How Much Does an Overhead Crane Cost in Singapore – Budget Guide

Introduction

Why Cost Matters for Small and Medium Workshops in Singapore

Running a small or medium workshop in Singapore means every dollar has to stretch. Overhead cranes are crucial for moving heavy items safely and efficiently, but the price can be a concern. Choosing the wrong crane may seem like a savings at first, but it can lead to unexpected expenses in repairs, downtime, or energy use.

- Small workshops usually handle lighter loads and lift less frequently.

- Medium workshops often need higher lifting capacities and more frequent use.

- Balancing the upfront cost with long-term expenses is key for smooth operations.

Making informed decisions upfront prevents headaches down the line.

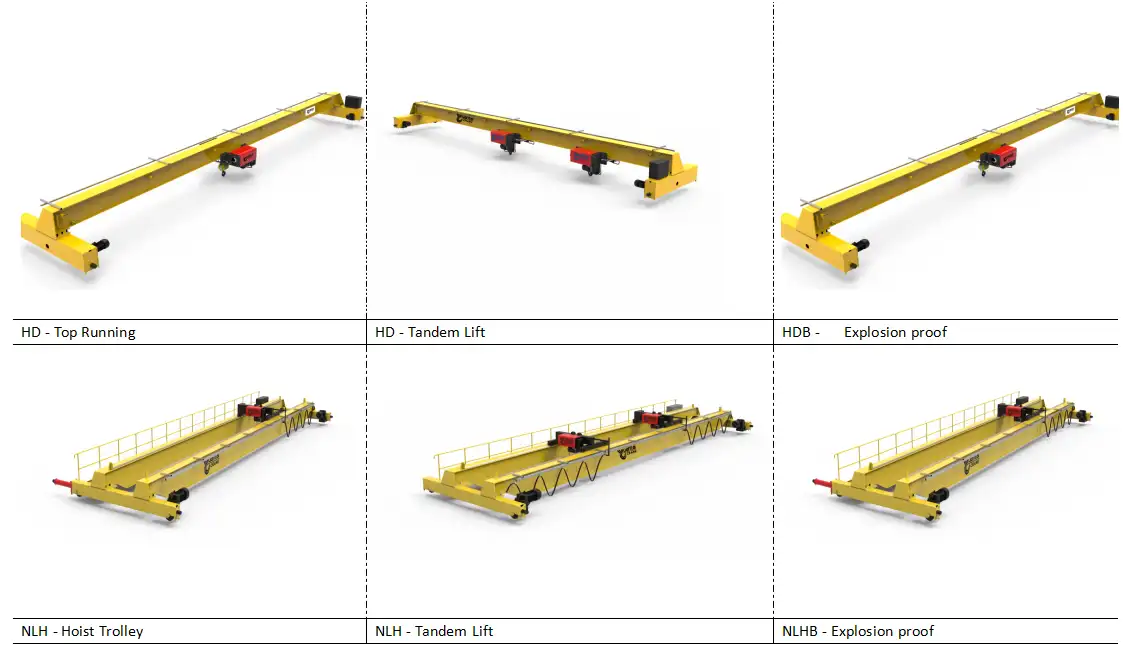

Overview of Overhead Crane Types

Not all cranes are created equal. Understanding the main types can help you pick the right one for your workshop:

- Designed for lighter loads and shorter spans.

- Cost-effective, simple to install, and easy to maintain.

- Common in small workshops or areas with occasional lifting needs.

- Handle heavier loads and longer spans.

- Higher initial cost and more complex installation.

- Ideal for medium workshops with frequent heavy lifting.

- Can be single or double-girder.

- Equipped with electric hoists and modern control systems.

- Offers low headroom crane solution for limited space workshops.

Knowing which type suits your operation is the first step in controlling costs while meeting your daily needs.

Key Cost Drivers That Buyers Need to Know

Several factors determine how much an overhead crane will cost. Being aware of them helps avoid surprises:

- Lifting Capacity (Tonnage) – Heavier loads require stronger materials and larger hoists.

- Span Length – Longer spans need bigger girders and stronger support structures.

- Hoist Type – Wire rope hoists are durable but pricier; chain hoists cost less but are slower.

- Control System – Pendant controls are simple and affordable; remote or PLC systems cost more.

- Duty Class – Frequent or heavy use demands cranes built for higher cycles.

- Certifications & Safety Features – ISO, CE, or local safety standards slightly increase cost but ensure compliance.

- Installation & Foundation Costs – Some workshops may need extra support or structural modifications.

Typical Price Ranges in Singapore

Local Pricing Benchmarks in Singapore Dollars

For small and medium workshops, you can expect approximate ranges like:

- Single-Girder Cranes (1–5 ton): SGD 8,000 – 20,000

- Double-Girder Cranes (5–10 ton): SGD 25,000 – 60,000

- EOT Cranes with modern hoists and controls: SGD 15,000 – 50,000 depending on capacity and features

These numbers give a practical starting point for budgeting and comparing local suppliers.

Comparison with Imported Cranes or International Suppliers

Imported cranes often cost more due to shipping, import duties, and compliance requirements.

Pros of Imported Cranes

- Higher-quality components and advanced control systems.

- Longer lifespan and sometimes more precise engineering.

Cons of Imported Cranes

- Higher upfront cost may not suit small or medium workshops.

- Delivery and installation take longer, and spare parts may be harder to source locally.

Local suppliers usually provide a good balance of cost, quality, and support for workshops in Singapore.

Budget-Friendly Crane Options for Workshops

Single-Girder EOT Cranes

These cranes are popular with smaller workshops because they are simple, effective, and affordable.

Advantages:

- Lower cost compared to double-girder options.

- Simple structure, easy to maintain.

- Ideal for light to moderate lifting tasks.

Typical price range for small capacities (1–5 ton): SGD 8,000 – 20,000

Electric Hoist + I-Beam Solutions

If a full overhead crane feels too expensive, this setup can work for small workshops with occasional lifting needs.

Practical points:

- Hoist mounted on a sturdy I-beam can handle lifting without full crane infrastructure.

- Cost includes the hoist, beam, and installation.

- Flexible for workshops with limited space.

Jib cranes are excellent for localized lifting where full overhead coverage isn’t needed.

- Options: wall-mounted or freestanding.

- Pros: smaller footprint, lower cost, easy to move loads within a specific area.

- Cost comparison: typically lower than single-girder EOT cranes but limited in span and capacity.

Used or Refurbished Cranes (Optional)

Buying second-hand cranes can reduce initial investment, but it comes with trade-offs.

- Pros: lower upfront cost, quicker availability.

- Cons: unknown history, potential higher maintenance, shorter lifespan.

- Practical advice: Inspect thoroughly, ask for service records, and verify structural integrity before buying.

Key Cost Components & What Impacts Price

Understanding these cost factors helps buyers balance upfront investment with long-term efficiency and safety.

| Cost Component | Description | Practical Notes / Considerations |

|---|---|---|

| Lifting Capacity / Tonnage | Determines materials, hoist type, and design; small tonnage increases can affect cost. | - Small workshops: 1–5 ton - Medium workshops: 5–10 ton - Plan 20–30% safety margin |

| Span Length & Runway Infrastructure | Distance affects girder size and runway strength; longer spans require stronger structures. | - Short spans (5–10m): cheaper, easy to install - Long spans (10m+): higher material & installation cost - Existing buildings may need reinforcement |

| Hoist Mechanism Type | Impacts speed, durability, and maintenance; choose based on load and frequency. | - Wire rope: durable, faster, higher cost - Chain: cheaper, slower, more maintenance - VFD: smooth, precise, slightly higher cost |

| Control System | How the crane is operated affects convenience and price. | - Pendant: simple, cost-effective - Remote: flexible, slightly higher cost - PLC / automated: precise, adds upfront & maintenance cost |

| Duty Class / Usage Frequency | Level of usage determines crane robustness. | - Light duty: occasional lifting - Medium duty: daily use, stronger components - Heavy duty: continuous operation, often double-girder |

| Certifications & Safety Compliance | Safety standards ensure legal compliance and protect operators. | - ISO, CE, or local Singapore compliance - Reduces downtime risk - Protects equipment and team |

| Installation & Foundation Costs | Structural requirements and labor affect total cost. | - Runway beams may need new supports - Labor for installation, welding, alignment - Plan ahead to avoid surprises |

| Maintenance & Operating Costs | Routine care ensures safe operation and reduces downtime. | - Wire ropes, chains, hoists need inspection - Motors, VFDs, electrical parts require servicing |

Cost Breakdown Examples

Understanding actual costs helps small and medium workshop owners make informed decisions. Below are three typical scenarios with practical cost considerations.

| Workshop Type | Crane Type / Setup | Base Price (SGD) | Optional / Additional Costs | Notes / Practical Advice |

|---|---|---|---|---|

| Small Workshop | 3-Ton Single-Girder Crane | 8,000 – 12,000 | VFD: 1,500 – 3,000 Remote control: 1,000 – 2,000 Safety add-ons: 500 – 1,000 | Ideal for light loads and occasional lifting. Pendant control often sufficient. |

| Medium Workshop | 5-Ton Double-Girder Crane | 30,000 – 45,000 | Extended span / higher lifting height: 5,000 – 10,000 Advanced control (PLC / remote): 2,000 – 5,000 Additional safety features: 1,000 – 3,000 | Suitable for frequent lifting and heavier loads. Plan for future needs to avoid overspending. |

| Minimal Budget Workshop | Hoist + I-Beam Setup | 5,000 – 10,000 | Hoist type (electric chain or wire rope) affects cost Installation of I-beam | Best for occasional lifting or light loads. Not recommended for continuous heavy use. |

Notes and Practical Advice

- Small Workshops: Single-girder cranes are compact, cost-effective, and easy to maintain. A simple pendant control may be enough.

- Medium Workshops: Double-girder cranes are more robust and versatile but come with higher upfront and optional costs. Consider the crane’s span, lifting height, and duty class carefully.

- Minimal Budget: A hoist mounted on an I-beam is a low-cost alternative for light lifting tasks. Check that the I-beam and hoist are rated for your expected loads.

This format provides a clear, visual cost breakdown while including practical insights, helping buyers quickly compare options and make informed choices.

Cost-Saving Strategies for Buyers

Managing overhead crane costs doesn't mean cutting corners. With smart planning, small and medium workshop owners in Singapore can save money while keeping operations safe and efficient.

Buy from Local or Regional Manufacturers

Sourcing from nearby suppliers can save a lot on shipping, import duties, and delivery delays. Local or regional manufacturers also usually provide faster support and easier access to spare parts.

- Reduces import and shipping costs

- Faster delivery and installation

- Easier access to spare parts and after-sales service

Optimize Specifications

Many buyers overspend by ordering cranes with more capacity than they actually need. Matching tonnage, span, and lifting height to your workshop's real requirements prevents unnecessary costs.

- Avoid over-specifying the crane

- Plan for a realistic safety margin

- Consider future workshop needs without overloading the budget

Consider Modular or Standardized Designs

Modular cranes or standardized components make installation and maintenance simpler and cheaper. They are also easier to upgrade in the future.

- Lower installation and assembly costs

- Easier to maintain and replace parts

- Simplifies future upgrades or expansions

Explore Leasing or Financing Options

For medium-sized workshops, leasing or financing can spread out the cost over time. This is especially useful if upfront capital is limited.

- Reduces immediate budget pressure

- Flexible payment options

- Keeps cash flow available for other operations

Negotiate Training and Maintenance Support

Ask your supplier to include operator training, maintenance guidance, or spare parts in the package. This helps avoid costly mistakes and ensures smooth crane operation over time.

- Operator training reduces accidents and downtime

- Regular maintenance guidance prevents unexpected repairs

- Bundled spare parts lower future expenses

Risks of Under-Budgeting

Trying to save money by under-budgeting for an overhead crane can lead to serious problems. Understanding these risks helps buyers make smarter, safer choices.

Safety and Compliance Issues

Cutting corners on cost can compromise safety. Cheap or improperly specified cranes may fail to meet Singapore's safety standards, putting operators and equipment at risk.

- Non-compliant cranes may violate ISO, CE, or local regulations

- Increased risk of accidents and injuries

- Possible fines or insurance complications

Higher Maintenance Costs

Low-budget cranes may use lower-quality components. Over time, this can lead to more frequent repairs, downtime, and higher long-term costs than a slightly more expensive, reliable crane.

- Frequent breakdowns increase repair costs

- More downtime affects productivity

- Spare parts may be harder to source for low-quality components

Hidden Costs

Under-budgeting often ignores additional expenses like installation, certification, or hiring qualified crane operators. These hidden costs can quickly add up and exceed the initial savings.

- Crane installation and alignment costs

- Safety certification and inspections

- Costs for trained operators or crew

Resale Value and Future Upgrades

A cheaper crane may be harder to sell later and may limit your options for future upgrades. Investing wisely upfront can protect your workshop's flexibility and long-term value.

- Lower resale value for under-specified cranes

- Limited options for expanding or upgrading capacity

- May require early replacement if workshop needs grow

Careful budgeting ensures your crane is safe, compliant, and cost-effective over its entire lifecycle, avoiding these common pitfalls of under-budgeting.

Conclusion

Careful planning and realistic budgeting are key when buying an overhead crane for small and medium workshops in Singapore.

Recap of Typical Budget-Friendly Crane Costs

Understanding cost ranges helps buyers make informed decisions.

- Small workshops: 3-ton single-girder cranes – SGD 8,000 to 12,000

- Medium workshops: 5-ton double-girder cranes – SGD 30,000 to 45,000

- Minimal budget setups: Hoist + I-beam – SGD 5,000 to 10,000

Align Crane Specifications with Workshop Needs

Matching crane capacity, span, and features to your actual lifting requirements ensures efficiency without overspending.

- Avoid over-specifying tonnage or span

- Choose the right control system for your workflow

- Plan for maintenance, safety, and long-term operation

Recommendation: Request Multiple Quotes

Always request detailed quotations from multiple suppliers. This helps you:

- Compare base prices and optional features

- Understand installation, maintenance, and training costs

- Make a confident decision without unexpected expenses

Appendix / Resources

A handy set of tools and notes to guide crane buyers through quotes, terminology, and installation planning.

Cost-Comparison Checklist

Use this checklist when requesting quotes from multiple suppliers. It helps you compare prices and features accurately:

- Crane type and lifting capacity (tonnage)

- Span length and lifting height

- Hoist type (wire rope, chain, VFD)

- Control system (pendant, remote, PLC)

- Duty class and expected usage frequency

- Certifications and safety compliance

- Installation, foundation, and delivery costs

- Maintenance, warranty, and spare parts

Glossary of Common Terms

Understanding crane terminology makes it easier to read quotes and avoid confusion:

- Span: Distance the crane travels along the runway

- Duty Class: Indicates frequency and intensity of use

- VFD (Variable Frequency Drive): Controls lifting speed and smoothness

- Hoist Type: Wire rope or chain hoist used for lifting

- Pendant / Remote Control: Operator interface for crane movement

Installation & Negotiation Notes

Practical tips for planning installation and negotiating costs:

- Request detailed, itemized quotes to clearly compare features and pricing

- Ask suppliers about included training, maintenance, and spare parts support

- Verify that your workshop structure can safely support the crane runway

- Consider modular or phased installation to reduce setup time and cost