All You Should To Know When Asking for Overhead Crane Prices

What you need & want to know when seeking overhead crane prices, main parameters, costs, terms & others that are essential when requesting for quotation.

Category: Overhead Crane Prices

Your Trusted Overhead Crane Manufacturer & Supplier

All You Should To Know When Asking for Overhead Crane Prices

What you need & want to know when seeking overhead crane prices, main parameters, costs, terms & others that are essential when requesting for quotation.

An overhead crane is a type of machine used for lifting and moving heavy objects within a facility. Unlike traditional floor-based equipment, overhead cranes are mounted on elevated runways or tracks, allowing them to traverse large areas while carrying loads. Equipped with a hoist and trolley system, overhead cranes can lift, lower, and horizontally transport materials with remarkable accuracy and efficiency. Whether it's loading raw materials onto assembly lines or moving finished products for storage or shipment, overhead cranes excel in handling a wide range of tasks with ease.

The significance of overhead cranes in industrial settings cannot be overstated. These mechanical marvels serve as the backbone of material handling operations, facilitating the movement of goods and materials with unparalleled efficiency. By lifting heavy loads off the ground and transporting them overhead, overhead cranes minimize floor clutter, maximize workspace utilization, and streamline workflow processes. This not only enhances productivity but also reduces the risk of accidents and injuries associated with manual material handling.

Overhead cranes come in various configurations to suit different applications and environments. The two primary types of overhead cranes are single girder and double girder cranes. Single girder cranes feature a single bridge beam supported by end trucks, making them ideal for light to moderate lifting tasks. Double girder cranes, on the other hand, utilize two parallel bridge beams for increased load capacity and stability, making them suitable for heavy-duty applications.

Within these categories, overhead cranes can be further customized with additional features such as automation, specialized lifting attachments, and safety enhancements. By tailoring the design to specific operational requirements, businesses can maximize the utility and effectiveness of their overhead crane systems.

What Affect Overhead Crane Price

As for overhead cranes, pricing is influenced by a multitude of factors that must be carefully considered to ensure an accurate estimation of costs. Whether you're in the market for a single girder or double girder overhead crane, understanding the elements that contribute to pricing is essential for making informed decisions. Let's delve deeper into the intricacies of overhead crane pricing and explore the factors that influence it:

Factors Influencing Pricing

When evaluating the cost of an overhead crane, whether it's a single girder, double girder, or underhung bridge configuration, several key factors come into play:

- Crane Designs and Configurations: Different crane designs and configurations, such as single girder, double girder, or underhung bridge cranes, have varying material and manufacturing costs, which directly influence their pricing. Single Girder Overhead Crane Price & Double Girder Overhead Crane Price, Underhung Bridge Crane Price

- Capacity: Perhaps the most significant factor impacting overhead crane pricing is its lifting capacity. Higher capacity cranes require more robust components, such as larger beams and stronger hoists, driving up manufacturing and installation costs.

- Span: The span of an overhead crane refers to the distance between the runways or tracks on which it travels. Longer spans require additional structural support and specialized engineering, contributing to higher overall costs.

- Height: The height at which an overhead crane operates is another crucial consideration. Cranes designed for taller lifting heights necessitate taller support structures and longer hoist cables, adding to the complexity and cost of the system.

- Duty Class: Duty class categorizes overhead cranes based on their intended usage and workload capacity. Cranes designed for heavier-duty applications typically feature more robust construction and components, resulting in higher upfront costs.

- Smart Features: The level of automation integrated into an overhead crane system can significantly impact its price. Features such as automated load positioning, collision avoidance systems, and remote operation capabilities add value but also increase the overall cost of the crane.

Navigating the realm of overhead crane pricing requires a keen understanding of these factors and their interplay. By carefully assessing your specific lifting requirements and considering the implications of each specification, you can make informed decisions that align with your budget and operational needs. Whether you opt for a single girder, double girder, or underhung bridge configuration, ensuring that your overhead crane meets your performance criteria while remaining cost-effective is key to maximizing its value and utility.

Pricing Variations Across Different Capacities

When it comes to overhead cranes, capacity plays a pivotal role not only in determining the crane's lifting capabilities but also in influencing its price. From smaller-tonnage cranes suited for lighter loads to heavy-duty behemoths capable of hoisting massive weights, each capacity comes with its own price tag. Let's explore the pricing variations across different capacities and understand how they impact your purchasing decisions:

- 1 Ton Overhead Crane Price: Ideal for light-duty applications and smaller workspaces, 1-ton overhead cranes are compact and cost-effective. Their relatively lower capacity results in more affordable pricing compared to larger-tonnage cranes.

- 2 Ton Overhead Crane Price: Slightly more robust than their 1-ton counterparts, 2-ton overhead cranes strike a balance between capacity and affordability. They offer increased lifting capabilities without significantly higher price tags.

- 3 Ton Overhead Crane Price: As the lifting capacity increases, so does the price of the overhead crane. 3-ton cranes are versatile enough to handle a wide range of loads while still remaining relatively budget-friendly compared to larger models.

- 5 Ton Overhead Crane Price: 5-ton overhead cranes are popular choices for medium-duty lifting tasks in various industries. Their increased capacity comes with a higher price point, reflecting the additional engineering and components required to support heavier loads.

- 10 Ton Overhead Crane Price: Stepping into the realm of heavy-duty lifting, 10-ton overhead cranes offer substantial capacity for demanding applications. However, their increased size and complexity contribute to higher upfront costs.

- 20 Ton Overhead Crane Price: Designed for handling substantial loads in industrial environments, 20-ton overhead cranes command a premium price due to their robust construction and specialized components.

- 40 Ton Overhead Crane Price: Moving into the realm of high-capacity lifting, 40-ton overhead cranes are engineered to tackle the most challenging material handling tasks. Their hefty price tags reflect the advanced engineering and customization required to meet stringent performance requirements.

- 50 Ton Overhead Crane Price: At the pinnacle of lifting capacity, 50-ton overhead cranes are reserved for the most demanding applications where strength and reliability are paramount. Their substantial price reflects the unparalleled performance and capabilities they offer.

These pricing variations empowers you to make informed decisions based on your specific lifting requirements and budget constraints. Whether you're in need of a nimble 1-ton crane or a mighty 50-ton behemoth, assessing the trade-offs between capacity, performance, and price ensures that you invest in the overhead crane that best suits your operational needs.

What to Know Before Asking for Overhead Crane Prices

Essential Preparations for Inquiring About Overhead Crane Prices

Before you start soliciting quotes for overhead cranes, it's crucial to lay the groundwork by thoroughly understanding your operational needs, evaluating space constraints, assessing long-term cost implications, and ensuring compliance with regulatory standards. This preliminary groundwork will arm you with the necessary knowledge to navigate the procurement process with confidence and make informed decisions. Let's delve deeper into each aspect:

Determine Operational Needs

- Lifting Requirements: Evaluate the types of loads you'll be lifting, their weights, and how frequently they need to be moved. This will help determine the crane's capacity and configuration required to meet your operational demands.

- Usage Frequency: Consider how often the crane will be in use and whether it will be subjected to continuous or intermittent operation. This will influence factors such as duty cycle and maintenance requirements.

- Environmental Conditions: Assess the environmental conditions in which the crane will operate, including temperature, humidity, and exposure to corrosive substances. Choose equipment that is suitable for the conditions to ensure optimal performance and longevity.

Consider Space and Installation Requirements

- Available Space: Measure the available space in your facility, including ceiling height, floor layout, and any obstructions that may impact crane installation and operation. Ensure that the crane's dimensions and clearances align with your spatial constraints.

- Runway Configuration: Determine the layout and configuration of the crane's runway system, considering factors such as runway length, support structures, and alignment with workflow processes.

- Power and Infrastructure: Assess the availability of power sources and infrastructure required for crane operation, including electrical wiring, runway support beams, and anchoring points.

Assess Long-Term Cost Considerations

- Total Cost of Ownership: Look beyond the upfront purchase price and consider the total cost of ownership over the crane's lifespan, including maintenance, repairs, and potential upgrades.

- Maintenance Requirements: Evaluate the maintenance needs of the crane, including routine inspections, lubrication, and component replacements. Factor these costs into your long-term budget planning.

- Lifecycle Analysis: Conduct a lifecycle analysis to assess the economic viability of different crane options over their operational lifespan. Consider factors such as energy efficiency, productivity gains, and potential cost savings.

Research Regulatory Requirements and Safety Standards

- Regulatory Compliance: Familiarize yourself with local regulations and industry standards governing overhead crane operation, including safety, inspection, and certification requirements.

- Safety Standards: Ensure that the crane you select complies with relevant safety standards and features built-in safety mechanisms to protect against accidents and injuries.

By diligently considering these factors before seeking overhead crane prices, you'll be better equipped to make informed decisions that align with your operational needs, budget constraints, and regulatory obligations. This proactive approach will set the stage for a successful procurement process and ensure that you invest in the right overhead crane solution for your business.

Key Considerations When Asking for Overhead Crane Prices

When it comes to procuring an overhead crane, the process extends far beyond simply comparing price tags. It's essential to delve into various aspects of the purchase to ensure you're making an informed decision that aligns with your needs and budget. Here are some key considerations to keep in mind when asking for overhead crane prices:

Requesting Quotes from Multiple Suppliers

- Supplier Evaluation: Cast a wide net by requesting quotes from multiple suppliers. This allows you to compare offerings, assess pricing competitiveness, and evaluate the reputation and reliability of each supplier.

- Comparative Analysis: Analyze the quotes received from different suppliers to identify any significant variations in pricing, terms, or included services. This comparative analysis will help you identify the most cost-effective solution without compromising on quality or service.

- Negotiation Opportunities: Use the information gathered from multiple quotes as leverage for negotiation. Engage in constructive discussions with suppliers to seek favorable pricing terms, additional value-added services, or potential discounts.

Understanding Pricing Components: Equipment, Installation, and Maintenance

- Breakdown of Costs: Look beyond the total price and seek a breakdown of costs for equipment, installation, and maintenance services. Understanding the individual components of pricing allows you to assess the value proposition and identify any areas where cost savings may be possible.

- Installation Charges: Inquire about installation charges, including site preparation, crane assembly, electrical wiring, and any additional services required to commission the crane. Clarify whether installation costs are included in the initial quote or billed separately.

- Maintenance Packages: Explore maintenance packages offered by suppliers, including routine inspections, repairs, and spare parts availability. Assess the long-term maintenance requirements and associated costs to ensure they align with your operational budget.

Inquiring About Customization Options and Additional Features

- Tailored Solutions: Discuss customization options with suppliers to tailor the crane system to your specific operational requirements. Inquire about customizable features such as lifting attachments, control systems, and safety enhancements to optimize crane performance.

- Additional Features: Explore additional features or advanced technologies that may enhance the functionality, efficiency, or safety of the overhead crane system. Consider features such as remote monitoring, anti-collision systems, or energy-saving technologies that offer long-term benefits.

Clarifying Warranty and Support Services

- Warranty Coverage: Seek clarity on the warranty coverage provided for the overhead crane system, including duration, scope, and terms. Understand what is covered under the warranty and any conditions or exclusions that may apply.

- Support Services: Inquire about post-sales support services offered by the supplier, including technical support, training programs, and emergency assistance. Clarify the availability of support resources and response times to ensure prompt resolution of any issues that may arise.

By carefully considering these key factors when asking for overhead crane prices, you'll gain a comprehensive understanding of the investment you're about to make and ensure that you select the right supplier and solution for your operational needs. This proactive approach will help you navigate the procurement process with confidence and secure a cost-effective overhead crane solution that delivers value and reliability for years to come.

Overhead Crane Installation Costs

Installing an overhead crane is a pivotal step in optimizing your material handling operations, but it's essential to understand the associated installation costs and considerations. From site preparation to regulatory compliance, each aspect of the installation process plays a crucial role in determining the overall expenses. Let's delve into the factors affecting installation costs and explore your options for a successful installation:

Factors Affecting Installation Costs

- Site Preparation: Before installing an overhead crane, the installation site must be adequately prepared. This may involve tasks such as leveling the ground, reinforcing the floor, or making structural modifications to accommodate the crane system.

- Crane Assembly: The assembly of the crane itself is a labor-intensive process that requires skilled personnel and specialized equipment. Erecting the bridge beams, installing the runway system, and assembling the hoist and trolley components are all critical aspects of crane assembly.

- Electrical Wiring: Proper electrical wiring is essential for the safe and efficient operation of the overhead crane. This includes running power lines to the crane, installing control panels, and ensuring compliance with electrical codes and standards.

- Permitting and Regulations: Obtaining the necessary permits and complying with regulatory requirements is a fundamental aspect of crane installation. This may involve securing permits for structural modifications, electrical work, or crane operation, as well as adhering to safety regulations and building codes. Check more on What Affect Overhead Crane Price and The Price Range of Overhead Cranes for Your Reference.

Estimating Installation Expenses

Estimating installation expenses requires a detailed assessment of the project scope and requirements. Consider the following factors:

- Labor Costs: Labor costs for crane installation can vary depending on the complexity of the project and the experience level of the installation crew. Obtain quotes from reputable installation contractors to estimate labor expenses accurately.

- Material Costs: In addition to labor, material costs such as steel beams, bolts, electrical components, and structural supports contribute to installation expenses. Factor in the cost of materials when estimating installation costs.

DIY vs. Professional Installation

Deciding between DIY and professional installation depends on various factors, including your expertise, resources, and the complexity of the project. Consider the following:

- DIY Installation: While DIY installation may seem cost-effective, it requires technical expertise, proper tools, and adherence to safety protocols. DIY installation is more feasible for smaller, less complex crane systems.

- Professional Installation: Hiring a professional installation contractor ensures that the crane system is installed correctly, safely, and in compliance with regulations. Professional installers have the expertise, experience, and resources to handle complex installations efficiently.

By understanding these factors and weighing your options for installation, you can make informed decisions that align with your budget, timeline, and project requirements. Whether opting for DIY installation or professional assistance, prioritizing safety and compliance ensures a successful overhead crane installation that meets your operational needs.

Essential Information for Requesting Overhead Crane Prices

When inquiring about the price of an overhead crane, it's crucial to provide detailed and specific information to ensure you receive an accurate quote. Here's a breakdown of the main pieces of information you should provide:

- Crane Type: Specify the type of overhead crane you need, whether it's a single girder, double girder, gantry crane, jib crane, or any other configuration suited to your requirements.

- Capacity: Indicate the maximum weight the crane needs to lift, measured in tons. Whether it's 5 tons, 10 tons, 20 tons, or more, providing the exact capacity requirement is essential for accurate pricing.

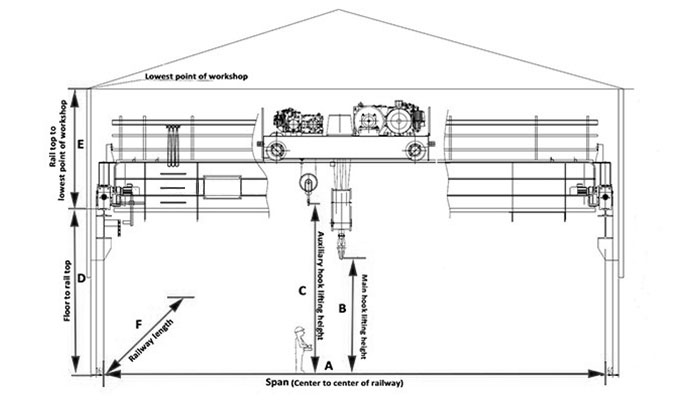

- Span: Provide the span of the crane, which is the distance between the runway rails. Whether it's 10 meters, 20 meters, or a custom span, this information helps determine the crane's structural requirements and pricing.

- Lift Height: Specify the maximum height the crane needs to lift the load. Whether it's 10 meters, 15 meters, or higher, knowing the lift height ensures the crane is tailored to your vertical lifting needs.

- Duty Cycle/Class: Describe the operational requirements, including how often the crane will be used and under what conditions. Whether it's light duty, moderate duty, heavy duty, or continuous use, this information guides the selection of components and materials for the crane.

- Travel Distances: State the required travel distances for the crane, both along the runway and for the hoist trolley. Whether it's short distances or extensive travel, specifying the travel requirements ensures the crane's capabilities match your operational needs.

- Power Supply: Mention the available power supply for the crane, including voltage, phase, and frequency. Providing this information ensures compatibility with the electrical system at your facility.

- Control Method: Indicate the preferred control method for operating the crane. Whether it's pendant control, radio remote control, cabin control, or other options, specifying the control method ensures usability and safety.

- Special Requirements: Detail any additional features or specifications, such as environmental conditions (outdoor or indoor use), explosion-proof requirements, specific hook types, speed requirements, and any other customizations needed for your application.

- Installation and After-sales Service: Inquire whether the quote includes installation, commissioning, and after-sales service support. Knowing the scope of services provided ensures a smooth transition from procurement to operation.

- Site Information: Provide details about the installation site, including spatial constraints, structural support information, and accessibility for delivery and installation. Site-specific considerations are crucial for planning and executing the crane installation.

- Budget and Timeline: If applicable, mention your budget range and the timeline for when you need the crane installed and operational. Clear budget and timeline expectations help align the supplier's proposal with your project requirements.

- 1. Number of cranes : ___________

- 2. Type of crane : 3. Capacity : ___________ Kg or : ___________Lb

- 4. Span : ___________ M

- 5. Lifting height required : ___________ (Max. including pits or wells below the floor level)

- 6. Approximate length of the crane runway : ___________

- 7. Number of cranes on the runway : ___________

- 8. Name of company : __________________________________________

- 9. Person in charge : __________________________________________

- 10. Contact details : __________________________________________

By providing these details upfront, you can help the supplier give you a more precise and tailored quotation for your overhead crane needs. This comprehensive approach ensures that the proposed crane solution meets your specifications, budget, and timeline, ultimately leading to a successful procurement process and reliable crane operation.If you have any questions or needs, please check out Buyer Guide for Overhead Crane: How to Buy an Overhead Crane or leave a message down below.

Main Parameters for Requesting Overhead Crane Prices

When requesting a price for overhead cranes, specific parameters are crucial for each type to ensure accurate quotations:

Single Girder Overhead Crane Price:

Capacity

Span

Lift Height

Crane Travelling Length/ Runway Length

Crane Control: Pendant control/ Remote Control / Cabin Control

Typical Application

Special Requirements

Double Girder Overhead Crane Price:

Capacity

Span

Lift Height

Crane Travelling Length/ Runway Length

Crane Control: Pendant control/ Remote Control / Cabin Control

Typical Application

Special Requirements

Underhung Bridge Crane Price:

Capacity

Span

Overhead Bridge Crane Cantilever length if required

Lift Height

Crane Travelling Length/ Runway Length

Crane Control: Pendant control/ Remote Control

Typical Application

Special Requirements

Considerations for clearance height and any structural modifications required for installation

Freestanding Bridge Crane Price:

Capacity

Span

Lift Height

Crane Travelling Length/ Runway Length

Crane Control: Pendant control/ Remote Control

Typical Application

Special Requirements

Installation: Cost of installation, including support structure construction

Space of freestanding column

Explosion Proof Overhead Crane Price:

Capacity

Span

Lift Height

Crane Travelling Length/ Runway Length

Crane Control: Pendant control/ Remote Control

Explosion-Proof Design: Specialized components and construction for hazardous environments

Customization: Any additional features or specifications needed

Installation: Cost of installation, including compliance with safety standards

Grab Bucket Overhead Crane Price:

Capacity

Span

Lift Height

Crane Travelling Length/ Runway Length

Crane Control: Pendant control/ Remote Control

Grab Bucket Design: Specifications for the grab bucket mechanism

Typical Application

Special Requirements

Magnetic Overhead Crane Price:

Capacity

Span

Lift Height

Crane Travelling Length/ Runway Length

Crane Control: Pendant control/ Remote Control

Magnetic Lifting System: Specifications for the magnetic lifting mechanism

Typical Application

Special Requirements

Cleanroom Overhead Crane Price:

Capacity

Span

Lift Height

Crane Travelling Length/ Runway Length

Crane Control: Pendant control/ Remote Control

Cleanroom Design: Features for cleanroom compatibility

Typical Application

Special Requirements

Exploring Different Pricing Terms for Overhead Crane Procurement

When considering the pricing of overhead cranes, it's vital to grasp the diverse pricing terms applicable based on delivery locations. Here's an overview of the primary types of overhead crane prices and their typical coverage:

Main Types of Overhead Crane Pricing

- Ex-Works (EXW) Price: Definition: This denotes the crane's cost at the manufacturer's premises. The buyer bears all transportation expenses from the manufacturer's location to the final destination. Coverage: Encompasses the manufacturing cost, including all components. Excludes any transportation, loading, or insurance costs.

- Free on Board (FOB) Price: Definition: This includes delivering the crane to a specified port and loading it onto a vessel. The buyer assumes responsibility for shipping, insurance, and further transportation from the departure port. Coverage: Includes manufacturing cost, transportation to the port, and loading onto the ship. Excludes sea freight, insurance, or unloading at the destination port.

- Cost and Freight (CFR) Price: Definition: Encompasses delivering the crane to the destination port. The buyer handles insurance and further transportation from the destination port. Coverage: Covers manufacturing cost, transportation to the port, loading onto the ship, and sea freight. Excludes insurance or unloading at the destination port.

- Cost, Insurance, and Freight (CIF) Price: Definition: Includes delivering the crane to the destination port and covers insurance during transit. The buyer takes responsibility for unloading and further transportation from the destination port. Coverage: Comprises manufacturing cost, transportation to the port, loading onto the ship, sea freight, and insurance. Excludes unloading at the destination port.

- Delivered at Place (DAP) Price: Definition: Involves delivery to the buyer's specified location, excluding unloading. The buyer unloads the crane at the destination. Coverage: Includes manufacturing cost, all transportation costs to the specified location, and necessary customs clearance. Excludes unloading at the destination.

- Delivered Duty Paid (DDP) Price: Definition: Incorporates delivery to the buyer's specified location, covering all customs duties and taxes. The buyer is solely responsible for unloading the crane at the destination. Coverage: Includes manufacturing cost, all transportation costs, customs duties, and taxes. Excludes unloading at the destination.

Conclusion

As you approach the procurement process for an overhead crane, it's essential to reflect on the key points discussed throughout this guide. Informed decision-making serves as the foundation for successful procurement, empowering you to select the optimal solution for your material handling needs. Let's recap the key points, emphasize the importance of informed decision-making, and explore available resources for further assistance:

- Crane operational needs is crucial for selecting the right overhead crane, considering factors such as lifting requirements, usage frequency, and environmental conditions.

- Pricing for overhead cranes is influenced by various factors, including capacity, span, duty class, and automation features. Requesting quotes from multiple suppliers and understanding pricing components is essential for budget planning.

- Installation costs for overhead cranes encompass site preparation, crane assembly, electrical wiring, and regulatory compliance. Deciding between DIY and professional installation depends on factors such as expertise and project complexity.

- Informed decision-making throughout the procurement process ensures that you invest in an overhead crane solution that meets your operational needs, budget constraints, and regulatory obligations.

In overhead crane procurement, knowledge truly is power. Informed decision-making enables you to navigate the complexities of pricing, installation, and maintenance with confidence and clarity. By understanding your operational requirements, assessing pricing components, and evaluating installation options, you can make strategic decisions that maximize the value and effectiveness of your overhead crane investment.

Resources for Further Assistance: Glossary, FAQs, References

As you embark on the journey to procure an overhead crane, it's essential to recognize that assistance and guidance are readily available. Here are some valuable resources to help deepen your understanding and make informed decisions:

Glossary: A comprehensive glossary of overhead crane terminology can be an invaluable tool for clarifying technical jargon and industry-specific terms. Whether you're new to the world of material handling or seeking to expand your knowledge, a glossary can provide clarity and facilitate effective communication with suppliers and contractors.

FAQs (Frequently Asked Questions)

Frequently Asked Questions (FAQs) serve as a valuable resource for individuals navigating the complexities of overhead crane technology, installation, operation, and maintenance. Here's a closer look at how consulting FAQs can empower you throughout the procurement process:

Overhead Crane Technology:

Question: What are the key components of an overhead crane?

Answer: Overhead cranes consist of several key components, including the bridge, hoist, trolley, runway, and controls. The bridge spans the width of the workspace and supports the hoist and trolley, which move along the runway to lift and transport loads. The controls enable operators to manipulate the crane's movements with precision.

Installation Guidance:

Question: What are the essential steps involved in installing an overhead crane?

Answer: The installation process typically begins with site preparation, including leveling the ground and ensuring adequate structural support. Next, the bridge beams and runway system are assembled and installed according to manufacturer specifications. Electrical wiring, including power supply and control panel installation, is then completed before final commissioning and testing.

Operational Best Practices:

Question: What are the recommended load capacity limits for overhead cranes?

Answer: It's essential to adhere to the manufacturer's specified load capacity limits for overhead cranes to ensure safe operation. Exceeding these limits can lead to equipment damage, accidents, or structural failure. Additionally, operators should be trained in proper lifting techniques and regularly inspect the crane for signs of wear or damage.

Maintenance Tips:

Question: How often should overhead cranes be inspected and maintained?

Answer: Regular maintenance is crucial for preserving the performance and longevity of overhead crane systems. Depending on usage and operating conditions, overhead cranes should undergo routine inspections, lubrication, and component replacements as recommended by the manufacturer or a qualified technician. Inspections should cover critical components such as wire ropes, brakes, and electrical systems.

Regulatory Compliance:

Question: What are the regulatory requirements for overhead crane operations?

Answer: Compliance with regulatory standards, such as those set forth by OSHA (Occupational Safety and Health Administration) and ANSI (American National Standards Institute), is essential for ensuring the safety and legality of overhead crane operations. This includes adherence to standards for equipment design, installation, operation, and maintenance, as well as employee training and certification requirements.

By consulting FAQs, you can gain insights into best practices, troubleshooting tips, and regulatory requirements, empowering you to navigate the procurement process with confidence. Whether you're a newcomer to the world of overhead cranes or a seasoned professional seeking to expand your knowledge, FAQs serve as a valuable resource to support your journey towards safe, efficient, and compliant overhead crane operations.

By leveraging these resources, you can enhance your understanding of overhead crane technology, terminology, and best practices, empowering you to make informed decisions throughout the procurement process. Whether you have questions about specific features, installation processes, or regulatory compliance, our team is here to provide personalized support tailored to your needs. Don't hesitate to reach out for assistance and guidance—we're committed to helping you achieve success in your overhead crane endeavors. Click to learn more on overhead crane price range for your reference. If you have any need, please feel free to contact us to check what we can do to save your crane cost.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch