How to Choose Single Girder Gantry Crane: Key Factors

Learn how to select a single girder gantry crane by considering capacity, span, and duty for safe, efficient operation.Get your single girder gantry crane!

Category: Featured

Your Trusted Single Girder Gantry Crane Manufacturer & Supplier

How to Choose Single Girder Gantry Crane: Key Factors

Capacity, Span, and Duty of Single Girder Gantry Crane

What Is a Single Girder Gantry Crane?

A single girder gantry crane is a lifting machine that uses one horizontal beam supported by two legs. The legs move either on rails or wheels, and an electric hoist runs along the beam to lift and move loads. It's built for handling materials where overhead cranes aren't practical or possible.

This type of crane is often used in:

- Small fabrication workshops

- Medium-sized warehouses

- Outdoor yards or construction sites

- Precast concrete and steel structure factories

It's a practical choice for jobs that don't need large lifting capacities or continuous heavy-duty cycles. Check more on European style single girder gantry crane for your reference.

Where Are Single Girder Gantry Cranes Commonly Used?

They're ideal for places with limited space, low headroom, or flexible work zones. Compared to double girder cranes, they're lighter, simpler to install, and cost less to operate.

Typical applications include:

- Moving steel beams or components across a yard

- Lifting molds in plastic or rubber factories

- Handling light machinery or tools in repair workshops

- Loading and unloading materials from trucks

If your tasks are straightforward and your space is open, a single girder gantry crane can be the right fit.

Why This Guide Matters

Choosing a gantry crane isn't just about picking a model and getting it delivered. There are three key factors that directly affect how well your crane will perform—and how long it will last:

- Capacity – Get it wrong, and your crane could be overloaded or underused

- Span – Misjudge it, and your crane might not cover your working area

- Duty class – If it's not rated for your work hours, breakdowns can happen faster

This guide helps you understand these critical parameters clearly—so you can choose a crane that works well, fits your space, and lasts longer.

Whether you're upgrading, replacing, or buying your first gantry crane, the tips in this article will help you avoid common mistakes and make a confident, informed decision.

Single Girder Gantry Crane

What Is a Single Girder Gantry Crane?A single girder gantry crane is a material handling crane that uses one main horizontal beam (girder) supported by legs on either side. The hoist runs along the girder to lift and move loads within a workspace. Compared to double girder cranes, this type is lighter, easier to install, and more cost-effective for medium and light lifting needs.

Main Structural Components:

- Main Girder: The single beam that supports the hoist trolley and carries the load.

- Legs: Vertical supports at each end, which can be fixed or movable.

- Hoist and Trolley: The lifting device and mechanism that moves along the girder.

- Runway Rails or Wheels: Depending on design, the crane moves along fixed rails or on rubber tires.

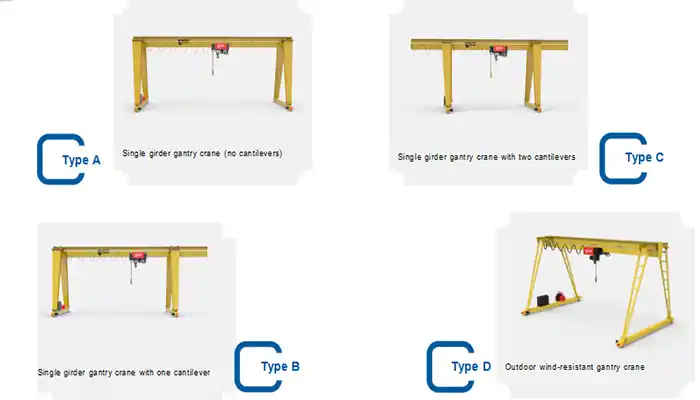

Common Configurations of Single Girder Gantry Cranes

Standard Single Girder Gantry Crane

The classic design consists of a main girder supported by two legs running on rails. This type is commonly used in workshops and yards.

Cantilever Gantry Crane Design Options Include:

- Double Cantilever: The girder extends beyond both legs, allowing the hoist to lift loads beyond the crane's legs.

- Single Cantilever: The girder extends beyond only one leg, useful when working near walls or obstructions.

- No Cantilever: The girder ends exactly at the legs, suited for straightforward lifting within the leg span.

Variations in Leg Design

- A-Frame Legs: Triangular leg structure providing good stability; common in standard models.

- L-Leg Design: Legs shaped like an "L" to allow easier access or to fit certain site conditions, often customized for specific client needs.

Specialized Single Girder Gantry Cranes

- Low Headroom Single Girder Gantry Crane: The hoist trolley is placed beside the main girder to reduce overall height—ideal where overhead clearance is limited.

- Semi-Gantry Crane: One leg runs on rails while the opposite side rests on a fixed runway beam, saving space and cost.

- Rubber-Tyred Gantry Crane: Equipped with rubber tires instead of rails for easy mobility on flat surfaces, commonly used in outdoor yards or logistics sites.

- Explosion-Proof Single Girder Gantry Cranes: Built with special components to safely operate in hazardous environments like chemical plants or oil refineries.

Common Applications Across Industries

Single girder gantry cranes serve a wide range of industries, especially where light to medium loads need to be lifted efficiently:

- Manufacturing and Fabrication Workshops: Moving machine parts, tools, and materials between stations.

- Steel and Metal Yards: Handling steel beams, plates, and fabricated structures.

- Plastic and Rubber Industries: Lifting molds and heavy equipment safely.

- Warehousing and Logistics: Loading/unloading goods and managing stock.

- Construction Sites: On-site material transport over short distances.

- Chemical and Hazardous Environments: Using explosion-proof models for safe operation.

Capacity: How Much Weight Will You Be Lifting?

Selecting the right lifting capacity is key when choosing a single girder gantry crane. The capacity directly affects safety, cost, and efficiency. If you pick a crane that's too weak, it won't handle your loads safely. If it's too big, you could be paying more than necessary.

Typical Capacity Range and Hot Sale Models

Single girder gantry cranes are commonly available with lifting capacities ranging from 1 ton up to 20 tons. Some manufacturers also offer custom cranes that can lift up to 32 tons, but these are less common and typically designed for special projects.

Among these, the most popular capacities in the market—or "hot sale" models—include:

- 3 ton single girder gantry crane: Ideal for small workshops and light-duty tasks.

- 5 ton single girder gantry crane: Widely used in fabrication plants and warehouses.

- 10 ton single girder gantry crane: Suitable for medium-duty industrial applications.

- 15 ton single girder gantry crane: For heavier loads in steel yards and manufacturing.

These capacities hit the sweet spot between affordability and practical use, making them the top choices for most buyers.

How to Select the Right Capacity for Your Needs

Here's a simple way to decide on capacity:

- Identify Your Heaviest Load: Start with the maximum weight of the heaviest material or equipment you plan to lift regularly.

- Add a Safety Margin: Always include an extra 20–30% capacity to cover unexpected heavier loads and dynamic stresses during lifting.

- Think Ahead: Consider whether your lifting requirements might grow in the future. It's usually cheaper and easier to buy a slightly bigger crane now than to upgrade later.

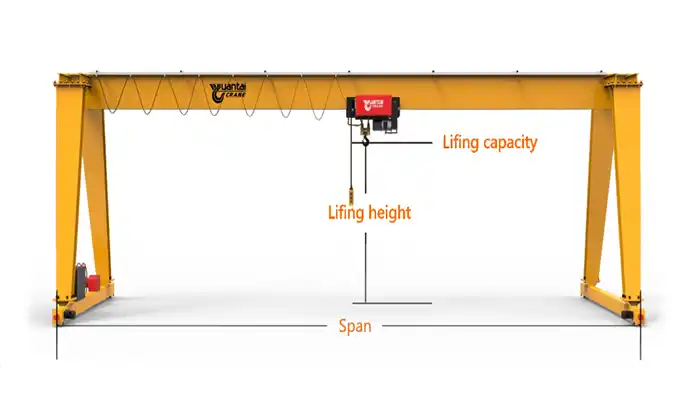

Span: How Wide Does the Crane Need to Be?

What Is Crane Span? The span of a single girder gantry crane refers to the distance between the inner sides of its two legs — essentially, how wide the crane can reach. This measurement is crucial because it determines the working area the crane can cover and affects the overall design, cost, and stability of the crane.

How to Determine the Right Span

When figuring out the proper span for your crane, consider these factors:

- Workshop or Yard Width: Measure the width of the area where the crane will operate. The span should allow the crane to reach across the entire workspace comfortably.

- Crane Track or Rail Layout: If the crane runs on rails, the span needs to match the distance between rails. For rubber-tired cranes, the leg spacing must suit the surface area and load distribution.

Important Considerations for Span Selection

Choosing the right span isn't just about reaching wide. Keep these points in mind:

- Cost and Weight Increase: A longer span means the girder and supporting structure must be stronger and heavier, which raises manufacturing and installation costs.

- Safety Clearances: There should be enough clearance on both sides for the crane to move safely without hitting obstacles or structures.

- End Stops: The span must allow space for end stops—devices that prevent the crane from running off the rails—which are essential for safe operation.

Example Span Ranges and Applications

| Typical Span (meters) | Suitable Applications | Notes |

|---|---|---|

| 6 – 10 | Small workshops, light material handling | Compact span for tight spaces |

| 10 – 15 | Medium-sized fabrication shops, warehouses | Balanced reach and cost |

| 15 – 20 | Larger yards, steel fabrication, outdoor areas | Covers wider area; higher cost |

| 20+ | Large industrial sites, heavy-duty operations | Requires stronger design, higher price |

Selecting the correct span ensures your crane covers the needed working area safely and efficiently, without unnecessary expenses.

Duty Class: How Often and How Intensely Will You Use the Crane?

What Is Duty Class? Duty class is a rating system that describes how often and how hard a crane is expected to work. It's a key factor in crane design and selection because it affects the strength, durability, and lifespan of the equipment.

Most manufacturers use standards from FEM (Fédération Européenne de la Manutention) or ISO to classify cranes by duty. These ratings help match the crane's construction to your actual working conditions.

Common Duty Classes Explained

- A3–A4 (Light to Moderate Use):: Suitable for cranes working 1 to 2 hours per day with occasional lifts. Typical for light manufacturing or maintenance tasks.

- A5 (Medium Duty):: Designed for cranes operating about 4 to 6 hours per day, often with multiple lifts per hour. Common in general workshops and factories with steady workflow.

- A6 (Heavy Duty):: For cranes used heavily throughout long shifts, sometimes running continuously for 8 hours or more. Found in steel mills, foundries, and heavy industrial sites.

How to Choose the Right Duty Class

Consider the following factors when selecting the duty class:

- Daily Working Hours: How many hours per day will the crane be operating? More hours mean a higher duty class.

- Lift Frequency: How many lifts per hour or per shift? Frequent lifting increases wear and requires a more robust crane.

- Working Environment: Conditions like dust, moisture, chemicals, or outdoor exposure can affect crane components and may require a higher duty rating or special protections.

Why Duty Class Matters

Choosing a crane with a duty class that matches your actual use is critical. If you pick a crane rated too low for your workload:

- The crane will wear out faster.

- Maintenance and repair costs will increase.

- You risk unplanned downtime and safety hazards.

On the other hand, over-specifying the duty class can add unnecessary cost. Finding the right balance ensures your crane performs reliably over its expected life.

Other Practical Selection Factors

When choosing a single girder gantry crane, besides capacity, span, and duty class, there are several other important details to consider. These factors can affect the crane's performance, cost, and suitability for your specific working environment.

Power Supply Requirements

Check the available power supply at your site before selecting a crane. Consider:

- Voltage level (e.g., 220V, 380V, 415V)

- Number of phases (single-phase or three-phase)

- Frequency (50Hz or 60Hz)

Matching the crane's electrical requirements with your site's power avoids costly modifications or installation delays.

Hoist Type: Wire Rope vs. Chain

The hoist is the heart of the crane. You'll usually choose between:

- Wire Rope Hoists:: Ideal for medium to heavy loads, offering smooth operation and longer service life.

- Chain Hoists:: Better suited for light to medium loads, compact design, and easier maintenance.

Your choice depends on load weight, frequency of use, and budget.

Indoor or Outdoor Use

Will your crane operate indoors or outdoors?

- Outdoor cranes may need weatherproofing such as protective coatings, covers, or explosion-proof components for hazardous areas.

- Indoor cranes typically have fewer exposure risks but may require adaptations for dust or temperature.

Mobility: Rail-Mounted or Free-Moving

Consider how the crane will move around your workspace:

- Rail-Mounted Gantry Cranes:: Run on fixed rails installed on the ground, providing precise movement along a defined path.

- Rubber-Tyred Gantry Cranes:: Equipped with wheels, offering flexible movement over flat surfaces without the need for rails.

Your choice depends on site layout, ground conditions, and how often you need to reposition the crane.

Future Plans and Flexibility

Think about your workshop's future:

- Will you need to upgrade capacity or span later?

- Might you relocate the crane to another building or site?

- Could your workflow or floor plan change, requiring a different crane setup?

Choosing a flexible design or modular crane can save time and money when your needs evolve.

Common Selection Mistakes to Avoid

Selecting a single girder gantry crane might seem straightforward, but many buyers make avoidable mistakes that can lead to operational headaches, higher costs, or safety issues. Here are some common pitfalls to watch out for:

- Mismatching Crane Span to Available Space:Choosing a span that's too wide or too narrow for your workshop or yard can cause problems. A span that's too small won't cover the needed working area, limiting crane usefulness. On the other hand, an oversized span adds unnecessary cost and requires a heavier structure, which can be harder to install.

- Underestimating Crane Usage and Duty Class: Some buyers pick a crane rated for light use when their operation demands a medium or heavy-duty machine. This mismatch leads to faster wear, more frequent repairs, and unexpected downtime. Make sure to accurately assess how often and how intensively the crane will be used.

- Overpaying for Capacity You Don't Need: t's tempting to buy a crane with the highest capacity just "to be safe." But this approach can backfire. Over-specifying capacity increases purchase price, energy consumption, and maintenance costs. Focus on your actual lifting needs plus a reasonable safety margin to avoid overspending.

- Ignoring Installation and Site Conditions: Site factors like power supply, floor strength, crane runway design, and environmental conditions matter a lot. Ignoring these can cause installation delays, compatibility issues, or poor crane performance. Always consider your specific site conditions before finalizing your crane choice.

Quick Selection Checklist

When choosing a single girder gantry crane, keep these key parameters in mind to make the right decision:

- Load Capacity: Consider the heaviest load you'll lift regularly, plus a safety margin of 20–30% to cover unexpected weight and ensure durability.

- Span: Measure your operational width accurately, including enough clearance on the sides. Also, consider the track or rail layout if the crane is rail-mounted.

- Duty Class: Assess how many hours per day the crane will work, how often lifts will be made, and the environment it will operate in (indoor, outdoor, dusty, corrosive, etc.).

- Installation: Take into account power supply specifications, installation location, whether the crane will be used indoors or outdoors, and mobility requirements such as fixed rails or rubber tires.

Conclusion

Choosing the right single girder gantry crane comes down to balancing three main factors: capacity, span, and duty class. Getting these right ensures your crane will deliver reliable, safe, and efficient performance over the long term.

A properly selected crane helps minimize maintenance costs and downtime, improves workplace safety, and ultimately saves money by matching your actual operational needs without overspending.

Ready to find the perfect crane for your needs? We invite you to:

- Request a Free Quote or Consultation: Our experts will help you customize the right crane solution based on your unique requirements.

- Explore Detailed Product Pages and Configuration Tools: Learn more about specifications, options, and pricing to make an informed choice.

- Download Our Selection Guide or Specification Form: Get handy resources to simplify your decision-making process.

Contact us today to start your crane selection journey!

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch