Power Supply Requirements for Overhead Cranes in Singapore

Power Supply Requirements for Overhead Cranes in Singapore Workshops

Introduction

Overhead cranes are essential equipment in many Singapore workshops, from small fabrication shops to medium-sized manufacturing facilities. They handle heavy loads, move materials efficiently, and play a central role in day-to-day operations. But one factor that is often overlooked is the power supply.

A reliable and properly designed power system is critical. Without it, even a well-built crane can underperform, cause frequent downtime, or worse—pose safety risks to operators. Voltage fluctuations, insufficient current, or improper grounding can damage motors, affect hoist speed, and shorten the lifespan of the crane.

This guide is designed to help buyers, engineers, and facility managers understand the electrical and power considerations before purchasing or installing an overhead crane. By knowing what to expect, you can plan your workshop layout, avoid unexpected costs, and ensure safe and efficient operation.

Key Points Covered in This Guide:

- How different types of cranes in Singapore workshops depend on power supply.

- Why proper electrical setup affects safety, efficiency, and maintenance.

- Practical tips for evaluating your workshop’s existing power system before installation.

With this information, you can make informed decisions that save money, reduce downtime, and ensure your crane works reliably for years.

Electrical Needs of Overhead Cranes

A properly designed electrical system is just as important as the crane itself. If your workshop's power setup isn't sufficient, you may face performance issues, frequent trips, or even equipment damage. Let's break down the main electrical considerations.

Rated Voltage

Overhead cranes in Singapore workshops typically operate on 415V 3-phase AC, which is standard for industrial equipment. However, the required voltage can vary depending on crane type and capacity.

- Single-girder cranes: Generally require less power, so standard voltage circuits may suffice.

- Double-girder cranes: Often heavier and designed for higher duty cycles, which may require dedicated circuits or higher-rated supply.

Practical Tip: Always check the manufacturer's voltage requirements. Using a lower voltage supply can reduce performance, while overvoltage may damage motors.

Power Capacity

The crane's power demand depends on both lifting capacity and frequency of use. A 5-ton crane running continuously will draw much more power than the same crane used occasionally.

- Calculate total load demand considering maximum lift weight and operation cycles.

- If multiple cranes share the same circuit, the cumulative load can exceed supply capacity.

- Plan for future expansions—adding another crane later can overload your existing infrastructure.

Practical Tip: Consider installing a separate distribution board or breaker for each crane if frequent simultaneous use is expected.

Current Requirements

Each crane motor, hoist, and auxiliary system draws current. It's important to account for full-load amperage as well as start-up surge currents, which can be several times the running current.

- Motors and hoists have peak currents during lift start-up.

- Undersized wiring or breakers may trip repeatedly.

- Factor in auxiliary systems like lights, radio controls, or VFDs.

Practical Tip: Ask your supplier for detailed motor current ratings and include a 15–20% margin for safety.

Power Factor & Efficiency

Power factor measures how effectively electrical power is being used. A low power factor can result in higher utility charges and stress on your workshop's electrical system.

- Correcting power factor improves energy efficiency.

- Reduces heat in motors and wiring, extending equipment lifespan.

- Often achieved through capacitors or modern VFD drives.

Practical Tip: Check with your electricity provider if they charge penalties for low power factor—especially for larger workshops with continuous crane operation.

Types of Power Supply Systems

Choosing the right power supply system is just as important as selecting the crane itself. The system affects safety, reliability, maintenance, and long-term costs. Here's an overview of the main types commonly used in Singapore workshops.

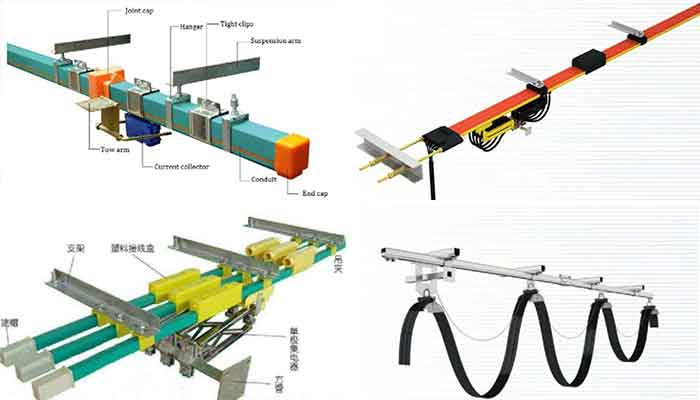

Busbar Conductor Systems

Busbar systems consist of rigid copper or aluminum conductors enclosed in a protective housing, running along the crane runway. They provide a stable and high-capacity power supply for heavy-duty or frequently used cranes.

Advantages:

- Reliable and stable power for high-capacity cranes

- Suitable for continuous, heavy-duty operation

- Low voltage drop even over long spans

Typical Use Cases:

- Steel fabrication or metal workshops

- Facilities with multiple cranes operating simultaneously

- Environments where downtime must be minimized

Maintenance Considerations:

- Inspect for dust, corrosion, or loose connections regularly

- Ensure proper grounding to prevent electrical hazards

- Replace worn contact shoes or damaged insulation promptly

Festoon Cable Systems

Festoon systems use a series of cables supported by trolleys and rollers along the crane runway. They are highly flexible and widely used for medium-duty cranes.

Advantages:

- Cost-effective for moderate lifting needs

- Easy to install and adapt to changing layouts

- Suitable for cranes with moderate travel distances

Limitations:

- Not ideal for long spans or very heavy cranes

- Cables may wear faster in high-speed or high-frequency operations

- Requires periodic inspection for cable tension and wear

Practical Tip: Festoon systems work best in workshops where cranes don't run continuously at full load for long hours.

Cable Reel Systems

Cable reel systems use a retractable drum to supply power, often used for mobile or intermittent crane operations.

Advantages:

- Compact and space-saving

- Ideal for portable cranes or temporary installations

- Minimizes floor clutter and improves safety

Comparison with Busbar and Festoon:

- Less suited for heavy, high-frequency lifting compared to busbars

- More flexible and mobile than busbars and festoons

- Best for short-term or low-duty applications

Selecting the right power supply system ensures that your crane runs efficiently, safely, and with minimal maintenance issues. Workshop layout, crane type, and operational frequency are the key factors in making the best choice.

Voltage Compatibility and Safety Standards

Ensuring voltage compatibility and following safety standards is crucial for overhead cranes in Singapore workshops. Proper planning protects operators, prevents equipment damage, and ensures compliance with local regulations.

Singapore Electrical Regulations

All industrial workshops in Singapore must comply with local electrical standards. This includes regulations such as CP5 and SS IEC standards, which cover installation, safety, and operational requirements for heavy machinery like overhead cranes.

- Ensures safe operation of cranes and associated power systems

- Prevents electrical hazards such as short circuits, overloads, or fire risks

- Required for insurance and legal compliance

Practical Tip: Always check if your crane supplier provides documentation confirming compliance with Singapore standards. This will save time during inspections.

Insulation and Grounding

Proper insulation and grounding are critical to crane safety. They prevent electrical shock, minimize risk of fire, and protect sensitive motors and controls.

- Insulation rating must match workshop environment (dry vs. humid conditions)

- Grounding ensures fault currents are safely diverted

- Regular checks help detect worn cables, moisture ingress, or loose connections

Practical Tip: In humid or coastal workshops, use moisture-resistant insulation and corrosion-protected grounding systems to extend equipment life.

Emergency Power Supply

For critical operations, having a reliable backup or emergency power supply is essential. This ensures that cranes can operate safely during power interruptions and integrate with safety systems.

- Backup generators or uninterruptible power supplies (UPS) for critical lifts

- Integration with fire alarm systems and emergency shutdowns

- Reduces risk of load dropping or unexpected downtime during outages

Practical Tip: Test emergency power systems regularly to ensure seamless operation in real scenarios.

Planning Power Supply for Workshop Layout

A well-planned power supply layout ensures overhead cranes operate safely and efficiently. Thoughtful planning helps avoid voltage drops, overloaded circuits, and costly retrofits in the future.

Single vs. Multiple Cranes

When a workshop has more than one crane, it’s important to coordinate how power is supplied. Shared circuits may save initial costs but can lead to voltage drops or trips if not sized correctly.

- Consider dedicated circuits for high-duty cranes to maintain performance

- Balance load between multiple cranes to prevent overload

- Include safety margins for peak operating conditions

Practical Tip: Use separate breakers or distribution boards if cranes frequently operate at full capacity at the same time.

Crane Span and Runway Length

The distance the crane travels (span and runway length) directly affects conductor sizing and system design. Longer spans increase voltage drop and require heavier conductors or higher-capacity power systems.

- Short spans (5–10 meters) generally have minimal voltage drop issues

- Long spans (10 meters or more) may require busbar or upgraded cable systems

- Proper conductor sizing ensures stable operation of hoists and motors

Practical Tip: Measure actual runway length and include future modifications when calculating conductor size and voltage drop.

Future Expansion

It’s always wise to plan for growth. Adding another crane or handling heavier loads later can strain an undersized power system. Designing with expansion in mind saves headaches and extra costs down the line.

- Include extra capacity in circuit design for additional cranes

- Choose scalable power systems such as busbars or modular cable systems

- Ensure distribution boards and breakers can handle future upgrades

Practical Tip: Even if you only need one crane now, sizing for two or more in the initial design is usually cheaper than retrofitting later.

Practical Considerations for Buyers

When buying an overhead crane, power supply planning is just as important as choosing the right crane. Taking a few practical steps early can save money, prevent delays, and ensure safe operation.

Check Local Utility Limits and Electrical Room Capacity

Before ordering a crane, verify your workshop’s existing electrical supply and distribution capacity. Overloading circuits can cause trips, downtime, or even damage to equipment.

- Confirm maximum available voltage and current from your utility provider

- Check the capacity of your main switchboard and subpanels

- Identify potential upgrades needed to support new cranes

Practical Tip: Avoid surprises by getting your workshop’s electrical capacity evaluated before finalizing the purchase.

Ensure Sufficient Clearances

Cables, busbars, and cable trays require adequate space to operate safely and allow maintenance. Cramped installations can lead to overheating, wear, and accessibility issues.

- Leave enough clearance around power rails and cable trays for inspection

- Plan paths that don’t interfere with cranes or other equipment

- Factor in access for maintenance or future expansions

Practical Tip: Sketch the workshop layout and mark all cable and busbar routes before installation.

Consult Electrical Engineers

Professional advice ensures accurate load calculations and safe design. Electrical engineers can help balance multiple cranes, calculate voltage drop, and select appropriate protective devices.

- Engineers can recommend conductor sizes, breakers, and power supply types

- Helps prevent costly mistakes and ensures compliance with Singapore regulations

- Provides documentation for safety audits or insurance

Choose Suppliers Offering Turnkey Solutions

Some suppliers can design and install the crane along with its complete power system. This reduces coordination issues and ensures that cranes operate reliably from day one.

- Turnkey suppliers handle design, installation, and testing

- Often include training, maintenance, and documentation

- Reduces delays and potential miscommunication between different contractors

Practical Tip: Ask suppliers if they offer complete electrical and crane solutions, not just the crane itself.

Conclusion

Planning the power supply for overhead cranes is just as important as selecting the crane itself. A well-designed system ensures safety, efficiency, and long-term reliability.

Key Takeaways

- Voltage & Current: Match crane requirements with your workshop’s electrical supply to avoid trips and downtime.

- Power Supply Types: Choose the right system—busbar, festoon, or cable reel—based on crane duty, span, and layout.

- Safety Compliance: Ensure adherence to Singapore regulations, proper insulation, grounding, and emergency power solutions.

- Early Integration: Incorporate power supply planning during the procurement stage, not after installation.

Recommendations for Buyers

- Request detailed power system specifications during RFQs.

- Verify supplier support for installation, testing, and maintenance.

- Consider future expansions when sizing circuits and selecting power systems.

Optional SEO & Buyer Engagement Add-Ons

FAQ Section for Buyers:

- “What voltage is required for a 10-ton overhead crane in Singapore?”

- “Can multiple cranes share a single power supply safely?”

- “What is the recommended cable system for a high-frequency workshop crane?”

Practical Tips:

- Keep documentation of all electrical load calculations and compliance certificates.

- Plan for operator training and routine inspection schedules.

- Maintain spare parts for critical electrical components to reduce downtime.

By integrating power supply considerations early in the crane purchasing process, buyers and facility managers can avoid costly retrofits, improve safety, and ensure smooth crane operation in Singapore workshops.