Common Cantilever Gantry Crane Problems & Prevention

Common Problems with Cantilever Gantry Cranes and How to Avoid Them – Overloading, Imbalance, and Rail Wear

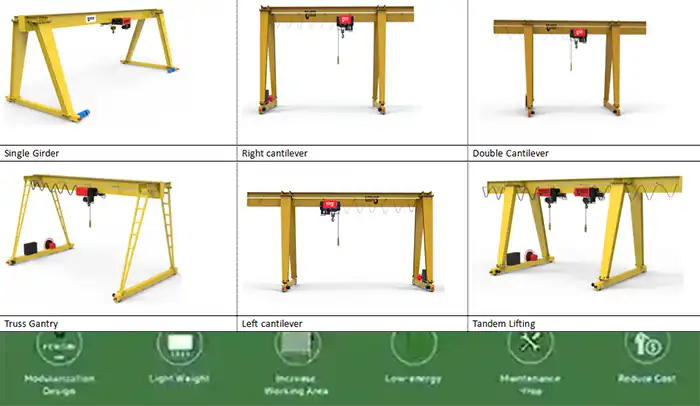

What Are Cantilever Gantry Cranes?: Cantilever gantry cranes are widely used in industrial workshops, steel plants, shipping yards, and outdoor storage areas. Their defining feature is the extended cantilever arms, which let the crane reach beyond the main runway. This makes them ideal for handling wide, heavy, or awkwardly shaped loads—think steel beams, marble blocks, or containers.

Why Safe Operation Matters: Operating these cranes safely is more than just a checklist item. Overloading, imbalance, and rail wear can lead to serious downtime, costly repairs, or even accidents. Some of these issues develop slowly and may not be obvious until it’s too late. Staying ahead of them is key to keeping your crane productive and safe.

What This Article Covers: We’ll walk through the most common problems cantilever gantry cranes face and provide practical tips to prevent them. Here’s a quick look at what you’ll learn:

- Overloading: How exceeding the crane’s capacity affects structure and hoist, and ways to avoid it.

- Imbalance: Why uneven loads happen, and practical strategies to maintain stability.

- Rail Wear: Causes of rail damage and simple steps to prolong rail life.

Cantilever Gantry Cranes

Structure and Function

Cantilever gantry cranes are designed to provide extra reach beyond the main runway. This makes them particularly useful when working with wide or long loads that a standard gantry crane can’t handle efficiently. Understanding the basic structure helps operators and buyers plan for safe and effective use.

Key Components:

- Main Girder: The primary horizontal beam that spans the runway and supports the crane’s weight.

- Cantilever Arms: Extend outward from the main girder, allowing the crane to reach over areas or loads beyond the main structure.

- Trolley: Moves along the cantilever or main girder, carrying the hoist to the load.

- Hoist: Lifts and lowers the load, typically powered electrically or hydraulically.

- Runway Rails: Provide the track for the crane to move along the facility or yard.

How Cantilever Design Differs from Standard Gantry Cranes:

- Standard gantry cranes lift loads within the width of the main girder, while cantilever cranes extend beyond it for extra reach.

- Cantilever cranes can handle uneven or awkwardly sized loads more flexibly.

- They often require more careful planning for balance and load distribution because the extended arms create additional stress on the structure.

Typical Applications

Cantilever gantry cranes are favored in industries and environments where standard cranes fall short due to reach or load configuration.

Common Use Cases:

- Outdoor Yards: Moving large or irregular loads in open storage areas.

- Shipping and Storage: Handling containers or oversized cargo that needs extended reach.

- Steel Handling: Transporting beams, billets, or coils in steel plants or fabrication yards.

- Stone and Marble Yards: Lifting heavy slabs or blocks where precise positioning is required.

These applications benefit from the crane’s extended reach and flexible lifting range, but they also demand careful attention to weight distribution, structural integrity, and maintenance.

no cantilver gantry crane 10 ton single cantilever gantry crane 10 ton double cantilever gantry craneCommon Problems

Overloading in Cantilever Gantry Cranes

Overloading is one of the most frequent issues with cantilever gantry cranes. It happens when a crane lifts more than it was designed to handle, or when operators miscalculate the weight of combined loads. Even experienced teams can fall into this trap if proper procedures aren't followed.

Causes

- Lifting loads that exceed the crane's rated capacity.

- Misjudging the weight when lifting multiple items together.

- Using a crane for a task it wasn't designed for, such as very long or uneven loads.

Consequences

Overloading puts enormous stress on the crane and can lead to serious problems:

- Structural damage to the main girder and cantilever arms.

- Premature wear or failure of hoist motors.

- Safety hazards for operators and anyone nearby—there's a real risk of accidents.

Prevention

Preventing overloading requires a mix of proper planning, equipment, and training:

- Perform regular checks on crane load capacity and ensure clear signage is displayed.

- Install load sensors, limiters, or alarms to prevent accidental overloading.

- Train operators to follow load charts and safe lifting practices.

- Plan lifts in advance, especially when handling irregular or combined loads.

Imbalance in Cantilever Gantry Cranes

Imbalance is another common problem with cantilever gantry cranes. Because the crane extends beyond its main girder, uneven loads or misaligned hoists can easily create instability. Even small errors in load positioning can put extra stress on the crane and affect safety.

Causes

- Unevenly distributed loads on the cantilever arms.

- Incorrect positioning of the hoist or trolley along the girder.

- Wind or environmental effects during outdoor operations, which can cause swaying.

Consequences

When a crane is operating with imbalance, the risks are significant:

- Increased stress on the crane structure, leading to bending or long-term damage.

- Swaying or tipping, especially with long or heavy loads.

- Accelerated wear of bearings, joints, and other moving components.

Prevention

Preventing imbalance requires careful planning and routine checks:

- Always position loads properly and plan lifts in advance to ensure even distribution.

- Use counterweights when necessary to maintain stability, especially for extended cantilever reaches.

- Conduct periodic inspections of crane alignment and structural integrity.

- Train operators to recognize warning signs of imbalance and act quickly.

Rail Wear in Cantilever Gantry Cranes

Rail wear is a gradual but serious issue that can affect the performance and safety of cantilever gantry cranes. Over time, repeated movements, heavy loads, or poor installation can damage the rails, making crane operation rough and less reliable. Left unchecked, rail wear can lead to higher maintenance costs and safety hazards.

Causes

- High frequency of operations or repeated handling of heavy loads.

- Misalignment of rails or uneven foundation, putting extra stress on wheels and bearings.

- Corrosion or lack of lubrication, especially outdoors.

Consequences

- Vibration and rough movement of the crane, reducing lifting precision.

- Increased maintenance and repair costs over time.

- Reduced efficiency and potential safety risks for operators and nearby personnel.

Prevention

- Conduct regular inspections and identify early signs of wear or damage.

- Ensure proper rail alignment and recheck periodically.

- Lubricate moving parts and apply anti-corrosion treatments in humid environments.

- Keep maintenance logs to track wear patterns and schedule repairs.

Practical Tips for Buyers and Operators

Operating a cantilever gantry crane safely isn't just about following instructions—it's about planning, regular care, and training. Whether you're buying a new crane or managing an existing one, practical steps can make a big difference in performance, safety, and lifespan.

Choose the Right Crane for Your Needs

- Select a crane with the correct lifting capacity, span, and cantilever reach for your operations.

- Consider the types of loads, frequency of lifts, and environment (indoor/outdoor).

- Avoid overspecifying—larger cranes can cost more and be harder to maintain.

Schedule Routine Inspections and Maintenance

- Inspect girders, cantilever arms, hoists, trolleys, and rails regularly.

- Check for wear, corrosion, misalignment, or vibration.

- Maintain logs of inspections and repairs to track recurring issues.

Train Operators Thoroughly

- Ensure operators understand load charts and safe lifting procedures.

- Teach proper load positioning and how to handle imbalance or sway.

- Encourage immediate reporting of unusual noise or vibration.

Document Incidents and Near-Misses

- Keep records of all accidents or near misses.

- Analyze recurring problems to prevent future incidents.

- Update training and maintenance plans based on lessons learned.

Case Studies / Examples

Real-world examples help illustrate how overloading, imbalance, and rail wear affect cantilever gantry cranes—and how proper precautions can prevent serious issues.

Example 1: Overloading in a Steel Yard: A steel fabrication plant once attempted to lift multiple steel beams together that exceeded the crane’s rated capacity. The result? Bent cantilever arms and downtime for emergency repairs. After this incident, the plant installed load sensors and enforced strict adherence to load charts. Downtime was reduced by 80% in the following year.

Example 2: Imbalance in Outdoor Operations: An outdoor shipping yard experienced crane sway during windy conditions while lifting unevenly loaded containers. Minor misalignment of the hoist caused stress on bearings and joints. By introducing careful load positioning, counterweights, and periodic structural inspections, the crane operated safely even in challenging weather.

Example 3: Rail Wear in a Marble Yard: A marble handling facility saw rough crane movement due to worn rails and uneven foundation. Regular maintenance checks were not in place initially, leading to increased vibration and slower operations. After implementing a strict rail inspection schedule, lubrication routines, and foundation leveling, rail life improved significantly, and operations became smoother and safer.

These examples show that proactive maintenance, proper load management, and regular inspections aren’t optional—they’re essential for safe, efficient crane operation.

Conclusion

Cantilever gantry cranes are versatile and valuable tools in many industrial and outdoor settings, but they come with specific challenges. Overloading, imbalance, and rail wear are the most common problems, and left unchecked, they can lead to costly repairs, downtime, and safety hazards.

Key Takeaways:

- Always choose a crane that fits your specific operational needs.

- Schedule regular inspections and maintenance to catch small problems before they escalate.

- Train operators thoroughly on load handling, positioning, and safety protocols.

- Document incidents and near-misses to continuously improve safety practices.

By adopting these practical measures, operators and buyers can ensure their cantilever gantry cranes run smoothly, safely, and efficiently for years. Proper planning, maintenance, and training make all the difference between frequent problems and consistent, reliable performance.