150 Ton Overhead Crane Installation Feedback – Paraguay Case

150 Ton Overhead Crane Installation Feedback (Paraguay)

We recently completed the delivery and installation of a 150-ton heavy-duty overhead crane for a client in Paraguay. This crane is not only large—it is an engineered lifting system designed for tough, daily industrial work. The customer needed equipment that could lift very heavy and oversized items with steady control and long-term reliability. For this reason, the QDX open-winch, built-up hoist crane was the best match.

In this article, you will see the installation photos and feedback videos from the site. We will also answer common questions buyers ask when choosing a 150-ton overhead crane, open-winch crane, built-up hoist crane, or any other heavy-duty industrial crane from China.

Why a 150 Ton Heavy-Duty Crane Is Important

A crane of this size is usually used in factories that work with steel structures, large machinery, mining equipment, molds, or energy components. The 150-ton open-winch crane installed in Paraguay helps the client work more safely and more efficiently.

Made for heavy, continuous work

- The built-up hoist uses strong motors, brakes, and gearboxes designed for frequent lifting.

- The open-winch layout makes maintenance easier because all parts are accessible.

Smooth and controlled lifting

- The crane uses VFD (variable-frequency control) for slower starts, smooth stops, and accurate positioning.

- Even when lifting 150 tons, the crane stays stable and reduces load sway.

Safe and reliable operation

- Includes overload protection, limit switches, emergency stop circuits, and monitoring for motors and brakes.

- Built-up hoists are easier to inspect, helping ensure long-term safe use.

Better workflow for the whole plant

- One heavy-duty crane replaces several small lifts, saving time.

- Large materials can be moved directly to the exact point needed in the workshop.

Summary

This introduction gives a clear overview of the project. Next, the article will show the installation process, the actual operation on site, and customer feedback—helping buyers understand what to expect when choosing a 150-ton engineered overhead crane for their own facility.

Project Overview – Paraguay Heavy Lifting Crane

Project Background

This project involves a customer in Paraguay who needed a reliable heavy-lifting solution for daily production work. The client operates in a sector where large and heavy components must be moved safely—such as steel structures, heavy machinery parts, or oversized fabrication pieces. Their existing lifting equipment could no longer handle the increasing workload or the growing size of the products being manufactured.

To solve this, the customer decided to upgrade to a 150 ton overhead crane, an engineered crane designed for continuous, demanding operations. The goal was to improve workshop efficiency, reduce manual handling time, and make lifting operations safer and more controlled.

Before choosing the crane, the customer clearly outlined the main tasks it would handle. These tasks required not only high capacity but also stable and precise movement, which is why an open winch crane—also known as a built-up hoist crane—was the best match for their needs.

Here are the main lifting tasks the crane is designed for:

- Handling oversized steel components

- Moving heavy machinery and fabrication assemblies

- Lifting large industrial equipment during maintenance

- Supporting continuous production with high-duty cycles

With these daily requirements, a standard crane was not enough. What they needed was a heavy-duty engineered crane built for long service life and high-frequency lifting.

Crane Specifications

The Paraguay project uses a customized QDX European-style overhead crane, built to deliver higher efficiency, smoother operation, and improved safety compared to traditional cranes. Before installation, the customer reviewed the technical configuration to ensure every detail matched their workshop layout.

Basics of 150 Ton Overhead Bridge Crane for Sale

Below is a clear overview of the crane's main specifications:

- Crane Type: QDX European-style industrial overhead crane

- Working System: Open winch type with built-up hoist

- Rated Capacity: 150 tons

- Span: 23 meters

- Lifting Height: 15 meters

- Power Supply: 380V, 50Hz, 3-phase

Special Features:

- Low-headroom trolley design

- Frequency inverter for smooth lifting and traveling

- Precise speed control for safe handling of heavy loads

- High-duty cycle suitable for continuous industrial operation

These specifications show that the crane is not only built for strength but also for stability and accuracy. The combination of open winch hoisting, inverter control, and a solid steel structure makes it suitable for demanding environments where reliability is essential.

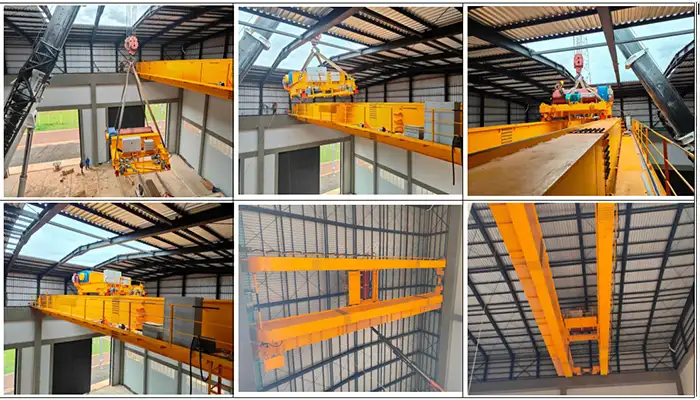

Installation Gallery (Pictures + Video Section)

Delivery & Assembly Photos

Once the 150 ton heavy-duty overhead crane arrived at the customer's workshop, the installation team began preparing the site and positioning the main components. The assembly process was carried out step by step to ensure accuracy, stability, and safe alignment of the open winch trolley system.

Below are the key moments captured during delivery and assembly:

- Arrival at the site

- Main girder installation

- End carriages installation

- Power supply connection

- Trolley and hoist alignment

These photos help buyers understand the full installation workflow and what to expect when setting up a large engineered crane.

On-Site Testing & Commissioning

After assembly, the team performed a full series of tests to confirm the crane's performance. Testing ensures that the 150-ton crane runs smoothly, stops safely, and meets the required working conditions before entering service.

The commissioning stage included the following key checks:

- No-load test

- Load test

- Safety system verification

- Control system calibration

Each step helps guarantee that the open winch crane operates reliably from day one.

Client Feedback Summary

After the installation and initial operation, the client shared detailed feedback about the crane and the overall project experience. Their comments focused on build quality, installation efficiency, and how the 150-ton overhead crane performs in real daily work. The feedback highlights how the crane fits their heavy lifting needs and the improvements they noticed immediately after commissioning.

The main points from the client include:

- Client's impression of crane build quality: They noted that the crane structure is solid, the open winch trolley feels steady during lifting, and the overall finish meets their expectations for a high-duty industrial crane.

- Feedback on installation speed and technical support: The client appreciated the smooth installation process. They mentioned that the technical team responded quickly, explained each step clearly, and completed the setup within the expected timeline.

- Performance evaluation after first operation: They reported that the crane lifts with good precision, operates with stable motion, and produces lower noise than their older equipment. Safety functions such as overload protection and emergency braking worked as expected.

- How the crane improved their plant operation efficiency: Thanks to the 150-ton capacity and reliable built-up hoist system, heavy components can now be moved faster and with fewer interruptions. This helped reduce handling time and improved workflow inside the workshop.

- Client's satisfaction with value and long-term performance: The customer expressed confidence in the crane's durability and felt that the overall investment matched the performance and service they received.

This summarized feedback gives future buyers a clear and practical view of what to expect when choosing a similar heavy-duty overhead crane.

FAQs – Tailored Heavy-Lifting Industrial Overhead Cranes (100 Ton – 200 Ton+)

Answers to common questions for buyers of 150-ton and higher heavy-duty cranes, including customization, safety, and installation guidance.

FAQ 1: What industries typically require a 150-ton or higher overhead crane?

Industrial sectors such as steel mills, foundries, heavy fabrication workshops, hydropower, mining machinery, pressure vessel manufacturing, and shipyards frequently use cranes in the 100–200-ton range.

FAQ 2: How do I customize a heavy-duty crane for my specific lifting needs?

Customization is based on multiple factors to ensure the crane fits your workshop and workflow:

- Maximum lifting weight and lifting cycle frequency

- Workshop dimensions and runway structure

- Operating environment (indoor, outdoor, high-temperature, dusty)

- Special hoist requirements (open winch, heavy-duty motors, dual hooks)

- Control systems (remote, cabin, semi-automation) – Manufacturers can design tailored solutions after reviewing technical drawings or site measurements.

FAQ 3: What is the advantage of the QDX European-style open winch design?

- Smoother, more precise lifting

- Higher duty cycle and continuous operation capability

- Longer service life

- Energy-saving motors

- Compact structure with higher lifting height

- Suitable for large, heavy, and repetitive lifting tasks

FAQ 4: How is safety ensured for a 150-ton heavy lifting crane?

Safety features integrated into heavy-duty overhead cranes include:

- Load limiters

- Overspeed protection

- Overload protection system

- Anti-sway control

- Emergency stop

- Rail clamps and buffer systems

- Real-time monitoring for motors and brakes

- Third-party inspection if required

FAQ 5: How long does installation of a heavy-duty crane take?

Typical timelines for installation and commissioning are:

- Civil work preparation: 2–4 weeks

- Crane installation: 5–12 days depending on workshop size

- Testing & certification: 2–3 days – Remote or on-site technical support is available from the manufacturer.

FAQ 6: What after-sales services are available for cranes installed overseas?

- Remote troubleshooting

- On-site installation guidance

- Spare parts supply

- Annual maintenance plans

- Training for local operators

- Full technical documentation and manuals

Why Choose Chinese Manufacturers for Heavy-Lifting Cranes?

Many buyers looking for 100–200-ton overhead cranes compare suppliers from different regions. In recent years, China has become a major source for heavy-duty overhead cranes, especially for projects that require engineered designs, built-up hoists, and strict safety control. For customers who need strong lifting capability without paying a premium price, Chinese suppliers offer a balance of technology, performance, and customization.

- Strong experience in 100–200-ton industrial crane manufacturing: Chinese factories have completed large numbers of ladle cranes, turbine hall cranes, steel mill cranes, and heavy fabrication cranes, giving them mature engineering capability.

- Competitive pricing with European-level technology: Many cranes follow European designs such as QDX or open-winch configurations, but the cost is more manageable for buyers.

- CE, ISO, and third-party inspection available: Certifications from CE, ISO, SGS, or BV help ensure product quality meets international standards.

- Customized engineering solutions: Buyers can request specific lifting speeds, duty cycles, hoist designs, motor brands, control systems, and special working conditions.

- Fast production and reliable global delivery: Lead time is often shorter than Western suppliers, and shipping arrangements are flexible for different countries and project schedules.

Conclusion : Send Us An Inquiry to Get Tailored Heavy Duty Cranes

The successful installation of the 150-ton QDX overhead crane in Paraguay shows how well-designed heavy-duty cranes can improve daily operations in large industrial plants. The client's feedback highlights stable lifting, smooth movement, and a noticeable increase in workflow efficiency. It also shows that a customized crane, when properly engineered and installed, can deliver long-term value and reliability.

If your project also requires a 150-ton heavy-lifting crane—or any open-winch, built-up hoist, or high-capacity overhead crane—we can help you choose the right design. Our team provides full technical support from the first inquiry to installation.

Contact us today for a customized heavy-lifting overhead crane solution tailored to your project.: Free consultation, technical drawings, and quotations are available.