1–100 Ton Gantry Crane for Sale, Customized Gantry Crane Solution

1 ton to 100 ton gantry cranes tailored to your needs—covering structure, hoist, span, height, cantilever & industrial uses. Get industrial gantry crane!

Category: Featured

Your Trusted Gantry Crane Manufacturer & Supplier

0.5 Ton to 100 Ton Gantry Crane for Sale

Industrial Gantry Cranes Tailored to Your needs

Tailored Structure, Hoist, Span, Height, Cantilever & Industrial applications.

Gantry Crane Customization

When it comes to lifting heavy materials efficiently, gantry cranes offer a dependable solution. Whether you're handling steel beams in a fabrication shop or managing container loads in an outdoor yard, choosing the right gantry crane can make your daily operations smoother—and safer.

Gantry cranes with capacities ranging from 0.5 ton to 100 ton are commonly used in a variety of settings, including:

- Manufacturing plants

- Structural steel and welding workshops

- Shipbuilding and marine yards

- Warehouses and distribution centers

- Hydropower, thermal, and nuclear plants

- Outdoor construction or assembly zones

Why Customization Matters for Your Gantry Crane

Not all gantry cranes are built the same. In fact, they shouldn't be. Your lifting needs vary based on your materials, floor space, hook height requirements, and how often the crane runs during a shift. That's why customization is not a luxury—it's essential.

Here's what customization helps with:

- Matching crane specifications to your actual working conditions

A 3-ton crane in a confined indoor space has very different needs than a 50-ton crane operating in an open-air shipyard. - Reducing operational delays

When the crane fits your layout, lifting happens more smoothly, with fewer adjustments and workarounds. - Improving safety and control

A properly selected hoist and travel system minimizes sway and unexpected movement, especially with longer loads.

What You'll Learn in This Guide

This practical guide walks you through the main components and choices involved in customizing your gantry crane—based on real-world usage. From the girder structure and leg type to hoist systems and travel mechanisms, we'll help you make sense of it all.

You'll also get:

- A breakdown of girder types (single, double, box, truss) and where they fit best

- Insights into travel options like rail, castor, and wheel movement

- Considerations for hoists and trolleys, including when to use wire rope or open winch

- A look at leg structures such as A-frame, U-frame, and L-frame

- An overview of optional features and below-the-hook devices for different industries

If you're in the market for a gantry crane—or planning to upgrade an existing one—this guide will help you ask the right questions, avoid common pitfalls, and make a purchase decision with confidence.

Girder Customization: Select Structure for Capacity and Use

The girder is the main load-bearing structure of your gantry crane. Choosing the right girder type is the first step in making sure your crane performs well and lasts long. It affects not only how much your crane can lift but also how high it can lift, how far it can span, and how it behaves under real working conditions. Let's break down the four most commonly used girder types for gantry cranes—and how to match them to your job.

Single Girder

If you're working with lighter loads and want a more economical solution, single girder gantry cranes are often the way to go.

- Typically used for lifting capacities from 0.5 ton to 20 tons

- Lighter self-weight, which can reduce support structure and cost

- Easier and quicker to fabricate and install

- Ideal for general-purpose material handling in workshops, warehouses, and assembly areas

- Can be used with electric chain hoists or wire rope hoists mounted on a trolley

This design is compact and efficient, especially for facilities with limited headroom or moderate lifting cycles.

Double Girder

For heavier loads or longer spans, double girder cranes offer the strength and performance needed for tougher work environments.

- Commonly selected for capacities ranging from 10 tons to 100 tons

- Provides higher hook height since the hoist is mounted between the girders rather than below

- Suitable for longer spans, such as those needed in fabrication yards or heavy equipment shops

- Can accommodate open winch trolleys, which are essential for high-duty applications

- Better suited for frequent, heavy-duty lifting in demanding industrial operations

While more complex and costly than single girder models, they provide better flexibility and lifting power for larger-scale operations.

Box Girder

Box girders are a specialized option designed for high performance and stability. They are especially useful where precision and structural integrity matter most.

- Made from closed, welded steel sections for superior strength and torsional resistance

- Used in cranes with long spans, high loads, and tight deflection requirements

- A go-to choice in industries like power generation, bridge construction, and shipyards

- Compatible with heavy hoists and automation systems

This type of girder is typically part of a double girder crane configuration and can be customized in size and wall thickness to match specific lifting needs.

Truss Girder

Truss girders are built for environments where wind and weather play a major role. You'll often see these in outdoor installations.

- Constructed with triangular lattice structures, making them lightweight but strong

- Provide good performance against side winds and outdoor conditions

- Best suited for long-span, low- to medium-capacity gantry cranes

- Frequently used in precast concrete yards, container handling, and shipbuilding areas

- Easy to maintain and visually open, making inspections straightforward

Keep in mind, truss girders are not designed for extremely heavy loads but are ideal when weight, wind, and mobility need to be balanced.

Practical Tips for Buyers

Choosing a girder isn't just about capacity. It's about how and where the crane will work.

- Lifting Capacity: Match the girder strength to the heaviest load you expect—plus a safety margin

- Duty Frequency: For frequent lifting or long hours, go with box or double girders for durability

- Span and Height Requirements: Longer spans and higher lifts generally call for stronger girders

- Site Environment: Use truss girders for outdoor work and box girders for precision applications

Selecting the right girder up front prevents costly design changes later—and ensures your gantry crane is built for the job you actually need it to do.

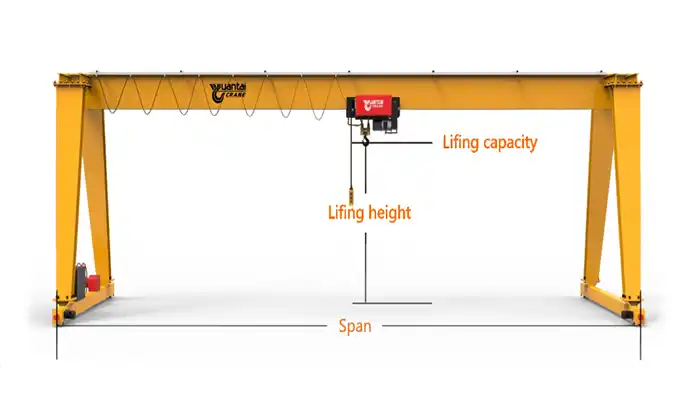

Span Customization: Define Your Coverage

When choosing or designing a gantry crane, one of the most critical dimensions you'll need to define is the span—that is, the distance between the two supporting legs of the crane. This measurement directly affects how much floor area the crane can cover and how efficiently it can move loads within your workspace. Put simply, if the span is too short, you limit your working width. If it's too wide for your site or structure, installation becomes complicated, and the crane may lose stability or cost more than necessary.

How to Determine the Right Span

Every workshop, yard, or construction site is laid out differently, so there's no one-size-fits-all span. You need to think through your operating area and lifting workflow before locking in your numbers.

Key factors to consider include:

- Building or site width: The span should allow the crane to reach the full usable area without hitting walls or obstructions.

- Rail or track layout: For rail-mounted cranes, check if the rail foundations are already fixed or if you can adjust placement.

- Clearance zones: Consider the space needed for operator movement, forklifts, and nearby equipment.

- Obstacles in the work area: Include columns, walls, pipes, or electrical lines in your planning.

- Crane type and load behavior: Heavier loads and longer spans increase the need for stronger girders and precise balance.

Planning Ahead: Think Beyond Today's Setup

While your current layout is important, also consider how your needs might grow or change in the next few years. A span that fits today's operation might fall short if you expand your production line or rearrange your facility.

Here are a few tips to keep in mind:

- Leave buffer zones on each end if your crane needs to load/unload from vehicles or storage racks.

- Check for possible expansion of your runway or building—will the crane still work if you add more bays?

- Avoid customizing a span too tightly; it's better to allow a little extra width than be forced into a redesign later.

Final Advice for Crane Buyers

Before finalizing your crane's span:

- Measure your usable floor space carefully—not just total building width

- Review any existing crane rails or install locations with your contractor or engineer

- Ask about clearance requirements specific to the hoist and trolley system

- Discuss future layout changes with your crane supplier—they may recommend a modular or extendable design

Getting the span right from the start ensures smooth operation, prevents structural interference, and gives your gantry crane the flexibility to grow with your business.

Cantilever Options: Extended Reach When Needed

Sometimes, the standard setup of a gantry crane—where the load moves between the two supporting legs—is not enough. That's where cantilever extensions come into play. A cantilever allows part of the crane to extend beyond its legs, giving you extra reach and flexibility.

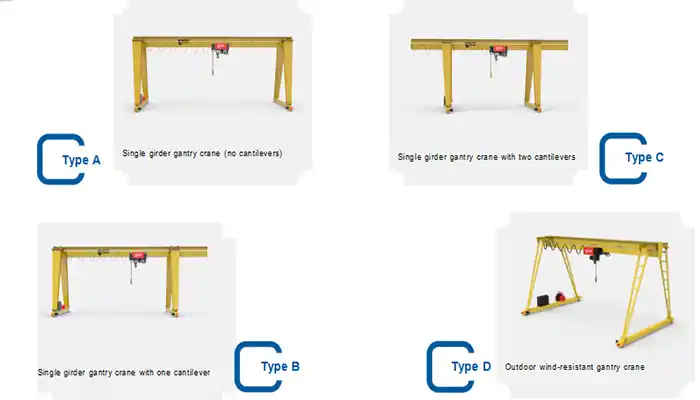

Cantilevers can be designed as either single-sided or double-sided cantilever gantry cranes depending on your needs:

- Single-sided cantilever: Extends on one side only, useful when you need to load or unload from one direction, such as over a truck or loading dock.

- Double-sided cantilever: Extends equally on both sides, providing extra reach on both ends. This is common when your operation requires loading or unloading on either side of the crane.

When to Consider Cantilever Extensions

Adding a cantilever is practical when your lifting needs extend beyond the basic footprint of your crane legs. For example:

- You need to lift and place loads outside the edge of your runway or rails

- Your loading and unloading points are positioned away from the crane supports, such as beside a truck, railcar, or storage area

- Space constraints require you to minimize the size or number of legs while maximizing reach

- Your operation requires extra clearance for vehicles or equipment moving under the crane

What You Should Keep in Mind

While cantilevers add versatility, they also increase structural demands on your crane. The longer the extension, the more stress on the girder and legs, which means your crane needs to be designed accordingly.

Here are some practical points to consider:

- Cantilever length is usually limited to a percentage of the total span—commonly 10% to 20%—to maintain stability

- Longer cantilevers may require additional reinforcement on the girder or supporting legs

- Be aware that adding cantilevers can increase the crane's overall footprint, so plan for extra clearance on the floor

- The crane's travel system and hoist trolley must be capable of safely operating over the cantilevered section

Buyer Tip

If your workflow involves loading/unloading beyond your crane's leg supports or requires reaching into tricky spots, a cantilevered design is worth considering. Always discuss your specific layout and load patterns with your crane supplier to determine the safest and most cost-effective cantilever length.

A well-planned cantilever can improve productivity by reducing the need for additional equipment or manual handling—and help you get the most out of your gantry crane investment.

Height Configuration: Total vs. Lifting Height

Height is a critical dimension when customizing your gantry crane. Getting it right means your crane will operate safely and efficiently without unnecessary restrictions or risks.

There are a few key height measurements to keep in mind:

- Total Height: The overall height from the ground up to the highest point of the crane structure, including the girder and supporting legs. This is important for fitting the crane within the building or site environment.

- Under-beam Clearance: The clear vertical space available below the crane girder for the load to move freely. This must be enough to safely accommodate the largest load you plan to lift, plus any rigging or slings.

- Hook Travel Distance: How far the hook can move vertically, from the lowest point to the highest lifting position. This determines your maximum lifting height and how you handle different load sizes.

Why These Heights Matter

If your crane is too tall, it may interfere with overhead structures such as ceilings, lighting, pipes, or cranes in adjacent bays. On the other hand, if the lifting height is too low, you might struggle to position loads properly or handle tall items safely.

You want to make sure there is enough clearance not just for the load, but also for rigging hardware, slings, or any lifting attachments you use below the hook.

Practical Considerations

When deciding on your crane's height setup, keep these points in mind:

- Measure the maximum height of your loads, including any slings or spreaders attached.

- Consider operator access and safety—there should be enough space for personnel to work around and under the crane safely.

- Account for any overhead obstacles like lighting fixtures, ventilation ducts, or fire suppression systems.

- If your facility has multiple cranes or equipment, ensure your gantry crane won't clash with others when operating at full height.

Buyer Tip

Don't just think about the load itself—always include the extra space needed for slings and rigging gear when specifying hook height. Also, make sure there's safe clearance for operators and maintenance access. Taking these factors into account early will save you from costly adjustments and downtime later on.

Setting the right height means your crane will be a better fit for your space and tasks, improving productivity and safety every day.

Supporting Leg Design: Match Structure to Site Layout

The design of the gantry crane's supporting legs is just as important as the girder and hoist. Legs hold the entire structure up and affect how the crane fits into your workspace. Choosing the right leg style helps maximize your operational space and makes daily tasks easier. Let's look at some common leg designs and when each one makes sense.

A-Frame Legs

A-frame legs are the most traditional and straightforward design.

- Simple, strong, and rigid structure

- Commonly used for portable cranes or fixed indoor gantries

- Easy to manufacture and maintain

- Provides stable support but can take up more floor space compared to other designs

This design is great for workshops or yards where you have enough room around the crane and want a reliable, no-fuss setup.

U-Frame Legs

U-frame legs offer a wider opening underneath the crane, which is useful in busy environments.

- Provides greater vertical clearance between the legs

- Allows forklifts, trucks, or other vehicles to pass safely under the crane without obstruction

- Often used in warehouses, loading docks, or manufacturing floors where multiple types of equipment operate side by side

If you need to keep your workspace flexible for different types of traffic, U-frame legs are a solid choice.

L-Frame Legs

L-frame legs are designed for space-limited or one-sided operations.

- Compact design, ideal for placing the crane close to walls or other structures

- Common in workshops or narrow aisles where you want to maximize floor area

- Supports crane operations mainly from one side, perfect for loading or unloading along a wall

If your operation requires efficient use of tight spaces, L-frame legs help you keep the crane footprint small without sacrificing function.

Custom Legs

Sometimes, standard leg designs aren't enough—especially if you need portability or specific environmental protections.

- Options include foldable legs for easy transport and storage

- Telescoping or adjustable-height legs to adapt to uneven floors or different lifting heights

- Outdoor legs can be treated with anti-corrosion coatings like galvanizing or special paint to withstand weather and humidity

Custom legs allow you to tailor the crane to unique site challenges or workflow requirements.

Buyer Tip

When selecting your gantry crane legs, think carefully about:

- How much floor space you have available

- Whether forklifts, trucks, or people need to move underneath

- If your site is indoors or outdoors, and whether weather protection is needed

- Your need for portability or height adjustment

Matching the leg design to your actual site conditions will make your crane easier to use, safer, and better integrated into your workflow.

Travelling Mechanism: Mobility to Match Your Operation

How your gantry crane moves around your workspace can make a big difference in efficiency and safety. The travelling mechanism determines whether your crane is fixed, semi-mobile, or fully portable—and it needs to fit your site conditions and lifting demands.

Let's explore the main types of travelling systems and when each one works best.

Rail travelling is the most common setup for permanent, heavy-duty gantry cranes.

- The crane moves smoothly along rails fixed to the ground or runway beams

- Provides precise and stable travel, which is critical when handling heavy loads from 10 to 100 tons

- Ideal for factories, shipyards, or warehouses with a dedicated, well-prepared runway system

- Requires upfront investment in installing rails but delivers reliable, repeatable performance over the long term

If your operation involves frequent heavy lifts over the same path, rail travelling offers the best combination of safety and control.

Castor Travelling Portable Gantry Cranes

Castor travelling uses swivel casters to provide flexible movement for lighter cranes.

- Designed mostly for portable gantry cranes with capacities from 0.5 up to about 5 tons

- Wheels can swivel, making it easy to maneuver the crane by hand or with minimal power assistance

- Works best on smooth, flat floors such as polished concrete or factory slabs

- Ideal for shops or maintenance areas where the crane needs to be moved occasionally to different locations

This option offers great flexibility but is not suited for heavy loads or rough surfaces.

Rubber Tyred Wheel Travelling Gantry Cranes- Single Girder RTG Gantry Crane VS. Double Girder RTG Crane , Vs. U Frame RTG Crane

Wheel travelling systems use fixed or steerable wheels made from rubber or steel to move cranes around.

- Suitable for semi-permanent or outdoor gantries in the 5 to 50-ton range

- Rubber-tyred wheels are common on concrete floors, providing good grip and less floor damage

- Steel wheels are more durable on rougher or uneven surfaces like asphalt or gravel

- This system offers more mobility than rail travelling but requires solid floor surfaces to handle wheel loads

Wheel travelling gantries are popular in construction yards, precast plants, and outdoor storage areas where fixed rails are impractical.

Buyer Tip

When choosing your crane's travelling mechanism, consider these factors carefully:

- How heavy are your typical loads and how often will the crane travel?

- Is your floor surface smooth, uneven, indoor, or outdoor?

- Can you invest in rail installation, or do you need a more portable option?

- What kind of maneuverability do you require within your workspace?

Selecting the right travel system upfront prevents operational headaches and helps keep your material handling smooth and safe.

Hoist Options: Match Lifting Method to Your Operation

The hoist is the heart of your gantry crane—it does the actual lifting, lowering, and load handling. Picking the right hoist type is crucial for efficiency, safety, and durability. Different hoists work better for different loads, working environments, and control preferences.

Electric Hoist

Electric hoists are the go-to choice for most modern crane applications.

- Available in both chain and wire rope versions

- Provide reliable, smooth lifting with electric power, reducing manual effort

- Suitable for a wide range of lifting capacities, depending on model

- Often come with options like variable speed control and built-in safety features

They're versatile and easy to integrate with various gantry crane designs, making them a popular all-around solution.

Chain Hoist

Chain hoists are simple, compact, and budget-friendly.

- Best suited for lighter loads, generally 0.5 to 5 tons

- Use a chain to lift loads, making them easier to maintain and repair

- Perfect for small workshops, maintenance bays, or light-duty lifting

- Often manually operated but also available in electric versions for added convenience

If you need a straightforward hoist for occasional or lighter lifting tasks, a chain hoist is a practical choice.

Wire Rope Hoist

Wire rope hoists are built for heavier loads and more demanding use.

- Ideal for lifting capacities of 5 tons and above

- Provide smooth, fast operation with higher lifting speeds compared to chain hoists

- Longer service life thanks to durable wire ropes and robust construction

- Can handle tough industrial environments like steel plants, shipyards, and power stations

Wire rope hoists are the preferred choice when you need strength, speed, and reliability.

Electric Hoist Trolley

The hoist trolley carries the hoist along the crane girder, giving you full coverage over the span.

- Available as motorized or manual versions

- Motorized trolleys move automatically along the girder for precise positioning

- Manual trolleys require physical effort to move but cost less

- Choosing the right trolley depends on your load weight, span length, and operational needs

A good trolley system ensures your hoist can reach any point within your workspace efficiently.

Open Winch Trolley

Open winch trolleys are heavy-duty and often custom-made.

- Designed for very large loads from 20 to 100 tons

- Commonly used in power plants, shipyards, steel mills, and other heavy industries

- Feature large winches with open design for easy inspection and maintenance

- Can handle special rigging and hoisting requirements that standard hoists cannot

If your operation demands high-capacity lifts with robust equipment, an open winch trolley might be the best fit.

Special Hoist Features

Beyond basic types, hoists can be equipped with features to fit special conditions:

- Explosion-proof hoists designed for hazardous environments with flammable gases or dust

- Low-headroom hoists ideal for facilities where vertical space is limited

- Dual-speed or inverter-controlled hoists provide smooth acceleration and deceleration for precise load handling

These options improve safety, efficiency, and adaptability for challenging workplaces.

Buyer Tip

When choosing your hoist, keep in mind:

- The maximum load capacity you need to lift

- The working duty class—how often and intensely the hoist will be used

- Your preferred control method—manual, electric, remote, or automated

- Any safety or environmental requirements, such as explosion-proof certification

Matching the right hoist to your crane and operation will make a big difference in performance and longevity. Don't hesitate to consult with your supplier to find the best hoist for your specific needs.

Below-the-Hook Devices: Adapted for Material and Environment

Below-the-hook devices are attachments fitted under the crane's hoist hook to handle specific types of loads. Choosing the right device is just as important as selecting the crane and hoist—it ensures safe, efficient lifting and protects both your materials and operators. Different materials and shapes require different handling tools. Let's explore the common below-the-hook devices and where they fit best.

Lifting Beams and Spreaders

These devices distribute the load evenly across multiple lifting points.

- Ideal for long, wide, or irregularly shaped loads like steel plates, large machinery, or structural components

- Help prevent damage by reducing stress concentrations on fragile or flexible items

- Available in adjustable or fixed-length designs to suit various load sizes

If your materials require multiple lifting points to stay balanced, lifting beams or spreaders are essential.

C-Hooks

C-hooks are specially designed for handling coils, rolls, or other circular materials.

- Wrap around coils to lift them safely and securely without damaging the surface

- Common in steel mills, coil yards, and manufacturing plants dealing with rolled metal

- Available in manual or powered versions depending on load size and handling speed

Using the right C-hook protects your coils and speeds up loading and unloading operations.

Electromagnets

Electromagnets use magnetic force to pick up and move ferrous materials.

- Perfect for steel plates, billets, scrap metal, and other magnetic loads

- Allow quick, secure lifting without the need for slings or clamps

- Widely used in steel mills, scrap yards, and recycling plants

- Come in various sizes and power ratings depending on the material weight and size

If you regularly handle steel products, an electromagnet can save time and reduce labor costs.

Grabs, Tongs, and Buckets

These mechanical attachments are designed for bulk materials or oddly shaped loads.

- Grabs and tongs are common in scrap handling, waste management, and timber yards

- Buckets are used for loose materials like gravel, sand, or grain

- Designed to securely grip or scoop loads that are difficult to handle with hooks alone

Choose these devices when you deal with irregular, loose, or bulk materials that don't stack easily.

Vacuum Lifters

Vacuum lifters provide a gentle, secure grip on fragile or smooth materials.

- Ideal for glass sheets, aluminum plates, stone slabs, or other delicate items

- Use suction pads powered by vacuum pumps to lift without damage

- Often used in industries like glass manufacturing, aluminum processing, and stone fabrication

For fragile materials, vacuum lifters reduce the risk of cracks or scratches during handling.

Buyer Tip

When selecting below-the-hook devices, consider:

- The shape and size of the materials you'll lift

- The weight and center of gravity of the load

- The temperature of the material (hot loads need special devices)

- Safety features like load locking mechanisms and balanced lifting points

The right below-the-hook attachment not only protects your materials but also improves lifting safety and operational efficiency. Always work with your crane supplier to match the device to your specific handling needs.

Special and Optional Features for Industrial Applications

Gantry cranes don't all come with the same features. Depending on your industry, site conditions, and operational needs, certain special or optional features can make a big difference in safety, efficiency, and ease of use. Let's explore the main categories of optional features you can consider for your gantry crane.

Control Options

How you control your crane impacts both productivity and safety.

- Pendant Control: A wired handheld controller, simple and reliable for most basic crane operations

- Remote Control: Wireless operation gives the operator freedom to move around the load area for better visibility and safer handling

- Cabin Control: An enclosed operator cabin, often used for large-capacity or outdoor cranes, provides protection from weather and improved control for complex tasks

Choosing the right control type depends on your workflow, safety requirements, and operator comfort.

Power Supply Options

Power delivery systems keep your crane running smoothly, whether stationary or mobile.

- Festoon Cable Systems: Flexible cable carriers that move along with the crane, ideal for fixed runways

- Cable Reels and Busbars: Used for cranes that travel long distances or need to move freely over a wide area

- Diesel Generators: Provide off-grid power solutions for sites without reliable electricity or for temporary setups

Selecting the appropriate power system ensures uninterrupted crane operation tailored to your site's infrastructure.

Environmental Protection Features

Outdoor or harsh environments demand extra protection for your crane components.

- Weatherproof Covers: Protect hoists and electrical parts from rain, dust, and extreme temperatures

- Anti-Rust Painting and Hot-Dip Galvanizing: Extend the life of steel components in corrosive or humid environments

- Sealed Components: Help prevent dust and moisture ingress, crucial in dusty or wet industrial settings like cement plants or food processing

These features reduce maintenance costs and downtime caused by environmental wear.

Safety Features

Keeping operators and equipment safe is non-negotiable.

- Overload Protection: Prevents lifting loads beyond the crane's rated capacity

- Limit Switches: Stop crane travel or hoist movement at preset points to avoid collisions or over-travel

- Emergency Stop Systems: Allow operators to quickly halt all crane functions in an emergency

- Load Weighing and Warning Devices: Provide real-time feedback on load weight and alert operators to unsafe conditions

Robust safety features are essential to meet regulatory standards and protect your team.

Automation and Smart Systems

For modern industrial operations, automation can boost efficiency and precision.

- Anti-Sway Control: Reduces load swinging during lifting and moving for safer, faster operation

- Auto-Positioning: Enables the crane to move loads to preset locations repeatedly without operator input

- PLC Integration and Remote Monitoring: Allow connection to factory automation systems for data tracking, diagnostics, and predictive maintenance

Smart features can optimize workflow and reduce human error in demanding production environments.

Buyer Tip

When choosing special features, focus on:

- Your industry's regulations and safety standards

- The environmental conditions your crane will face

- How much automation and control sophistication fits your operation

- Your goals for improving efficiency, reliability, and operator safety

Working closely with your supplier to select the right options will ensure your gantry crane is tailored to your exact needs—and ready to perform reliably for years to come.

Application-Based Configuration Examples

Different industries and work environments call for specific gantry crane configurations. Understanding which setups suit your application can save time, avoid costly mistakes, and ensure your crane performs exactly as needed.

Here are some common application types with recommended crane features to consider.

Light Workshop (0.5–3 ton)

For small workshops or light manufacturing tasks, the focus is on flexibility, ease of use, and cost-effectiveness.

- Girder: Single girder for simplicity and lower weight

- Supporting Legs: A-frame legs for straightforward, stable support

- Travelling Mechanism: Castor wheels for portability and easy repositioning

- Hoist Type: Chain hoist—compact and cost-effective for light loads

- Trolley: Manual trolley for simple horizontal movement

This setup is ideal for maintenance shops, small fabrication areas, or light assembly lines.

Outdoor Precast Yard (5–10 ton)

Handling heavy precast concrete units outdoors requires durable, weather-resistant equipment with good mobility.

- Girder: Truss girder, lightweight yet strong and resistant to wind loads

- Leg Design: U-frame legs to allow forklifts and trucks to move underneath

- Travelling: Wheel travelling for easy movement on rough outdoor surfaces

- Hoist: Wire rope hoist for smooth lifting of medium loads

- Additional Feature: Rain covers to protect hoist and controls from weather

This combination suits precast plants, construction sites, and other outdoor material handling areas.

Steel Mill (20–50 ton)

Heavy steel handling demands cranes with strong structures and specialized below-the-hook tools.

- Girder: Box or double girder designs for high load capacity and rigidity

- Travelling: Rail travelling to ensure precise, stable movement over long distances

- Hoist: Open winch trolley to handle heavy steel coils or plates

- Below-the-Hook: Electromagnets or grabs customized for steel handling

This configuration is common in steel mills, rolling plants, and heavy fabrication workshops.

Shipyard (50–100 ton)

Shipbuilding requires powerful cranes with safety features and high precision for large, heavy components.

- Girder: Double box girder for maximum strength and stiffness

- Supporting Legs: L-frame legs to optimize space near dock walls or confined areas

- Travelling: Rail travelling for accurate positioning along the quay or slipway

- Hoist: Explosion-proof hoist suitable for hazardous environments

- Control: Cabin control to provide operators with full visibility and protection

This setup is tailored for shipyards, heavy fabrication plants, and marine repair facilities.

Using these examples as a starting point can help you narrow down the features and options that fit your operation. Always consult with your crane supplier to fine-tune specifications based on your unique site and workflow needs.

| Application Type | Recommended Setup |

|---|---|

| Light Workshop (0.5–3 ton Gantry Crane Rail Travelling Gantry, Castor Rolling Gantry ) | Single girder, A-frame, castor wheels, chain hoist, manual trolley |

| Outdoor Precast Yard (Gantry Cranes 5–10 ton) | Truss girder, wheel travelling, U-frame legs, wire rope hoist, rain cover |

| Steel Mill (20–50 ton) | Box or double girder, rail travelling, open winch, magnets or grabs |

| Shipyard (50–100 ton) | Double box girder, L-frame, rail travelling, explosion-proof hoist, cabin control |

Final Selection Checklist for Buyers

Choosing the right gantry crane involves many factors. To help you stay organized and confident in your decision, here's a straightforward checklist to guide your final selection.

Key Questions to Ask Yourself

- What is the maximum load weight and size?

Know the heaviest and largest item you'll lift to ensure the crane's capacity and hook reach match your needs. - How often will the crane operate each day?

Consider your duty cycle. Frequent or continuous use requires more robust components and possibly automation. - What span and lifting height are needed?

Measure your working area carefully—make sure the crane covers the necessary width and has enough vertical clearance. - Do you need a cantilever or extra reach?

If you need to work beyond the supporting legs or reach over vehicles, a cantilever might be essential. - What are the ground conditions and space limitations?

Check floor strength, available clearance, and whether you have room for rail installation or need portable options. - Is your application indoors, outdoors, or in a hazardous environment?

This affects your choice of materials, coatings, hoist types, and safety features. - What power supply is available?

Confirm if you have access to electricity, need diesel generators, or require special cable management systems. - What special lifting tools are required?

Identify below-the-hook devices like magnets, grabs, or vacuum lifters to handle your specific materials safely.

Answering these questions thoroughly will help you communicate your needs clearly to your crane supplier and avoid costly mistakes. A well-chosen gantry crane tailored to your operation saves time, improves safety, and boosts productivity.

Conclusion

Gantry cranes ranging from 0.5 ton up to 100 tons can be carefully engineered to suit a wide variety of industries and applications. Every aspect—from the girder design and supporting legs to hoist options and control systems—can be customized to fit your facility's unique requirements.

Taking the time to properly customize your gantry crane not only improves safety but also boosts operational efficiency and extends the service life of your equipment.

For a reliable, high-performance gantry crane tailored specifically to your project, reach out to Yuantai Crane. Our experienced team offers comprehensive consultation, detailed design services, and fast, accurate quotations based on your exact specifications. Let us help you find the perfect solution for your lifting needs.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch