Customized 60 Ton Overhead Crane for Industrial Use in Poland

60-ton overhead crane project in Poland, highlighting custom design, low-headroom operation, and efficient, reliable heavy industrial lifting solutions.

Category: Poland

Your Trusted 60 Ton Overhead Crane Manufacturer & Supplier

60 Ton Overhead Crane for Sale Poland

Customized 60-Ton Overhead Crane for Heavy Industrial Applications in Polande

Poland's industrial sector is expanding, especially in areas like steel fabrication, machinery manufacturing, and large-scale equipment assembly. As factories handle heavier and larger components, there's a growing need for high-capacity and heavy lifting solutions that are safe, reliable, and efficient. Overhead cranes are no longer optional equipment — they're essential for keeping production running smoothly.

This project focuses on a customized 60-ton European-style overhead crane for a Polish industrial client. The crane was designed to meet specific requirements, including lifting heavy loads, operating in low headroom spaces, and providing precise control for continuous-duty operations.

Why this crane matters for the client:

- Custom design: Tailored to fit the client's workshop layout and lifting needs

- High efficiency: Smooth operation reduces handling time and speeds up production

- Reliability: Built for continuous-duty use in demanding industrial conditions

- Safety and control: Equipped with multi-hook operation and advanced safety features

By combining practical engineering with real-world operational considerations, this crane provides a solution that meets the client's daily challenges while supporting long-term productivity.

Project Background

This project was commissioned by a client operating in the machinery manufacturing industry. Their facility in Poland handles large, heavy components that require precise positioning during assembly and maintenance. The existing lifting equipment could not meet the growing demands of their workflow, so a custom solution was needed.

The client had several specific requirements for the new crane:

Customer Requirements:

- High lifting capacity with multi-hook functionality: The crane needed a main hook capable of lifting 60 tons, plus auxiliary hooks for handling medium loads simultaneously. This allows more flexibility and reduces the number of lifts required for complex components.

- Smooth and precise control: For assembly and maintenance tasks, the crane must move loads gently and stop accurately to prevent damage or misalignment.

- Low headroom design: The workshop space was limited vertically, so the crane had to be compact without compromising capacity.

- Energy efficiency and reduced maintenance: The client wanted a system that would minimize energy consumption and lower the frequency of maintenance, keeping operating costs down while ensuring reliability.

This background sets the stage for why a customized European-style overhead crane with an open winch trolley was the ideal solution for the client, combining practical functionality, efficiency, and safety in one tailored package.

Crane Configuration Overview

The 60-ton overhead crane supplied to the client in Poland is a QDX European-style double girder crane designed for heavy-duty industrial applications. Its configuration ensures safe, precise, and efficient handling of large and heavy components, meeting the client's operational needs.

The crane uses an open winch type trolley, which is ideal for low headroom workshops. This design maximizes lifting capacity while keeping the crane compact, making it suitable for facilities where vertical space is limited.

The crane is built according to European FEM/DIN standards, ensuring reliable performance, structural integrity, and compliance with international safety requirements. These standards also guarantee that the crane can operate smoothly under continuous-duty conditions without compromising safety or efficiency.

Key Configuration Details:

- Crane Model: QDX European-style double girder overhead crane

- Crane Type: Open winch trolley, low headroom design

- Design Standard: FEM/DIN compliant European configuration

Operation Mode:

- Standard cabin control for operator comfort and visibility

- Optional remote control for flexible operation and improved workflow

This configuration allows the client to handle heavy and medium loads efficiently, maintain precise control during lifting, and make the most of available workshop space, all while keeping energy use and maintenance requirements manageable.

Open winch trolley with European style

main girder of 60 ton overhead crane double girder , with a span length of 18.55 meters

Main Technical Specifications

| Parameter | Specification |

|---|---|

| Crane Type | QDX Overhead Crane |

| Rated Lifting Capacity | 60 / 12.5 / 3.2 tons |

| Span | 18.55 meters |

| Lifting Height | 16.5 / 16.5 / 18 meters |

| Power Supply | 400V, 50Hz, 3 Phase |

| Lifting Mechanism | European-style open winch trolley |

| Duty Class | FEM 2M / 3M (depending on operation frequency) |

| Control Mode | Cabin + Remote Control |

| Protection Grade | IP54 |

Key Features and Engineering Highlights

This 60-ton QDX overhead crane is packed with features that make it reliable, precise, and efficient for heavy industrial operations. Every component has been carefully engineered to meet the client's workflow and facility constraints.

European Open Winch Hoisting System

The crane uses a European-style open winch hoisting system, designed to handle heavy loads efficiently while fitting into low-headroom workshops.

- Compact, modular design with high mechanical efficiency

- Dual-speed or variable frequency drive (VFD) control for smooth and precise lifting

- Low headroom configuration to make the most of available building space

Heavy-Duty Double Girder Construction

The bridge structure is built with welded box-type girders, optimized according to FEM design standards.

- Finite element analysis ensures strength, rigidity, and long-term durability

- Supports heavy loads safely and reduces stress on mechanical components

Advanced Drive and Control System

The crane's motion system uses high-quality European electrical components from Schneider or Siemens.

- Frequency inverter provides smooth acceleration and deceleration

- Overload protection and optional anti-sway system for precise load handling

- Reliable operation even under continuous-duty conditions

Safety and Reliability

Safety is built into every aspect of this crane.

- Overload limiter and emergency stop for instant load control

- Limit switches on all motions to prevent over-travel

- Anti-collision sensors for safe operation in multi-crane workshops

- Redundant braking systems on the main hoist to ensure secure lifting

Customization for Client Site

The crane was tailored to fit the client's specific workshop layout and operational workflow.

- Adapted to building dimensions and lifting points

- Hook approaches optimized to maximize lifting coverage across the workspace

- Customized paint and anti-corrosion treatment suitable for indoor conditions in Poland

Overall Benefits

This combination of features ensures the crane is safe, precise, and reliable, while also being energy-efficient and easy to maintain for long-term industrial use.

Performance & Customer Feedback

The 60-ton QDX overhead crane delivered to the Polish client has proven to be reliable and easy to operate, meeting all performance expectations from day one. Operators noticed the difference immediately, with smooth motion, precise positioning, and low noise levels during lifting and traveling operations.

Performance Highlights

- Smooth and precise operation: Dual-speed or VFD-controlled hoist allows careful positioning of heavy loads without sudden jerks

- Improved production efficiency: Multi-hook lifting and low headroom design reduce handling time and streamline workflow

- Enhanced safety: Advanced limit switches, overload protection, and anti-collision sensors give operators confidence while handling large components

- Reduced maintenance downtime: The robust design and quality components minimize wear and maintenance compared to conventional cranes

Customer Feedback

- The client emphasized the crane's operational reliability, noting that it handles heavy and medium loads with ease and reduces delays in daily operations

- Multi-hook functionality and precise control have improved workflow efficiency, making assembly and maintenance tasks faster and safer

Overall Performance Summary

Overall, the crane has exceeded expectations in daily use, proving that careful design, high-quality components, and proper customization translate into real benefits on the workshop floor.

Project Value and Impact

The installation of the 60-ton QDX overhead crane brought measurable benefits to the client's operations in Poland. By combining high lifting capacity with precise multi-hook control, the crane improved material handling efficiency across the workshop.

Operational Efficiency

- Operational efficiency: Faster and safer movement of heavy components reduces downtime and streamlines workflows

- Energy-saving design: The VFD-controlled hoist and optimized drive system lower electricity consumption and operational costs

- Custom engineering capability: This project showcases Yuantai Crane's ability to deliver tailored solutions that meet the requirements of European industrial facilities, including low-headroom spaces and continuous-duty operations

Long-Term Value

The crane has not only met the client's immediate needs but also positioned the facility for long-term productivity and reliability, demonstrating the real-world value of investing in a customized lifting solution.

Get Your Design

Looking for a customized overhead crane solution that meets your exact lifting and production needs?

Our engineering team specializes in European-style open winch cranes tailored for demanding industrial environments in Poland, Europe, and worldwide.

Whether you require a single-unit installation or a complete material handling system, our experts can design, manufacture, and deliver a solution that ensures safety, efficiency, and long-term reliability.

Connect with us today:

- [Request a Quote] – Get a detailed proposal based on your lifting requirements.

- [Click to Learn the Main Specificaitons of QDX Double Girder Overhead Cranes ] – Learn more about our QDX overhead crane range and engineering capabilities.

- [Contact Our Project Team] – Speak directly with our engineers for personalized technical support.

Main Projects

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

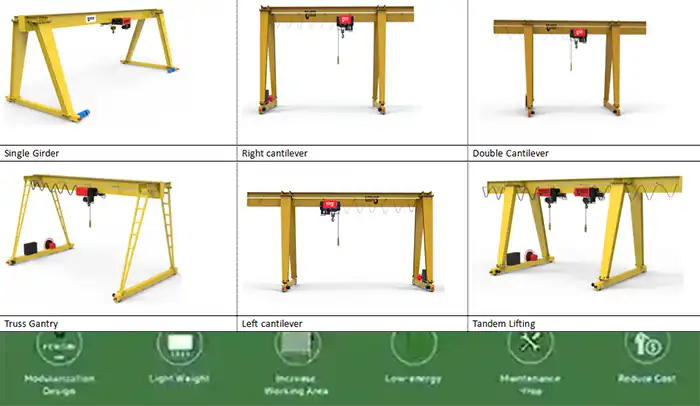

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch