Portable jib crane- Jib crane with movable & mobile roller design

Portable jib crane on wheels/ rollers, self-supportive jib mobile crane design, no foundation, wide application. Mobile jib crane & Movable jib crane for sale, economical & profitable.

| Jib crane types | Portable jib cranes on wheels |

| Rated load | 0.08t, 0.125, 0.25t, 0.5t, 1 ton, 2 ton |

| Lifting height | 1.5m, 2m, 3m |

| Turning radius | 2m, 3m |

| Rotation angle | 360° |

| Lifting speed | 8m/min or 8/0.8m/min |

Category: Jib Crane

Your Trusted Portable jib Crane on Wheels/ Rollers Manufacturer & Supplier

Portable Jib crane for Sale 500kg, 1 Ton, 2 Ton

Jib Crane with Movable & Mobile Roller Design

Portable jib cranes is a new series of jib cranes with self-supportive jib design, mounted on wheels and rollers for wide material handling with maneuverability and wide adaptability.The portable jib crane on wheels or on rolling rollers is a small and light duty movable jib crane with small & medium-speed lifting equipment, with the features of unique jib structure design, safe &reliable operation, time & energy saving , high efficiency and flexibility, cost-effective. Due to portable jib crane design, the cantilever jib crane is widely used for various applications in outdoor and indoor, a perfect choice for short distance &concentrated material handling, a good alternative lifting equipment for automatic production line with high efficiency under emergency.

Portable jib crane design with electric wire rope hoist

Portable jib crane design with electric motor driven rotating

Portable jib crane design with counter balanced weight

Portable jib crane design with light crane design

A portable jib crane is a versatile lifting device designed to move and position loads within a defined area. Unlike fixed jib cranes, these cranes can be relocated easily, making them suitable for various applications where space and flexibility are crucial. Key characteristics include:

- Mobility: Many models come with wheels or casters, allowing them to be moved effortlessly within a workshop or site.

- Adjustable Design: They often feature adjustable arm lengths and heights to accommodate different lifting needs.

- Compact Size: Portable jib cranes are designed to fit in tight spaces, offering efficient solutions for small and medium-duty tasks.

- Simple Operation: They typically have straightforward controls, making them easy to operate even for those with limited training.

Importance in Various Industries: Portable jib cranes are essential across multiple industries due to their adaptability and efficiency. In manufacturing, they streamline material handling on assembly lines, enhance workflow, and reduce manual lifting. In warehousing, they facilitate quick loading and unloading of goods, improving inventory management. Construction sites benefit from their ability to lift and position materials in temporary setups, while marine and port operations use them to handle equipment and supplies near docks. Their versatility and ease of use make them invaluable in any setting where space and flexibility are key.

Benefits of Using Portable Jib Cranes

- Flexibility and Mobility: Portable jib cranes can be easily repositioned, allowing for dynamic use in various locations and tasks. This flexibility enhances operational efficiency and adaptability.

- Cost-Effective Solutions: Compared to larger, fixed cranes, portable jib cranes are more affordable, offering a budget-friendly option for lifting needs without compromising performance.

- Quick Installation and Ease of Use: Their straightforward design means they can be set up quickly and operated with minimal training, reducing downtime and increasing productivity.

Types and Capacities

- 500kg Portable Jib Crane: The 500kg portable jib crane is ideal for light-duty tasks and small workspaces. It is designed to handle loads up to 500 kilograms, making it suitable for lifting small machinery parts, tools, and workshop equipment. Its compact size and ease of maneuverability make it perfect for use in areas with limited space.

- 1 Ton Portable Jib Crane: The 1 ton portable jib crane offers a balance between capacity and portability, making it versatile for medium-duty applications. It can lift up to 1,000 kilograms, which suits a range of tasks from handling medium-sized machinery parts to managing industrial containers and bulk materials.

- 2 Ton Portable Jib Cranes: The 2 ton portable jib crane is designed for heavy-duty applications, capable of lifting loads up to 2,000 kilograms. This crane is built to handle large and heavy materials efficiently, making it suitable for demanding environments.

Your Trusted Portable Jib Crane Manufacturer & Supplier

Portable Jib Crane for Sale

Mobile Jib Crane for Sale 0.5 Ton to 2 Ton

The portable jib crane is a 360°rotation movable jib crane, installed with a manual hoist or electrical hoist,including, electric chain hoist & electric wire rope hoists with capacity of 0.08 ton, 0.125 ton, 0.25 ton, 0.5 ton and 1 ton, 110 volt single phase or 240-480 volts, 3 phase. For hazardous applications, special designed explosion proof hoists & air powered pneumatic spark proof hoists are provided. The main parameters of the mobile jib cranes for your reference.

Custom Portale Jib Crane 1 Ton, 2 Ton Design 3D Presentation

Portable jib crane 3D Presentation for your reference to get your customized mobile jib crane with roller handling up to 2000kg

Main Parameters of Portable Jib Crane

- Jib crane types: Portable jib cranes on wheels, equipped with manual hoist or electric hoists

- Rated load of portable jib crane : 0.08 ton, 0.125 ton, 0.25 ton, 0.5 ton , 1 ton, 2 ton,

- Lifting height of portable jib crane : 1.5m, 2m, 3m

- Turning radius of portable jib crane : 2m, 3m

- Rotation angle of portable jib crane : 360°

- Rotary way of portable jib crane : electric or manual

- Lifting speed of portable jib crane : 8m/min or 8/0.8m/min

Features and advantages of Mobile Jib Crane

- Cost-saving - With simple structure,the mobile jib crane can be processed with lower production cost than an overhead travelling crane with few mounted structure installed around your workshop and at same time the portable jib crane can be a good complement to the stationary type overhead crane system.

- Space saving- Portable jib crane are designed with self-supportive jib column mounted on broad base to ensure stability but without concrete foundation or being bolted to the ground, which will save your workshop floor space and enable the portable crane to relocate from site to site easily and flexibly.

- High flexibility - The portable jib crane on wheels with wheels and broad base can be move smoothly in any direction to the designated location with high flexibility and safety.

- 360°rotation -With 360°rotation design, the cantilever or jib arm of the movable floor jib crane can rotate around the supporting column with wide working coverage area and go beyond the limitations and obstacles on the ground in the workshop.

- Easy operation - No formal training or certifications are required to operate these units, and their design is intentionally simple to encourage accessibility

- High efficiency -With the use of movable jib cranes, your working efficiency can be improved, the handling time can be shortened and the labor intensity of workers can be lowered.

- High safety - Various protection divers are used to ensure the safety of the portable crane. Overloading protection,Top quality long time bearing polyurethane materials buffer , Crane traveling and cross limit switch ,Voltage lower protection function, reduce energy consumption

- Various configurations, wide applications - With various types of lifting hoists, the portable roller jib crane can be designed with various configurations to meet various needs , such as, manual hoist or air hoists, or electric hoists, including electric chain hoist, electric wire rope hoist, or European standard overhead hoist, etc. With the suspended hoist , the roller movable jib crane can lift loads in any direction up and down, traveling horizontally on the cantilever forwards & backwards.

With unique advantages, the small portable jib cranes can be a good choices for light duty material handling . With particular applications and requirements,a customized jib crane solutions can be offed at cost-effective crane price. No matter what types of jib cranes are needed, we can offer your customized design at good price, including mast-style jib crane, wall traveling crane, wall mounted crane, column mounted crane, freestanding crane and so on.

Structure & components

The portable jib crane is a movable small crane which is consisted of a cantilever, column, rotating arm device, manual hoist or electric hoist and broad mobile base. The lifting hoist is suspended on the jib cantilever, which is supported on the column,mounted on the broad base with wheels and rollers. With hoist trolley , the portable jib crane can lift loads up and down and travel horizontally on the jib arm. With wheels and broad base, the portable jib crane can be moved to any designated place in any direction stably and smoothly. With the use of movable jib cranes, your working efficiency can be improved, the handling time can be shortened and the labor intensity of workers can be lowered.

The small jib crane can be used at many sites with great versatility saving cost of crane construction in different locations and saves workshop floor space. With high adaptability, the jib crane can be detached from the base and mounted to the floor.

Portable Jib Hoists

For different jib crane designs and application requirements, there are various jib hoists are available for selection. The jib hoisting systems are including the electric hoist, manual hoist, chain fall hoist or wire rope hoists,and others, etc. Custom designed swing cranes are ideal for your application.

FEM wire rope crane hoist specifications: Capacity: 0.25 ton -50 ton,Ask for electric wire rope jib hoist price.

Chinese style electric crane hoist specifications: Capacity: 0.25 ton -80 ton,, Ask for Chinese type electric jib hoist price.

Electric chain hoist specifications: Capacity: 0.25 ton -50 ton,, Ask for electric chain jib hoist price.

Low headroom hoist specifications: Capacity: 500kg - 80 ton, Ask for low headroom crane jib hoist price.

Explosion proof hoist specifications: Capacity: 500kg ton- 50 ton, Ask for explosion proof jib hoist price.

Optional Accessories

Electric Hoists and Manual Winches: Adding accessories like hoists and winches expands the crane's functionality and adaptability:

- Electric Hoists: Offer automated lifting and lowering, which improves efficiency and reduces manual effort. Electric hoists are ideal for repetitive tasks and heavy loads, providing consistent performance and speed.

- Manual Winches: Provide a more cost-effective solution for lifting lighter loads. Manual winches are easy to operate and suitable for applications where automation is not required.

Rotation Locks and Control Systems: Optional features enhance the control and stability of the crane during operation:

- Rotation Locks: Secure the crane's rotation to prevent unintended movement. This feature is crucial for maintaining precision when positioning loads and ensuring safety during operation.

- Control Systems: Advanced control systems, such as remote controls or programmable interfaces, offer improved operation and flexibility. They allow for precise handling and can be customized to suit specific operational requirements.

Your Trusted Portable Jib Crane Manufacturer & Supplier

Hot Sale Portable Jib Cranes

500kg Portable Jib Crane

Design and Construction: The 500kg portable jib crane is engineered for light-duty tasks, featuring a lightweight yet sturdy frame. It typically includes an adjustable arm that allows for a range of lifting operations. The crane's base can be stationary or equipped with wheels for enhanced mobility. Its design prioritizes ease of use and maneuverability in tight spaces.

Typical Applications and Environments

- Small Workshops: Ideal for handling small machinery parts and tools.

- Repair Shops: Useful for lifting and positioning equipment and parts.

- Assembly Areas: Facilitates easy and precise placement of components in assembly lines.

Key Features

- Height: Adjustable from 1 to 3 meters to match various lifting needs.

- Arm Length: Customizable arm length to suit different load sizes and workspace dimensions.

- Rotation Angle: Provides 360° rotation for flexibility in load positioning.

1 Ton Portable Jib Crane

Design and Construction: The 1 ton portable jib crane is built for medium-duty tasks, featuring a more robust construction compared to the 500kg model. It includes a strong frame and an adjustable arm, designed to handle a higher capacity while maintaining portability. The crane may come with a mobile base or wheels for easy repositioning.

Versatility in Medium-Duty Applications

- Manufacturing Plants: Efficient for handling medium-sized machinery parts and tools.

- Warehouses: Ideal for lifting and moving industrial containers and bulk materials.

- Construction Sites: Suitable for various medium-duty lifting tasks.

Key Features

- Height: Adjustable from 1 to 3 meters for flexible lifting.

- Arm Length: Adjustable to accommodate different lifting requirements.

- Rotation Angle: 360° rotation allows for easy maneuvering and load placement.

2 Ton Portable Jib Cranes

Design and Construction: The 2 ton portable jib crane is designed for heavy-duty applications, featuring a heavy-duty frame and reinforced construction. It is built to handle larger and heavier loads with ease. The crane often includes a sturdy base or robust wheels for stability and mobility.

Heavy-Duty Applications and Industries

- Manufacturing Facilities: Handles large machinery and equipment efficiently.

- Construction Sites: Suitable for lifting heavy construction materials such as steel beams and pipes.

- Industrial Maintenance: Ideal for moving bulk industrial products and large containers.

Key Features

- Height: Adjustable up to 3 meters to reach high lifting points.

- Arm Length: Designed to handle larger loads with an adjustable arm.

- Rotation Angle: 360° rotation for versatile and effective load handling.

Features and benifits of Portable Jib Cranes 0.5 Ton to 2 Ton

Key Features Across All Capacities

Portable Jib Crane Base: Importance and Design Considerations

- Stability: A strong base is crucial for safe operation and load stability. The base may be fixed or equipped with wheels for added mobility.

- Design: Base design impacts the crane's stability and ease of movement. Considerations include load distribution and compatibility with different surfaces.

Portable Jib Crane Hoist: Types and Functions

- Types: Hoists can be manual or electric, depending on the crane's intended use and load capacity.

- Functions: Hoists facilitate lifting and lowering of loads, with options available to suit various operational needs and preferences.

Portable Jib Crane on Wheels: Mobility and Adaptability

- Mobility: Wheels enhance the crane's flexibility, allowing for easy relocation and positioning within different areas of a workspace.

- Adaptability: Portable jib cranes on wheels can be adjusted for various tasks, making them versatile in dynamic environments.

Small Portable Jib Crane: Special Considerations for Compact Designs

- Design: Compact design ensures the crane fits in tight spaces while providing effective lifting capabilities.

- Applications: Suitable for environments where space is limited but efficient material handling is required.

500kg Portable Jib Crane & Typical Objects Handled

Benefits: Ideal for Light-Duty Tasks, Maneuverability, and Safety: The 500kg portable jib crane is specifically designed for light-duty applications, offering several key benefits:

- Ideal for Light-Duty Tasks: Perfect for handling smaller loads, making it a practical choice for applications where heavy lifting is not required.

- Maneuverability: Its compact and lightweight design allows for easy movement and positioning, even in confined spaces. This feature is particularly valuable in small workshops or maintenance areas.

- Safety: Reduces the need for manual lifting, minimizing the risk of injury associated with heavy or awkward loads. Its design ensures stability and ease of operation.

Typical Loads or Objects: Small Machinery Components, Tools, and Equipment

- Small Machinery Components: Suitable for lifting and positioning smaller parts and components used in machinery assembly or repair.

- Tools and Equipment: Ideal for moving various tools and equipment within a workshop, enhancing organization and efficiency.

- Boxes and Containers: Handles small boxes and containers, streamlining material handling processes.

1 Ton Portable Jib Crane & Typical Objects Handled

Benefits: Versatile for Medium-Duty Tasks, Balance Between Capacity and Portability: The 1 ton portable jib crane offers a versatile solution for medium-duty tasks, combining capacity with portability:

- Versatile for Medium-Duty Tasks: Capable of handling a wider range of loads compared to the 500kg model, making it suitable for more demanding applications.

- Balance Between Capacity and Portability: Provides a good balance between lifting capacity and ease of movement, allowing for efficient handling of medium-sized loads without sacrificing mobility.

- Increased Efficiency: Enhances workflow in environments where both medium-duty lifting and flexibility are required.

Typical Loads or Objects: Medium-Sized Machinery Parts, Industrial Containers, and Bulk Materials

- Medium-Sized Machinery Parts: Suitable for handling components and assemblies used in various industrial applications.

- Industrial Containers: Effective for moving and positioning containers holding materials or products.

- Bulk Materials: Handles bulk materials such as palletized goods, enhancing material handling efficiency in warehouses and manufacturing settings.

2 Ton Portable Jib Cranes & Typical Objects Handled

Benefits: Heavy-Duty Tasks, Durability, and Increased Productivity: The 2 ton portable jib crane is designed for heavy-duty applications, offering robust performance and reliability:

- Heavy-Duty Tasks: Capable of lifting and handling larger and heavier loads, making it suitable for demanding industrial environments.

- Durability: Built with a strong and durable frame to withstand the rigors of heavy lifting and extended use.

- Increased Productivity: Enhances operational efficiency by handling large materials quickly and safely, contributing to higher productivity levels.

Typical Loads or Objects: Large Machinery, Construction Materials, and Bulk Industrial Products

- Large Machinery: Efficiently lifts and positions large machinery components and equipment.

- Construction Materials: Handles heavy construction materials like steel beams, pipes, and other large items used in construction projects.

- Bulk Industrial Products: Suitable for moving bulk products and large containers, improving material handling processes in industrial settings.

Mobile Slewing Jib Crane Application

Due to portable jib crane design, the cantilever jib crane is usually used as lifting solution for short distance &concentrated material handling, or be used in workshops where overhead travelling cranes systems are not possible. Specially , the small portable jib cranes can be a good alternative lifting equipment for automatic production line with high efficiency under emergency. However, the regular rolling jib cranes is not allowed to lifting molten metal, toxic substances, flammable and explosive materials.

Mobile jib crane widely used in factories, mines, workshops, field, warehouse,workshop production lines, assembly lines, mechanical processing, small equipment installation, and light lifting of warehouses, docks and other occasions.

Portable jib crane with wire rope hoist design

Portable jib crane with counter-weight design

Portable jib crane with drop cantilever design

Portable jib crane with kbk cantilever arm design

Industrial Manufacturing

Applications in Assembly Lines, Material Handling, and Production Support: Portable jib cranes play a crucial role in industrial manufacturing by streamlining various processes:

- Assembly Lines: Jib cranes assist in moving parts along assembly lines, enhancing workflow and reducing manual handling. They provide precise positioning and efficient material handling, which is essential for maintaining a steady production pace.

- Material Handling: These cranes simplify the movement of raw materials and components to different stages of production. Their flexibility and mobility ensure that materials can be transported quickly and safely within the manufacturing facility.

- Production Support: They support production operations by facilitating the lifting and positioning of tools, machinery, and parts, improving overall efficiency and productivity.

Specific Uses for Each Crane Capacity

- 500kg Portable Jib Crane: Used for handling small parts and tools in assembly areas, and positioning lightweight machinery components.

- 1 Ton Portable Jib Crane: Suitable for lifting medium-sized machinery parts, industrial containers, and assisting in the movement of larger production components.

- 2 Ton Portable Jib Crane: Ideal for managing heavy machinery components, large assembly parts, and providing support for substantial production equipment.

Warehousing and Logistics

Loading and Unloading Goods: In warehousing and logistics, portable jib cranes are essential for efficient material handling:

- Loading: They facilitate the loading of goods onto trucks, containers, or pallets. Their mobility and adjustable height ensure that goods can be positioned accurately and safely.

- Unloading: Jib cranes assist in unloading goods from transportation vehicles, making it easier to move items into storage areas or distribution centers.

Storage and Retrieval Processes

- Storage: Portable jib cranes help in placing and organizing items on shelves, racks, or in storage bins. They are particularly useful for warehouses with limited space where precise placement is necessary.

- Retrieval: They aid in retrieving stored items, reducing the time and effort required to locate and move products from storage to shipping or production areas.

Typical Loads Handled in Warehouse Settings

- 500kg Portable Jib Crane: Handles small boxes, lightweight equipment, and smaller containers.

- 1 Ton Portable Jib Crane: Suitable for moving medium-sized boxes, bulk materials, and pallets.

- 2 Ton Portable Jib Crane: Manages larger containers, heavy industrial products, and bulk goods.

Construction Sites

Lifting and Positioning Materials: Portable jib cranes are invaluable on construction sites for their lifting and positioning capabilities:

- Lifting Materials: They are used to lift and position construction materials such as steel beams, pipes, and heavy equipment. This functionality is crucial for efficient site operations and timely project completion.

- Positioning: They help in precisely positioning materials and equipment, ensuring that they are placed accurately for construction tasks.

Portability Advantages in Temporary Sites

- Ease of Relocation: The portable nature of these cranes allows for easy relocation across different areas of a construction site, adapting to changing project needs and layouts.

- Adaptability: They can be moved to different parts of the site as work progresses, providing flexibility in managing materials and equipment.

Example Loads Handled by Each Crane Capacity

- 500kg Portable Jib Crane: Handles smaller construction tools, parts, and light materials.

- 1 Ton Portable Jib Crane: Suitable for lifting medium-sized construction materials and equipment.

- 2 Ton Portable Jib Crane: Manages heavy construction materials such as steel beams and large equipment.

Tailoring Solutions to Specific Needs

Industry-Specific Customization Options: Customizing cranes to meet industry-specific requirements ensures optimal performance and compliance:

- Industrial Manufacturing: Custom solutions may include specialized lifting gear or attachments designed for handling specific types of machinery or materials.

- Construction Sites: Tailored features such as increased lifting height or additional support structures can be provided to meet the demands of construction environments.

- Marine and Port Operations: Customizations might include corrosion-resistant materials or enhanced mobility features to handle marine conditions and heavy cargo.

Consultation for Unique Applications: Consulting with experts can help tailor solutions to meet unique operational needs:

- Expert Consultation: Engaging with professionals allows for a thorough assessment of specific requirements, leading to customized crane solutions that address unique challenges and enhance operational efficiency.

- Bespoke Designs: For applications with unique constraints or requirements, bespoke crane designs can be developed to provide optimal performance and reliability. This approach ensures that the crane is perfectly suited to the intended use and environment.

By incorporating customizable features and optional add-ons, users can tailor portable jib cranes to their specific needs, enhancing functionality, performance, and durability for various applications.

Safety Features and Compliance

Built-in Safety Mechanisms

Overload Protection: Overload protection is a crucial safety feature for portable jib cranes. It prevents the crane from lifting loads that exceed its rated capacity, which can prevent structural damage and ensure safe operation. This mechanism typically includes:

- Load Sensors: These sensors monitor the weight being lifted and trigger an alarm or automatic shutdown if the load exceeds the crane's capacity.

- Safety Cut-offs: These systems halt operations if an overload is detected, protecting both the crane and the operator from potential hazards.

Brake Systems and Locking Mechanisms: Reliable brake systems and locking mechanisms are essential for maintaining stability and safety during operation:

- Brake Systems: High-quality brakes ensure that the crane's load remains secure while being lifted or lowered. They prevent accidental movement and ensure that the crane holds its position when stationary.

- Locking Mechanisms: Locking features, such as arm locks and base locks, secure the crane in place and prevent unintended movement. This is particularly important during loading, unloading, or when the crane is not in use.

Compliance with Industry Standards

Certifications and Regulatory Compliance: Ensuring that portable jib cranes meet industry standards and regulations is essential for safety and legal compliance:

- Certifications: Look for cranes that are certified by recognized safety organizations or standards bodies, such as the American National Standards Institute (ANSI) or the International Organization for Standardization (ISO). These certifications verify that the crane meets specific safety and performance standards.

- Regulatory Compliance: Compliance with local and international regulations, such as OSHA (Occupational Safety and Health Administration) standards in the U.S. or CE marking in Europe, ensures that the crane adheres to safety and operational requirements specific to different regions.

Importance of Meeting Safety Standards in Different Environments: Meeting safety standards is vital for ensuring safe operation across various environments:

- Industrial Settings: In industrial environments, adhering to safety standards helps prevent accidents, protects workers, and ensures that the crane operates effectively within the demands of the workplace.

- Construction Sites: On construction sites, compliance with safety regulations is crucial to managing risks associated with lifting heavy materials and operating in potentially hazardous conditions.

- Marine and Port Operations: In marine environments, cranes must meet standards that account for exposure to corrosive elements and dynamic conditions, ensuring reliability and safety in challenging environments.

By incorporating these safety features and ensuring compliance with industry standards, portable jib cranes offer a secure and reliable solution for various lifting and handling tasks.

Your Trusted Overhead Crane Manufacturer & Supplier

Send Us An Inquiry on Portable Jib Cranes

Portable Jib Crane for Sale, Get Your Customized Design

Key Advantages

- Versatility: Portable jib cranes offer exceptional flexibility, making them suitable for a wide range of applications across different industries. Their adjustable features, including arm length and height, allow them to handle various load sizes and operational needs, from light-duty tasks to heavy lifting.

- Safety: These cranes are equipped with built-in safety mechanisms such as overload protection and reliable brake systems, ensuring safe operation and minimizing the risk of accidents. Compliance with industry standards and regulatory requirements further enhances their safety in diverse working environments.

- Customization: Our portable jib cranes come with a range of customizable options, including material choices and additional accessories. This ensures that the cranes can be tailored to meet specific operational needs and environmental conditions, providing a solution that fits perfectly with your unique requirements.

Why Choose Our Portable Jib Cranes

We prioritize high standards in manufacturing, ensuring that our portable jib cranes are built with durable materials and advanced engineering. This commitment to quality translates into reliable performance and long-term value for our customers.

Our focus on customer satisfaction includes providing excellent pre-sales and after-sales support. From helping you choose the right crane to offering comprehensive training and maintenance services, we are dedicated to ensuring that you receive the best possible experience and support.

Purchasing and After-Sales Support

Factors to Consider When Buying

Assessing Capacity Needs: Determining the right capacity is crucial for selecting the appropriate portable jib crane. Key considerations include:

- Load Weight: Calculate the maximum weight of the loads you intend to lift and ensure the crane's capacity matches or exceeds this requirement. For example, choose a 500kg portable jib crane for light loads, a 1-ton crane for medium loads, and a 2-ton crane for heavier tasks.

- Frequency of Use: Consider how often the crane will be used. Frequent lifting of heavy loads may require a crane with a higher capacity and more robust construction.

- Operational Requirements: Assess the types of materials or objects that need to be handled, as well as any specific operational needs, such as adjustable arm lengths or variable lifting heights.

Evaluating Mobility and Space Requirements: Ensure the crane fits well within your workspace and meets mobility needs:

- Workspace Dimensions: Measure the available space where the crane will be used. Check the crane's dimensions, including the span and lifting height, to ensure it fits comfortably within your facility.

- Mobility Needs: For environments where space is tight or the crane needs to be moved frequently, consider a portable jib crane on wheels. Evaluate how easily the crane can be repositioned or relocated to different areas.

Installation and Setup Services

Professional Installation Guidance: Proper installation is essential for safe and effective crane operation:

- Expert Installation: Engage professionals for the installation of your portable jib crane to ensure it is set up correctly and complies with safety standards. Professional installation also helps in optimizing the crane's performance and longevity.

- Site Preparation: Ensure that the installation site is prepared according to specifications, including appropriate flooring and clearance, to support the crane's base and operation.

Training for Safe Operation: Training is vital for ensuring safe and efficient crane use:

- Operator Training: Provide training for crane operators to familiarize them with the crane's controls, safety features, and operational procedures. Proper training helps in preventing accidents and ensuring efficient use of the crane.

- Safety Procedures: Educate operators on safety procedures, including load handling, emergency protocols, and routine inspections.

Maintenance and Warranty

Maintenance Schedules and Best Practices: Regular maintenance ensures the crane remains in good working condition:

- Maintenance Schedules: Follow a recommended maintenance schedule that includes regular inspections, lubrication, and part replacements. Adhering to these schedules helps prevent breakdowns and extends the crane's service life.

- Best Practices: Implement best practices for maintaining the crane, such as keeping it clean, checking for wear and tear, and ensuring all safety features are functioning correctly.

Warranty Coverage and After-Sales Support: Ensure comprehensive support and coverage for your crane investment:

- Warranty Coverage: Verify the warranty terms provided by the manufacturer or supplier, including the duration and what is covered. A good warranty provides protection against defects and potential issues.

- After-Sales Support: Access to reliable after-sales support is important for addressing any issues that arise after purchase. This support may include technical assistance, repair services, and spare parts availability.

By carefully considering these factors and ensuring proper installation, training, maintenance, and support, you can maximize the benefits of your portable jib crane and ensure it performs effectively and safely in your operations.

2 Ton Mobile Jib Cranes for Glass Handling Qatar

4 sets mobile jib cranes are provided for client from Qatar. It's the second order from the Qatar customer.

On December 20, 2021, 4 mobile jib cranes for clients for Qatar, second order

2 ton light duty small mobile jig crane for glass handling crane

Glass handing jib cranes requirement of Qatar client

The customer's business is relatively extensive, mainly including concrete & asphalt plants, concrete placing booms, concrete cooling plants, concrete recycling plants, lifting equipment, building maintenance units, generators and related parts and services. This time, the customer needs mobile jib crane, in order to solve his client lifting glass problem, the working conditions are very representative.

The basic requirements and working conditions are as follows:

- The glass handling jib crane will be used on the roof, lifting the glass placed on the ground.

- The glass handling crane is required to be mobile and movable from working site to site and when not in use or when the project is completed

- The jib hoist arm does not need to be rotated and can be fixed

- The maximum lifting capacity of overhead jib does not exceed 2 ton.

- Lifting height of jib column is 50m (48.16m in building height + 1.84m in height from the roof)

- Arm length of cantilever jib crane is 3m

- Click to learn more about 2 ton portable jib crane for sale Qatar.

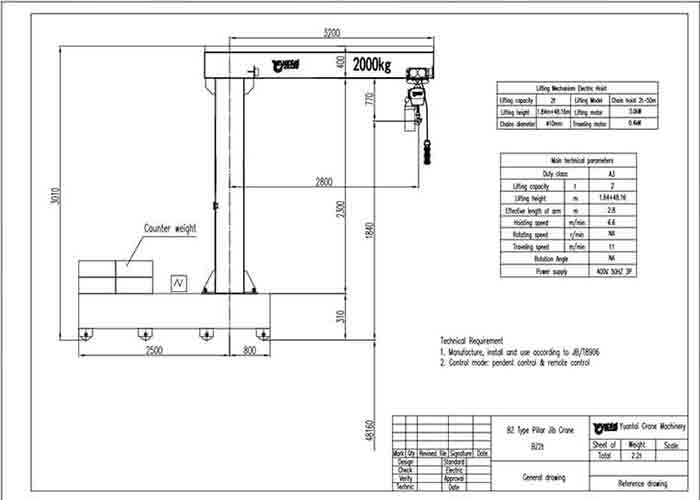

2 ton mobile jib crane design drawing

Based on customer requirements, glass handling jib crane 2 ton is designed as the following crane drawing:

2000kg mobile jib crane design drawing for Qatar client for glass handling - glass handling cranes

- Lifting capacity: 2 ton

- Lifting height: 50m(1.84m+48.16m)

- Span (arm length): 3m (effective arm length: 2.8m)

- Power supply: 400v/50hz/3p

- Working duty: A3

- Control: Pendant control & Remote control

- Hoist type: electric chain hoist with electric trolley

- Rotation: No

- Wheels No.: 8

- Equipped with counter weight

The client is very satisfied with the light duty jib crane solution design and quotation. Due to the previous successful cooperation last time, the Qatar customer purchased 4 mobile jib cranes directly, the purchasing of portable jib crane was very smooth. Quality and reasonable price help us to win more and more long term cooperation partner.

Mobile jib crane main parts and components at Qatar

2 ton mobile jib crane assembly at Qatar

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch