Budgeting for a 5 Ton Gantry Crane: Price Ranges and Options

Budgeting for 5 ton gantry crane, aspects of budgeting, ie. influencing costs, price ranges for different types, customization & cost-saving strategies.

Category: 5 Ton Gantry Crane

Your Trusted Gantry Crane Manufacturer & Supplier

Budgeting for a 5 Ton Gantry Crane: Price Ranges and Options

Budgeting for 5 Ton Gantry Crane, Price Ranges for Different Types, Customization & Cost-saving Strategies

Budgeting for 5 ton gantry crane, aspects of budgeting, ie. influencing costs, price ranges for different types, customization & cost-saving strategies.

Budgeting for a 5-ton gantry crane is a critical process that involves evaluating various factors to make informed decisions. This comprehensive article delves into the key aspects of budgeting, including factors influencing costs, price ranges for different configurations, customization, and cost-saving strategies. Real-world case studies highlight successful budgeting decisions in various industries. The importance of informed budgeting is emphasized, along with encouraging readers to consider their specific needs when making budgeting decisions for a 5-ton gantry crane.

A 5-ton gantry crane can be an invaluable asset, capable of lifting and transporting substantial weights with precision and safety. However, before diving into the world of gantry crane procurement, it's crucial to embark on a journey of budgeting. Budgeting for a 5-ton gantry crane is not merely about counting the dollars; it's about making an informed decision that aligns with your specific needs and financial considerations.

In this comprehensive guide, we will explore the nuances of budgeting for a 5-ton gantry crane, shedding light on the price ranges and options available. We'll dissect the factors that influence gantry crane costs, break down the price ranges for various configurations, and delve into the art of customization and additional expenses. Ultimately, our aim is to equip you with the knowledge needed to make a well-informed decision that suits your operation's requirements and your financial capabilities.

Factors Influencing Gantry Crane Costs

Budgeting for a 5-ton gantry crane involves a comprehensive understanding of the factors that influence its pricing. Each element plays a critical role in determining the overall cost of the crane. Let's explore these key factors in detail and how they contribute to the pricing structure:

Load Capacity Requirements

Load capacity requirements:One of the most fundamental factors impacting the cost of a gantry crane is its load capacity. A 5-ton gantry crane is specifically designed to handle loads up to 5 tons in weight. However, it's essential to evaluate your specific lifting needs accurately. If your operation occasionally requires lifting heavier loads, you may need to consider a crane with a higher load capacity, which would come at a higher cost. Conversely, if you overestimate your load capacity needs, you may be investing more than necessary.

Girder Design and Materials

Girder design and materials:Gantry cranes come with different girder designs and materials, which significantly affect their pricing.

Single Girder vs. Double Girder Gantry Cranes:

Single girder gantry cranes are typically more cost-effective due to their simplicity. They are suitable for moderate-load applications.

Double girder gantry cranes feature two girders for increased stability and load capacity, but they come at a higher initial cost.

Girder Materials (Steel vs. Aluminum):

Steel gantry cranes are generally more affordable but tend to be heavier. They are suitable for rugged environments and heavy lifting.

Aluminum gantry cranes are lightweight and corrosion-resistant, making them ideal for applications where weight is a critical factor, but they may come at a higher cost.

The choice between single or double girder and the selection of steel or aluminum will have a significant impact on your gantry crane's cost. It's essential to balance your requirements with your budget.

Lifting Mechanism and Hoisting System

Lifting mechanism and hoisting system:The type of lifting mechanism and hoisting system used in a gantry crane can vary, affecting both the upfront cost and long-term efficiency.

- Wire Rope Hoist Gantry Crane:These cranes use a wire rope hoist as the primary lifting mechanism. They are suitable for precise and controlled lifting operations and may have a higher initial cost.

- Electric Chain Hoist Gantry Crane:Electric chain hoist gantry cranes utilize an electric chain hoist for lifting and lowering loads efficiently. They offer a balance between reliability and cost-effectiveness.

- Magnet Gantry Crane:Equipped with a magnet attachment for lifting ferrous materials, these cranes are commonly used in metalworking and recycling industries. The magnet attachment adds to the cost but can significantly improve efficiency in specific applications.

The choice of lifting mechanism should align with your operational requirements and precision needs, which can influence the initial cost and long-term efficiency.

Traveling Type and Mobility

Traveling type and mobility:Gantry cranes come in various traveling types, and your choice should match your specific operational needs.

- Stationary Gantry Crane:Stationary gantry cranes are fixed in one location, providing stability but limited mobility. They are often used for specific tasks in workshops. The stationary nature keeps the cost relatively lower.

- Portable Gantry Crane:Portable gantry cranes are equipped with wheels or casters, allowing for easy mobility within a workspace. They are commonly used for maintenance and repair work, and their mobility adds to the upfront cost.

- Rail-Mounted Gantry Crane (RMG):RMGs are designed to run on rails for precise and efficient load handling. They are commonly used in industries with high throughput, such as container terminals. The inclusion of rail systems can increase the initial cost.

- Rubber-Tired Gantry Crane (RTG):RTGs are mobile gantry cranes with rubber tires for flexibility in moving and positioning loads. They are often used in container yards and ports, offering high mobility and efficiency, but at a higher initial cost.

- Adjustable Height Gantry Crane:These gantry cranes are designed with an adjustable height feature, allowing for vertical movement to accommodate various load sizes and heights. The adjustable height mechanism can increase the upfront cost due to its added complexity.

Your choice of traveling type should be driven by your workspace requirements and operational needs. The level of mobility and precision required can influence the overall cost.

Additional Features and Customization

Additional features and customization:Customization options and additional features can significantly impact the overall cost of a gantry crane. These features can enhance the crane's functionality and long-term efficiency, but they come at an additional expense. Customization options may include remote control systems, specialized attachments, safety enhancements, or automation capabilities. When considering customization, it's essential to weigh the added cost against the benefits and improvements in operational efficiency.

Understanding how each of these factors contributes to the overall cost of a 5-ton gantry crane is crucial for making an informed budgeting decision. It allows you to align your specific needs with your budget constraints, ensuring that you invest in the right crane for your operation. In the following sections, we will delve into the specific price ranges for different gantry crane configurations and provide insights into customization and additional costs.

Price Ranges for 5 Ton Gantry Cranes

Budgeting for a 5-ton gantry crane requires a detailed understanding of the price ranges for various configurations and options. Let's break down the estimated price ranges based on different crane types, lifting mechanisms, traveling types, and materials:

Breakdown of Price Ranges Based on Crane Types and Configurations

Single Girder vs. Double Girder Gantry Cranes:

- Single Girder Gantry Crane (5-ton):Single girder gantry cranes are known for their simplicity and cost-effectiveness. They are suitable for moderate-load applications.

Price Range:$3000~41500. - Double Girder Gantry Crane (5-ton):Double girder gantry cranes feature two girders for increased load capacity and stability. They are ideal for heavy-duty lifting tasks but come at a higher initial cost.

Price Range: $5800-72000.

Different Lifting Mechanisms:

- Wire Rope Hoist Gantry Crane (5-ton):These cranes use a wire rope hoist as the primary lifting mechanism, offering precise and controlled lifting operations.

Price Range: $3,000 - $70,000. - Electric Chain Hoist Gantry Crane (5-ton):Electric chain hoist gantry cranes provide efficient lifting and lowering of loads, balancing reliability and cost-effectiveness.

Price Range: $3,000 - $50,000. - Magnet Gantry Crane (5-ton):Equipped with a magnet attachment for lifting ferrous materials, these cranes are commonly used in metalworking and recycling industries.

Price Range: $5,800 - $60,000.

Various Traveling Types:

- Stationary Gantry Crane (5-ton):Stationary gantry cranes are fixed in one location, providing stability but limited mobility. They are often used for specific tasks in workshops.

Price Range: $3,000 - $30,000. - Portable Gantry Crane (5-ton):Portable gantry cranes, equipped with wheels or casters, allow for easy mobility within a workspace. Commonly used for maintenance and repair work.

Price Range: $3,000 - $20,000. - Rail-Mounted Gantry Crane (RMG) (5-ton):RMGs are designed to run on rails for precise and efficient load handling. They are commonly used in industries with high throughput, such as container terminals.

Price Range: $5,800 - $300,000. - Rubber-Tired Gantry Crane (RTG) (5-ton):RTGs are mobile gantry cranes with rubber tires for flexibility in moving and positioning loads. Often used in container yards and ports.

Price Range: $5,800 - $200,000. - Adjustable Height Gantry Crane (5-ton):These gantry cranes are designed with an adjustable height feature, allowing for vertical movement to accommodate various load sizes and heights.

Price Range: $3,000 - $40,000.

Steel vs. Aluminum Gantry Cranes:

- Steel Gantry Crane (5-ton):Steel gantry cranes are generally more affordable but tend to be heavier. They are suitable for rugged environments and heavy lifting.

Price Range: $3,000 - $80,000. - Aluminum Gantry Crane (5-ton):Aluminum gantry cranes are lightweight and corrosion-resistant, making them ideal for applications where weight is a critical factor. They may come at a higher cost.

Price Range: $30,000 - $100,000.

Estimated Price Ranges for Each Combination

It's important to note that these price ranges are approximate figures and can vary depending on factors such as manufacturer, location, customization options, and additional features. When budgeting for a 5-ton gantry crane, it's essential to consider the specific requirements of your operation and select the configuration that best aligns with your needs and budget constraints.

In the next section, we will delve into the implications of customization and additional costs in the procurement process, helping you make an informed decision while staying within your budget.

Hot Sales of 5 Ton Gantry Cranes in China

General-purpose Portable Gantry Crane

Portable Gantry Crane For Sale

Portable Gantry Crane is mobile and flexible, can be moved to other places at any time after use, and can be used in multiple environments. It is an excellent equipment for handling materials under 10 tons.

Lifting Capacity: 0.25~10 ton

Lifting Height: 1~9m

Span: 2~12m

Working Duty: A3, A4

General-purpose Single Girder Gantry Crane

Single Girder Gantry Crane For Sale

The gantry crane is equipped with duel-speed electric hoist, widely used in workshop, storage, port, and hydroelectric power station and outdoor places. The lifting capacity of the gantry crane is 1 to 20 tons.

Lifting Capacity: 1~20 ton

Lifting Height: 6-30m

Span: 7.5~35m

Working Duty: A3, A4

General-purpose Double Girder Gantry Crane

Double Girder Gantry Crane For Sale

The gantry crane is applied to the open warehouse or rail along for general handling and lifting work. The lifting capacity of the gantry crane is 5 ton - 500 tons.

Lifting Capacity: 5~500 ton

Lifting Height: 6-30m

Span: 7.5~35m

Working Duty: A3, A4, A5

Portable Gantry Crane | Span(m) | Lifting Height(m) | Power Supply(V) | Price(USD) | |

5 ton portable gantry crane | 2~12 | 1~9 | 220-480/3/50 | $4500~46000 | |

10 ton portable gantry crane | 2~12 | 1~9 | 220-480/3/50 | $7000~65000 | |

Single Girder Gantry Crane | Span(m) | Lifting Height(m) | Power Supply(V) | Price(USD) | |

5 ton single girder gantry crane | 7.5~31.5 | 6~30 | 220-480/3/50 | $3000~41500 | |

10 ton single girder gantry cranes | 7.5~31.5 | 6~30 | 220-480/3/50 | $4000~45000 | |

Double Girder Gantry Crane | Span(m) | Lifting Height(m) | Power Supply(V) | Price(USD) | |

5 ton double girder gantry crane | 7.5~31.5 | 6~30 | 220-480/3/50 | $5800-72000 | |

10 ton double girder gantry crane | 7.5~31.5 | 6~30 | 220-480/3/50 | $6500-79000 | |

Customization and Additional Costs

As you budget for a 5-ton gantry crane, it's important to consider not only the base price but also potential customization options and additional costs that may arise during the procurement process. These factors can significantly impact the overall cost of the crane and should be carefully evaluated.

A. Impact of Customization on Overall Cost

Customization and Specific Requirements:

Customization allows you to tailor the gantry crane to meet the specific needs of your operation. While customization can enhance the crane's functionality, it can also add to the overall cost. Here's how customization can impact the cost:

- Specialized Attachments:If your operation requires specialized lifting attachments, such as hooks, magnets, or clamps, the cost of these attachments will be added to the crane's price.

- Automation and Control Systems:Automation features, such as remote control systems or automated load positioning, can improve efficiency but come with additional costs.

- Adjustable Height Features:Gantry cranes with adjustable height features, which allow for vertical movement to accommodate various load sizes and heights, often come at a higher cost due to their added complexity.

- Safety Enhancements:Adding safety features like collision avoidance systems or overload protection may increase the upfront cost but can contribute to long-term safety and cost savings.

- Customized Dimensions:If you require a gantry crane with specific dimensions to fit your workspace, customization may be necessary and can impact the price.

It's essential to carefully assess the benefits of customization against the added cost to determine whether the investment aligns with your operational requirements.

Additional Costs in Gantry Crane Procurement

Installation Costs:

Installation is a significant additional cost to consider when budgeting for a 5-ton gantry crane. Installation costs can vary based on several factors:

- Complexity of Installation:The complexity of the installation process, including the foundation work and assembly of the crane, can impact installation costs. More complex installations may require specialized expertise.

- Site Preparation:Preparing the site, including ensuring a level surface and adequate support, is essential for safe crane operation and can contribute to installation costs.

- Labor and Equipment:Labor costs for the installation team and any equipment rentals needed for installation should be factored into the budget.

- Safety Measures:Implementing safety measures during installation, such as ensuring proper anchoring and structural integrity, may incur additional costs.

Shipping and Transportation Costs:

The transportation of the gantry crane from the manufacturer or supplier to your location can also add to the overall cost. Shipping costs can vary based on factors like distance, shipping method, and the size and weight of the crane. It's important to obtain shipping quotes and include these costs in your budget.

Maintenance Costs:

While maintenance costs are ongoing expenses, they should be considered as part of the overall cost of owning a gantry crane. Regular maintenance is essential to ensure the crane's safe and efficient operation. Maintenance costs may include:

- Routine Inspections:Periodic inspections and maintenance checks by qualified technicians to identify and address any issues.

- Replacement Parts:Costs associated with replacing worn or damaged components and parts.

- Service Contracts:Consideration of service contracts with the manufacturer or a third-party service provider for scheduled maintenance and repairs.

- Downtime Costs:Factoring in the potential costs associated with downtime during maintenance and repairs, including lost productivity.

By accounting for these potential customization and additional costs, you can develop a more accurate and comprehensive budget for your 5-ton gantry crane procurement. It's important to work closely with suppliers, manufacturers, and installation teams to obtain detailed cost estimates and ensure that your budget aligns with your operational needs and financial capabilities.

Cost-Benefit Analysis

Budgeting for a 5-ton gantry crane involves not only considering the upfront costs but also conducting a comprehensive cost-benefit analysis. Evaluating different options and configurations based on their cost-effectiveness and long-term advantages is essential to make an informed decision. Here's how you can conduct a cost-benefit analysis and the factors to consider:

Cost-Benefit Analysis of Different Options and Configurations

- 1. Single Girder vs. Double Girder:Consider the cost difference between single girder and double girder gantry cranes. Single girder cranes are more budget-friendly initially, but double girder cranes offer higher load capacity and stability. Evaluate whether the increased capacity justifies the higher upfront cost.

- 2. Lifting Mechanism:Compare the cost and benefits of different lifting mechanisms (wire rope hoist, electric chain hoist, magnet). While some mechanisms may have a higher initial cost, they might offer improved precision and efficiency, potentially leading to long-term savings.

- 3. Traveling Type:Assess the cost-effectiveness of various traveling types based on your operational needs. Consider factors such as mobility, precision, and efficiency. A higher upfront investment in a rail-mounted gantry crane (RMG), for example, may lead to greater efficiency in industries with high throughput.

- 4. Girder Materials:Weigh the cost difference between steel and aluminum gantry cranes against their respective advantages. Steel cranes may be more affordable, but aluminum cranes are lightweight and corrosion-resistant, potentially reducing maintenance costs over time.

Considerations in the Cost-Benefit Analysis

- 1. Durability:Factor in the durability of the gantry crane. While a cheaper option might be appealing upfront, a more durable and robust crane can provide long-term reliability, reducing the need for frequent replacements or repairs.

- 2. Maintenance:Evaluate the maintenance requirements and costs associated with each configuration. Cranes with advanced safety features and efficient lifting mechanisms may have lower maintenance costs over their lifespan.

- 3. Long-Term Savings:Consider the potential long-term savings. A crane with a higher upfront cost but greater efficiency and load capacity can lead to increased productivity and revenue generation, offsetting the initial investment.

- 4. Operational Efficiency:Assess how each configuration contributes to operational efficiency. A crane that offers faster load handling and precise positioning may improve overall productivity, potentially justifying a higher cost.

- 5. Safety:Prioritize safety features and their impact on cost. Safety enhancements can prevent accidents, reduce downtime, and save on potential injury-related costs.

- 6. Total Cost of Ownership:Calculate the total cost of ownership over the expected lifespan of the gantry crane, including acquisition, installation, maintenance, and potential upgrades. This holistic view will provide a more accurate understanding of the investment.

- 7. Return on Investment (ROI):Estimate the ROI for each configuration by analyzing how quickly the crane can pay for itself through increased productivity, reduced maintenance costs, and improved safety.

In conclusion, a cost-benefit analysis is a crucial step in budgeting for a 5-ton gantry crane. It helps you make a well-informed decision by considering not only the initial cost but also the long-term advantages and savings associated with different options and configurations. Remember that the choice should align with your specific operational needs and financial constraints to achieve the best balance between cost and performance.

Tips for Cost Savings

When budgeting for a 5-ton gantry crane, finding ways to reduce costs without compromising safety or functionality is essential. Here are some tips and strategies to help you save on the overall cost of your gantry crane purchase:

Tips and Strategies for Cost Savings

- 1. Clarify Your Requirements:Begin by precisely defining your operational requirements. Determine the necessary load capacity, lifting height, span, and other specifications to avoid overpaying for features you don't need.

- 2. Choose the Right Configuration:Select the gantry crane configuration that best suits your needs. Avoid over-specifying or under-specifying the crane's capacity and features. Consider factors like load frequency and workspace constraints.

- 3. Compare Multiple Quotes:Obtain quotes from different manufacturers and suppliers. Compare prices, configurations, and services offered to ensure you're getting the best value for your budget.

- 4. Consider Used Equipment:Explore the option of purchasing used or refurbished gantry cranes. These can be more cost-effective while still providing reliable performance. Ensure that used equipment has been properly inspected and maintained.

- 5. Explore Financing Options:Investigate financing and leasing options that can help you spread the cost of the gantry crane over time. Leasing can be particularly beneficial for managing cash flow.

- 6. Negotiate with Suppliers:Don't hesitate to negotiate with suppliers. Ask if there are any available discounts, promotions, or package deals. Suppliers may be willing to work with you to meet your budgetary constraints.

- 7. Optimize Installation:Streamline the installation process to minimize labor and equipment costs. Ensure that your site is prepared adequately, and all necessary resources are available to expedite installation.

- 8. Regular Maintenance:Invest in regular maintenance to prolong the lifespan of your gantry crane and prevent costly breakdowns. Scheduled maintenance is more cost-effective than emergency repairs.

- 9. Safety Measures:Prioritize safety features but avoid unnecessary extras that don't contribute significantly to safety. Strike a balance between safety and cost-effectiveness.

- 10. Training and Certification:Invest in training and certification programs for your crane operators and maintenance personnel. Well-trained staff can help prevent accidents and extend the life of your equipment.

Recommendations for Negotiating and Used Equipment

Negotiating with Suppliers:

When negotiating with suppliers, be prepared to ask questions and seek concessions. Consider the following negotiating tips:

Inquire about bulk purchase discounts if you are buying multiple cranes.

Request flexibility in payment terms or financing options.

Ask if they can include installation and training as part of the package.

Used Equipment Considerations:

When considering used equipment, follow these guidelines:

Inspect the equipment thoroughly or hire a qualified inspector to assess its condition.

Request maintenance records to ensure that the crane has been properly cared for.

Verify that the crane meets safety and regulatory standards.

Negotiate a warranty or service agreement with the seller to cover potential issues.

By applying these tips and strategies, you can make the most of your budget when purchasing a 5-ton gantry crane while ensuring that your investment meets your operational requirements and safety standards.

Case Studies

Let's explore some real-world case studies of organizations and projects that successfully budgeted for and implemented 5-ton gantry cranes. These case studies illustrate the decisions they made and the outcomes achieved.

Case Study 1: Manufacturing Facility Efficiency

Organization:A manufacturing facility specializing in automotive parts.

Challenge:The facility required a gantry crane to streamline its production process. They needed a crane with a 5-ton capacity to lift and transport heavy components across the shop floor efficiently.

Budget Considerations:

The organization conducted a thorough analysis of its production needs, determining that a 5-ton gantry crane was the ideal solution.

They explored used equipment options and negotiated with several suppliers to find the best deal.

Outcome:

The gantry crane improved production efficiency by reducing material handling time.

Cost savings were achieved by choosing a used crane that had been well-maintained and met safety standards.

Employee safety was enhanced, resulting in fewer accidents and lower insurance costs.

Case Study 2: Container Terminal Productivity

Organization:A container terminal at a busy seaport.

Challenge:The container terminal needed a gantry crane to handle container loading and unloading efficiently. They required a high-capacity gantry crane with a 5-ton load capacity for efficient container handling.

Budget Considerations:

The organization evaluated the benefits of rail-mounted gantry cranes (RMGs) due to their high throughput capacity.

They compared quotes from multiple suppliers and negotiated a package deal that included installation and training.

Outcome:

The RMG gantry crane significantly improved container handling productivity, reducing vessel turnaround times.

While the initial investment was substantial, the long-term cost savings from increased efficiency justified the expenditure.

The ability to handle more containers resulted in increased revenue for the terminal.

Case Study 3: Workshop Optimization

Organization:A machine shop specializing in custom metal fabrication.

Challenge:The workshop required a gantry crane to lift heavy metal sheets and components for machining and welding. They needed a 5-ton gantry crane that could operate within the confined space of the workshop.

Budget Considerations:

The organization opted for a single girder gantry crane due to the workshop's limited ceiling height.

They negotiated with suppliers to include installation, operator training, and a maintenance package.

Outcome:

The gantry crane improved workflow and reduced manual labor, resulting in faster project completion.

By negotiating a comprehensive package, the organization simplified budgeting and maintenance planning.

The investment in the crane led to increased project capacity and profitability.

These case studies demonstrate how organizations successfully budgeted for 5-ton gantry cranes by carefully assessing their needs, exploring budget-friendly options, and negotiating effectively with suppliers. In each case, the decision to invest in the right gantry crane configuration yielded improved efficiency, safety, and long-term cost savings.

Conclusion

In conclusion, budgeting for a 5-ton gantry crane is a crucial process that requires careful consideration of various factors. This article has provided valuable insights into the key aspects of budgeting for a gantry crane and making informed decisions. Let's summarize the key points and emphasize the importance of informed budgeting:

Understanding the factors that influence gantry crane costs, including load capacity, girder design, lifting mechanisms, traveling types, and materials, is essential to make informed budgeting decisions.

- Price ranges for 5-ton gantry cranes vary based on crane types and configurations, such as single or double girder, lifting mechanisms, traveling types, and materials.

- Customization, installation, shipping, and maintenance are important cost considerations that impact the overall budget for a gantry crane.

- Conducting a cost-benefit analysis helps assess different options and configurations, taking into account factors like durability, maintenance, and long-term savings.

- Tips for cost savings include clarifying requirements, comparing quotes, considering used equipment, and negotiating with suppliers.

- Real-world case studies highlight successful budgeting decisions and outcomes in various industries.

Importance of Informed Budgeting:

Informed budgeting for a 5-ton gantry crane is paramount for several reasons:

- It ensures that you acquire a crane that meets your specific operational requirements and provides value for your investment.

- Informed budgeting helps identify potential cost-saving opportunities, enabling you to make the most of your budget.

- A well-considered budget minimizes the risk of overspending on unnecessary features or configurations.

- It contributes to workplace safety by ensuring that the chosen crane aligns with safety standards and requirements.

Consider Your Specific Needs:

As you embark on the journey of budgeting for a 5-ton gantry crane, remember to consider your unique needs and requirements. Every organization and project is different, and a one-size-fits-all approach may not be suitable. Take the time to:

- Clearly define your operational requirements, load capacities, and workspace constraints.

- Explore various configurations and options to determine which best aligns with your goals.

- Seek quotes, negotiate effectively, and explore financing options to maximize your budget's impact.

- Prioritize safety, efficiency, and long-term cost savings in your decision-making process.

Informed budgeting for a 5-ton gantry crane is an investment in your organization's efficiency, safety, and productivity. By following the guidelines and strategies outlined in this article, you can make a well-informed decision that aligns with your budgetary constraints and operational needs.

How to get the specific Gantry Crane Price?

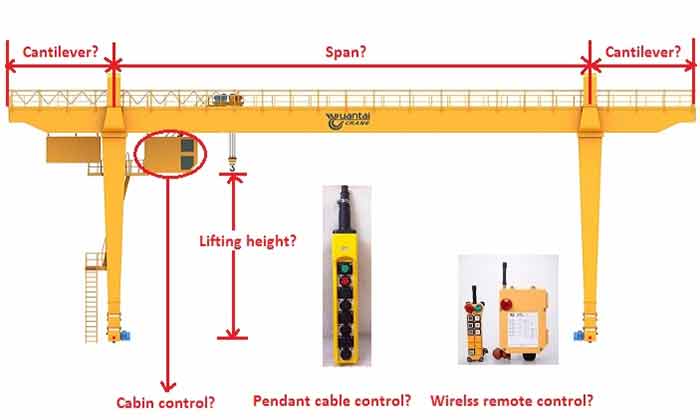

Given the unique working conditions of each customer, the cost of a gantry crane with the same load capacity can vary significantly. Price disparities primarily arise from factors such as lifting capacity, span, height, power supply, working environment, and specific customer requirements. Any variation in these factors can lead to price discrepancies. To obtain an accurate quote for a gantry crane tailored to your specific needs, please provide us with a detailed request that includes the following information:

Parameters Needed to Get Custom Gantry Crane 5 Ton

- Lifting capacity

- Span (S)

- Lifting height (H)

- Power supply(e.g. 380V 50Hz 3Phase)

- Crane traveling length (L)

- Detailed working conditions of the crane

- How many hours does the crane need to work each day

- Shall we provide you the crane traveling rails?

- Other requirements

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch