Magnetic Gantry Crane vs. Slewing Jib Crane: Choosing the Best Crane

Magnetic Gantry Crane vs. Slewing Jib Crane: Choosing the Best Crane for Your Metal Waste Yard

Introduction

What Cranes Do in a Metal Waste Yard

In a metal waste yard, cranes help move heavy scrap metal every day. They pick up, carry, and sort large pieces of metal to keep the yard running smoothly. But not all cranes are the same. You need to choose one that fits your space, the weight of your scrap, and how you want to move things around.

Why Choosing the Right Crane Matters

Picking the right magnetic crane is more than just looking at the price. It affects how fast and safely your yard works. The wrong crane can slow down work, cause more repairs, and cost you more in the long run. The right crane will save time, reduce problems, and keep your workers safe.

A good crane should fit your yard well, handle your scrap without trouble, and be easy to keep in good shape. That’s why it’s important to choose carefully.

What This Guide Will Help You Decide

This guide compares two popular cranes for scrap yards: magnetic gantry cranes and slewing jib cranes. Both work well but in different ways.

- Magnetic gantry cranes can lift very heavy loads and cover a large area.

- Slewing jib cranes have a rotating arm and are good for smaller spaces.

We will look at how these cranes work, what they cost, and what’s best for your yard’s size and budget. This will help managers and engineers pick the right crane without guesswork.

Overview of Crane Types

A breakdown of the main crane types used in scrap yards, highlighting their functions, advantages, and where they are most effective.

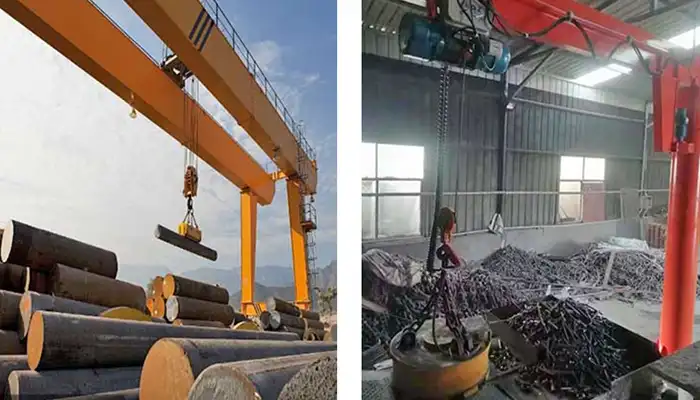

Magnetic Gantry Crane

What Is a Magnetic Gantry Crane?

A magnetic gantry crane is a large crane that moves on rails or wheels set on the ground. It has a big overhead frame (called a gantry) that spans across the working area. Suspended from this frame is a powerful electromagnet used to pick up metal scrap.

Where Are They Used in Metal Waste Yards?

These cranes are common in big scrap yards where large amounts of heavy metal need to be moved quickly. They are especially useful when handling bulky steel plates, scrap bundles, or heavy metal pieces that are hard to grab with regular hooks or clamps.

Key Features to Know:

- Wide Span: Covers a large working area because it runs along rails or wheels.

- Heavy Lifting: Can handle very heavy loads, often tens of tons at a time.

- Magnet System: Uses an electromagnet that turns on and off to pick up and release scrap safely and quickly.

- Stable and Strong: Built to operate continuously in tough outdoor conditions.

Slewing Jib Crane

What Is a Slewing Jib Crane?

A slewing jib crane has a horizontal arm (called a jib) that rotates around a fixed base or pillar. The arm swings in a circle, allowing the crane to reach different spots nearby. It can be mounted on the floor, a wall, or a column, and often includes a magnet for scrap handling.

Where Are They Used in Scrap Yards?

Slewing jib cranes are common in smaller yards or confined spaces where full gantry cranes won't fit. They are good for lifting medium-weight scrap and moving it within a limited area.

Key Features to Know:

- Rotating Arm: The jib can turn 360°, making it easy to reach multiple spots without moving the base.

- Fixed or Mobile Base: Can be set on a pillar, wall, or sometimes on a small trolley for limited movement.

- Magnet or Grab: Often equipped with an electromagnet for handling scrap metal.

- Space-Saving: Takes up less floor space compared to gantry cranes, ideal for tight yards.

Technical Comparison

A detailed technical comparison between magnetic gantry cranes and slewing jib cranes, covering capacity, layout, mobility, power systems, and maintenance considerations.

Capacity and Lifting Range

When it comes to lifting heavy scrap metal, capacity is key.

- Maximum Load Capacity: Magnetic gantry cranes usually handle much heavier loads, often ranging from 10 to 50 tons or more, depending on the model. Slewing jib cranes typically have lower capacity, usually between 1 to 10 tons, making them better for lighter or medium loads.

- Height and Reach: Gantry cranes can lift materials higher because of their large frame and tall structure. They also have a longer horizontal reach since they span across a wide area. Slewing jib cranes have a shorter reach — their arm length is limited — but they can rotate fully to cover their surrounding area.

- Span Coverage: Magnetic gantry cranes cover a large rectangular work area by moving along rails or wheels, making them ideal for big yards. Slewing jib cranes cover a circular area around their fixed base, which is smaller but flexible.

Space and Yard Layout Considerations

How much space the crane needs and how it fits in your yard matters a lot.

- Footprint and Ground Space: Magnetic gantry cranes require a larger footprint due to their wide frame and track system. They need clear rails or pathways to move along. Slewing jib cranes have a smaller base and take up less ground space, perfect for yards with limited room.

- Impact on Yard Traffic: Gantry cranes' movement along fixed rails can limit traffic flow if the yard is busy or congested. Jib cranes, fixed in one spot but able to rotate, generally cause less interference with vehicle or worker movement.

- Layout Flexibility: Slewing jib cranes work better in tight or irregular yard layouts where installing gantry rails is not possible or practical.

Mobility and Operational Flexibility

Moving scrap quickly from one spot to another depends on how the crane moves.

- Movement Type: Magnetic gantry cranes travel along rails or wheels on the ground, covering long distances in a straight line. Slewing jib cranes rotate around a fixed base but cannot travel across the yard.

- Work Zone Coverage: Gantry cranes can serve large work zones, moving scrap over wide areas. Jib cranes focus on a smaller work zone, but their 360-degree rotation allows them to reach all points around the base.

- Repositioning: Gantry cranes are generally fixed in place because rails are installed permanently. Slewing jib cranes can be relocated more easily if mounted on mobile bases or wheels.

Power and Control Systems

Power source and control type impact efficiency and ease of use.

- Power Options: Both cranes usually run on electricity. Magnetic gantry cranes require a stable power supply to operate heavy lifting and electromagnets. Slewing jib cranes can be electric or hydraulic, depending on the model and size.

- Control Methods: Gantry cranes are often controlled by operators in a cabin or remotely via radio control. Slewing jib cranes are usually operated from the ground using remote controls or control panels. Automation options exist for both but are more common in larger gantry systems.

- Integration: Gantry cranes require infrastructure like rails and electrical wiring. Jib cranes need less infrastructure, making them easier to fit into existing yards.

Maintenance and Durability

Keeping cranes running smoothly requires attention to maintenance and durability.

- Maintenance Frequency: Magnetic gantry cranes have more complex systems and may require more frequent maintenance checks, especially for the magnet, rails, and moving parts. Slewing jib cranes are simpler, needing less frequent but still regular maintenance.

- Wear Parts and Costs: Both cranes have wear parts like cables, motors, and brakes. Gantry cranes can have higher replacement costs because of their larger components and rail systems. Jib cranes' parts tend to be smaller and less expensive.

- Durability: Both crane types are built tough to withstand harsh outdoor environments, but gantry cranes' larger size and exposure to more moving parts can mean more wear over time. Proper maintenance extends the life of both.

Cost Comparison

A detailed comparison of costs associated with magnetic gantry cranes and slewing jib cranes, including purchase, installation, operation, and total cost of ownership.

Initial Purchase Price

The price tag is often the first thing on a buyer's mind.

- Magnetic Gantry Cranes: These cranes are big machines with heavy-duty parts and powerful magnets. Prices usually start around $150,000 and can go well above $500,000 depending on size and features.

- Slewing Jib Cranes: Smaller and simpler, slewing jib cranes generally cost much less. Prices typically range from $20,000 to $100,000, depending on capacity and options.

What Affects Cost?

- Load capacity (heavier loads mean bigger, more expensive cranes)

- Custom features like advanced magnet systems or automation

- Materials and build quality

- Control system complexity

Installation and Setup Costs

Buying the crane is just the start; installation adds to the budget.

- Foundations and Runways: Magnetic gantry cranes need strong, level foundations and rails for smooth movement, which can be costly and time-consuming. Slewing jib cranes usually require a solid base or pillar, but no rails, making installation simpler and cheaper.

- Labor and Time: Installing a gantry crane can take weeks, involving heavy equipment and skilled labor. Slewing jib cranes typically take less time and can sometimes be set up in days.

- Extra Infrastructure: Gantry cranes might need electrical wiring along the rails and special safety barriers. Jib cranes often require fewer extras.

Operating Costs

What it costs to keep the crane running matters a lot over time.

- Energy Use: Magnetic gantry cranes use more power because they lift heavier loads and run motors to move along rails. Slewing jib cranes consume less energy, as they handle lighter loads and have simpler movement.

- Maintenance and Spare Parts: Bigger cranes usually mean bigger maintenance bills. Gantry cranes have more parts to inspect and repair—rails, wheels, magnet coils, and more. Slewing jib cranes have fewer components and lower maintenance costs.

- Downtime Costs: When a crane is out of order, the yard slows down. Gantry cranes are critical to operations, so downtime can be costly. Jib cranes' smaller role may mean less impact during repairs.

Total Cost of Ownership (TCO)

Looking at just the purchase price doesn't tell the whole story.

- Summing It Up: Consider all costs: buying the crane, installing it, running it day-to-day, and maintaining it over years. Magnetic gantry cranes cost more upfront and to run, but for large yards, their efficiency can balance that out. Slewing jib cranes cost less overall but may not handle heavy workloads as well.

- Return on Investment: A gantry crane's higher cost makes sense if you need to move big loads fast and cover a large area. For smaller yards or lighter tasks, a jib crane can deliver good value without breaking the bank.

Pros and Cons Summary

When deciding between a magnetic gantry crane and a slewing jib crane, it helps to see their strengths and weaknesses side by side. Each crane type offers different benefits depending on your yard size, the weight of scrap you handle, and your budget. Understanding these differences makes it easier to choose the right fit.

Below is a clear comparison of key aspects, showing where each crane excels and where it may have limitations.

| Aspect | Magnetic Gantry Crane | Slewing Jib Crane |

|---|---|---|

| Space Efficiency | Requires larger footprint | Smaller footprint, good for tight spaces |

| Mobility | Moves along gantry rails, limited flexibility | 360° rotation, good for localized operations |

| Capacity | Generally higher load capacity | Suitable for medium loads |

| Maintenance | Higher maintenance complexity | Simpler maintenance |

| Cost | Higher upfront and installation cost | Lower upfront cost |

| Suitability | Best for large yards with heavy loads | Ideal for smaller yards, confined areas |

In summary, magnetic gantry cranes are a strong choice if your yard is large and you need to lift heavy scrap often. They offer wide coverage and powerful lifting but require more space and maintenance. Slewing jib cranes, on the other hand, are great for smaller yards or tighter spaces where you need flexibility and lower costs. They handle moderate loads well and are easier to maintain.

Decision-Making Guidelines for Procurement Managers and Engineers

Guidelines to help procurement managers and engineers select the right crane based on yard layout, operational needs, budget, and long-term plans.

Assess Yard Size and Layout Constraints

Before anything else, take a good look at your yard. How much space do you have? Is the yard open and wide, or tight and cluttered?

- Large, open yards can usually accommodate bigger cranes like magnetic gantry cranes.

- Smaller yards or those with obstacles might require more compact cranes like slewing jib cranes.

- Consider whether you can install rails or foundations, as some cranes need these.

Match Crane Capacity to Operational Needs

Think about the weight and size of the scrap metal you move daily.

- For heavy, bulky scrap, go for cranes with higher lifting capacities.

- If most of your loads are medium weight, a smaller crane may be more cost-effective and practical.

- Don't forget to factor in any occasional heavier loads to avoid surprises.

Budget Considerations and Cost-Benefit Analysis

Your budget plays a big role, but remember to look beyond the sticker price.

- Consider upfront costs, installation expenses, and ongoing maintenance and energy costs.

- Sometimes paying more upfront saves money over the long run through greater efficiency or lower downtime.

- Balance cost with expected performance to get the best value.

Future Expansion and Flexibility Needs

Your yard might grow or change over time, so think ahead.

- Will you need to handle heavier loads or cover a bigger area in the future?

- Magnetic gantry cranes usually support larger operations but are harder to move or modify.

- Slewing jib cranes can often be relocated or adjusted more easily if your needs change.

Maintenance Resources and Expertise Available

A crane is only as good as your ability to keep it running.

- Check if your team has the skills to maintain complex cranes like gantry systems.

- Simpler cranes like jib cranes might be easier to maintain with limited staff.

- Factor in the availability of spare parts and technical support nearby.

Case Examples

Example 1: Metal Waste Yard Using a Magnetic Gantry Crane

A large metal recycling yard in the Midwest handles tons of heavy steel scrap every day. They installed a magnetic gantry crane that runs on rails across the entire yard. This setup lets them quickly lift and move large scrap bundles from trucks to sorting areas without delay. The crane's high lifting capacity and wide coverage improved their workflow and cut loading times in half. While installation was costly, the yard's size and heavy scrap volumes made it the right choice.

Example 2: Yard Operating Efficiently with a Slewing Jib Crane

A smaller scrap yard near the city center uses a slewing jib crane mounted on a sturdy pillar. Space is limited, and the yard handles medium-weight scrap from local businesses. The jib crane's 360-degree rotation helps operators move scrap around tight corners and into storage piles without needing to reposition trucks or forklifts. This crane's lower cost and simple maintenance have made it a reliable tool that fits well in their smaller, busy space.

Conclusion

Choosing between a magnetic gantry crane and a slewing jib crane depends mostly on your yard’s size, the type of scrap you handle, and your budget. Magnetic gantry cranes work best for large yards with heavy loads, offering broad coverage and powerful lifting. Slewing jib cranes fit smaller yards, tight spaces, and moderate lifting needs, while being more cost-effective and easier to maintain.

Remember, there’s no one-size-fits-all answer. Match the crane’s strengths to your specific yard layout, workload, and future plans. When in doubt, consulting crane experts can save you time, money, and headaches by finding the solution that truly fits your needs.