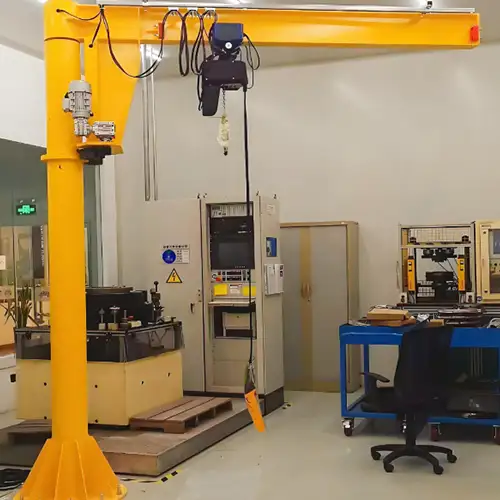

Heavy-Duty Pillar Jib Crane & 10 Ton Jib Cranes for Industries

10 ton jib crane for sale. Reliable, space-saving pillar mounted jib crane for workshops & factories—ideal for handling heavy loads with precision& safety.

Category: Jib Crane Capacity & Tonnages

Your Trusted Pillar Mounted Jib Crane Manufacturer & Supplier

Heavy-Duty Jib Cranes & 10-Ton Jib Cranes for Sale, Good Price

When compared to wall-mounted and wall-traveling jib cranes, free-standing jib cranes offer higher load capacities, extended arm reach, and a greater range of rotation. Their self-supporting structure allows them to be customized for unique applications, making them a versatile choice for various industries. The only installation requirement is that the foundation must support at least 2,500 lbs per square foot to ensure stability.

Key Specifications of Heavy-Duty Jib Cranes

These cranes are ideal for short-distance lifting and material handling in congested workspaces, offering excellent maneuverability and performance.

- Rotation: 360 degrees

- Arm length: Up to 16 meters

- Rotating speed: 0.5 r/min

- Safe working load: Up to 16 tons (including 10-ton models)

- Lifting height: Up to 12 meters (floor to underside of boom)

- Operating temperature: -20℃ to +40℃

- Traveling speed: 20 or 30 m/min

- Control options: Pendant handle, remote control, or cabin operation

- Applications: Suitable for warehouses, shipyards, docks, factories, and more

- Power supply: AC 380V, 50Hz, 3-phase

Note: Users can choose between single-speed and double-speed chain hoists or wire rope hoists based on specific lifting needs.

Why Choose a Heavy-Duty Jib Crane?

Maximum Flexibility

Heavy-duty free-standing jib cranes can be installed both indoors and outdoors, making them highly adaptable to various work environments. They can function as independent lifting solutions or complement existing material handling systems, such as overhead cranes in production lines. Additionally, their installation and relocation process is simple, requiring minimal structural modifications.

Easy & Precise Operation

Our 10-ton jib cranes are designed for smooth and accurate movement, ensuring efficient and precise load handling. Advanced control systems minimize unintended movements, reducing the risk of damage to equipment and personnel. This extends the crane's lifespan while improving workplace safety.

Enhanced Safety Features

Safety is our top priority! Our cranes are equipped with emergency stop systems, ensuring immediate shutdown in case of an emergency. Every unit undergoes rigorous quality and load testing before installation. If needed, our professional technicians can assist with installation and inspection to guarantee 100% operational reliability.

Core Components of a Heavy-Duty Jib Crane

Column

Manufactured in compliance with JB/8906-1999 standards, the column supports the crane's rotation mechanism using double-row tapered self-aligning bearings to handle radial and axial forces.

Arm Beam

The arm beam, built from I-beam or box beam construction, supports the trolley and hoist, allowing for both manual and electric rotation as well as horizontal movement of loads.

Rotation Mechanism (Reducer)

The reducer, designed as per GB/T292-1994 standards, is installed under the arm beam and drives the rotation of the crane via a roller system.

Lifting Mechanism (Electric Hoist)

The lifting system can be configured with electric wire rope hoists or chain hoists, enabling smooth vertical and horizontal movement along the beam.

Electrical Cabinet

Our cranes operate on a standard 380V, 50Hz, 3-phase power supply. However, customized power configurations (up to 690V, 50-60Hz) are available upon request.

Conclusion

Whether you require a 10-ton jib crane for moderate lifting or a heavy-duty jib crane for more demanding tasks, our solutions provide efficiency, safety, and long-lasting durability. With easy installation, precise control, and advanced safety features, these cranes are ideal for a variety of industries.

Need a customized solution? Contact us today to discuss your specific lifting requirements!

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch