of Clean Room Cranes in different industrial sectors?

Clean rooms are more typically used to refer to manufacturing facilities that must be kept pollutant-free due to the needs of the product. These requirements are often found in the following industries:

- beverages

- electronics

- food

- pharmaceutical

- aerospace industries

Because the goods created by the food, beverage, and pharmaceutical industries are meant for consumption by people, they must be free of contaminants in order to be put on the market. Furthermore, due to their sensitivity and potential for instant failure if contaminated during production, aeronautical and electronic products must be created in a clean room environment.

The production of the aforementioned products requires a contaminant-free environment, so every piece of equipment that is installed or placed in a clean room must adhere to a number of very high regulations. Equipment for lifting and handling materials, such as cranes, is included in this. For instance, many businesses today are building their clean room equipment to satisfy the exacting standards and demands. The following is a list of unique characteristics that are frequently seen on equipment made in a clean room environment:

- The lower block's debris shield serves as a barrier between flying wire rope debris and a spacecraft's internal components.

- Stainless steel track in the shape of a diamond that is combined with festoons to remove regions where trash and dust collect.

- Runaway conductor bars that are covered in an extruded plastic to lessen the chance of debris leaking into the clean room environment.

- Self-locking stainless steel fasteners will prevent any crane fallout (e.g. Bolts and other debris).

- Shielded electrical enclosures make sure that EMI or RFI don't get to the spacecraft.

- Walkways with fixed kick plates for removing dirt and debris.

These are only a few of the more typical types of parts and tools produced in clean rooms. Today, a lot of crane manufacturers produce clean room equipment and include it in their line of goods. In fact, some businesses only make equipment for handling materials in clean rooms. Each industry's unique needs are taken into account when designing cranes and other equipment for clean room settings.

To maintain the purity of manufacturing and production settings, cleanliness and hygiene requirements must be implemented everywhere. The production of clean room cranes makes use of special lubricants, components, and surfaces to prevent contamination of the air and interference with the manufacturing process. This places a high demand on the product's purity for many crane producers. It's critical to select the appropriate supplier when a company wants to invest in a gantry crane. Compare the crane's features and prices to get the best deal.

Semiconductor manufactering

One of the industries that changes the fastest can be the semiconductor sector. Smaller, quicker, and cheaper is the guiding principle of the semiconductor production process. And Cleanroom Cranes are ideally suited to fill that role.

Solutions for lifting and hoisting that are incredibly clean are produced by Cleanroom Cranes and used in regulated settings. These cranes help in the construction and assembly of equipment required for the production of semiconductors. Building these machines takes a lot of time, just like making semiconductors. It requires the highest precision to assemble thousands of large, small, and tiny pieces made in various locations throughout the world in a controlled environment.

Although only a small portion of the larger semiconductor ecosystem, these cranes are crucial for long-term production capacity growth. To increase the capacity of semiconductor production, selecting the appropriate cleanroom crane is crucial. You can carry big components precisely, easily, and safely thanks to it. Meaning: You'll become more effective.

There are stringent regulations in the semiconductor business. We are here to support you in achieving those. We offer atomic and molecular controlled lifting options for both light and heavy equipment and components. We create equipment for cleanrooms that is hygienic, precise, and comfortable. And matched to your cleanroom just so.

Learn how the appropriate lifting and hoisting solutions might assist meet the demands. procedure for making semiconductors

High-tech industry

Millions of people worldwide are employed by the high-tech sector, which is a significant component of the global economy. In addition, the industry is undergoing rapid change due to the constant invention of new technology and solutions. But maintaining clean lifting equipment remains essential.

You have to lift a variety of objects. We provide cutting-edge, ergonomic solutions that lighten your workload and boost capacity. The most significant factor is that our cranes reduce contamination in your cleanroom. For your high-tech products, find a high-tech lifting solution.

Food industry

Food is processed, prepared, preserved, and/or packaged by your business. All of which must take place in regulated settings. But how can you promise your clients the highest possible standard of quality? by spending money on a cleanroom crane.

A quality crane offers a lot of advantages. It not only improves the efficiency of your production process, but it also provides you more control over it. We will work together to find the ideal hoisting solution for your cleanroom. Because a smooth manufacturing process can significantly increase the shelf life of your products.

Medical sector

One of the greatest industries, the medical sector is anticipated to develop significantly in the years to come. In this process, technological innovation will be crucial. We provide cutting-edge, sanitary cranes for your cleanroom that will increase productivity.Our sanitary cranes' accuracy will boost efficiency while also lowering the possibility of workplace accidents. They are creative and economical. Most importantly, they abide by the hygiene standards set forth by the medical sector.

The hygienic cranes are required. Our cleanroom cranes have smooth, hygienic surfaces and silver ion coatings to prevent bacteria and other microbes from growing. Our cranes also operate quietly and with maximum accuracy. Your final output will be of consistently high quality thanks to our solution.

Pharmaceutical cleanroom standards

Pharmaceutical cleanrooms are not specifically covered by any laws or regulations. Yet, governmental organizations like the US FDA, the EMA, or the Dutch CBG heavily regulate the pharmaceutical sector itself. which in turn have an impact on a pharmaceutical cleanroom's production procedures.

Also, businesses in the pharmaceutical sector with cleanrooms set very high requirements for themselves to avoid: Microbacterial expansion. blasts of gas or dust (ATEX). oMigration (preventative) Contamination (active)

Cranes in a clean room for pharmaceuticals

Cleanroom Cranes need to be exceedingly sanitary in pharma cleanrooms. Even the smallest particles have the potential to harm industrial procedures or have other unforeseen consequences. Cleanroom Cranes is featured with smooth, easy-to-clean surfaces and silver ion coatings to prevent bacteria and other germs from growing. These cleanroom overhead cranes also operate quietly and offer the best accuracy.

Custom Cleanroom Crane Design & Construction for You

Using cutting-edge cleanroom lifting equipment, our Cleanroom Cranes assists you in locating the ideal solution for your hoisting needs within controlled environments and cleanrooms.Investing in a high-quality cleanroom crane offers many benefits. It effortlessly complies with all applicable laws, rules, and (international) standards, including ISO 14644.In addition to providing correct work, a competent cleanroom crane makes it possible to handle unstable material without having to worry about mishaps.Furthermore, an accurate cleanroom crane ensures that your products are consistently of excellent quality.

We take pride in exceeding all of your expectations for the effectiveness of your cleanroom. For any industry or purpose, we can design controlled environments that adhere to any standard. No matter your application, we have the knowledge to guide you in choosing a cleanroom crane or other components for your industrial cleanroom. If you have any need, please feel free to contact us to get your design of cleanroom crane.