10 Ton Portable Gantry Cranes Buying Guide from China to America

10 ton portable gantry crane from design to installation. A buyer's Guide to mobile gantry crane with chain hoist – from factory in China to American Market.

Category: Featured

Your Trusted Overhead Travelling Crane Manufacturer & Supplier

10 Ton Mobile & Portable Gantry Crane For Design to Assembly

A Buyer's Guide to 10 Ton Portable Gantry Crane with Chain Hoist – from Factory in China to American Market

10 Ton Portable Gantry Cranes Buying Guide from China to America . 10 ton mobile & portable gantry crane for sale from design to assembly. A buyer's Guide to 10 ton portable gantry crane with chain hoist – from factory in China to American Market.

A Comprehensive Buyer's Guide to 10 Ton Portable Gantry Cranes with Electric Chain Hoist – Unveiling China's Craftsmanship for the American Market

The industrial landscape in America is witnessing an unprecedented surge in the demand for 10-ton gantry cranes, a pivotal tool in material handling operations. As businesses seek efficiency and productivity, the quest for reliable and portable lifting solutions has intensified. In response to this growing need, importing options have become a focal point, and China emerges as a key player in providing cutting-edge gantry crane solutions.

Growing Demand for 10 Ton Gantry Cranes in America

The backbone of numerous industries, the 10-ton gantry crane has become indispensable for applications ranging from construction projects to manufacturing facilities. Its versatility in handling heavy loads and providing a stable lifting platform positions it as a cornerstone in the modern industrial landscape. As the demand for such cranes continues to escalate, businesses are exploring international markets for optimal solutions.

Importing Options, with a Focus on China

China has solidified its reputation as a global manufacturing hub, offering a wide array of industrial equipment, including gantry cranes. The nation's expertise in engineering and production has made it a prime destination for businesses seeking reliable and cost-effective solutions. This guide delves into the intricate process of importing 10-ton portable gantry cranes with electric chain hoists from China, providing prospective buyers in America with an insightful roadmap.

10 ton portable gantry crane from factory in China to America

Design Phase

Design Specifications

Navigating the intricate world of 10-ton portable gantry cranes demands a meticulous consideration of design specifications. As the backbone of your material handling operations, understanding the following aspects ensures a tailored solution that aligns with your business requirements.

Capacity Requirements

The first and foremost consideration in the design phase is determining the lifting capacity required for your operations. Rigorous assessment of your workload, both current and future, is essential. Avoid overestimating or underestimating, as finding the optimal balance ensures efficient and safe crane performance.

Considering factors such as the maximum load weight, frequency of lifts, and the nature of materials being handled provides a comprehensive overview of your capacity needs. This nuanced understanding enables you to select a 10-ton gantry crane with the precision required for your specific industry demands.

Size and Dimensions

The physical layout of your workspace plays a pivotal role in the selection of an ideal gantry crane. Carefully evaluate the size and dimensions of the crane to ensure seamless integration into your operational environment. Factors such as aisle width, clearance height, and overall spatial constraints should be taken into account.

Opting for a gantry crane with a size that complements your workspace minimizes disruptions, enhances maneuverability, and optimizes efficiency. By aligning the crane's dimensions with your facility's layout, you create a harmonious work environment conducive to productivity.

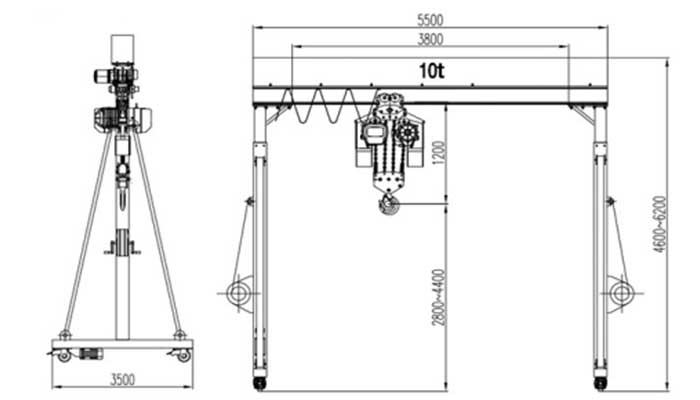

Main specification confirmation to design your custom portable gantry crane and mobile gantry crane

10 ton portable gantry crane drawing based on your main specifications

Material Selection and Durability

The longevity and performance of your 10-ton gantry crane hinge on the materials used in its construction. Robust material selection directly impacts the crane's durability, resilience, and ability to withstand the challenges of heavy-duty operations.

Explore the materials used in critical components such as the frame, trolley, and hoist system. High-strength steel alloys, corrosion-resistant coatings, and quality welding techniques contribute to a crane's structural integrity. A focus on durability ensures a long service life, minimizing downtime and optimizing your return on investment.

As you navigate the design specifications, balancing capacity requirements, size, and material durability will lead you towards a 10-ton gantry crane that not only meets but exceeds your operational expectations. Stay tuned for insights into the structural components of these cranes, unraveling the engineering excellence that defines their performance.

Structural Components

Embarking on the selection journey for a 10-ton portable gantry crane entails a close examination of its structural components. The intricacies of the frame design, trolley and hoist system, and mobility features for portability are pivotal elements that define the crane's efficiency and reliability.

Frame Design

The frame is the backbone of any gantry crane, providing stability and support for lifting heavy loads. The following considerations should guide your assessment of the frame design:

- Structural Integrity: A robust frame design should exhibit structural integrity to withstand dynamic loads and ensure safe lifting operations. Analyze the design's load distribution to guarantee stability under various working conditions.

- Modularity: Opt for a gantry crane with a modular frame design, allowing for easy assembly, disassembly, and transportation. This feature enhances flexibility in adapting the crane to different work environments and facilitates convenient relocation.

- Corrosion Resistance: Given the diverse working conditions, especially in industrial settings, prioritizing corrosion-resistant materials ensures the longevity of the frame. Coatings and treatments that protect against rust and corrosion contribute to prolonged durability.

Trolley and Hoist System

The trolley and hoist system are integral components responsible for precise load handling. Assessing these elements ensures optimal performance and efficiency in material handling operations:

- Precision Engineering: Evaluate the precision engineering of the trolley and hoist system to guarantee accurate load positioning and smooth vertical movements. This is crucial for applications that demand delicate handling of materials.

- Variable Speed Control: A gantry crane equipped with variable speed control for the trolley and hoist system offers enhanced operational control. This feature accommodates diverse load requirements and contributes to overall workflow efficiency.

- Load Capacity Matching: Ensure that the trolley and hoist system's load capacities align with the crane's overall capacity. This ensures uniform performance and prevents overloading, safeguarding both the equipment and the materials being lifted.

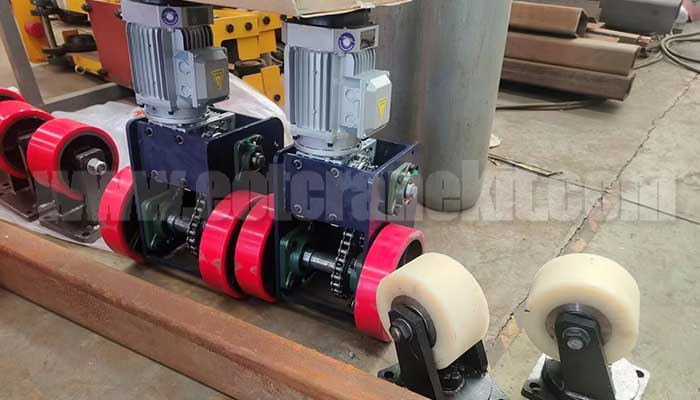

Mobility Features for Portability

The portability of a 10-ton gantry crane is a distinguishing feature, especially for dynamic work environments. Consider the following mobility features to optimize ease of movement and adaptability:

- Wheel Configuration: Select a gantry crane with wheels designed for ease of movement. Swivel and lockable wheels enhance maneuverability, enabling precise positioning and secure placement during operations.

- Compact Design for Transport: A gantry crane designed for portability should feature a compact design that facilitates easy transportation. Look for foldable or telescopic components that streamline the crane's packaging and assembly for transport.

- Stability Mechanisms: While emphasizing mobility, prioritize stability mechanisms that ensure secure positioning during lifts. Braking systems and stabilizing features contribute to a safe and efficient portable gantry crane.

The structural components of the gantry crane not only ensures its reliability but also aligns it with the unique demands of your operational environment. In the next section, we will delve into the intricate details of the electrical system, shedding light on crucial aspects such as power requirements, control mechanisms, and safety features.

Electrical System

In the realm of 10-ton portable gantry cranes, the electrical system serves as the nerve center, influencing both performance and safety. Understanding the nuances of power requirements, control mechanisms, and safety features is essential for making an informed decision when selecting a gantry crane for your operations.

Power Requirements

Efficient operation of a gantry crane hinges on meeting its specific power requirements. Consider the following factors to ensure seamless integration with your facility's infrastructure:

- Voltage Compatibility: Verify that the gantry crane's voltage specifications align with the power supply available in your facility. Ensuring compatibility prevents operational issues and minimizes the need for additional electrical modifications.

- Power Source Accessibility: Assess the accessibility of power sources within your workspace. Opt for a gantry crane design that accommodates the location of power outlets, minimizing the need for extensive electrical modifications during installation.

- Energy Efficiency: In an era emphasizing sustainability, consider gantry cranes designed with energy-efficient features. This not only contributes to environmental responsibility but also reduces operational costs over the crane's lifecycle.

Control Mechanisms

The control mechanisms of a gantry crane play a pivotal role in its usability, precision, and overall efficiency. Delve into the following aspects to ensure optimal control:

- User-Friendly Interface: Select a gantry crane with a user-friendly control interface. Intuitive controls enhance operator proficiency and minimize the learning curve, contributing to swift and precise load handling.

- Variable Speed Control: Variable speed control for both trolley and hoist operations provides the flexibility needed for diverse material handling tasks. This feature ensures adaptability to different loads and contributes to enhanced operational efficiency.

- Remote Control Options: For added convenience and safety, consider gantry cranes equipped with remote control options. Remote controls empower operators to manage crane operations from a safe vantage point, optimizing visibility and control.

Safety Features

Prioritizing safety in material handling operations is paramount. Evaluate the safety features integrated into the gantry crane's electrical system to safeguard both personnel and equipment:

- Emergency Stop Mechanism: A crucial safety feature, the emergency stop mechanism ensures swift halting of crane operations in critical situations. Confirm that the gantry crane adheres to safety standards requiring robust emergency stop functionalities.

- Overload Protection: Gantry cranes should be equipped with reliable overload protection systems. These systems prevent the crane from surpassing its designated capacity, mitigating the risk of accidents and equipment damage.

- Limit Switches and Sensors: Implementing limit switches and sensors enhances operational safety. These components prevent collisions, detect potential hazards, and contribute to a responsive and secure material handling environment.

The intricacies of the electrical system ensures not only operational efficiency but also adherence to safety standards. As we progress further, the next segment will unravel the manufacturing processes in China, shedding light on the production facilities, quality control measures, and customization options available for 10-ton portable gantry cranes. Stay tuned for insights into the craftsmanship that defines these industrial workhorses.

Production Process

Manufacturing Facilities in China

China stands as a global epicenter for industrial manufacturing, offering a diverse array of options for sourcing 10-ton portable gantry cranes. Understanding the manufacturing facilities in China is pivotal for making informed decisions during the procurement process.

Overview of Selected Manufacturers

Before delving into the specifics of production facilities, gaining insights into the reputation and track record of selected manufacturers is essential. Consider the following factors when evaluating manufacturers:

- Industry Experience: Prioritize manufacturers with a robust track record and extensive experience in producing gantry cranes. A seasoned manufacturer is likely to exhibit a deeper understanding of industry nuances and adhere to stringent quality standards.

- Customer Reviews: Seek out customer reviews and testimonials to gauge the satisfaction levels of previous buyers. Positive feedback on product quality, customer support, and adherence to delivery schedules can be indicative of a reliable manufacturer.

- Compliance with Standards: Verify that the selected manufacturers adhere to international safety and quality standards. Certifications such as CE (Conformité Européenne) and ISO (International Organization for Standardization) underscore a commitment to producing reliable and compliant equipment.

Production Capacity and Capabilities

Understanding the production capabilities of the selected manufacturers is crucial for ensuring timely delivery and consistent quality. Consider the following aspects when assessing production capacity:

- Facility Infrastructure: Evaluate the infrastructure of the manufacturing facilities. State-of-the-art facilities equipped with modern machinery and technology contribute to efficient production processes and high-quality output.

- Workforce Expertise: A skilled and experienced workforce is integral to the manufacturing process. Assess the expertise of the personnel involved in the production of gantry cranes, including engineers, technicians, and quality control specialists.

- Scalability: Choose manufacturers with scalable production capabilities to accommodate fluctuations in demand. Scalability ensures that the manufacturer can meet your requirements even as your business grows or experiences variations in workload.

- Quality Control Measures: Inquire about the quality control measures implemented during the production process. Manufacturers employing rigorous quality control protocols are more likely to deliver products that meet or exceed industry standards.

Navigating the manufacturing landscape in China requires a comprehensive understanding of the capabilities and reputation of selected manufacturers. By prioritizing industry experience, customer feedback, and production infrastructure, buyers can forge partnerships with manufacturers capable of delivering high-quality 10-ton portable gantry cranes.

10 ton portable gantry crane feedback picture from American client and customer

Steel gantry crane frame painted

10 ton chain hoist for electric motorized portable gantry crane 10 ton

Pendant wire control of 10 ton motor driven rolling gantry crane

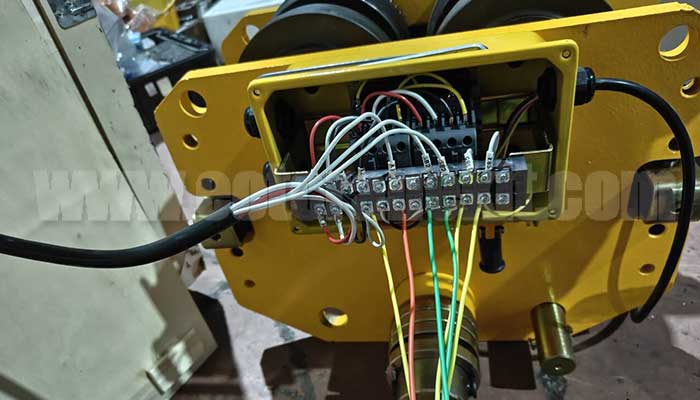

Electric box with clearly labled wires

Electric chain hoist wiring of gantry crane hoist

Quality Control Measures

Ensuring the reliability and safety of a 10-ton portable gantry crane hinges on robust quality control measures implemented during the production process. Scrutinizing inspection protocols and adherence to international standards are paramount in guaranteeing the crane's performance and longevity.

Inspection Protocols During Production

The integration of meticulous inspection protocols at various stages of production is a hallmark of a reputable manufacturer. Consider the following aspects when evaluating inspection measures:

- Material Inspection: Rigorous checks on raw materials ensure that only high-quality components are used in the gantry crane's construction. Verification of material certifications and testing for durability are key elements of this stage.

- Welding Quality: Welding is a critical aspect of gantry crane construction. Inspections at this stage focus on the integrity of welds, checking for proper penetration, alignment, and overall structural strength.

- Dimensional Accuracy: Regular measurements and checks ensure that the gantry crane components adhere to precise dimensional specifications. This is vital for the seamless assembly and optimal functioning of the crane.

- Functional Testing: Comprehensive functional tests at different production milestones guarantee that the gantry crane meets its performance specifications. This includes testing the trolley and hoist system, as well as other critical functionalities.

- Surface Finish Inspection: Aesthetics matter, and a thorough examination of surface finishes ensures that the gantry crane not only performs well but also presents a professional and corrosion-resistant exterior.

Compliance with International Standards

Adherence to international standards is a non-negotiable aspect of selecting a reliable gantry crane. Look for the following indicators of compliance:

- CE Certification: The CE mark indicates conformity with European Union safety standards. A gantry crane with CE certification attests to its compliance with stringent safety and environmental requirements.

- ISO Standards: Verify whether the manufacturer operates under ISO standards, particularly ISO 9001 for quality management. ISO certification reflects a commitment to consistent quality and continuous improvement in manufacturing processes.

- OSHA Compliance: For cranes destined for the American market, compliance with the Occupational Safety and Health Administration (OSHA) regulations is imperative. Ensure that the gantry crane adheres to OSHA standards to guarantee workplace safety.

- Other Applicable Standards: Depending on your industry and specific requirements, confirm that the gantry crane complies with any additional standards relevant to your application.

By prioritizing manufacturers with stringent inspection protocols and adherence to international standards, buyers can have confidence in the quality and safety of the 10-ton portable gantry crane. In the subsequent section, we will explore customization options, allowing businesses to tailor the crane to their unique operational needs.

Customization Options

Recognizing the diverse needs of industries and applications, the ability to customize a 10-ton portable gantry crane is a crucial factor in ensuring optimal performance. This section explores the avenues for tailoring the gantry crane to specific buyer needs and the importance of effective communication with manufacturers for modifications.

Tailoring the Gantry Crane to Specific Buyer Needs

The concept of one-size-fits-all does not apply to gantry cranes, considering the varied demands of industries. Customization options empower buyers to align the crane with their unique operational requirements. Key aspects of customization include:

- Lifting Height and Span: Tailor the gantry crane's lifting height and span to match the vertical and horizontal requirements of your workspace. This customization ensures precise load handling within the designated area.

- Control System Preferences: Different industries may have specific preferences for control systems. Whether it's a wired pendant control, radio remote control, or advanced automation features, customization allows buyers to choose the control system that best suits their operational needs.

- Additional Safety Features: Enhance the safety of your gantry crane by incorporating additional safety features based on your industry requirements. This may include proximity sensors, emergency stop buttons, or advanced overload protection mechanisms.

- Weatherproofing and Corrosion Resistance: Industries operating in challenging environments may benefit from enhanced weatherproofing and corrosion-resistant coatings. Customizing the gantry crane to withstand specific environmental conditions contributes to its longevity and reliability.

Communication with Manufacturers for Modifications

Effective communication with manufacturers is the linchpin in the customization process. Establishing a clear channel of communication ensures that modifications align with buyer expectations. Consider the following strategies for seamless communication:

- Detailed Specifications: Provide comprehensive and detailed specifications for the modifications you require. This includes precise measurements, functionality requirements, and any specific standards that must be met.

- Collaborative Design Process: Engage in a collaborative design process with the manufacturer. Solicit their expertise and recommendations to ensure that the proposed modifications align with the gantry crane's structural integrity and performance capabilities.

- Transparent Documentation: Maintain transparent documentation of all communication regarding modifications. This includes written agreements, design drawings, and any changes to the original specifications. Clear documentation helps prevent misunderstandings and ensures that the final product meets expectations.

- Regular Updates: Establish a communication cadence for regular updates on the progress of modifications. This ensures that any issues can be addressed promptly, preventing delays in the production timeline.

Customization options not only cater to the unique needs of buyers but also reflect the manufacturer's commitment to delivering solutions that seamlessly integrate into diverse operational environments. In the subsequent section, we will delve into the testing phase, where the gantry crane undergoes rigorous assessments to ensure compliance with safety standards and optimal performance.

Testing Phase

Factory Testing

As the 10-ton portable gantry crane transitions from the production floor to the testing phase, meticulous assessments are conducted to ensure it meets stringent quality and safety standards. This section explores the intricacies of factory testing, focusing on load testing procedures and quality assurance checks.

Load Testing Procedures

Load testing is a pivotal aspect of the factory testing phase, serving as a comprehensive evaluation of the gantry crane's lifting capacity and structural integrity. The following procedures are typically involved in load testing:

- Incremental Load Testing: Gradually apply loads in increments, monitoring the gantry crane's response at each stage. This procedure ensures that the crane can handle varying loads without compromising safety or performance.

- Maximum Load Capacity Verification: Test the crane at its maximum load capacity to verify that it performs within the specified limits. This is crucial for assessing the crane's suitability for heavy-duty applications.

- Dynamic Load Testing: Simulate dynamic conditions by subjecting the crane to dynamic loads, mimicking real-world scenarios. Dynamic load testing assesses the crane's stability and response to sudden changes in load.

- Duration Testing: Evaluate the gantry crane's endurance by subjecting it to extended periods of operation under load. This test ensures that the crane can sustain continuous use without performance degradation.

- Emergency Stop Testing: Assess the effectiveness of the emergency stop mechanism by triggering it under load. This test verifies that the crane can rapidly halt operations in case of an emergency.

Quality Assurance Checks

Quality assurance checks are integral to confirming that the gantry crane aligns with the specified design and manufacturing standards. The following aspects are typically scrutinized during quality assurance checks:

- Dimensional Accuracy: Verify that the gantry crane components adhere to precise dimensional specifications. Any deviations are thoroughly examined to ensure that they do not compromise the crane's performance.

- Weld Quality Inspection: Conduct a detailed inspection of welds to confirm proper penetration, alignment, and structural integrity. Weld quality is crucial for the overall stability and safety of the gantry crane.

- Electrical System Functionality: Test the functionality of the electrical system, including the control mechanisms and safety features. This ensures that the gantry crane operates seamlessly and complies with safety standards.

- Surface Finish Examination: Assess the surface finish for uniformity and corrosion resistance. Aesthetic considerations aside, a quality surface finish contributes to the crane's durability and resistance to environmental elements.

- Documentation Review: Confirm that all documentation, including test reports, certifications, and user manuals, is complete and accurate. Comprehensive documentation is vital for regulatory compliance and future maintenance.

The testing phase serves as the final crucible for the 10-ton portable gantry crane, validating its performance, safety, and adherence to quality standards. In the forthcoming section, we will explore the intricacies of the delivery process, from shipping logistics to on-site installation and commissioning.

Compliance with Safety Standards

Ensuring the safety of the 10-ton portable gantry crane is paramount during the testing phase. This section focuses on the critical aspect of compliance with safety standards, covering conformity to OSHA regulations, CE certification, and adherence to other international safety standards.

Conformity to OSHA Regulations

Operating in the American market demands strict adherence to Occupational Safety and Health Administration (OSHA) regulations. The testing phase includes thorough assessments to confirm the gantry crane's conformity to OSHA standards. Key considerations include:

- Load Capacity Limits: Verify that the gantry crane's load capacities align with OSHA-prescribed limits. Adherence to these limits is crucial for preventing overloading and ensuring the safety of personnel and equipment.

- Emergency Stop Functionality: Confirm the effectiveness of the emergency stop mechanism. OSHA mandates that gantry cranes are equipped with reliable emergency stop features to rapidly halt operations in case of a safety hazard.

- Operator Training Requirements: Ensure that the gantry crane meets OSHA requirements regarding operator training and certification. Adequate provisions for training and certification contribute to a safe working environment.

- Fall Protection Measures: Assess the presence and effectiveness of fall protection measures, especially for personnel working in proximity to the gantry crane. Compliance with OSHA fall protection regulations is imperative for worker safety.

CE Certification and Other International Safety Standards

Beyond OSHA regulations, international safety standards play a crucial role in the global acceptance of gantry cranes. CE certification, in particular, is a hallmark of compliance with European safety standards. Additional international safety standards may also be applicable depending on the intended market. Considerations include:

- CE Certification: Ensure that the gantry crane carries the CE mark, indicating conformity with European safety directives. CE certification encompasses various safety aspects, including electrical safety, structural integrity, and environmental considerations.

- ISO Standards: Evaluate adherence to ISO standards relevant to safety, such as ISO 13849 for control system safety or ISO 14122 for machinery access. Compliance with these standards underscores the manufacturer's commitment to delivering a safe and reliable gantry crane.

- National Standards for Export: Confirm compliance with any national safety standards applicable to the country of export. This may include additional safety certifications or approvals required for the gantry crane to enter specific markets.

- Risk Assessments: Manufacturers may conduct comprehensive risk assessments to identify and mitigate potential safety hazards. Documentation of these assessments provides transparency regarding the safety features implemented in the gantry crane.

Ensuring that the 10-ton portable gantry crane complies with safety standards not only facilitates regulatory compliance but also establishes a foundation for a secure and risk-free operational environment. In the next section, we will navigate through the intricacies of the delivery process, covering shipping logistics, packaging, and on-site installation and commissioning.

Documentation of Test Results

The transparency and reliability of a 10-ton portable gantry crane's performance are underscored by comprehensive documentation of test results. This section explores the importance of compiling detailed test reports and transparently sharing these results with buyers.

Compilation of Test Reports

The compilation of test reports is a meticulous process that encapsulates the various assessments and evaluations conducted during the testing phase. The purpose of these reports is to provide a comprehensive overview of the gantry crane's performance, safety features, and adherence to standards. Key elements of test reports include:

- Load Testing Data: Detailed data from load testing procedures, including incremental load tests, maximum load capacity verifications, and dynamic load testing. This data should clearly outline the crane's response to varying loads and its overall lifting capacity.

- Quality Assurance Checks: Documentation of quality assurance checks, covering dimensional accuracy, weld quality inspection, electrical system functionality, surface finish examination, and other relevant aspects. This section verifies that the gantry crane meets the specified design and manufacturing standards.

- Compliance with Safety Standards: Explicit documentation confirming conformity to safety standards, including OSHA regulations, CE certification, ISO standards, and any other relevant international safety standards. This ensures that the gantry crane aligns with industry-specific safety requirements.

- Documentation Review: Compilation of documentation reviews, confirming the completeness and accuracy of all documents related to the gantry crane's testing phase. This includes user manuals, certifications, and any written agreements regarding modifications or customization.

Transparency in Sharing Results with Buyers

Transparency in sharing test results with buyers is a cornerstone of establishing trust and confidence in the purchased gantry crane. The manufacturer should adopt a proactive approach in communicating the results, fostering a transparent and collaborative relationship. Strategies for transparent communication include:

- Timely Reporting: Share test results with buyers in a timely manner, allowing them to make informed decisions. Timeliness is crucial, especially if modifications or additional testing is required before finalizing the purchase.

- Clarity in Communication: Clearly communicate the findings of the test reports, using non-technical language where necessary. Buyers should easily comprehend the performance metrics and safety assurances presented in the documentation.

- Accessibility of Information: Provide convenient access to the complete set of test reports and related documentation. This may involve creating a secure online portal or sharing electronic copies to ensure that buyers can review the information at their convenience.

- Addressing Queries: Be responsive to any queries or concerns raised by buyers regarding the test results. A willingness to address questions demonstrates a commitment to transparency and customer satisfaction.

By prioritizing the compilation of comprehensive test reports and fostering transparency in sharing results with buyers, manufacturers contribute to a collaborative and informed decision-making process. In the upcoming section, we will unravel the intricacies of the delivery process, covering shipping logistics, packaging, and on-site installation and commissioning.

Delivery Process

Shipping Logistics

Efficient shipping logistics are integral to the successful delivery of a 10-ton portable gantry crane. This section explores key considerations in shipping, including the mode of transportation and the critical aspects of customs clearance and documentation.

Mode of Transportation

Choosing the right mode of transportation is a strategic decision that impacts delivery timelines, costs, and the condition of the gantry crane upon arrival. Consider the following modes of transportation:

- Sea Freight: Ideal for larger shipments, sea freight is a cost-effective option for transporting 10-ton gantry cranes. Containerized shipping ensures protection from the elements, and sea freight is suitable for longer distances.

- Air Freight: Air freight offers rapid delivery, making it a preferred choice for urgent shipments. While it is generally more expensive than sea freight, the speed and efficiency of air transportation may justify the cost, especially for time-sensitive projects.

- Land Transportation: For nearby locations or regions with well-developed land infrastructure, road transportation may be a viable option. This is particularly relevant for short-distance deliveries within a continent or country.

- Rail Transportation: In some regions, rail transportation may offer a balance between cost-effectiveness and speed. It is especially relevant for landlocked regions with efficient rail networks.

Customs Clearance and Documentation

Navigating the complexities of customs clearance is a critical aspect of the international shipping process. To ensure a smooth and timely delivery, attention to customs clearance and documentation is paramount:

- Customs Documentation: Compile and submit all necessary customs documentation, including the commercial invoice, packing list, bill of lading or airway bill, and any relevant certificates of origin or compliance. Accurate and complete documentation is crucial for customs clearance.

- Tariffs and Duties: Understand and comply with the tariffs and duties applicable to the shipment. Stay informed about any preferential trade agreements or exemptions that may reduce the financial impact of customs duties.

- Customs Brokerage: Consider engaging the services of a reputable customs broker to facilitate the customs clearance process. A knowledgeable broker can navigate regulatory requirements, ensuring compliance and minimizing delays.

- Compliance with Import Regulations: Ensure that the gantry crane complies with the import regulations of the destination country. This may include specific safety certifications, labeling requirements, or other standards that vary by region.

- Incoterms: Clearly define the Incoterms (International Commercial Terms) that govern the responsibilities and liabilities of both the buyer and the seller during the transportation process. Clarity on these terms avoids misunderstandings and disputes.

Effective management of shipping logistics, coupled with meticulous attention to customs clearance and documentation, streamlines the delivery process and minimizes the risk of delays or complications. In the following section, we will explore the critical considerations in packaging the gantry crane for secure transportation.

Packaging

Packaging plays a pivotal role in safeguarding the 10-ton portable gantry crane during international shipping. This section delves into the critical considerations for secure packaging and ensuring protection against potential damage during transit.

Electric parts and components packed in wooden cases

10 ton gantry crane with portable frame design for delivery

Secure Packaging for International Shipping

Creating a robust packaging strategy is essential to withstand the rigors of international shipping. Secure packaging involves the following key considerations:

- Customized Packaging: Tailor the packaging to the specific dimensions and components of the gantry crane. Customized packaging ensures a snug fit, minimizing the risk of movement and potential damage during transit.

- Use of Quality Materials: Opt for high-quality packaging materials, including heavy-duty cardboard, wooden crates, or metal frames. The packaging should withstand handling, loading, and unloading processes, providing a protective barrier against external forces.

- Secure Fastening: Securely fasten all components of the gantry crane within the packaging to prevent shifting during transportation. Use straps, braces, or other secure fastening mechanisms to immobilize the crane components.

- Weather-Resistant Packaging: Consider weather-resistant packaging, especially for shipments exposed to the elements during sea transport. Weather-resistant materials and coatings protect the gantry crane from moisture, salt, and other environmental factors.

Protection Against Potential Damage During Transit

Mitigating the risk of damage during transit requires a proactive approach to protection. Implement the following measures to safeguard the gantry crane:

- Shock-Absorbing Materials: Incorporate shock-absorbing materials, such as foam padding or cushioning, around vulnerable components. This provides a buffer against impacts and vibrations during transportation.

- Secure Internal Bracing: Reinforce the internal structure of the packaging with bracing or support structures. This helps distribute the load evenly and prevents concentrated pressure on specific areas of the gantry crane.

- Fragile Component Protection: Identify and provide extra protection for fragile components or sensitive parts. Use additional padding or specialized packaging for critical elements that may be prone to damage.

- Clear Handling Instructions: Clearly label the packaging with handling instructions to guide shipping personnel. Indicate the correct orientation of the package, highlight fragile components, and provide information on weight distribution.

- Insurance Coverage: Consider obtaining insurance coverage for the shipment. While robust packaging reduces the likelihood of damage, insurance provides financial protection in the rare event of unforeseen circumstances or accidents during transit.

By prioritizing secure packaging and implementing measures to protect against potential damage, manufacturers and buyers can ensure that the 10-ton portable gantry crane arrives at its destination in optimal condition. In the subsequent section, we will explore the critical steps involved in on-site installation and commissioning to seamlessly integrate the gantry crane into its operational environment.

Tracking and Communication

The transparency and efficiency of the delivery process are enhanced through real-time tracking for buyers and proactive communication on shipment status. This section explores the critical steps involved in providing buyers with real-time tracking information and maintaining open lines of communication throughout the shipment process.

Real-Time Tracking for Buyers

Real-time tracking empowers buyers with visibility into the location and status of their 10-ton portable gantry crane during transit. Key components of effective real-time tracking include:

- GPS Technology: Implement GPS tracking technology to monitor the precise location of the shipment. GPS enables real-time updates on the movement of the gantry crane, allowing buyers to track its progress.

- Online Tracking Portals: Provide buyers with access to online tracking portals where they can input shipment details and receive instant updates. User-friendly interfaces enhance the tracking experience and promote buyer engagement.

- Notification Alerts: Set up automated notification alerts to inform buyers of key milestones in the shipment process. Alerts may include departure from the origin, arrival at ports, customs clearance, and estimated delivery times.

- Secure Access: Ensure that the tracking system is secure, with access limited to authorized personnel. Implement measures to protect sensitive information while providing buyers with the necessary visibility into their shipment.

Proactive Communication on Shipment Status

Maintaining open lines of communication is paramount to assuage any concerns and keep buyers informed throughout the shipment process. Strategies for proactive communication include:

- Scheduled Updates: Establish a schedule for regular updates on the shipment status. This may involve weekly or bi-weekly communications, providing comprehensive overviews of progress and anticipated timelines.

- Responsive Customer Support: Offer responsive customer support channels for buyers to address inquiries or concerns. Prompt responses to queries contribute to a positive customer experience and foster trust in the delivery process.

- Issue Resolution Protocols: Develop clear protocols for addressing any issues that may arise during transit. Communicate these protocols to buyers, outlining the steps taken to resolve challenges and ensure a successful delivery.

- Emergency Communication Plan: In the event of unexpected delays or challenges, have an emergency communication plan in place. Notify buyers promptly, providing transparent information on the issue and the steps being taken to mitigate it.

By incorporating real-time tracking capabilities and maintaining proactive communication on shipment status, manufacturers enhance the overall customer experience and build trust with buyers. In the final section, we will delve into the critical steps of on-site installation and commissioning, ensuring that the 10-ton portable gantry crane seamlessly integrates into its operational environment.

Installation and Commissioning

Installation Guidelines

The successful integration of the 10-ton portable gantry crane into its operational environment relies on comprehensive installation guidelines and technical support from the manufacturer. This section outlines the key components of installation guidelines and the importance of manufacturer-provided technical support.

Comprehensive Installation Manual

A detailed and user-friendly installation manual serves as a crucial resource for ensuring the proper assembly and setup of the gantry crane. Key elements of a comprehensive installation manual include:

- Step-by-Step Instructions: Provide step-by-step instructions for the assembly process, including clear diagrams and illustrations. A sequential guide ensures that each component is installed correctly.

- Safety Precautions: Incorporate comprehensive safety precautions and guidelines to minimize the risk of accidents during installation. Clear communication of safety measures is paramount to protecting both personnel and equipment.

- Tool and Equipment Requirements: Specify the tools and equipment required for installation. This includes a detailed list of necessary tools, recommended safety gear, and any specialized equipment essential for the assembly process.

- Quality Checks: Outline checkpoints for quality checks at different stages of installation. Quality assurance measures during assembly contribute to the overall reliability and performance of the gantry crane.

- Troubleshooting Guidance: Include troubleshooting guidance for common issues that may arise during installation. Equipping personnel with the knowledge to address challenges ensures a smoother installation process.

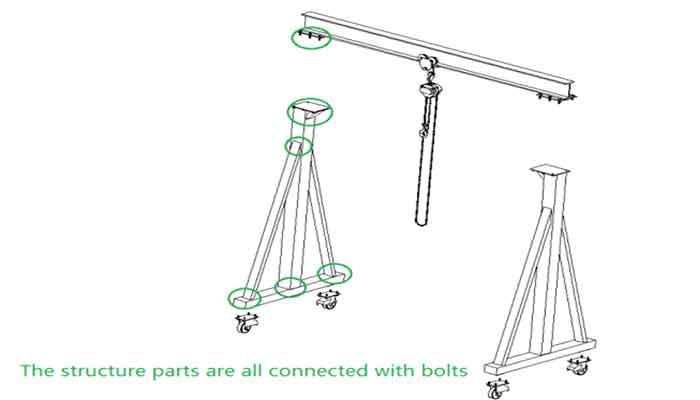

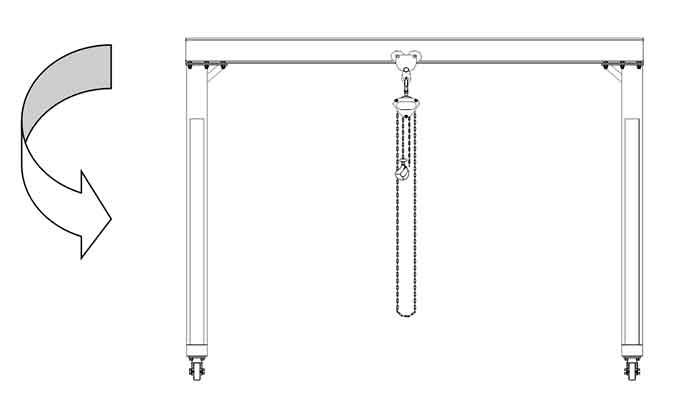

Main gantry crane structure acan be connected with bolts.

All the main structure of the small gantry crane is conncted by bolts. The small gantry crane drawing is for your reference. The roller gantry and rail travelling gantry crane are designed with similar gantry frame structure except the travelling types .

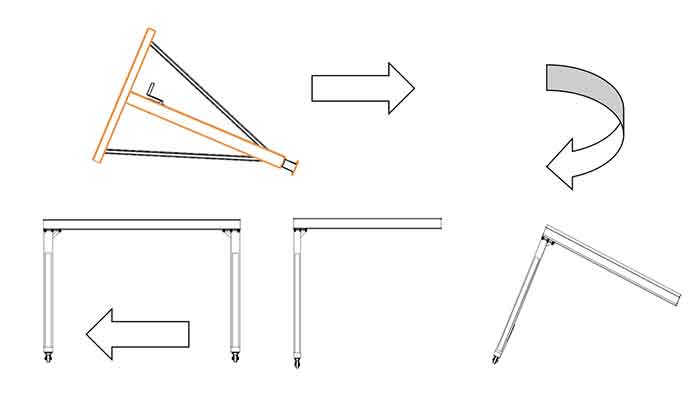

Assembly method 1: Small portable gantry crane installation proceture drawing : 1. Install one leg, 2. Connect the main girder with the leg, 3. Supporting the finished frame & installed the other legs. 4, Small gantry finished assembly.

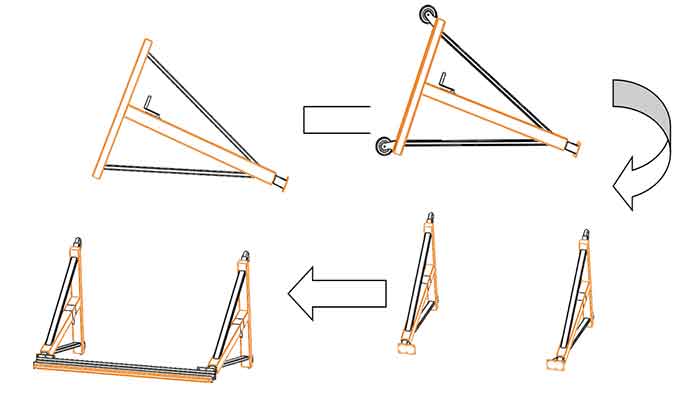

Assembly method 2: Mini portable gantry crane assembly procetures drawing: 1. Assembly the both legs, 2. Connect the gantry girder with the both gantry supporting legs

Mobile gantry crane finished installation.

Note: The gantry hoist and power supply line installation should be installed after the completion of the gantry structure.

Technical Support from the Manufacturer

Manufacturer-provided technical support is a valuable resource for addressing complex installation challenges and ensuring that the gantry crane is set up optimally. Components of effective technical support include:

- Hotline or Online Support: Establish a hotline or online support system where personnel involved in installation can reach out for immediate assistance. Responsive support channels contribute to timely issue resolution.

- Video Tutorials: Supplement the installation manual with video tutorials that visually guide personnel through the assembly process. Video content enhances comprehension and serves as a useful reference.

- Remote Assistance: Leverage technology for remote assistance, allowing manufacturer representatives to assess installation progress and provide guidance in real-time. Remote support can expedite issue resolution and reduce downtime.

- FAQs and Knowledge Base: Develop a comprehensive FAQ section and knowledge base that addresses common queries related to installation. This self-help resource empowers personnel to find solutions independently.

On-Site Assistance

On-site assistance, including the availability of technicians for installation and troubleshooting support during commissioning, further ensures the successful integration of the gantry crane into its operational environment.

Availability of Technicians for Installation

Ensuring the availability of qualified technicians from the manufacturer for on-site installation provides several advantages:

- Expertise and Experience: Manufacturer technicians bring in-depth knowledge and experience with the specific gantry crane model. Their expertise ensures that the installation is carried out efficiently and accurately.

- Efficient Problem Resolution: In the event of unforeseen challenges during installation, on-site technicians can swiftly address issues and implement solutions. Their presence contributes to a smoother and faster installation process.

Troubleshooting Support During Commissioning

Commissioning is a critical phase where the gantry crane is tested and fine-tuned for optimal performance. Troubleshooting support during this phase is essential:

- Real-Time Issue Resolution: Having manufacturer technicians available for real-time troubleshooting during commissioning helps identify and address any issues promptly. This minimizes downtime and ensures that the gantry crane operates at peak efficiency.

- Performance Optimization: Technicians can assist in fine-tuning the gantry crane's settings to align with specific operational requirements. Optimization during commissioning contributes to enhanced performance and longevity.

By providing comprehensive installation guidelines, technical support, and on-site assistance, manufacturers contribute to a seamless and efficient process, ensuring that the 10-ton portable gantry crane is ready to deliver reliable performance in its intended operational environment.

Post-Delivery Support

Warranty Coverage

Ensuring that buyers receive robust post-delivery support is paramount for their satisfaction and the long-term performance of the 10-ton portable gantry crane. This section focuses on warranty coverage, addressing the duration and terms of the warranty, as well as outlining procedures for warranty claims.

Duration and Terms of the Warranty

Understanding the warranty coverage is essential for buyers to assess the long-term reliability and support for their investment. Key elements of warranty coverage include:

- Duration: Clearly specify the duration of the warranty coverage. This may vary for different components of the gantry crane, such as the structure, electrical system, or other critical parts. Common durations range from one to five years, depending on the manufacturer.

- Comprehensive Coverage: Outline the scope of coverage provided by the warranty. This includes structural integrity, mechanical components, electrical systems, and other critical aspects of the gantry crane. A comprehensive warranty instills confidence in the product's overall reliability.

- Exclusions and Limitations: Transparently communicate any exclusions or limitations within the warranty. This may involve specifying conditions that could void the warranty or detailing components that are subject to wear and tear.

- Proactive Maintenance Requirements: Highlight any proactive maintenance requirements that must be fulfilled to maintain warranty coverage. Encouraging buyers to adhere to recommended maintenance practices ensures optimal performance and longevity.

Procedures for Warranty Claims

Streamlining the warranty claims process is crucial for providing buyers with prompt and effective support. Clearly define the procedures for warranty claims, addressing the following aspects:

- Submission Requirements: Specify the documentation and information required for submitting a warranty claim. This may include proof of purchase, detailed descriptions of issues, and photographs or videos illustrating the problem.

- Contact Points: Provide clear and accessible contact points for initiating warranty claims. This may involve dedicated customer support channels, online portals, or direct communication with assigned warranty representatives.

- Response Times: Outline the expected response times for warranty claims. Buyers should have a clear understanding of how quickly their claims will be acknowledged and addressed by the manufacturer.

- Resolution Process: Communicate the steps involved in the resolution process, from the initial assessment of the claim to the implementation of repairs or replacements. Clarity in the resolution process instills confidence in the manufacturer's commitment to post-delivery support.

- Costs and Responsibilities: Clearly articulate any costs or responsibilities associated with warranty claims. Buyers should be aware of whether transportation costs, labor, or replacement parts are covered under the warranty.

By providing transparent and comprehensive warranty coverage, manufacturers not only safeguard buyer satisfaction but also establish a framework for maintaining the gantry crane's performance over its operational life. In the subsequent section, we will conclude our comprehensive guide by summarizing key takeaways and emphasizing the importance of a holistic approach to the purchase, delivery, and post-delivery phases of a 10-ton portable gantry crane.

Maintenance Guidelines

Beyond warranty coverage, establishing clear maintenance guidelines is essential for the long-term performance and durability of the 10-ton portable gantry crane. This section delves into recommended maintenance schedules and the availability of spare parts.

Recommended Maintenance Schedule

Providing buyers with a comprehensive and realistic maintenance schedule ensures the continued reliability of the gantry crane. Key elements of maintenance guidelines include:

- Routine Inspections: Recommend routine inspections to identify any signs of wear, corrosion, or potential issues. Inspections may include checks on structural components, electrical systems, and movable parts.

- Lubrication Requirements: Clearly outline the lubrication requirements for the gantry crane, specifying the type of lubricants and the frequency of application. Proper lubrication is crucial for preventing friction-related wear and maintaining smooth operations.

- Electrical System Checks: Include regular checks on the electrical system, including wiring, connections, and control mechanisms. Routine inspections contribute to early detection of potential electrical issues.

- Load Testing: Recommend periodic load testing to verify the gantry crane's lifting capacity and overall performance. Load testing under controlled conditions helps identify any deviations from specified standards.

- Emergency Stop System Verification: Emphasize the importance of regularly testing the emergency stop system to ensure its effectiveness in halting operations in case of an emergency.

Availability of Spare Parts

Ensuring the availability of spare parts is crucial for minimizing downtime in the event of component failures or wear and tear. Key considerations related to spare parts availability include:

- Comprehensive Spare Parts List: Provide buyers with a comprehensive list of critical spare parts for the gantry crane. This list should cover components that may require replacement due to routine wear or unexpected failures.

- Efficient Supply Chain: Establish an efficient supply chain for spare parts to facilitate prompt delivery. Collaborate with reputable suppliers to ensure a steady and reliable source of replacement components.

- Documentation on Spare Parts Compatibility: Include documentation specifying the compatibility of spare parts with different gantry crane models. This ensures that buyers can confidently source and install the correct replacement parts.

- Technical Support for Replacement: Offer technical support to assist buyers in the replacement of spare parts. Clear instructions, diagrams, and, if necessary, remote assistance contribute to a seamless replacement process.

By providing buyers with comprehensive maintenance guidelines and ensuring the availability of spare parts, manufacturers contribute to the longevity and optimal performance of the 10-ton portable gantry crane. In the concluding section, we will summarize key takeaways and emphasize the importance of a holistic approach to the purchase, delivery, and post-delivery phases of the gantry crane lifecycle.

Customer Feedback and Case Studies

Compilation of Customer Testimonials

Compiling customer testimonials is a valuable component of showcasing the real-world impact and satisfaction levels associated with the 10-ton portable gantry crane. This section emphasizes the importance of customer feedback and highlights the benefits of incorporating positive testimonials into the overall narrative.

Importance of Customer Testimonials:

- Credibility: Genuine testimonials from satisfied customers enhance the credibility of the manufacturer and the gantry crane itself. Buyers often rely on the experiences of their peers to make informed decisions.

- Validation of Performance: Customer testimonials serve as a validation of the gantry crane's performance and the manufacturer's commitment to quality. Positive feedback reinforces the trustworthiness of the product.

- Addressing Buyer Concerns: Addressing common buyer concerns through specific testimonials helps alleviate uncertainties and showcases how the gantry crane successfully met the needs of diverse industries and applications.

- Decision-Making Support: Prospective buyers can use customer testimonials as a valuable resource during their decision-making process. Positive experiences shared by existing customers provide insights into the real-world benefits of the gantry crane.

Examples of Successful Implementations

Illustrating real-world examples of successful gantry crane implementations through case studies provides a deeper understanding of the crane's versatility and adaptability. This section highlights the significance of presenting case studies and their potential impact on potential buyers.

Benefits of Case Studies:

- Demonstration of Versatility: Case studies showcase how the 10-ton portable gantry crane adapts to diverse environments and industries. Whether it's manufacturing, construction, or logistics, real-world examples illustrate the crane's versatility.

- Problem-Solution Narratives: Case studies often present a problem-solution narrative, detailing specific challenges faced by customers and how the gantry crane provided effective solutions. This format resonates with buyers confronting similar issues.

- Operational Efficiency: Highlighting improvements in operational efficiency and workflow optimization achieved through the implementation of the gantry crane establishes its practical value in different scenarios.

- Industry-Specific Insights: Tailoring case studies to specific industries provides targeted insights for buyers operating within those sectors. Understanding how the gantry crane addresses industry-specific challenges enhances its appeal.

- Quantifiable Results: Whenever possible, include quantifiable results in case studies. Metrics such as increased productivity, reduced downtime, or improved safety measures provide tangible evidence of the gantry crane's positive impact.

Incorporating customer testimonials and real-world case studies into the comprehensive guide enhances its depth and authenticity. These elements not only provide valuable insights for potential buyers but also reinforce the manufacturer's commitment to customer satisfaction and the successful implementation of the 10-ton portable gantry crane in diverse operational settings.

Conclusion

In summary, this comprehensive guide has explored the entire lifecycle of a 10-ton portable gantry crane, focusing on the design, production, testing, delivery, and post-delivery support. Key points covered include:

Design Phase:

Specifications including capacity, size, and material selection.

Structural components encompassing frame design, trolley systems, and portability features.

Electrical system details, including power requirements, control mechanisms, and safety features.

Production Process:

Overview of manufacturing facilities in China, emphasizing capacity and capabilities.

Quality control measures, including inspection protocols and compliance with international standards.

Customization options, enabling buyers to tailor the gantry crane to their specific needs.

Testing Phase:

Factory testing procedures, with a focus on load testing and quality assurance checks.

Compliance with safety standards, including OSHA regulations, CE certification, and adherence to international safety standards.

Comprehensive documentation of test results, promoting transparency with buyers.

Delivery Process:

Shipping logistics considerations such as transportation modes and customs clearance.

Secure packaging for international shipping and protection against potential damage during transit.

Tracking and communication strategies, offering real-time tracking for buyers and proactive updates on shipment status.

Installation and Commissioning:

Installation guidelines with a comprehensive manual and technical support from the manufacturer.

On-site assistance, emphasizing the availability of technicians for installation and troubleshooting support during commissioning.

Post-Delivery Support:

Warranty coverage details, including duration, terms, and procedures for warranty claims.

Maintenance guidelines, outlining recommended schedules and the availability of spare parts.

Recommendations for Potential Buyers

For potential buyers considering the purchase of a 10-ton portable gantry crane, the following recommendations are offered:

- Thorough Assessment of Requirements: Conduct a detailed assessment of your operational requirements to ensure the gantry crane aligns with your specific needs.

- Collaborative Communication with Manufacturers: Engage in open and collaborative communication with manufacturers to discuss customization options and address any questions or concerns.

- Comprehensive Evaluation of Testing and Compliance: Thoroughly evaluate the testing phase results and confirm compliance with safety standards, including OSHA regulations and international certifications.

- Holistic Approach to Delivery Logistics: Consider the holistic approach to the delivery process, from shipping logistics and secure packaging to real-time tracking and proactive communication.

- Emphasis on Post-Delivery Support: Prioritize manufacturers that offer robust post-delivery support, including warranty coverage, clear maintenance guidelines, and the availability of spare parts.

In conclusion, this guide serves as a comprehensive resource for potential buyers of 10-ton portable gantry cranes, offering insights into various aspects of the procurement process and ensuring a well-informed decision-making journey.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch