When A Gantry Crane Is More Economical Than An Overhead Crane

Discover when a gantry crane is more economical than an overhead crane. Compare costs, installation, operation & long-term efficiency for industrial buyers.

Introduction

When it comes to moving heavy materials in factories, warehouses, or construction sites, having the right crane can make a big difference. Industrial lifting solutions aren't just about picking a piece of equipment—they're about efficiency, safety, and long-term costs.

There are two main types of cranes you'll see in industrial settings: gantry cranes and overhead (bridge) cranes. Both get the job done, but in very different ways.

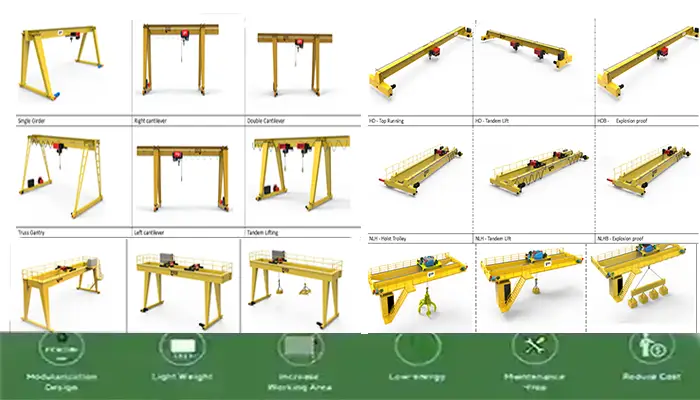

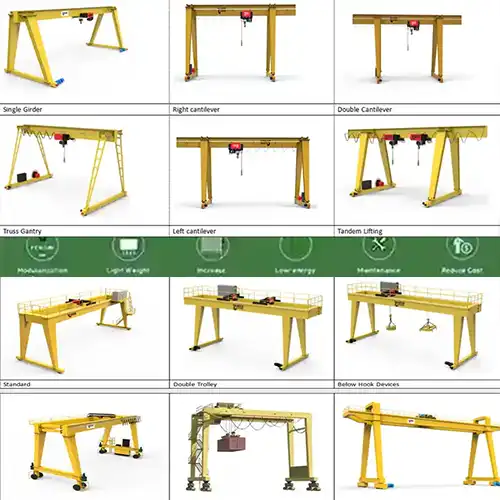

- Standalone structures, no permanent runway required.

- Can be installed indoors or outdoors.

- Portable and flexible for temporary or changing work areas.

- Fixed cranes running on a building-mounted runway.

- Ideal for consistent, heavy-duty lifting across production lines.

- Best suited for high-volume operations with predictable material flow.

When we talk about cost efficiency, it's not just the price tag. You need to consider:

- How much the crane costs to buy.

- Installation and building modifications.

- Daily operation and energy consumption.

- Maintenance and long-term durability.

This article is aimed at industrial buyers, engineers, and plant managers who want practical advice. The goal is simple: to show when a gantry crane can save money and make sense compared to an overhead crane. By the end, you'll have clear guidance to make decisions based on your site, lifting needs, and budget—without guesswork.

Takeaways from this introduction:

- Heavy lifting requires the right crane choice for safety and efficiency.

- Gantry cranes are flexible and portable, overhead cranes are fixed and heavy-duty.

- True cost efficiency includes purchase, installation, operation, and maintenance.

- This guide helps buyers identify practical scenarios where gantry cranes are more economical.

Cost Factors in Crane Selection

Choosing the right crane is more than just picking the one that lifts the heaviest load. For industrial buyers, the key is to balance upfront costs, ongoing expenses, and long-term value. Let's break down the main cost factors that determine whether a gantry crane or an overhead crane is more economical.

Initial Purchase Cost

The first thing most buyers notice is the price tag, but there's more behind it than meets the eye.

- Material and Fabrication Costs: Gantry cranes often use less steel and simpler construction, which can lower initial costs. Overhead cranes, on the other hand, require heavy-duty girders, end trucks, and precise fabrication, which increases the price.

- Standardization vs Customization: Standard gantry cranes are often modular and easier to source. Overhead cranes may need custom designs to fit your building's dimensions and load paths, adding extra cost.

- Typical Cost Comparison: In general, for small to medium capacities (up to 20 tons), a gantry crane can cost 20–40% less than a similarly rated overhead crane, depending on features and span.

Installation Costs

Installation can be a hidden expense that significantly impacts your budget.

- Overhead Cranes: Require runway beams, structural modifications, and sometimes building reinforcements. This can add weeks of work and a substantial labor cost.

- Gantry Cranes: Freestanding structures that can often be bolted to the floor or moved around with minimal building changes. Some models are even mobile, eliminating the need for any permanent installation.

- Labor and Time: Because gantry cranes are simpler to install, setup time is shorter, reducing labor costs and downtime in your operations.

Operational Costs

The crane you choose will affect your day-to-day expenses.

- Power Consumption Differences: Gantry cranes, especially smaller models, often consume less energy than overhead cranes, particularly if the overhead system has long spans and high trolley speeds.

- Maintenance Requirements: Gantry cranes have simpler mechanisms and easier access for inspections, which lowers maintenance labor and downtime. Overhead cranes require runway inspection, electrical system checks, and sometimes specialized maintenance staff.

- Ease of Relocation: If your production layout changes frequently, gantry cranes can be moved with minimal cost. Overhead cranes are fixed, so moving them requires expensive disassembly and structural work.

Lifetime & Depreciation

Long-term costs are just as important as the upfront price.

- Expected Lifespan: Overhead cranes can last decades when properly maintained. Gantry cranes have slightly shorter lifespans but still provide years of reliable service.

- Resale or Repurposing Value: Gantry cranes are easier to sell or repurpose because they are freestanding and portable. Overhead cranes are tied to a specific building, limiting resale options.

- Impact on Total Cost of Ownership (TCO): When evaluating cost efficiency, include purchase, installation, operation, maintenance, and potential resale value. In many cases, a gantry crane's lower upfront and flexible costs result in a lower TCO for temporary or variable lifting needs.

Practical Takeaways

- Upfront cost is just one part of the picture—installation and ongoing operation can add more to your budget than expected.

- Gantry cranes generally offer lower initial and installation costs, and simpler maintenance.

- Overhead cranes may be more expensive but excel in high-frequency, heavy-duty applications.

- Always consider total cost of ownership, not just the purchase price.

Situations Where Gantry Cranes Are More Economical

Not every lifting job calls for a fixed overhead crane. Sometimes, a gantry crane can get the job done just as well—often for less money, less hassle, and more flexibility. Let's explore the situations where a gantry crane makes more economic sense.

Low-Volume or Irregular Operations

If your lifting needs aren't constant, an overhead crane might be overkill.

- Temporary Projects: Construction sites, seasonal workshops, or short-term jobs often only need lifting equipment for a few months at a time.

- Why Gantry Cranes Make Sense: Since they don't require permanent runways, you save on structural work and installation. This can cut costs significantly, especially for short-term projects.

Limited Infrastructure or Building Constraints

Sometimes your workspace just isn't built for heavy overhead cranes.

- Low Ceilings or Weak Structures: Older buildings or smaller workshops often can't handle the heavy girders and runway beams that an overhead crane needs. A freestanding gantry crane solves this problem with no permanent modifications.

- Outdoor or Open Areas: Gantry cranes are also perfect for yards, loading docks, or temporary storage areas. They can be placed almost anywhere, giving you flexibility that a fixed crane simply can't.

Portability and Flexibility Needs

Operations change, and your crane should be able to change with them.

- Move It Where You Need It: Gantry cranes can be relocated from one production line to another—or even to a completely different site—without the expense of tearing out and reinstalling runways.

- Multiple Applications: A single gantry crane can handle molds, steel sheets, pallets, or construction materials. You get more versatility for less cost, which is especially useful in dynamic workshops.

Small to Medium Lifting Capacities

How much weight you need to lift also affects cost efficiency.

- Best Range for Gantry Cranes: Generally, small-to-medium loads—up to about 20 tons—are where gantry cranes shine. Overhead cranes in the same capacity range often cost more because of the runway and building requirements.

- Cost Efficiency: If your lifting requirements fit this range, a gantry crane usually provides the same performance for less money upfront, lower installation cost, and simpler operation.

Practical Takeaways

- Gantry cranes are ideal when lifting needs are temporary or infrequent.

- They work in spaces where overhead cranes can't fit, including outdoors.

- Portability allows one crane to serve multiple areas or purposes.

- Small-to-medium loads are often more economical with gantry cranes than overhead systems.

Cost Comparison Example

To make the differences between gantry cranes and overhead cranes more tangible, let's look at a realistic scenario. We'll compare the costs for a small-to-medium lifting application over a 10-year period. This example is based on typical industrial setups and common capacities (up to 15–20 tons).

Scenario:

A medium-sized workshop needs a crane for lifting steel sheets and components up to 15 tons. The workshop has moderate space constraints and may change the layout in the future.

Cost Comparison Table

Below is a side-by-side comparison of gantry and overhead cranes, showing how purchase, installation, and operational costs add up over time.

| Cost Component | Gantry Crane (15t) | Overhead Crane (15t) | Notes |

|---|---|---|---|

| Initial Purchase Cost | $25,000 | $40,000 | Gantry crane uses less steel and simpler design. |

| Installation Cost | $5,000 | $20,000 | Overhead requires runway beams and structural work. |

| Operational Cost (annual) | $2,000 | $3,500 | Energy use, routine maintenance, and inspections. |

| Maintenance Cost (annual) | $1,000 | $2,500 | Gantry cranes are easier to maintain and inspect. |

| Total 5-Year Cost | $40,000 | $72,500 | Includes purchase, installation, operation, and maintenance. |

| Total 10-Year Cost | $55,000 | $105,000 | Shows long-term difference and break-even impact. |

Analysis:

When we look at the numbers, the advantages of a gantry crane become clear. The lower initial purchase and installation costs mean you don't need a huge upfront budget. Over the years, operational and maintenance costs stay lower, adding up to significant savings.

- Initial Advantage: The gantry crane costs much less upfront—about 40% cheaper.

- Installation Savings: A freestanding gantry avoids runway and structural modifications, saving significant labor and material costs.

- Operational Costs: Gantry cranes are simpler to operate, use slightly less power, and require less frequent maintenance.

- Long-Term Impact: Over 10 years, the total cost of a gantry crane is nearly half that of a comparable overhead crane in this scenario.

Break-even Point:

Understanding when a gantry crane pays for itself is crucial for planning. For short-term or flexible lifting needs, the cost benefits appear almost immediately. Overhead cranes start to make sense only in high-frequency, heavy-duty operations where the higher upfront costs are offset by continuous productivity.

- In projects with short-term or flexible lifting needs, the gantry crane becomes cost-effective almost immediately due to lower installation and purchase costs.

- For high-frequency, heavy-duty operations, overhead cranes may make sense only if the operational benefits outweigh the higher upfront and maintenance costs.

Practical Takeaways:

It's important to look at the bigger picture, not just the price tag. By considering all cost factors—including installation, operation, and potential relocation—you can make a smarter investment.

- A gantry crane is generally cheaper in small-to-medium capacity operations, especially when flexibility is required.

- Overhead cranes are only more economical if your operation is continuous, heavy-duty, and fixed in one location.

- Total cost of ownership (TCO) is the key metric—don't focus solely on purchase price.

- Always consider installation, maintenance, and relocation costs before making a final decision.

Other Economic Considerations

Beyond purchase, installation, and operation, there are several other factors that can affect the total cost of owning a crane. These often get overlooked during the decision-making process, but they can have a big impact on overall efficiency and budget.

Insurance and Safety-Related Costs

Safety is not optional in industrial operations, and insurance costs can vary depending on the type of crane you use. Overhead cranes may require more rigorous inspections and structural certifications, which can increase insurance premiums. Gantry cranes, being simpler and often freestanding, generally have lower insurance and safety compliance costs.

- Insurance premiums may differ based on crane type, capacity, and installation complexity.

- Overhead cranes often require extra safety measures such as runway inspections and emergency stops.

- Gantry cranes can reduce costs with simpler safety requirements and easier access for routine checks.

Downtime Due to Maintenance or Relocation

Unexpected downtime is a hidden cost that can disrupt operations and reduce productivity. Overhead cranes are fixed and may require specialized staff to maintain or repair, resulting in longer interruptions. Gantry cranes, on the other hand, are easier to service and can be relocated without significant downtime, making them more practical for dynamic production environments.

- Maintenance of overhead cranes can take longer and may require shutting down entire production areas.

- Gantry cranes are easier to inspect, maintain, and adjust without halting workflow.

- Moving a gantry crane to another location is often faster and less disruptive than relocating an overhead system.

Customization Costs for Special Loads or Environments

Some operations require cranes that handle unusual weights, shapes, or environmental conditions such as outdoor weather, chemical exposure, or extreme temperatures. Customization can quickly add to the total cost. Gantry cranes are often easier and cheaper to customize because their modular design allows for simpler modifications. Overhead cranes may need significant engineering work to meet the same specifications.

- Special hoists, trolleys, or weatherproofing can add to the cost.

- Gantry cranes' modular frames make it easier to adapt to unique requirements.

- Overhead cranes may require structural reinforcements or custom-designed runways, increasing cost and installation time.

Practical Takeaways

- Always factor in insurance, safety, and regulatory compliance costs when comparing cranes.

- Consider potential downtime for maintenance or relocation as part of your long-term budget.

- Customization needs can significantly affect costs; gantry cranes often offer more affordable flexibility.

When Overhead Cranes Still Make Sense

While gantry cranes are often more economical in many scenarios, there are situations where an overhead crane is the better choice. Understanding when an overhead crane is worth the investment helps industrial buyers make informed decisions.

High-Frequency, Heavy-Duty Lifting

If your operation involves lifting heavy loads on a daily or hourly basis, an overhead crane is usually the most reliable option. These cranes are built for continuous, high-capacity work and can handle repeated lifting cycles without excessive wear.

- Ideal for factories moving steel plates, heavy molds, or machinery parts.

- Handles larger loads than most gantry cranes in the same footprint.

- Designed for long-term durability under heavy use.

Large-Scale Production Facilities Requiring Permanent Installation

Overhead cranes are perfect for facilities with high-volume production and fixed workflows. When a plant layout doesn't change frequently, a fixed crane system can provide consistent efficiency and maximize floor space.

- Permanent runway systems support long spans and multiple crane operations.

- Reduces congestion on the shop floor, as material moves overhead rather than at ground level.

- Provides predictable workflow and higher throughput for continuous production lines.

Automated or Integrated Lifting Operations

Modern industrial operations often integrate cranes into automated material handling systems. Overhead cranes are more compatible with automation due to their fixed paths, precise movement, and compatibility with sensors, conveyors, and control systems.

- Supports semi-automated or fully automated lifting operations.

- Enables integration with ERP or warehouse management systems for improved efficiency.

- Provides precise load placement, reducing errors and improving safety.

Practical Takeaways

- Choose overhead cranes for daily, heavy-duty lifting that requires long-term reliability.

- They are ideal for large, fixed facilities with consistent workflows.

- Overhead cranes are the go-to option for operations that require automation or integration with other systems.

Conclusion

Choosing the right crane can have a major impact on both your budget and operational efficiency. This guide has highlighted the scenarios where a gantry crane can be more economical than an overhead crane, helping industrial buyers make informed decisions.

Key Takeaways

Gantry cranes tend to be more cost-effective in situations such as:

- Low-volume or irregular lifting operations, where temporary or seasonal use makes permanent overhead systems unnecessary.

- Facilities with limited infrastructure, including low ceilings, weak building structures, or outdoor workspaces.

- Operations that require portability, flexibility, or multi-purpose use across different areas.

- Small to medium lifting capacities, typically up to 20 tons, where installation and maintenance costs of overhead cranes would outweigh the benefits.

Consider Site and Operational Factors

When evaluating cost efficiency, buyers should look beyond the purchase price:

- Consider the site constraints such as building height, structural capacity, and available floor space.

- Factor in load frequency and operational demands to determine whether the flexibility of a gantry crane or the reliability of an overhead crane makes more sense.

- Include long-term costs, like maintenance, relocation, energy consumption, and potential downtime, in your total cost of ownership calculation.

Consult a Crane Supplier for Tailored Solutions

Every facility and lifting requirement is different. Working with an experienced crane supplier can help you:

- Choose the right crane type and capacity for your workflow.

- Explore customization options for special loads or environmental conditions.

- Ensure cost efficiency while meeting safety and regulatory requirements.

Gantry cranes often offer a practical, lower-cost solution for many small-to-medium lifting needs. Overhead cranes still have their place in high-volume, heavy-duty, or automated operations. By carefully evaluating your site, lifting requirements, and long-term costs, you can make a decision that balances performance and budget—without surprises down the line.

Optional Add-Ons for SEO & Buyer Engagement

To make your crane selection guide more practical and helpful for industrial buyers, adding an FAQ section and actionable tips can improve both usability and SEO performance.

FAQ Section

Q1: Can gantry cranes replace overhead cranes entirely?

Not always. Gantry cranes are ideal for small-to-medium loads, temporary lifting, or flexible layouts. Overhead cranes are better suited for high-frequency, heavy-duty, or automated operations where fixed runways and long spans are required.

Q2: What is the maximum economical lifting capacity for a gantry crane?

Generally, gantry cranes are most cost-effective up to 20 tons. Heavier loads are possible, but installation, structural stability, and safety requirements may make overhead cranes more economical in the long run.

Q3: Are mobile gantry cranes cost-effective for long-term use?

Yes, especially if your lifting needs involve multiple locations or variable layouts. Mobile gantry cranes reduce installation costs, downtime, and relocation expenses, making them practical for dynamic operations.

Practical Tips for Buyers

Selecting the right crane isn't just about the upfront price. Consider these practical tips to ensure long-term efficiency and cost savings:

- Evaluate Relocation Frequency: If your operations or production layout change often, a portable or mobile gantry crane can save both time and money.

- Compare Total Cost of Ownership (TCO): Look beyond the purchase price. Include installation, operation, maintenance, downtime, and potential resale value in your decision.

- Consider Future Expansion: Plan for potential production growth or layout changes. A flexible crane solution today can save expensive modifications tomorrow.

Takeaway:

Including an FAQ and practical tips helps buyers quickly address common concerns while highlighting the cost benefits of gantry cranes. It also improves SEO by targeting search queries like "gantry crane vs overhead crane cost" or "mobile gantry crane long-term use."