Manual Gantry Crane 3 Ton for Sale Saudi Arabia, Cost-effective

3 ton manual gantry cranes for sale to Saudi Arabia—cost-effective, flexible, and safe lifting for workshops, warehouses, and construction sites.

Category: 3 Ton Gantry Cranes

Your Trusted Overhead Gantry Crane Manufacturer & Supplier

3 Ton Gantry Crane for Sale

Case Study: 3 Ton Manual Gantry Cranes in Saudi Arabia

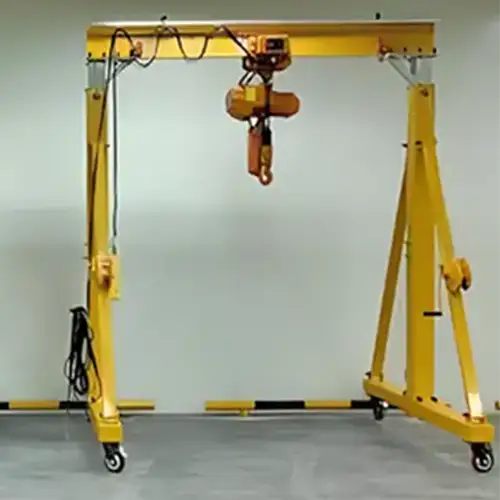

Manual gantry cranes are a staple in many small and medium-sized industrial operations. In Saudi Arabia, these cranes are widely used because they are simple, reliable, and flexible. The focus here is on 3 ton manual gantry cranes, especially those that are manual traveling, non-rail rolling, and come with an electric chain hoist.

The goal is straightforward: to give you a clear picture of how these cranes work, what they are made for, and why they are practical for industries in Saudi Arabia. We will look at their features, main specifications, and the situations where they make work easier.

Scope of this case study:

- Manual gantry cranes with 3 ton lifting capacity.

- Non-rail rolling design that moves easily on flat surfaces.

- Cranes equipped with electric chain hoists for smoother lifting.

- Suitable for workshops, warehouses, construction sites, and maintenance operations.

This is not just theory—we will include details that a buyer or operator would need to know when choosing or using a 3 ton gantry crane.

Market Overview in Saudi Arabia

The industrial scene in Saudi Arabia is quite diverse. From factories to construction sites, there's a strong need for reliable lifting solutions. Manual gantry cranes fit into this picture because they are simple, low-maintenance, and don't require complicated infrastructure.

Industrial Landscape

Manual gantry cranes are used in a variety of sectors:

- Construction: For lifting beams, panels, and heavy building materials.

- Manufacturing plants: Moving machinery parts, raw materials, and assembled products.

- Maintenance workshops: Lifting engines, gearboxes, and heavy equipment for repair.

- Warehousing: Handling goods in areas where forklifts might not reach.

Demand Drivers

Why are these cranes popular? A few reasons stand out:

- Affordability: Lower upfront cost compared to motorized or rail-mounted cranes.

- Flexibility: Can be moved and adjusted to fit different workshop layouts.

- Ease of use: Manual movement combined with an electric hoist makes lifting easier without needing a large crew.

- Durability: Strong steel construction ensures years of service with minimal maintenance.

Local Regulations

When using lifting equipment in Saudi Arabia, safety and compliance are key:

- Cranes must meet Saudi safety standards for load handling.

- Proper inspection and maintenance are required to keep the crane in safe working condition.

- Operators need basic training on manual and electric lifting procedures.

Product Overview: Manual Gantry Crane – 3 Ton Capacity

Manual gantry cranes with a 3 ton capacity are designed for practical, everyday lifting tasks. They are straightforward, robust, and easy to operate. Unlike overhead cranes, these gantry cranes do not need rails, making them ideal for workshops, warehouses, and temporary work areas where flexibility is important.

Design Features

These cranes are built to make lifting simple and safe. Key design points include:

- Manual movement without rails: The crane rolls on wheels, allowing it to be moved across flat surfaces without the need for complex installation.

- Electric chain hoist: While the crane moves manually, the hoist is powered, so lifting heavy loads requires less physical effort and is more controlled.

- Adjustable height and span: You can modify the crane height and span to fit different tasks or workspace layouts. This means one crane can serve multiple lifting needs without major changes.

Construction

Durability is a must for cranes that handle tons of material daily. These 3 ton gantry cranes are built to last:

- Steel frame: The main structure is made from high-strength steel, providing stability and load-bearing strength.

- Corrosion-resistant finish: A protective coating helps prevent rust and wear, which is especially important in humid or dusty workshop conditions.

With this combination of flexible design and strong construction, the crane can handle daily industrial tasks reliably, whether it's lifting machinery parts, moving raw materials, or assisting in maintenance operations.

Applications in Saudi Arabia

The 3 ton manual gantry crane is a flexible lifting solution widely used across Saudi industries. Its mobility and simplicity make it ideal where permanent cranes aren't practical.

- Construction Sites: Lifts and moves materials like steel beams and panels in areas without existing crane infrastructure.

- Manufacturing Plants: Supports assembly and maintenance tasks, moving machinery parts and raw materials efficiently.

- Warehouses: Handles goods in tight spaces, loads trucks, and stacks materials safely.

- Workshops: Assists with repairs and installation of heavy equipment, reducing manual effort and improving safety.

Compact, adjustable, and easy to move, this crane fits small and medium facilities perfectly, providing practical lifting wherever it's needed.

Key Features and Benefits

A 3 ton manual gantry crane isn't just about lifting loads—it's about making daily work easier, safer, and more efficient. These cranes combine simplicity, strength, and flexibility to meet the needs of workshops, factories, and warehouses in Saudi Arabia.

Portability

One of the biggest advantages of this crane is its mobility:

- The crane rolls on wheels and doesn't require rails.

- You can move it across flat surfaces quickly, repositioning it as your workspace or tasks change.

- Perfect for facilities where space is limited or layouts frequently change.

Adjustability

Flexibility is key in small and medium-sized operations:

- The height and span can be adjusted to match different loads or workflow setups.

- This means the same crane can handle multiple tasks without needing a separate unit.

- Ideal for lifting equipment onto platforms, trucks, or workbenches.

Ease of Use

Even though it handles heavy loads, this crane is easy to operate:

- Manual travel allows precise positioning of the crane over the load.

- The electric chain hoist reduces the physical effort required for lifting.

- Operators can safely handle loads without needing extra manpower.

Cost-Effectiveness

Compared to permanent rail-mounted or motorized overhead cranes, this manual gantry crane is budget-friendly:

- Lower initial investment and installation costs.

- No need for expensive rails or structural modifications.

- Offers practical lifting solutions without overspending.

Maintenance

Built to last, these cranes are low-maintenance:

- Robust steel construction ensures durability even in demanding environments.

- Corrosion-resistant coatings reduce wear and protect against rust.

- Routine inspections and simple lubrication are usually enough to keep the crane in service for years.

Tailored 3 Ton Manual Gantry Crane – Optional Features

The 3 ton manual gantry crane is versatile and portable, designed for workshops, factories, and maintenance areas. Options include electric or wire rope hoists, swivel caster wheels for full mobility, low headroom design, explosion-proof versions, and adjustable height settings. Durable, reliable, and easy to move, this crane is ideal for engines, molds, coils, and other heavy equipment.

Optional Features:

- Hoist Options: Electric or wire rope hoists for precise lifting.

- Mobility: 360° swivel caster wheels for easy positioning.

- Low Headroom Design: Perfect for tight workshop spaces.

- Explosion-Proof: Safe for hazardous environments.

- Adjustable Height: Customize to fit your workspace.

- Portable & Versatile: Moveable between workshops or storage areas.

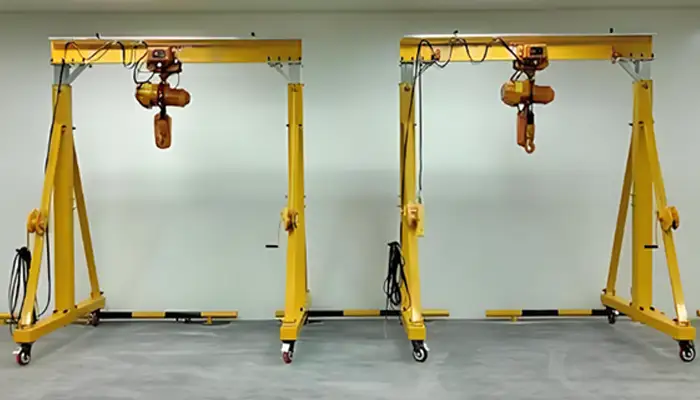

Case Study: 3 Ton Portable Gantry Crane in Saudi Arabia

Project Overview

A 3 ton manual gantry crane was deployed in a Saudi manufacturing facility to support daily lifting tasks. The facility needed a practical solution for moving machinery parts and heavy equipment without installing permanent overhead cranes.

Technical Specifications

Understanding the exact specifications of a 3 ton manual gantry crane is crucial for selecting the right crane for your workshop or warehouse. These specifications ensure the crane can safely handle your daily lifting tasks while fitting your space and power requirements.

manual gantry crane project for your reference, contact us to get tailored gantry cranes

Key Specifications

- Capacity – 3 tons: This crane can lift loads up to 3,000 kg, making it suitable for medium-duty industrial tasks such as moving machinery parts, raw materials, or heavy tools.

- Span – 3.5 meters: The distance between the legs of the crane is 3.5 meters, which provides enough working width for most workshop layouts without taking up excessive floor space.

- Lifting Height – 5 meters: The maximum vertical reach allows for loading and unloading tall equipment, stacking materials, or lifting onto platforms.

- Power Supply – 380V, 50Hz, 3-phase: The electric chain hoist requires standard industrial power, common in Saudi factories and workshops, ensuring compatibility without major modifications.

- Hoist Type – Electric chain hoist: Provides smooth lifting action, reduces manual effort, and improves safety during load handling.

- Mobility – Non-rail rolling design: The crane moves on wheels manually, which means no permanent rails are needed. This makes it easy to reposition the crane wherever needed on flat surfaces.

These technical details are practical and straightforward. They give operators and buyers a clear understanding of what the crane can do and how it fits into their workspace.

Challenges Addressed

- No existing crane infrastructure on-site.

- Requirement for a flexible, mobile lifting solution that could be repositioned as needed.

Outcomes

- Improved efficiency: Operators could lift and move loads faster and with less effort.

- Enhanced safety: Reduced manual handling lowered the risk of workplace injuries.

- Positive ROI: The crane provided a cost-effective solution that met operational needs without major investment.

This case demonstrates how a portable 3 ton gantry crane can solve real-world lifting challenges in Saudi workshops and manufacturing facilities.

Conclusion

3 ton manual gantry cranes provide a practical, flexible, and cost-effective solution for lifting and moving loads in Saudi Arabia. They fit well in workshops, warehouses, construction sites, and manufacturing plants, especially where permanent crane systems aren't feasible.

Recommendations for buyers:

- Choose crane specifications that match your specific operational needs, including span, lifting height, and workspace layout.

- Work with reputable suppliers to ensure product quality, proper installation, and access to support services.

- Perform regular maintenance to keep the crane in safe working condition and extend its service life.

With the right selection and care, a 3 ton manual gantry crane can deliver reliable performance and tangible benefits for years.

Related Products

Affordable 10 ton double girder overhead crane with CD/MD hoist trolley, built for U.S. standards, ideal for construction and industrial lifting

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch