Crane Span Measurement: Save Cost on Overhead, Gantry, Jib Crane

Learn how accurate crane span measurement affects cost, design, and efficiency. Practical tips to save money on overhead, gantry, and jib cranes.

Category: Overhead Crane Prices

Your Trusted Overhead Crane Manufacturer & Supplier

Crane Span Measurement: Save Cost on Overhead, Gantry, Jib Crane

Introduction

When it comes to buying a crane—whether it’s an overhead, gantry, or jib crane—one of the most important measurements you need to get right is the crane span. Simply put, the span is the distance the crane covers from one side to the other. It’s not just a number; it affects how the crane fits your space, what it can lift, and, importantly, how much it will cost.

Getting the span measurement wrong can lead to all sorts of headaches down the line. Imagine ordering a crane that’s too wide for your workshop or too narrow to cover your entire workspace. Either way, it means extra work, delays, or even having to buy a new crane altogether. For buyers, knowing exactly how to measure the span is the first step to making a smart purchase.

But why does span matter so much beyond just fitting into your facility? The length of the span directly influences the crane’s design and the amount of material used. This means longer spans usually lead to higher prices because of the extra steel, stronger motors, and more complex engineering needed. On the flip side, choosing the right span—not too big, not too small—can help you save money and still get the job done efficiently.

In this section, you’ll get a clear picture of what crane span is, why it’s critical, and how it affects both the price and performance of your crane. This foundation will help you understand the rest of the guide and make better decisions when buying your crane.

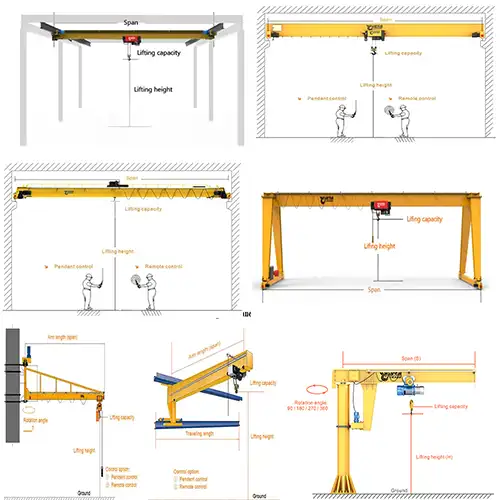

overhead crane span

gantry crane span

jib crane span

Crane Span

Before you buy a crane, it’s important to fully understand what crane span means and how it applies to different crane types. Because overhead, gantry, and jib cranes work differently, the way you measure and plan for their span will vary. Here’s a detailed yet easy-to-follow explanation.

What Is Crane Span?

- Crane span refers to the horizontal distance the crane can cover while moving or operating.

- It represents the working width of the crane—the total distance between the points where the crane moves or lifts.

- Knowing the exact span helps ensure the crane fits your workspace and covers the area you need.

Span in Different Crane Types

| Crane Type | What Span Means | How It's Measured |

|---|---|---|

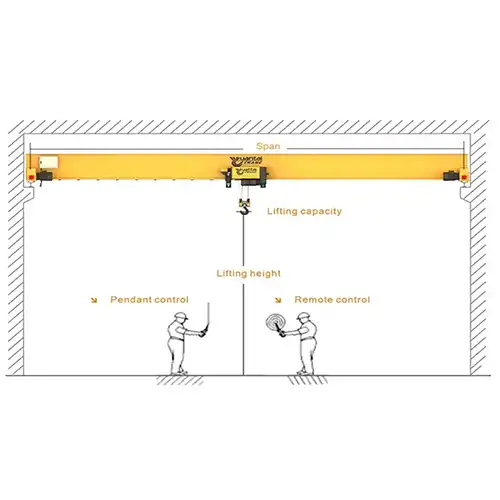

| Overhead Crane | Distance between the runway beams where the crane bridge runs | Center-to-center distance between runway beams or rails |

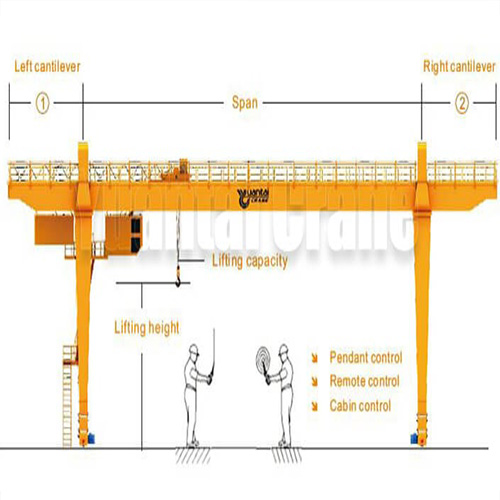

| Gantry Crane | Distance between the legs or wheels running on rails or ground | Outer clear distance between crane's legs or rails |

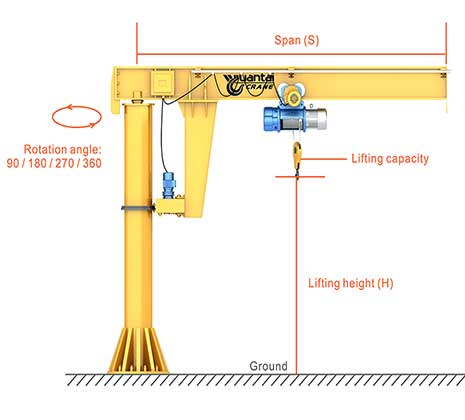

| Jib Crane | Length of the horizontal arm (jib) from the pivot point to the hoist | Measured as jib arm length or swing radius |

Common Span Measurements You Should Know

- Runway Beam Center-to-Center Distance:

This is the most critical measurement for overhead cranes. It’s the distance between the centers of the two runway beams that the crane bridge travels along. This distance determines how wide the crane’s bridge needs to be. - Inside Distance Between Rails:

Sometimes, especially depending on the crane wheel tread width, the inside clearance between the rails (the faces of the rails) is used instead of center-to-center distance. This affects wheel fit and clearance. - Jib Arm Length (Radius):

For jib cranes, the span is usually the length of the jib arm from its center of rotation (the mast or wall mount) out to the farthest point the hoist can reach. Because jib cranes rotate, this radius defines their working area. - Span Between Gantry Legs:

For gantry cranes, the span is the clear distance between the crane’s legs, which typically corresponds to the spacing of the rails or tracks the legs run on. This is important to know for site preparation and crane movement.

Key Differences in Span Considerations by Crane Type

Overhead Cranes:

- The span is fixed by the building’s width and the runway beam installation.

- A longer span means the bridge girders must be stronger and heavier to maintain stability, which drives up the material and engineering costs.

- Accurate span measurement avoids clearance problems and ensures the crane can safely and smoothly travel the full width of the workspace.

- Overhead cranes require precise runway beam alignment for proper operation.

Gantry Cranes:

- Span depends on rail or wheel spacing on the ground or foundation.

- Gantry cranes are often used outdoors or in flexible layouts, so sometimes the span can be adjusted or customized.

- Adjustable spans add versatility but also increase design complexity and potential cost.

- You’ll need to consider ground conditions, rail alignment, and installation constraints when finalizing span.

Jib Cranes:

- Unlike overhead and gantry cranes, jib crane span is about the reach of the jib arm—the radius of the crane’s working circle.

- Since the jib rotates, it’s essential to consider any obstructions like walls, machines, or other equipment within the jib’s swing area.

- A longer jib arm increases working range but also adds stress on the mast and requires stronger construction, influencing price.

- Jib span affects workflow efficiency and operator safety, so accurate measurement helps maximize productivity.

Knowing these details helps you avoid mistakes like ordering a crane that’s too wide or too short for your needs. By understanding how to measure the span correctly and what factors influence it for different crane types, you’ll be better prepared to make a smart, cost-effective choice that fits your workspace perfectly.

How Crane Span Affects Price

The span of a crane doesn't just determine how far it can reach—it plays a big role in how much the crane will cost you. Here's a closer look at how and why span impacts the price.

Material and Manufacturing Costs Related to Longer Spans

- Longer spans mean more steel and materials.

- The bridge girders or beams have to be bigger and stronger to safely carry the load over the wider distance.

- More material leads to higher raw material costs and longer fabrication times.

- Welding, machining, and quality control efforts increase as the size and weight of components grow.

Impact on Structural Design and Engineering Complexity

- A bigger span calls for more careful engineering to maintain stability and safety.

- Engineering teams may need to design custom girders, reinforcements, or support structures.

- Complex calculations are necessary to ensure the crane doesn't bend, sway, or fail under load.

- This extra design work adds to engineering fees and can increase lead times.

Increased Installation and Maintenance Costs with Larger Spans

- Installation becomes more difficult and time-consuming as spans increase.

- Larger cranes require bigger cranes or special equipment to install components safely.

- The runway beams or supporting structures may need to be reinforced or specially designed.

- Maintenance costs can also rise because bigger cranes have more parts exposed to wear and need regular inspections.

Examples of Cost Variations with Different Span Lengths

- A 10-meter overhead crane might cost significantly less than a 20-meter span crane—even with the same lifting capacity.

- Doubling the span doesn't just double the cost; it can increase it by 1.5 to 2 times or more depending on the complexity.

- Gantry cranes with adjustable spans can add initial costs but may save money in the long run by serving multiple applications.

- Choosing the right span—not too big and not too small—helps balance cost with functionality.

Practical Steps for Accurate Span Measurement

Measuring crane span may sound simple, but it requires care and the right approach to avoid costly errors. Here's how you can get accurate measurements for overhead, gantry, and jib cranes — plus some handy tips and common pitfalls to watch out for.

Tools and Equipment Needed for Precise Measurement

- Measuring tape or laser distance meter: For straightforward, reliable distance measurement.

- Spirit level or laser level: To check that beams or rails are level before measuring.

- Measuring wheel: Useful for longer spans or outdoor sites, especially for gantry cranes.

- Notebook or digital device: To record measurements clearly.

- Helper: It's always easier and more accurate to have someone assist, especially for long distances.

Step-by-Step Guide for Measuring Overhead Crane Span

- Locate the runway beams: Identify the two parallel beams or rails where the crane bridge will run.

- Measure center-to-center: Using a tape or laser meter, measure the distance from the center of one runway beam to the center of the other.

- Check beam alignment: Ensure both beams are level and properly aligned to avoid skewed measurements.

- Double-check measurements: Measure twice or more to confirm accuracy.

- Record and label: Note down the measurement with details like building name or location for easy reference.

Tips for Measuring Gantry Crane Spans (Including Runway Considerations)

- Measure between rail centers or leg edges: Depending on the gantry design, measure the clear distance between the rails or the outer edge of the legs.

- Consider rail placement: Ensure rails are properly installed and level before measuring. Uneven or misaligned rails can affect the span.

- Account for ground conditions: If the gantry is mobile, check the level and smoothness of the ground where rails or wheels run.

- Measure the entire rail length: If possible, measure along the full length of the runway to confirm consistent span.

Specific Considerations When Measuring Jib Crane Span and Radius

- Identify the pivot point: This is the center where the jib arm rotates, either a post or wall mount.

- Measure jib arm length: From the pivot center out to the farthest point the hoist will travel along the jib arm.

- Check for obstructions: Consider walls, machines, or other equipment within the swing radius that could limit jib movement.

- Account for swing angle: Jib cranes rotate, so knowing the working arc is just as important as the radius.

Common Mistakes Buyers Should Avoid During Measurement

- Measuring outside edges instead of centers: For overhead cranes, always measure center-to-center on runway beams to get the true span.

- Ignoring beam or rail misalignment: Warped or uneven runways can lead to incorrect span calculations.

- Not considering obstacles for jib cranes: Forgetting about obstructions can cause unusable working areas or the need to reorder the crane.

- Rushing the process: Skipping double-checks or not using proper tools can lead to costly mistakes.

- Failing to communicate measurements clearly: Confusing or incomplete measurements can cause supplier errors.

Taking time to measure accurately saves money and hassle later. With these practical steps and tips, you'll be confident that your crane span fits your needs perfectly.

WCost-Saving Tips Related to Span

Choosing the right crane span isn't just about fit—it can have a big impact on your budget. Here are some practical ways to save costs related to crane span while still meeting your operational needs.

Choosing the Optimal Span for Operational Needs (Avoiding Oversizing)

- Don’t automatically pick the longest span just because it “might be useful.”

- Measure your workspace carefully and select a span that covers the needed area without extra.

- Oversized spans lead to higher material, engineering, and installation costs—plus they can make the crane harder to operate.

- Matching span size closely to actual work requirements saves money and improves efficiency.

Benefits of Modular or Adjustable Span Designs

- Modular cranes let you adjust the span length as your needs change.

- This flexibility can reduce upfront costs if you’re unsure about future requirements.

- Adjustable spans help when the crane must serve different areas or be relocated.

- Modular designs also simplify maintenance and replacement parts handling.

Considering Standard Span Sizes to Reduce Custom Fabrication Costs

- Custom spans often mean custom engineering and manufacturing, which add to cost and delivery time.

- Choosing a standard span size within common industry ranges can cut fabrication costs.

- Standard spans often have readily available components and proven designs.

- This choice reduces lead times and sometimes gives you access to better warranties.

Negotiating with Manufacturers Based on Accurate Span Data

- Provide your supplier with precise span measurements to get a tailored, realistic quote.

- Accurate data minimizes back-and-forth, reducing delays and extra charges.

- Use your measurements to discuss options that fit your budget and operational needs.

- Manufacturers may offer discounts or alternative designs if they see you’ve done your homework.

Planning for Future Expansion Without Overspending Upfront

- If you expect your lifting needs to grow, consider cranes that allow span extension later.

- Avoid paying a premium now for a maximum span you don’t yet need.

- Talk to suppliers about modular or upgrade-friendly designs.

- This approach spreads out costs and lets you scale as your business grows.

By thinking carefully about span size and design choices, you can get a crane that fits your current needs, saves money, and stays flexible for the future. It’s all about balancing practicality with cost efficiency.

Conclusion

Measuring the crane span accurately is one of the most important steps in buying the right crane for your needs. It’s not just a simple number—it affects how well the crane fits your space, how smoothly it operates, and how much you’ll end up paying.

The span you choose directly impacts the crane’s design complexity, material costs, installation, and maintenance expenses. A small difference in measurement can lead to big changes in price and long-term value. Oversizing means you pay more upfront and for upkeep; undersizing can limit your operations or cause costly modifications later.

By following practical measurement steps and avoiding common mistakes, you can save money and avoid delays. Take your time, use the right tools, and double-check your numbers.

Lastly, work closely with experienced crane manufacturers and suppliers. They can guide you through measuring, offer the best span options for your budget, and ensure your crane matches your operational needs perfectly.

Getting the span right is a simple but powerful way to protect your investment and keep your operations running smoothly.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch