Your Trusted Overhead Crane Manufacturer & Supplier

Overhead Crane Prices of Hot Sale Crane Types

Bridge Crane, Gantry Crane & Jib Cranes

9 Tips to Get Cost-effective Crane Price & Ask for Your Customized Crane Price

Crane Price: Crane Pricing Factors and Getting a Quote

When considering purchasing a crane, it's essential to understand that the price can vary significantly depending on the type of crane you need, its specifications, and the specific requirements of your work environment. The three primary types of cranes commonly used in industries are overhead bridge cranes, gantry cranes, and jib cranes. Each of these cranes has a wide range of prices based on various factors, including lifting capacity, span, height, material, and custom features.

Your Trusted Overhead Crane Manufacturer & Supplier

Overviw of Overhead Bridge Crane Price

Overhead bridge cranes, often referred to as bridge cranes, are widely used in industries such as manufacturing, steel mills, and warehouses. They are designed to move loads across a horizontal plane, making them perfect for large-scale, heavy-duty tasks. The price of an overhead bridge crane generally depends on its lifting capacity, span, lifting height, and the work environment. Here's a breakdown of price ranges for different types of overhead cranes:

- Small-Capacity Overhead Cranes (1-10 tons): These cranes typically range from $5,000 to $30,000. They are best suited for small workshops, light-duty manufacturing, or warehouse tasks.

- Medium-Capacity Overhead Cranes (10-20 tons): Prices for these cranes fall between $15,000 and $45,000. They are commonly used in medium-sized factories, steel mills, or logistics centers.

- Heavy-Duty Overhead Cranes (20-50 tons): For larger models, the price range is between $30,000 and $100,000 or more, depending on the specifications. These are ideal for large-scale industries, such as steel production, heavy equipment manufacturing, and large warehouses.

Typical Overhead Bridge Crane Price Range by Crane Type and Capacity

| Crane Type | Lifting Capacity | Span | Lifting Height | Price Range (USD) | Common Applications |

|---|---|---|---|---|---|

| Single Girder Overhead Crane for Sale | 1 ton | 3~12 m | 3~8 m | $2,200 - $4,000 | Small maintenance shops, warehouses |

| 3 ton | 3~12 m | 3~8 m | $2,600 - $4,500 | Light manufacturing, assembly lines | |

| 5 ton | 3~12 m | 3~8 m | $3,000 - $5,000 | Warehouses, light-duty workshops | |

| 10 ton | 3~15 m | 3~8 m | $4,000 - $6,500 | Medium factories, logistics | |

| 20 ton | 3~15 m | 3~8 m | $6,000 - $10,000 | Medium production lines, light steel mills | |

| Double Girder Overhead Bridge Crane for Sale | 5 ton | 6~16 m | 6~12 m | $6,000 - $12,000 | Repetitive industrial lifting, manufacturing |

| 10 ton | 6~16 m | 6~12 m | $7,000 - $15,000 | Heavy-duty manufacturing, logistics | |

| 20 ton | 6~16 m | 6~12 m | $10,000 - $20,000 | Steel mills, large workshops | |

| 25 ton | 6~16 m | 6~12 m | $15,000 - $30,000 | Fabrication shops, large manufacturing plants | |

| 50 ton | 6~16 m | 6~12 m | $30,000 - $60,000 | Heavy-duty lifting, foundries | |

| Explosion-Proof Overhead Bridge Crane for Sale | 1 ton | 3~12 m | 3~8 m | $4,000 - $7,000 | Explosion-proof environments, chemical plants |

| 5 ton | 3~12 m | 3~8 m | $7,000 - $15,000 | Hazardous zones, petrochemical facilities | |

| 10 ton | 3~12 m | 3~8 m | $10,000 - $18,000 | Hazardous manufacturing, chemical plants |

These overehad crane prices are estimates based on general specifications and current market conditions. They may vary based on location, steel prices, and technical requirements.

What's Typically Included in the Price?

Most crane quotations include:

- Complete crane structure (bridge beams and end trucks)

- Electric hoist or trolley (wire rope or chain)

- Basic control system (pendant or wireless remote)

- Electrical components and wiring

- Technical drawings and documentation

Note: Crane runway rails, shipping, installation, and taxes are typically quoted separately unless specified otherwise. Customized overhead crane solution is provied for your needs. Click to leanr moren on Customized Overhead Crane Price - 15 Ton Electromagnetic Overhead Crane Cost

Overhead Bridge Crane Prices: What Affect Overhead Cost and How to Get a Quotation

Overhead cranes are critical lifting equipment widely used in factories, warehouses, steel plants, and many industrial environments. However, their prices vary significantly depending on the specific application and design. There is no one-size-fits-all price—each crane is engineered to meet unique requirements such as lifting capacity, span, and duty cycle.

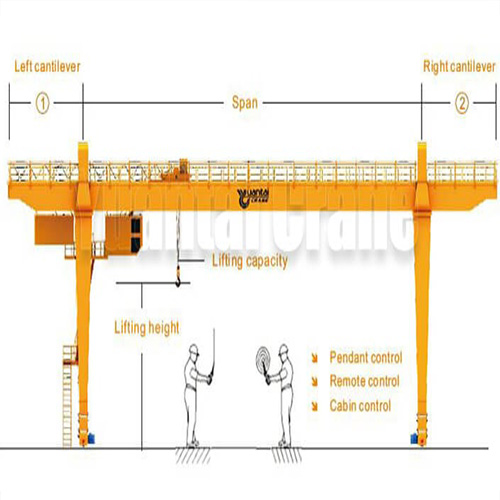

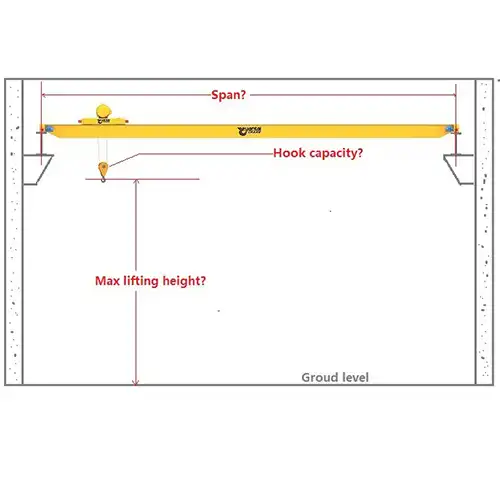

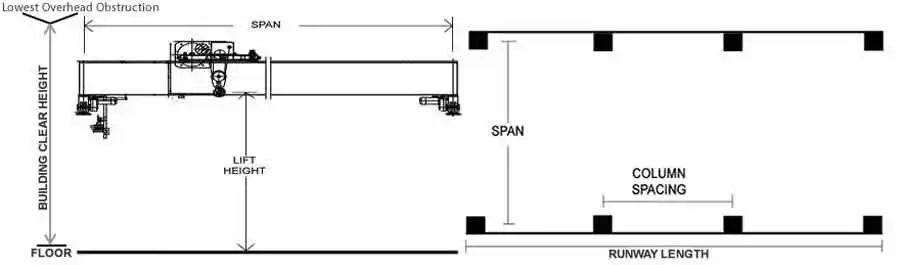

top running single gider overhead crane main specificaitons including capacity, span, and lifting height required to get your overhead crane price

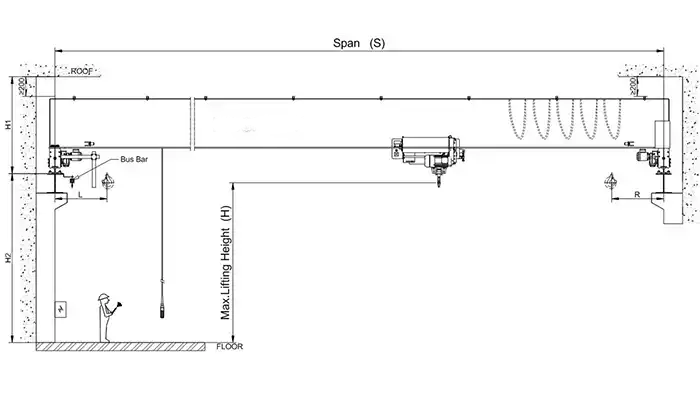

Underrhung bridge crane specifciations including capacity, lifting height, and crane span to get your underhung bridge crane pricce

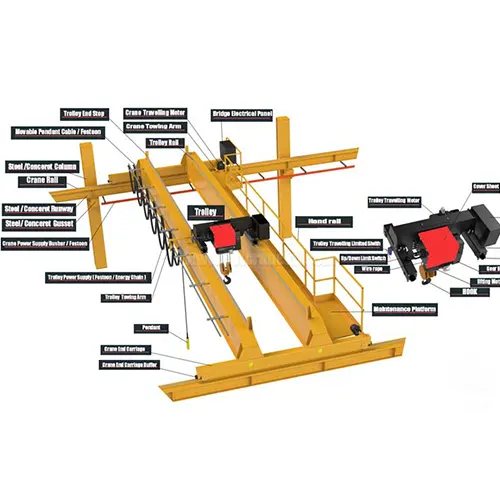

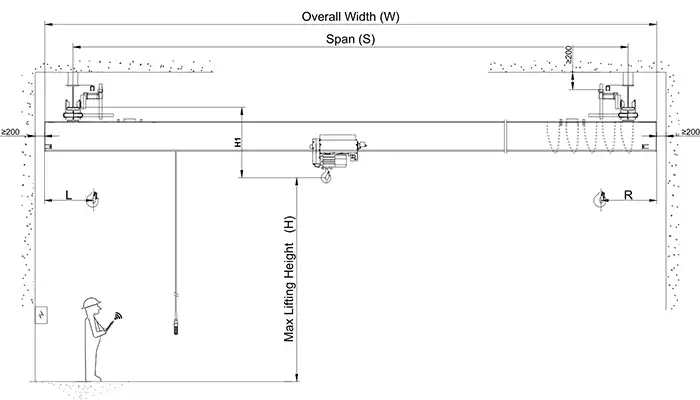

double girder overhead crane specifications that affect its price including capacity, span, liffting height

Key Factors That Influence Overhead Crane Price

Several factors directly affect the final cost of an overhead crane. These include:

- Lifting Capacity: The heavier the load, the more robust the structural design and mechanical components required, increasing the price.

- Span (Distance Between Rails): Longer spans require more materials and precise engineering, which also increases costs.

- Lifting Height: Cranes that lift loads to greater heights need longer ropes, reinforced structures, and stronger motors.

- Crane Type:Single Girder Cranes are more affordable and suitable for lighter loads (1 to 20 tons).Double Girder Cranes are used for medium to heavy loads (5 to 63+ tons) and are more expensive due to their design and lifting capacity.

- Power Supply Requirements: Voltage and frequency differ by region, and special power configurations may involve additional customization costs.

- Working Environment: Outdoor cranes, high-temperature zones, or hazardous environments require features like weather protection, explosion-proof components, or special coatings.

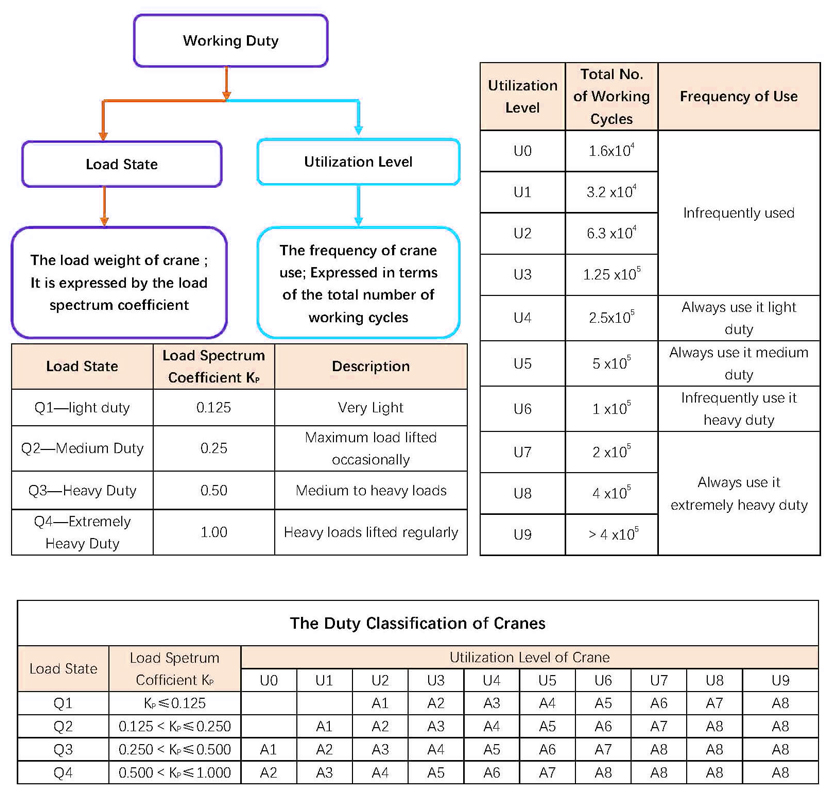

- Operating Duty (Usage Frequency): Cranes with a high duty class (A5 to A7) used for frequent or continuous operation are built with more durable systems and cost more.

- Custom Features: Optional components such as remote controls, frequency inverters, crane rails, anti-sway systems, or maintenance walkways can raise the price.

Click to Learn Mor on What Affect Your Overhead Crane Price & Crane Rate?

Your Trusted Overhead Crane Manufacturer & Supplier

Oveview of Gantry Crane Price

Gantry cranes are versatile and used in open spaces for lifting and moving large loads. They are commonly found in construction sites, ports, and shipyards, and their price depends on the lifting capacity, span, and specific application.

- Small-Capacity Gantry Cranes (5-10 tons): These cranes generally cost $3,000 to $10,000 and are suitable for light-duty lifting tasks in warehouses or workshops.

- Medium-Capacity Gantry Cranes (10-30 tons): The price range for these cranes is between $10,000 and $50,000. They are typically used in industrial environments, such as construction or manufacturing sites.

- Heavy-Capacity Gantry Cranes (50-100 tons): Heavy-duty gantry cranes can cost anywhere from $50,000 to $150,000 or more, depending on the specifications and intended use, such as in shipbuilding or large-scale construction projects.

Factors Affecting Gantry Crane Prices:

- Lifting Capacity: As with overhead cranes, the price of a gantry crane increases with its lifting capacity. Larger cranes that lift heavier loads will cost more.

- Rail Length and Mobility: Gantry cranes that require longer spans or additional mobility features will be priced higher due to the complexity of their design and the amount of material used.

- Custom Features: Adjustments such as variable heights, extra stability, or enhanced mobility systems can significantly increase the price.

Typical Gantry Crane Price Overview by Type and Capacity

| Crane Type | Lifting Capacity | Span | Lifting Height | Price Range (USD) | Common Applications |

|---|---|---|---|---|---|

| Single Girder Gantry Crane for Sale | 3 ton | 6~16 m | 6~12 m | $5,000 - $10,000 | Light manufacturing, warehouses |

| 5 ton | 6~16 m | 6~12 m | $6,500 - $12,000 | Small workshops, factories | |

| 10 ton | 6~16 m | 6~12 m | $8,000 - $18,000 | Medium factories, construction | |

| 15 ton | 6~16 m | 6~12 m | $12,000 - $25,000 | Heavy manufacturing, logistics | |

| 20 ton | 6~16 m | 6~12 m | $15,000 - $30,000 | Large warehouses, steel yards | |

| Double Girder Gantry Crane for Sale | 5 ton | 12~30 m | 6~18 m | $15,000 - $30,000 | Heavy-duty manufacturing, construction |

| 10 ton | 12~30 m | 6~18 m | $18,000 - $35,000 | Medium to large factories, loading docks | |

| 20 ton | 12~30 m | 6~18 m | $25,000 - $50,000 | Steel mills, container yards | |

| 30 ton | 12~30 m | 6~18 m | $40,000 - $70,000 | Port handling, large workshops | |

| 50 ton | 12~30 m | 6~18 m | $60,000 - $100,000 | Heavy-duty lifting, foundries | |

| Portable Gantry Crane for Sale | 0.5 ton | 3~6 m | 3~6 m | $500 - $2,000 | Workshop, small tasks |

| 1 ton | 3~6 m | 3~6 m | $1,000 - $3,000 | Light-duty assembly, maintenance | |

| 2 ton | 3~6 m | 3~6 m | $2,500 - $5,000 | Small manufacturing, repair shops | |

| 3 ton | 3~6 m | 3~6 m | $3,500 - $7,000 | Heavy lifting, small warehouses |

These gantry crane prices are estimates based on general specifications and current market conditions. They may vary based on location, steel prices, and technical requirements.

Hot Types Gantry Crane Prices for Your Reference

Gantry Crane Prices: What Affects the Cost and How to Get a Quotation

Gantry cranes are essential lifting equipment in many industries, including manufacturing, construction, warehousing, shipyards, and power plants. However, the price of a gantry crane can vary widely—even for cranes with the same lifting capacity—because each application is different.

If you're exploring the cost of gantry cranes, it's important to understand the main factors that affect the price and how to obtain an accurate quotation tailored to your needs.

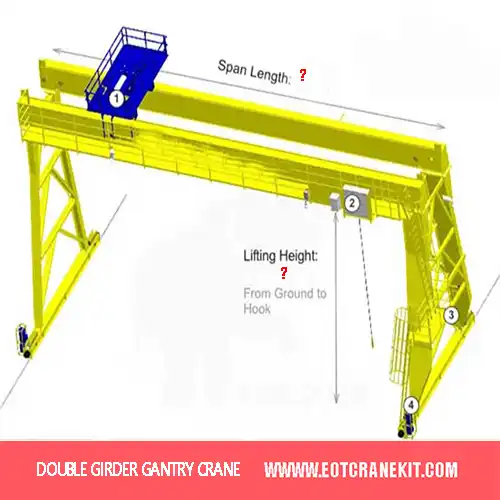

main specificaitons of single girder gantry crane affecting crane price, capacity, crane span, and lifting height

main specificaitons of double girder gantry crane affecting crane price, capacity, crane span, and lifting height

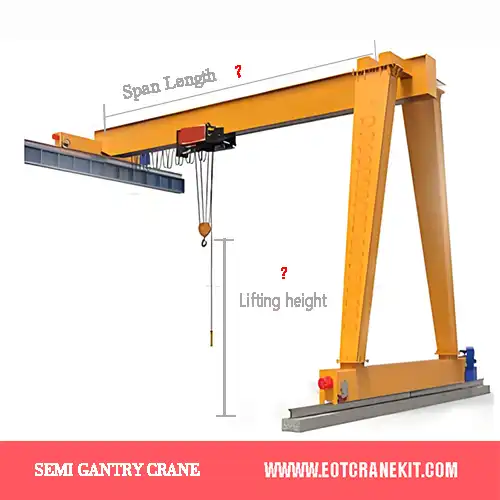

main specificaitons of semi gantry crane affecting crane price, capacity, crane span, and lifting height

Why Gantry Crane Prices Vary: Key Factors That Impact Cost

The price of a gantry crane can vary significantly based on a range of factors. Even small adjustments to these parameters can lead to substantial differences in the overall price. Below are the primary factors that determine the cost of a gantry crane:

1. Lifting Capacity

Lifting capacity is one of the most significant factors influencing the cost of a gantry crane. Gantry cranes come in a wide range of capacities, from smaller models capable of lifting under 1 ton, to massive units that can handle 500 tons or more. Naturally, the higher the lifting capacity, the more robust the crane's construction, requiring more powerful motors, larger structural components, and advanced safety features.

- Small-Capacity Gantry Cranes (under 5 tons): Lower prices, generally ranging from $3,000 to $15,000.

- Medium-Capacity Gantry Cranes (5-30 tons): Mid-range prices fall between $10,000 and $50,000.

- Heavy-Duty Gantry Cranes (50 tons and above): Larger cranes can range from $50,000 to $150,000 or more.

2. Span (Distance Between Legs)

The span of the gantry crane—the distance between the two legs supporting the crane bridge—directly affects the materials and structural complexity required. Wider spans necessitate stronger beams and more durable materials to ensure stability and safety. Larger spans often lead to increased material costs and more elaborate designs.

- Narrower Spans (for small tasks or confined areas) generally cost less because of simpler designs and fewer materials.

- Wider Spans (for larger operational areas like ports or construction sites) lead to higher prices due to the added engineering challenges and materials required.

3. Lifting Height

The height at which the gantry crane needs to lift loads is another critical factor in determining cost. Cranes that need to lift to greater heights will require more hoist rope, enhanced stability features, and possibly taller support structures, all of which increase the price.

- Standard Lifting Heights (e.g., 10-20 feet) are more affordable and require less material for structural integrity.

- Higher Lifting Heights (e.g., 30 feet or more) will add to the cost due to additional hoist capacity, extended lifting ropes, and reinforced structures to ensure safety and performance.

4. Power Supply Configuration

The power supply required by the gantry crane also plays a role in determining cost. Different voltages and frequencies (such as 380V, 50Hz, 3-phase) require specific motors and electrical control systems. If your location uses a non-standard power supply, this could necessitate special modifications or components that increase the price.

- Standard power supplies (380V, 50Hz, 3-phase) are usually more cost-effective because they require standard components.

- Custom power configurations (e.g., 220V, 60Hz, or non-standard voltages) may require more costly electrical components and could lead to a higher overall price.

5. Working Environment

The environment in which the gantry crane will operate has a significant impact on its price. Cranes designed for harsh conditions—such as high temperatures, outdoor use, exposure to chemicals, or dusty environments—require specialized materials and protective features. For example:

- Outdoor Use: The crane may require corrosion-resistant materials, weatherproofing, and special seals to protect sensitive components from moisture and rust.

- Harsh Environments: For environments with extreme temperatures or chemicals, the crane may need explosion-proof designs, high-temperature motors, or additional protection for wiring and electrical systems.

6. Working Hours (Duty Cycle)

Duty cycle ratings (A3 to A5 and above) refer to the frequency and intensity of crane usage. The more frequently and heavily the crane is used, the more durable and robust it needs to be. Cranes with higher duty cycles need stronger components, such as reinforced motors, more durable structural elements, and enhanced safety systems, which increases the cost.

- Low Duty Cycles (A3): Suitable for light, occasional use, which lowers costs.

- High Duty Cycles (A5+): Suitable for continuous or heavy-duty operations, requiring more durable materials and higher-end components.

7. Special Requirements

Certain special features and customizations can significantly increase the price of a gantry crane. These can include:

- Anti-Sway Systems: To control load sway during movement, reducing the risk of accidents, particularly in high-speed applications.

- Frequency Inverters: To control the speed and smoothness of crane movements, which can be particularly beneficial in applications requiring precise control.

- Explosion-Proof Designs: For use in hazardous environments (e.g., oil rigs or chemical plants), where safety is a major concern. This requires specific components that prevent sparks or fires.

- Traveling Rails: If the crane needs to be able to move across large areas or distances, the cost of traveling rails (especially custom-made ones) will increase the price.

In summary, gantry crane prices are influenced by a combination of factors that include lifting capacity, span, lifting height, power supply, working environment, duty cycle, and any special requirements for customization. By understanding these key parameters, you can better determine the crane that fits your needs and budget. When requesting a quote, always provide detailed information on your requirements to ensure an accurate price estimate.

If you have any need of gantry crane , please feel free to contact us. Click to learn more on What's price of Gantry Crane? Goliath Crane& Gantry Crane Price.

Your Trusted Overhead Crane Manufacturer & Supplier

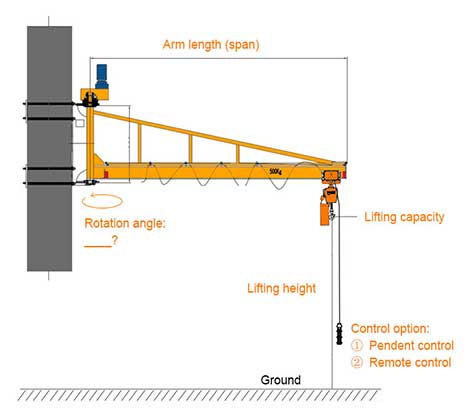

Overview of Slewing Jib Crane Price

Jib cranes are smaller and more affordable compared to overhead or gantry cranes, and they are used for lighter lifting tasks in confined spaces like workshops, loading docks, and warehouses. Jib cranes typically have a horizontal arm that can rotate around a central column or pillar.

- Small-Capacity Jib Cranes (0.5-1 ton): Prices for smaller jib cranes typically range from $2,000 to $6,000, ideal for light tasks in smaller maintenance or workshop environments.

- Medium-Capacity Jib Cranes (2-5 tons): These cranes cost between $4,000 and $15,000. They are often used in light manufacturing, assembly lines, and maintenance applications.

- Heavy-Duty Jib Cranes (10 tons or more): For more robust jib cranes, prices can range from $15,000 to $40,000 or higher, depending on the capacity and specific requirements for heavy-duty lifting.

Factors Affecting Jib Crane Prices:

- Lifting Capacity: The price of jib cranes increases with their lifting capacity. Larger jib cranes are generally more expensive.

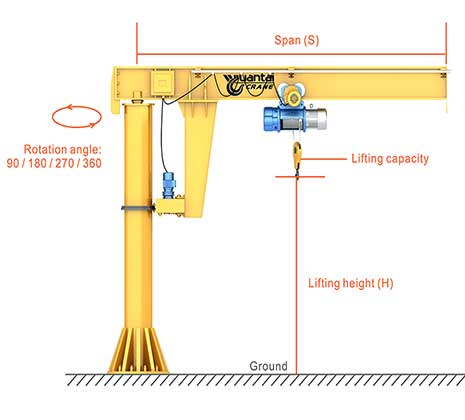

- Rotation and Reach: Jib cranes with 360-degree rotation or extended reach capabilities will cost more than those with limited movement.

- Mounting Type: Wall-mounted jib cranes, which are more affordable, typically cost less than pillar-mounted jib cranes, which require a foundation and more complex installation.

Typical Jib Crane Price Overview by Type and Capacity

| Crane Type | Lifting Capacity | Span | Lifting Height | Price Range (USD) | Common Applications |

|---|---|---|---|---|---|

| Pillar Jib Crane | 0.5 ton | 3-12 m | 3-8 m | $1,500 - $5,000 | Workstations, light-duty lifting |

| 1 ton | 3-12 m | 3-8 m | $2,000 - $7,000 | Small workshops, assembly areas | |

| 2 ton | 3-12 m | 3-8 m | $2,500 - $9,000 | Manufacturing, light-duty tasks | |

| 3 ton | 3-12 m | 3-8 m | $3,000 - $15,000 | Factories, warehouse operations | |

| 5 ton | 3-12 m | 3-8 m | $5,000 - $20,000 | Heavy workshops, steel fabrication | |

| 10 ton | 3-15 m | 3-8 m | $15,000 - $35,000 | Large production, machine shops | |

| 16 ton | 3-15 m | 3-8 m | $20,000 - $48,000 | Outdoor yards, heavy lifting | |

| 20 ton | 3-15 m | 3-8 m | $30,000 - $65,000 | Steel production, manufacturing | |

| Wall-Mounted Jib Crane | 0.5 ton | 3-8 m | 6-30 m | $2,000 - $5,000 | Space-saving, workshop walls |

| 1 ton | 3-8 m | 6-30 m | $2,500 - $8,000 | Small storage areas, limited space | |

| 2 ton | 3-8 m | 6-30 m | $4,000 - $11,000 | Maintenance, light manufacturing | |

| 3 ton | 3-8 m | 6-30 m | $5,000 - $13,000 | Industrial assembly, repair work | |

| 5 ton | 3-8 m | 6-30 m | $6,500 - $15,000 | Workshop lifting, smaller lines | |

| 10 ton | 3-8 m | 6-30 m | $10,000 - $30,000 | Heavy-duty lifting applications | |

| Wall-Travelling Jib Crane | 0.5 ton | 5-12.5 m | 6-30 m | $4,000 - $20,000 | Lateral movement, space-saving |

| 1 ton | 5-12.5 m | 6-30 m | $4,100 - $21,000 | Production lines, material handling | |

| 2 ton | 5-12.5 m | 6-30 m | $4,500 - $22,000 | Heavy materials, repetitive tasks | |

| 3 ton | 5-12.5 m | 6-30 m | $5,000 - $26,000 | Warehouses, small factory use | |

| 5 ton | 5-12.5 m | 6-30 m | $5,800 - $32,000 | Heavy-duty tasks, fabrication | |

| 10 ton | 5-12.5 m | 6-30 m | $6,500 - $39,000 | Large-scale lifting, assembly | |

| 16 ton | 5-9 m | 6-30 m | $7,800 - $46,000 | Large workshops, heavy lifting |

These jib prices are estimates based on general specifications and current market conditions. They may vary based on location, steel prices, and technical requirements.

Each type comes with its own price range depending on load capacity and customization. Entry-level models for light-duty applications may start around $1,500–$3,000, while heavy-duty or customized solutions for industrial use can exceed $50,000. Click to Learn more on Jib Cranes Capacity 1 Ton to 16 Ton for Sale Good Price.

To get an accurate and tailored jib crane price, it's important to provide detailed application requirements to the supplier, including lifting needs, available space, operating hours, and any environmental or safety considerations.

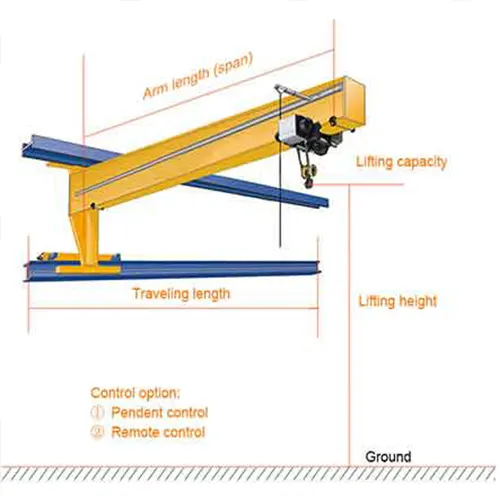

Overview of Swing Jib Crane Prices: What Affects the Cost and How to Get a Quotation

Jib cranes are a cost-effective and flexible lifting solution used in workshops, warehouses, assembly lines, and outdoor workstations. However, the price of a jib crane can vary significantly depending on its configuration and the specific working conditions where it will be installed.

Although the lifting capacity is a key factor, it is not the only one that determines the price. Other factors such as the crane's arm length (span), lifting height, rotation type, power supply, duty cycle, and installation environment also play a major role in pricing. For example, a 1-ton jib crane used outdoors with a longer span and corrosion-resistant coating will cost more than a basic 1-ton indoor model with standard features.

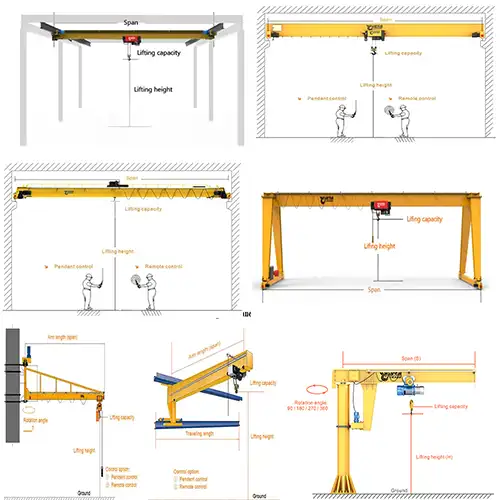

pillar jib crane main specificaitons affect jib cane price including capacity, rotating , lifting height, and crane span

Wall mounted jib crane main specificaitons affect jib cane price including capacity, rotating , lifting height, and crane span

Wall travelling jib crane main specificaitons affect jib cane price including capacity, travelling length, lifting height, and crane span

What Affects the Jib Crane Price?

The final price of a jib crane can vary significantly based on several crucial factors. Understanding how each of these factors influences the design, materials, and performance of the crane can help buyers make informed decisions and optimize their purchase for their specific needs.

1. Lifting Capacity

Lifting capacity is one of the most important factors in determining the price of a jib crane. The higher the capacity, the more robust the crane needs to be, and this increases the material costs and the complexity of the hoisting mechanism.

- Small Capacity (0.5 to 1 ton): For light-duty tasks, typically found in smaller workshops or maintenance applications, with prices ranging from $2,000 to $6,000.

- Medium Capacity (2 to 5 tons): Suitable for manufacturing and assembly operations, these cranes typically cost $4,000 to $15,000.

- Heavy Capacity (10 tons or more): Cranes that need to handle heavy loads in industrial environments may range from $15,000 to $40,000 or more, depending on customization and additional features.

Increasing lifting capacity requires stronger structural components, upgraded hoist mechanisms, and potentially more powerful motors, which all contribute to a higher price.

2. Arm Length (Span) and Lifting Height

Both the arm length (span) and lifting height are essential when choosing a jib crane. A longer arm or higher lifting height requires a more complex crane structure and more powerful lifting components, thereby increasing the cost.

- Arm Length (Span): The wider the span, the more material is needed to ensure stability. For example, a 3-meter span is less expensive than a 6-meter span, which demands more engineering, materials, and additional support.

- Lifting Height: Cranes designed for higher lifts require more hoist rope, larger beams, and additional structural reinforcement. Cranes with higher lifting capacities (over 10 meters) can be more costly due to the specialized components needed to achieve the desired height.

3. Power Supply

Jib cranes can operate under various power supply configurations, and this choice impacts the price due to the complexity of the electrical systems.

- Standard Power Supply (e.g., 380V, 50Hz, 3-phase): This is the most common and economical option, as it's compatible with a wide range of components.

- Custom Power Requirements: If your crane requires a different voltage or frequency, such as 220V or single-phase power, specialized motors and control systems may need to be designed, which could increase the cost.

Additionally, when your crane is used in regions with unstable power supply or extreme conditions, it may require additional components such as voltage regulators or surge protection systems.

4. Crane Traveling Length (Wall Traveling Jib Crane)

For jib cranes that need to travel across a space, such as wall traveling jib cranes, the inclusion of rails, motors, and traveling components adds significant complexity to the design, thereby raising the price.

- Wall Traveling Jib Cranes: These cranes allow the jib to travel along a wall or track, expanding their coverage area. The crane's ability to move along the track requires additional rail systems, motorized traveling units, and control systems, which increase the cost.

- Fixed Jib Cranes: For cranes that do not travel and are fixed in place, the price will be lower as no additional traveling mechanisms are required.

5. Working Environment

The environment in which the crane will operate can heavily influence its price. Harsh conditions often require specialized materials or designs to ensure safety and durability.

- Indoor Use: Jib cranes used indoors, in climate-controlled environments, typically have lower prices because they don't require additional protection against the elements.

- Outdoor Use: Jib cranes exposed to outdoor conditions require corrosion-resistant materials (e.g., galvanized steel), weatherproofing, and additional protective coatings, increasing costs.

- Hazardous Environments: If the crane operates in explosive, corrosive, or high-temperature environments (e.g., chemical plants, oil refineries, etc.), explosion-proof and heat-resistant components are required. These specialized components raise the cost due to their advanced design and higher material quality.

6. Work Frequency (Duty Cycle)

The duty cycle, or how frequently the crane will be used during the day, is a crucial factor in determining the crane's construction and price. The more frequent the crane operation, the more durable and robust it needs to be.

- Light Duty (A1, A2): For cranes that operate for short periods or only intermittently, the components can be made from lighter materials, and the price is relatively lower.

- Heavy Duty (A5 and above): For cranes with high-duty cycles (continuous use), the crane must be built with more durable components, such as higher-grade steel and advanced drive systems, which increases the price.

7. Rails or Installation Support (Floor-Mounted or Wall-Mounted)

Whether the crane is floor-mounted or wall-mounted also impacts the installation process and price.

- Floor-Mounted Jib Cranes: These cranes are free-standing and require a stable foundation, which adds to the cost. The foundation must be designed to support the crane's lifting capacity, and the price will vary depending on the complexity of the installation.

- Wall-Mounted Jib Cranes: These cranes are attached to a wall, which reduces the need for additional structural support, making them more cost-effective. However, the wall itself must be strong enough to support the crane, so additional reinforcements may be needed, which can add some cost.

- Installation Support: If you require additional installation assistance, such as custom-built foundations, support frames, or professional installation teams, these services will raise the total cost of the crane.

8. Special Customization Needs

Customization can significantly influence the final price of a jib crane. Depending on your specific needs, the crane may require unique features or modifications.

- Rotation Angle: Some cranes require a wider rotation range or 360-degree rotation, which requires more advanced mechanical systems, adding to the price.

- Explosion-Proof Features: If the crane is intended for use in hazardous environments, such as in chemical plants or areas with flammable gases, explosion-proof motors, electrical systems, and control panels are required. These components are made from specialized materials and cost more to manufacture and install.

- Automation: The addition of automated systems, such as remote controls or wireless controls, adds convenience but also raises costs due to the need for advanced control systems and sensors.

- Variable Frequency Drives (VFDs): VFDs can be added to improve crane operation and energy efficiency. While they increase the price of the crane, they can help reduce energy consumption in the long term.

A change in just one of these variables can significantly affect the final quote. Therefore, to get the most accurate and tailored pricing, we recommend sending a complete list of your requirements.

Your Trusted Overhead Crane Manufacturer & Supplier

Everything You Need to Know About Crane Pricing: Key Factors That Affect Your Purchase

Crane prices vary greatly depending on the type, specifications, and working environment. This article introduces the key factors that influence the cost of overhead cranes, gantry cranes, and jib cranes, serving as the first in a series that will guide you through crane pricing, features, and how to select the right solution for your application.