5 Ton, 10 Ton, 16 Ton, 20 Ton Top Running Crane Price Comparison

Explore the price differences between top running single and double girder cranes to determine the most cost-effective option for your needs.

Category: Top Running Crane

Your Trusted Top Running Crane Manufacturer & Supplier

5 Ton, 10 Ton, 16 Ton, 20 Ton Top Running Overhead Crane Price

Single Girder vs. Double Girder: Which One Saves You More Money & How to Select?

Why Top Running Overhead Cranes Matter

Top running overhead cranes are essential in industrial settings. They handle materials efficiently and reduce manual labor. These cranes are common in manufacturing, steel mills, warehouses, and heavy-duty production lines.

Single Girder vs. Double Girder: What's the Difference?

Choosing between a single girder and double girder crane is a key decision. It affects cost, lifting capacity, and long-term efficiency. Each type has its advantages, but picking the wrong one can increase expenses or limit performance.

- Single girder cranes are simpler and cost less. They are best for light to medium loads.

- Double girder cranes handle heavier loads and offer better lifting height, but they cost more upfront.

Why Focus on 5 Ton, 10 Ton, 16 Ton, and 20 Ton Cranes?

These four capacities cover most industrial needs. Whether lifting light materials or heavy steel components, one of these sizes will likely fit your application.

- 5 Ton cranes are for light-duty work like small workshops and warehouses.

- 10 Ton cranes are common in factories, assembly lines, and medium-load handling.

- 16 Ton cranes serve heavy-duty production, shipyards, and steel fabrication.

- 20 Ton cranes handle large-scale lifting in power plants, foundries, and heavy industries.

What Affects the Price?

The cost of a top running overhead crane varies. Even cranes of the same capacity can have different price tags. Key factors include:

- Lifting capacity – Higher capacity means a stronger structure and a higher price.

- Span – A longer span requires more material, increasing costs.

- Lifting height – Taller lifts need a more powerful hoist and stronger design.

- Working environment – Harsh conditions (heat, dust, chemicals) require special materials.

- Duty cycle – Cranes used all day need better components, increasing the price.

Making the Right Investment

Buying a crane is a long-term decision. A cheaper crane might save money today but cost more in maintenance and downtime later. A well-matched crane improves efficiency, lasts longer, and reduces operating costs.

This guide helps compare single vs. double girder cranes in different tonnages so you can choose wisely and save money.

This version keeps it simple, natural, and useful. Let me know if you need any tweaks!

What is a Top Running Overhead Crane?

Designed for Maximum Lifting Height

A top running overhead crane is mounted on rails installed on top of runway beams. This setup allows the crane to make full use of the workshop's height without being limited by building structures. It provides better clearance than underhung cranes, making it ideal for applications requiring extra lifting height.

- Installed on top of runway beams for higher lifting clearance.

- Maximizes workspace by avoiding obstructions at ground level.

- Ideal for heavy lifting in facilities with high ceilings.

Types of Top Running Overhead Cranes

There are two main types of top running overhead cranes. Each offers different advantages depending on cost, lifting capacity, and operational needs.

Single Girder Top Running Crane

A single girder crane has only one bridge girder, making it a simpler and more cost-effective option.

- Uses one main beam with a hoist running below it.

- More affordable for light to medium lifting applications.

- Easier to install, maintain, and operate.

- Best suited for warehouses, small workshops, and general manufacturing.

Double Girder Top Running Crane

A double girder crane has two bridge girders, providing greater strength and stability for heavier loads.

- Uses two main beams, allowing the hoist to be mounted between them.

- Can lift heavier loads and offers a higher hook position.

- Suitable for large industrial plants, steel mills, and heavy-duty manufacturing.

- Requires a higher initial investment but offers better long-term durability.

Where Are Top Running Cranes Used?

These cranes are widely used in industries where high lifting capacity and large spans are required.

- Steel mills and metal processing plants – Handling billets, steel coils, and heavy materials.

- Large manufacturing workshops – Moving industrial components, machinery, and assembly parts.

- Shipbuilding and aerospace industries – Transporting large structural parts for construction.

- Power plants and foundries – Lifting heavy equipment in high-temperature and demanding environments.

Choosing the Right Crane for Your Needs

Selecting between a single girder and a double girder crane depends on your lifting requirements, budget, and workspace conditions. A well-matched crane improves efficiency, reduces long-term costs, and ensures safe operations.

Top Running Single Girder Overhead Crane

Structure and Design

A single girder top running crane consists of a single bridge girder with the hoist running on the bottom flange. This design is more compact and lightweight compared to a double girder crane.

- Uses one main girder for support.

- Hoist runs along the lower flange of the girder.

- Requires fewer components, reducing overall weight.

Best Applications

Single girder cranes are well-suited for light to medium-duty lifting tasks where space and cost are key considerations.

- Ideal for small to mid-sized workshops, warehouses, and manufacturing facilities.

- Works best in areas with height limitations, as it requires less headroom.

- Common in assembly lines, maintenance shops, and material handling facilities.

Advantages of a Single Girder Crane

This type of crane offers several benefits, particularly in terms of cost and ease of use.

- Lower initial cost – Uses less steel, requires fewer components, and has a simpler design.

- Easier installation and maintenance – Fewer parts mean faster setup and reduced downtime.

- More energy-efficient – Lighter structure leads to lower power consumption.

- Flexible and versatile – Can be customized for specific lifting needs while maintaining affordability.

For businesses looking for a cost-effective and space-saving lifting solution, a top running single girder crane is often the best choice. However, for heavier loads or higher lifting requirements, a double girder crane may be a better option.

Top Running Double Girder Overhead Crane

Structure and Design

A double girder top running crane features two bridge girders with the hoist running on rails mounted above them. This design provides greater strength and stability for handling heavy loads.

- Uses two parallel girders for better load distribution.

- Hoist moves on top of the girders, allowing for higher lifting height.

- Can accommodate additional components such as walkways and service platforms.

Best Applications

Double girder cranes are designed for heavy-duty lifting and high-frequency operations where durability and efficiency are essential.

- Ideal for steel mills, power plants, shipyards, and large manufacturing plants.

- Suitable for handling large or oversized loads in industrial settings.

- Best for workshops requiring long spans and high hook positions.

Advantages of a Double Girder Crane

A double girder crane offers several benefits, particularly for operations that require higher lifting capacity and improved performance.

- Higher lifting capacity – Can handle heavier loads compared to single girder cranes.

- Better hook height – Provides more vertical lifting space, making it ideal for tall workspaces.

- Greater structural stability – Designed to support long spans and large load movements.

- Supports additional features – Can integrate walkways, maintenance platforms, and automation for improved safety and efficiency.

For operations that require frequent lifting of heavy loads or special features like walkways and control automation, a double girder top running crane is often the best investment. While it requires a higher initial cost, its durability and functionality make it a long-term cost-effective solution for demanding industries.

Price Comparison: Top Running Single Girder Crane vs. Double Girder Crane

The cost of a top running overhead crane depends on several factors, including lifting capacity, span, lifting height, power supply, and additional customizations. The type of crane—single girder or double girder—also significantly impacts the price.

Factors Affecting Crane Pricing

Before comparing specific prices, it's important to understand what influences the cost of a crane.

- Lifting Capacity – Heavier capacities require stronger structures and more powerful components, increasing costs.

- Span (Bridge Length) – A longer span requires a stronger girder, which raises material costs.

- Lifting Height – Higher lifting heights demand longer ropes, cables, and support structures.

- Power Supply – Voltage and frequency variations may require special electrical components.

- Work Duty & Environment – Cranes used in extreme conditions (e.g., high heat, dust, or explosive environments) may require specialized materials and coatings.

- Customization – Features such as remote controls, automation, anti-sway systems, or maintenance walkways add to the price.

Price Table for Top Running Single Girder Overhead Cranes

Single girder cranes are generally more affordable than double girder cranes due to their simpler design and lower material costs. They are ideal for light to medium-duty applications.

| Capacity | Span (m) | Lifting Height (m) | Power Supply (V) | Price (USD) |

|---|---|---|---|---|

| 5 Ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $3,000~41,500 |

| 10 Ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $4,000~45,000 |

| 16 Ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $5,000~48,000 |

| 20 Ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $6,000~50,000 |

Why Choose a Single Girder Crane?

- Lower initial cost due to fewer components.

- Easier to install and maintain, reducing long-term expenses.

- Best for light to moderate lifting needs in workshops, warehouses, and production lines.

Price Table for Top Running Double Girder Overhead Cranes

Double girder cranes have a higher price due to their increased load capacity, structural strength, and ability to accommodate additional features. These cranes are ideal for demanding industrial applications.

| Capacity | Span (m) | Lifting Height (m) | Power Supply (V) | Price (USD) |

|---|---|---|---|---|

| 5 Ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $5,800~72,000 |

| 10 Ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $6,500~79,000 |

| 16 Ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $7,800~86,000 |

| 20 Ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $8,600~95,000 |

Why Choose a Double Girder Crane?

- Higher lifting capacity and better stability for heavy loads.

- Greater lifting height, allowing more workspace clearance.

- Supports additional features like maintenance walkways, control automation, and custom attachments.

- Longer lifespan with a more robust design, making it a better long-term investment.

Choosing the Right Crane Based on Price and Needs

If you're working with light to medium loads and need a budget-friendly option, a single girder crane is the best choice. However, if your operations involve heavy-duty lifting, frequent use, or large workspaces, a double girder crane is worth the higher investment.

Since market conditions affect pricing, it's best to request an updated quote based on your specific requirements.

5 Ton, 10 Ton, 16 Ton, and 20 Ton Single Girder vs. Double GirderTop Running Cranes

These four lifting capacities cover a wide range of industrial applications, from light-duty handling to heavy-duty material transport. Each tonnage represents a different level of cost, performance, and structural requirements. Understanding these differences helps buyers make informed decisions based on budget, workspace constraints, and long-term operational needs.

Key Reasons for Comparison:

- Covers different lifting needs – From small workshops to large-scale industrial operations.

- Shows cost differences – Helps buyers see how crane price scales with capacity.

- Reveals performance variations – Different tonnages affect speed, durability, and efficiency.

- Guides selection – Helps businesses choose the best balance between cost and functionality.

5 Ton Top Running Overhead Crane

A 5 Ton top running overhead crane is ideal for light-duty lifting. It is commonly used in small workshops, warehouses, and assembly lines where frequent but moderate lifting is required.

Advantages of a 5 Ton Crane:

- Lower structural requirements – Reduces installation costs.

- Affordable investment – Costs less than higher Tonnage models.

- Easier maintenance – Fewer components mean reduced service needs.

- Efficient for daily operations – Provides enough capacity for general lifting tasks.

5 Ton Top Running Single Girder vs. 5 Ton Top Running Double Girder: Price Comparison

When choosing between a 5 Ton top running single girder crane and a 5 Ton top running double girder crane, the price differences are significant. Let's look at the price comparison based on the given price table and when to choose each design.

Price Comparison:

| Capacity | Span (m) | Lifting Height (m) | Power Supply (V) | Price (USD) |

|---|---|---|---|---|

| Single Girder | 7.5~31.5 | 6~30 | 220-480/3/50 | $3,000~41,500 |

| Double Girder | 7.5~31.5 | 6~30 | 220-480/3/50 | $5,800~72,000 |

When to Choose a 5 Ton Single Girder Crane:

- Lower ceiling height – The single girder crane is ideal when space is limited, as it takes up less vertical room. This makes it perfect for workshops or warehouses with lower ceiling height restrictions.

- Cost efficiency – A single girder crane uses fewer materials and has a simpler design, making it more affordable. The price range for a 5 Ton single girder crane is between $3,000 and $41,500, which is significantly lower than the double girder version.

- Lighter structural load – The simpler design of a single girder crane requires a less reinforced building structure, reducing installation costs.

- General-purpose lifting – The 5 Ton single girder crane is best for light-duty operations in small workshops, warehouses, and light manufacturing environments.

When to Choose a 5 Ton Double Girder Crane:

- Need for better hook height – A double girder crane offers more lifting clearance because the hoist runs on top of the girders. This is useful if you need to lift items to higher elevations.

- Future upgrades – The double girder crane supports additional features like walkways, operator cabs, and automation. If you plan to expand your operations in the future, the double girder crane is a more versatile choice.

- Stronger structure – A double girder crane is more durable and suitable for high-frequency lifting. It is built to withstand continuous and heavy-duty operations.

- Better for long spans – If your facility requires longer bridge lengths, the double girder crane offers better support and performance, making it a more efficient choice for larger workshops or plants.

Conclusion:

- 5 Ton single girder crane: A more cost-effective option, ideal for businesses with limited space and moderate lifting needs. It is the perfect choice for small to medium-sized operations where cost savings are a priority.

- 5 Ton double girder crane: The better investment if you need higher lifting clearance, greater durability, and future flexibility. Although the price is higher (ranging from $5,800 to $72,000), the double girder crane is better suited for heavy-duty operations and larger, more complex facilities.

For businesses that need to save on costs and have space constraints, the single girder crane is often the better choice. However, if you anticipate the need for longer spans, higher lifting capacity, and future upgrades, the double girder crane will provide greater value in the long term.

10 Ton Top Running Single Girder vs. 10 Ton Top Running Double Girder: Price Comparison

When choosing between a 10 Ton top running single girder crane and a 10 Ton top running double girder crane, the price differences are notable. Let's take a closer look at the price comparison and when to choose each crane design.

Price Comparison:

| Capacity | Span (m) | Lifting Height (m) | Power Supply (V) | Price (USD) |

|---|---|---|---|---|

| Single Girder | 7.5~31.5 | 6~30 | 220-480/3/50 | $4,000~45,000 |

| Double Girder | 7.5~31.5 | 6~30 | 220-480/3/50 | $6,500~79,000 |

When to Choose a 10 Ton Single Girder Crane:

- Cost-effective solution – The single girder crane is a more affordable option compared to the double girder version, with a price range of $4,000 to $45,000. If your business has a moderate budget, the single girder crane is a better financial choice.

- Compact design – The single girder crane takes up less vertical space, making it ideal for workshops with height restrictions. If you need to maximize headroom in a confined space, the single girder design is better.

- Simpler installation and maintenance – With fewer components, a single girder crane is easier and quicker to install, and it requires less maintenance. This can reduce downtime and improve operational efficiency.

- Good for moderate lifting applications – Suitable for general material handling, warehouse tasks, and assembly line operations, the 10 Ton single girder crane meets the needs of medium-duty lifting without compromising on performance.

When to Choose a 10 Ton Double Girder Crane:

- Higher lifting height – The double girder crane offers better hook height because the hoist runs on top of the girders. This is important if you need to lift items to greater heights for larger operations or facilities.

- More demanding tasks – The stronger design of a double girder crane can handle more continuous or heavy-duty lifting, making it the ideal choice for high-frequency lifting operations in manufacturing plants and larger warehouses.

- Longer spans and greater load distribution – The double girder crane is better suited for handling longer spans and distributed loads. This is essential for businesses with larger facilities that require cranes to cover significant distances or handle larger, more diverse loads.

- Future-proofing – A double girder crane offers more flexibility for future upgrades such as automation, walkways, and service platforms. If you expect to expand your operations or incorporate more advanced features down the road, the double girder crane is a better long-term investment.

Conclusion:

- 10 Ton single girder crane: The most cost-effective option for businesses with space limitations and a moderate budget. The price range of $4,000 to $45,000 makes it an affordable solution for medium-duty lifting needs in workshops, warehouses, and general material handling tasks.

- 10 Ton double girder crane: While more expensive (ranging from $6,500 to $79,000), the double girder crane provides higher lifting heights, greater durability, and the ability to handle heavier, distributed loads. It's the best choice for businesses needing heavy-duty lifting, longer spans, and future upgrades.

For businesses focused on cost-efficiency and space-saving, the 10 Ton single girder crane is the way to go. However, if you require more lifting capacity, greater durability, and expect to expand or upgrade your operations, the 10 Ton double girder crane offers a better return on investment over time.

16 Ton Top Running Single Girder vs. 16 Ton Top Running Double Girder: Price Comparison

When choosing between a 16 Ton top running single girder crane and a 16 Ton top running double girder crane, the price differences and application needs vary. Here's a breakdown of the price comparison and when each design might be the best option for your operations.

Price Comparison:

| Capacity | Span (m) | Lifting Height (m) | Power Supply (V) | Price (USD) |

|---|---|---|---|---|

| Single Girder | 7.5~31.5 | 6~30 | 220-480/3/50 | $5,000~48,000 |

| Double Girder | 7.5~31.5 | 6~30 | 220-480/3/50 | $7,800~86,000 |

When to Choose a 16 Ton Single Girder Crane:

- Cost-efficient solution – The single girder crane offers a more affordable option compared to the double girder crane, priced between $5,000 and $48,000. For businesses with a moderate budget, the single girder design is the best choice.

- Space-saving design – If your workshop or facility has limited ceiling height, the single girder crane is a space-saving option. The hoist runs on the bottom flange of the girder, meaning it takes up less vertical space and allows for more headroom.

- Simpler installation and lower maintenance costs – The single girder crane features fewer components, which makes it easier and quicker to install, reducing downtime. It also requires less maintenance, which saves on long-term costs.

- Good for medium-duty applications – The 16 Ton single girder crane is a great choice for medium to heavy-duty lifting in factories, warehouses, and general manufacturing applications. It can handle most industrial material handling tasks without needing the additional strength and cost of a double girder design.

When to Choose a 16 Ton Double Girder Crane:

- Higher lifting height – If your operations require greater lifting clearance, a double girder crane will provide a higher hook height. The hoist runs on top of the two girders, offering better vertical lifting space, making it ideal for industries with large machinery or heavy loads.

- Heavy-duty operations – The double girder design is stronger and more durable than the single girder option, making it suitable for continuous, high-frequency lifting. This crane can handle heavier loads over longer periods with less wear and tear, making it ideal for steel mills, shipyards, or large fabrication plants.

- Longer spans and distributed loads – If your facility requires a longer span (distance between supports), the double girder crane can handle larger spans and heavier, distributed loads. This makes it an excellent choice for larger industrial environments that need cranes to cover wide areas or move large items.

- Future upgrades – The double girder crane is better suited for future upgrades like automation, walkways, or maintenance platforms. This design is more adaptable and can accommodate expansion or advanced features as your operations grow.

Conclusion:

- 16 Ton single girder crane: The most cost-effective solution for businesses needing medium-duty lifting with limited space. With a price range of $5,000 to $48,000, it provides great value for general material handling and assembly line tasks in environments that don't require high lifting heights or heavy-duty operation.

- 16 Ton double girder crane: Although priced between $7,800 and $86,000, the double girder crane offers superior lifting height, longer spans, and greater durability. It's ideal for heavy-duty lifting, high-frequency operations, and industries where future-proofing is important.

For businesses that need cost savings, space efficiency, and are focused on general industrial lifting, the 16 Ton single girder crane is the right choice. However, if you require higher lifting heights, larger spans, and more durable operation over time, the 16 Ton double girder crane is the better option for long-term efficiency and flexibility.

20 Ton Top Running Single Girder vs. 20 Ton Top Running Double Girder: Price Comparison

When deciding between a 20 Ton top running single girder crane and a 20 Ton top running double girder crane, the cost difference is a significant consideration. Here's a detailed look at the price comparison and when each design is the best choice for your operations.

Price Comparison:

| Capacity | Span (m) | Lifting Height (m) | Power Supply (V) | Price (USD) |

|---|---|---|---|---|

| Single Girder | 7.5~31.5 | 6~30 | 220-480/3/50 | $6,000~50,000 |

| Double Girder | 7.5~31.5 | 6~30 | 220-480/3/50 | $8,600~95,000 |

When to Choose a 20 Ton Single Girder Crane:

- Cost-effective for moderate lifting – The 20 Ton single girder crane is a more affordable option, priced between $6,000 and $50,000. If you're on a moderate budget, this crane offers a great balance of cost and performance for businesses that need heavy lifting but with lower initial investment.

- Ideal for limited space – If your workshop or facility has height constraints, the single girder crane design works well since it takes up less vertical space. The hoist runs on the bottom flange of the crane, giving you more usable headroom and saving space in workshops with lower ceilings.

- Simpler design and installation – The single girder crane features a simpler design with fewer components, making it easier to install and maintain. This results in lower downtime and reduced maintenance costs, which can save you money over time.

- General lifting applications – Suitable for general heavy lifting tasks in environments like warehouses, manufacturing, and assembly lines, the 20 Ton single girder crane is a cost-effective solution for industries with medium-duty lifting needs.

When to Choose a 20 Ton Double Girder Crane:

- Higher lifting clearance – If your operations demand a higher lifting height, the double girder crane provides more vertical lifting space. The hoist runs above the girders, allowing for a higher hook height compared to the single girder option. This makes it ideal for environments that need to lift heavy loads above machinery or large equipment.

- Heavy-duty operations – The double girder design offers better durability for high-frequency lifting. It is perfect for environments where the crane will be used continuously or under heavy loads, such as steel mills, foundries, or power plants.

- Longer spans and heavy load distribution – The double girder crane is designed to handle longer spans and distribute heavy loads more evenly. If your facility requires a crane that can cover wider areas or handle large, heavy items, the double girder crane is the better choice.

- Future expansion potential – The double girder crane is built to accommodate future upgrades like automation, walkways, and maintenance platforms. If you anticipate needing to add more features to the crane as your operations grow, the double girder design offers better long-term flexibility.

Conclusion:

- 20 Ton single girder crane: The best option for businesses needing a cost-effective solution for heavy lifting in facilities with space limitations. Priced between $6,000 and $50,000, this crane is ideal for general heavy lifting applications with moderate lifting needs.

- 20 Ton double girder crane: With a price range of $8,600 to $95,000, the double girder crane is better suited for high-frequency operations, long spans, and future-proofing. It offers superior durability, higher lifting clearance, and can support additional features, making it the right choice for industries with continuous heavy lifting demands.

For businesses seeking cost efficiency and space-saving benefits, the 20 Ton single girder crane is the most suitable. However, if you need higher lifting height, greater durability, and longer spans, the 20 Ton double girder crane provides better long-term performance and future expansion potential.

Here's a simplified comparison table for the 5 Ton, 10 Ton, 16 Ton, and 20 Ton top running overhead cranes, comparing both single girder and double girder designs:

| Capacity | Crane Design | Price Range (USD) | Span (m) | Lifting Height (m) | Power Supply (V) | Advantages | Best For |

|---|---|---|---|---|---|---|---|

| 5 Ton | Single Girder | $3,000 - $41,500 | 7.5 - 31.5 | 6 - 30 | 220-480/3/50 | Cost-effective, space-saving, easy to install | Small workshops, warehouses, light tasks |

| Double Girder | $5,800 - $72,000 | 7.5 - 31.5 | 6 - 30 | 220-480/3/50 | Higher lifting height, stronger, better for long spans | Heavy-duty tasks, future upgrades | |

| 10 Ton | Single Girder | $4,000 - $45,000 | 7.5 - 31.5 | 6 - 30 | 220-480/3/50 | Affordable, easy setup, good for moderate lifting | Manufacturing, automotive, material handling |

| Double Girder | $6,500 - $79,000 | 7.5 - 31.5 | 6 - 30 | 220-480/3/50 | Stronger, better for high loads, ideal for bigger spaces | Heavy-duty work, long spans | |

| 16 Ton | Single Girder | $5,000 - $48,000 | 7.5 - 31.5 | 6 - 30 | 220-480/3/50 | Cost-effective for heavy-duty tasks, easy to install | Steel mills, large workshops, automotive |

| Double Girder | $7,800 - $86,000 | 7.5 - 31.5 | 6 - 30 | 220-480/3/50 | Stronger, better for continuous lifting, longer spans | Steel plants, shipbuilding | |

| 20 Ton | Single Girder | $6,000 - $50,000 | 7.5 - 31.5 | 6 - 30 | 220-480/3/50 | More affordable for heavy lifting, simple design | Heavy-duty lifting, industrial work |

| Double Girder | $8,600 - $95,000 | 7.5 - 31.5 | 6 - 30 | 220-480/3/50 | Higher lifting capacity, better for long spans and tough tasks | Power plants, foundries, large operations |

Key Points:

Top Running Single Girder Cranes:

- Cheaper and space-efficient.

- Best for light to medium-duty tasks.

- Works well in places with lower ceiling height or limited space.

Top Running Double Girder Cranes:

- Stronger and capable of handling heavier loads.

- Better lifting height and ideal for larger spans.

- Great for heavy-duty, high-frequency work, and facilities that need future upgrades (like automation).

Best Uses for Each Tonnage:

- 5 Ton Top Running Cranes: Perfect for small workshops, warehouses, and light tasks.

- 10 Ton Top Running Cranes: Best for manufacturing plants, automotive, and medium lifting tasks.

- 16 Ton Top Running Cranes: Designed for heavy-duty lifting, steel mills, and large-scale manufacturing.

- 20 Ton Top Running Cranes: Ideal for extreme-duty lifting, used in power plants, foundries, and large operations.

This table breaks down the key features and best uses of each crane size in an easy-to-understand way to help you make the right choice for your lifting needs!

Which One Saves You More Money? Cost vs. Long-Term Benefits

When deciding between a single girder and double girder top running overhead crane, the decision should not only focus on the initial purchase price. While the upfront cost is important, it's crucial to also consider long-term benefits such as maintenance, operational efficiency, and future upgrades. Here's a breakdown to help you understand which option offers the best value for your business.

When to Choose a Top Running Single Girder Crane

Lower purchase cost and installation expenses:

- A single girder crane is more affordable upfront, making it a cost-effective option for businesses on a budget.

- Installation costs are lower because of the simpler design and fewer components.

Ideal for light-duty, low-frequency use:

- If your operations involve lighter loads and less frequent lifting, a single girder crane is the ideal solution.

- It is well-suited for applications that do not require continuous or heavy-duty lifting.

Best for small workshops and warehouses with space limitations:

- Single girder cranes take up less vertical space, making them perfect for locations with low ceilings or limited height.

- They are a good choice for small workshops, warehouses, and other environments where space is constrained.

When you should choose it:

- A single girder crane is the best option for small-scale operations with limited budgets and low-volume lifting needs.

When to Choose a Top Running Double Girder Crane

Handles heavy loads and high-frequency operations:

- Double girder cranes are ideal for operations that involve heavy lifting or frequent use. They are built to handle larger and heavier loads.

- They can handle longer duty cycles, making them suitable for continuous operations.

Provides better lifting height and long-term efficiency:

- The hoist runs on top of the girders, allowing for higher vertical clearance and more lifting space.

- Over time, this extra lifting height can increase efficiency and reduce downtime, making it a more efficient solution for lifting larger items.

Recommended for large-scale production plants and steel mills:

- Double girder cranes are perfect for high-capacity environments like steel mills, manufacturing plants, and distribution centers.

- They are designed for continuous, high-frequency operations and are built to last.

When you should choose it:

- If your business involves heavy-duty or high-volume lifting, or if you're planning for future upgrades and automation, a double girder crane is a worthwhile investment.

Other Cost Considerations

Installation and maintenance costs:

- Single girder cranes have a lower installation cost because of their simpler design and fewer components.

- Maintenance costs are also lower for single girder cranes. However, double girder cranes, while having higher installation costs, tend to be more durable and require less maintenance over time.

Energy consumption:

- Single girder cranes are less expensive to operate initially, but double girder cranes can be more energy-efficient, especially when handling heavy loads or working for longer periods.

- For businesses that require continuous lifting or heavy-duty tasks, a double girder crane can help save on energy costs in the long run.

Productivity gains vs. upfront investment:

- While the initial cost of a double girder crane is higher, it often offers better long-term productivity and efficiency.

- A single girder crane may be cheaper to purchase, but it could limit your lifting capacity and potential for future growth.

Summary of cost considerations:

- The single girder crane offers a lower initial investment, easier installation, and lower maintenance costs. However, it is best suited for light-duty applications and businesses that do not need heavy lifting.

- The double girder crane has a higher initial cost but offers greater long-term value, particularly for heavy-duty applications and businesses with higher lifting demands.

Choosing between a single girder and double girder crane depends on the specific needs of your business. If you have a limited budget and require light-duty lifting, the single girder crane is a great choice. However, for heavy-duty and high-frequency operations, the double girder crane provides better long-term value despite its higher upfront cost. Consider your lifting capacity, usage frequency, and potential for future growth when making your decision.

How to Select the Right Overhead Crane?

Selecting the right overhead crane is crucial for ensuring it meets your operational needs and delivers the best performance over time. To get an accurate price and ensure the crane is suitable for your specific requirements, you'll need to provide the following details to the crane manufacturer or supplier:

Lifting Capacity (5T, 10T, 16T, 20T)

- Choose a crane based on the weight of the materials you need to lift.

- For light-duty lifting, a 5 Ton crane might suffice, while a 20 Ton crane is more suited for heavy-duty tasks.

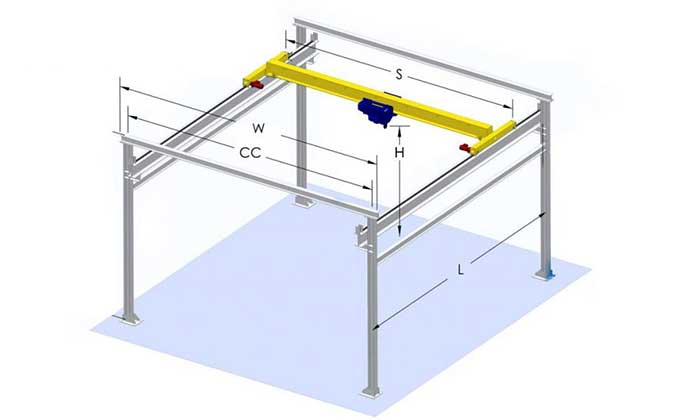

Span (S) – Distance Between Runway Beams

- The span refers to the width between the two supporting beams on which the crane moves.

- Accurate span measurement ensures the crane fits properly within your facility and meets operational requirements.

Lifting Height (H) – Required Vertical Lifting Distance

- This is the height from the crane's hook to the highest point it needs to lift materials.

- Adequate lifting height is essential to avoid limitations in lifting space and to maximize crane performance.

Power Supply (e.g., 380V 50Hz 3Phase)

- Ensure the crane's power supply matches your facility's electrical system.

- Specify the voltage, phase, and frequency to avoid compatibility issues during installation.

Crane Travel Length (L) – Distance the Crane Needs to Cover

- The travel length is how far the crane will need to move across the facility.

- Make sure the crane is sized to cover the required distance within your workshop or warehouse.

Working Conditions

- Consider where the crane will be used: indoors or outdoors.

- Some environments, like high-temperature areas or explosion-prone spaces, may require specialized cranes (e.g., explosion-proof or heat-resistant cranes).

Operating Hours Per Day – Determines Duty Classification

- The number of hours the crane will be in use each day helps determine its duty cycle (e.g., light, medium, or heavy-duty).

- Frequent use demands a more robust crane with higher durability.

Rails & Accessories

- If you need crane rails, ensure they are included in the overall crane design.

- Other accessories might include control systems, hook attachments, and lifting devices.

Customization Needs

- Consider whether you need additional features, such as remote controls, automation systems, or enhanced safety measures.

- Customizations can improve safety, ease of use, and efficiency, but may add to the cost.

By providing these details, you can ensure you select the most appropriate crane for your needs while receiving an accurate quote. Whether it's for light-duty tasks in a small workshop or heavy-duty applications in large industrial plants, getting the right crane will improve productivity, safety, and long-term performance.

Get Your Custom Top Running Overhead Crane Quote Today

If you're ready to get the best price for your custom top running overhead crane, contact us today. We offer tailored solutions based on your specific needs, ensuring that you get the most suitable crane for your operations.

How to Get Your Quote:

- Provide us with the details of your requirements, including lifting capacity, span, lifting height, power supply, and any customization needs.

- Our team will review your specifications and design a crane solution that fits perfectly within your facility.

We understand that every business has unique needs, and we are here to help you make an informed decision. Reach out now for a personalized quote and start optimizing your material handling operations today!

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch