Heavy-Duty EOT Cranes for Sale in Dhofar Oman

Reliable, large-capacity EOT cranes designed for tough outdoor lifting in Dhofar’s cement factories and logistics operations.

| Crane Type | heavy duty eot crane |

| Crane Capacity | 5 ton to 320 ton |

| Crane Span | As your request |

| Lifting Height | Customized. |

Category: Oman

Your Trusted Overhead Crane Manufacturer & Supplier

Heavy-Duty EOT Cranes for Sale in Dhofar Oman

Lifting Solutions for Cement and Logistics Plants

Introduction

Dhofar’s industrial growth is picking up speed, and with it comes the need for strong, dependable lifting equipment. If you work in cement manufacturing or logistics around here, you know how tough the conditions can be. Handling heavy materials day in and day out requires cranes that don’t just get the job done but do it safely and reliably.

That’s where heavy-duty EOT cranes come in. These cranes are made to lift large weights, operate outdoors, and withstand harsh environments like those found in Dhofar’s cement plants and busy logistics hubs. Whether you need to move raw materials, heavy containers, or large equipment parts, the right crane can save you time and reduce risks on the job.

Dhofar is a key area, especially near Salalah Port, where industrial projects are expanding fast. There’s been a noticeable increase in searches for heavy-duty cranes here—showing that businesses are actively looking for solid lifting solutions to match their growth and challenges.

Key points:

- Dhofar’s industrial sector is expanding, driving up demand for heavy-duty cranes.

- Outdoor-capable EOT cranes with large lifting capacity are essential for cement and logistics plants.

- Salalah Port’s proximity adds to the need for reliable crane equipment in this region.

This article will dive deeper into why these cranes matter in Dhofar and what features make them a smart choice for heavy-duty lifting in demanding conditions.

Industrial Landscape of Dhofar

Dhofar is home to a mix of heavy industries that keep the region’s economy moving. Among these, cement manufacturing stands out as a major player. The area has several plants producing and storing large amounts of cement, which means heavy lifting and constant material movement are everyday tasks.

Alongside cement, construction material processing is another big sector here. This includes everything from crushing stone to preparing aggregates for building projects. Handling these bulky, rough materials requires cranes that can handle tough workloads without breaking down.

Then there’s the bustling port logistics near Salalah. Containers, heavy equipment, and bulk goods are constantly loaded and unloaded. Efficient handling in this environment demands cranes that can work outdoors, rain or shine, and move heavy loads safely.

Key Sectors at a Glance:

- Cement manufacturing and storage: Continuous handling of raw materials, clinker, and finished cement bags or bulk containers.

- Construction material processing: Managing large volumes of aggregates, stones, and other heavy materials.

- Port logistics and container handling: Moving shipping containers and heavy machinery in open yards.

These industries face some tough environmental challenges that affect equipment performance and maintenance.

Environmental Challenges:

- Coastal humidity and salt corrosion: Dhofar’s proximity to the sea means cranes are exposed to salty air, which can quickly corrode metal parts if not properly protected.

- Cement dust and abrasive conditions: Cement dust is fine and abrasive, getting into motors, gears, and electrical components, causing wear if equipment isn’t sealed and maintained.

- Heavy-duty cycles and 24/7 operations: Many plants operate round the clock, so cranes must be durable, reliable, and easy to maintain under continuous use.

Types of Heavy-Duty EOT Cranes for Your Reference

Heavy-duty Electric Overhead Traveling (EOT) cranes come in several types, each suited for specific lifting tasks and environments. Here's a quick guide to the main types you might consider for your industrial needs in Dhofar:

Single Girder Heavy-Duty EOT Crane

- Description: Features one main girder that supports the trolley and hoist.

- Capacity Range: Typically up to 20-30 tons for heavy-duty versions.

- Advantages: Simpler structure, easier installation, and lower cost.

- Best For: Smaller spans or lighter heavy-duty tasks where space or budget is limited.

Double Girder Heavy-Duty EOT Crane

- Description: Has two main girders, providing greater strength and stability.

- Capacity Range: Commonly from 20 tons up to 100+ tons.

- Advantages: Supports heavier loads, longer spans, and offers smoother operation.

- Best For: Large cement plants, heavy material handling, and outdoor applications requiring robust lifting.

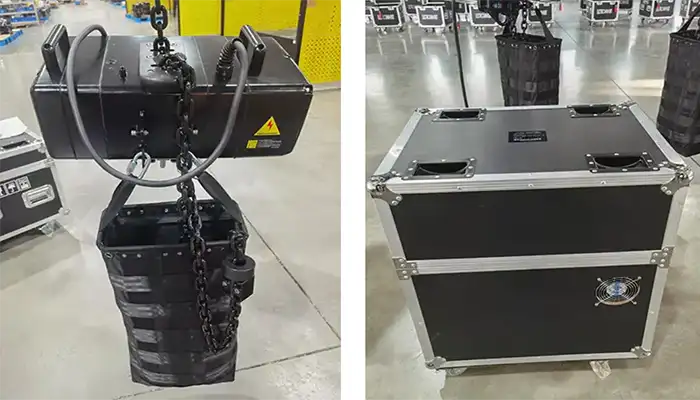

Dual Trolley Heavy-Duty EOT Crane

- Description: Equipped with two trolleys and hoists, often with different lifting capacities.

- Capacity Range: Varies widely, typically with a main hoist handling heavier loads and an auxiliary hoist for lighter tasks.

- Advantages: Allows simultaneous lifting at two points, increasing flexibility and efficiency.

- Best For: Complex logistics yards or plants handling multiple load types simultaneously.

Explosion-Proof Heavy-Duty EOT Crane

- Description: Designed with special features to operate safely in hazardous environments with flammable gases or dust.

- Capacity Range: Depends on design but can be heavy-duty.

- Advantages: Meets strict safety standards to prevent sparks or ignition sources.

- Best For: Cement plants or processing areas where explosive dust or gases are present.

Choosing the right type depends on your specific lifting needs, site conditions, and budget. If you need help deciding, we're ready to guide you through the options and find the best fit for your operation.

Why Choose Heavy-Duty EOT Cranes for These Industries

When working in cement plants and logistics hubs, regular lifting equipment just won't cut it. You need cranes built tough enough to handle heavy loads and harsh conditions without failing. Heavy-duty EOT (Electric Overhead Traveling) cranes are designed specifically for these demanding environments.

Cement Industry Needs

Cement production involves moving large amounts of bulk materials — think raw limestone, clinker, and finished cement. These materials are heavy and often stored in big containers or silos. Heavy-duty EOT cranes make it easier and safer to lift and transport these bulky loads across the plant.

Plus, these cranes handle kiln parts, molds, and other heavy components that are critical to the manufacturing process. Precise, strong lifting equipment reduces downtime and improves overall plant efficiency.

Logistics & Port Use

At ports and logistics centers, you're dealing with containers and heavy machinery daily. These loads can be massive and often need to be moved outdoors. Heavy-duty EOT cranes built for outdoor use offer the durability and protection necessary to work in all weather conditions — whether it's the intense sun, dust storms, or occasional rain.

Having cranes that won't break down in tough weather means your operations keep running smoothly without costly interruptions.

Technical Demands

Here's what makes these cranes fit for heavy industrial use:

- High lifting capacity: From 20 tons to over 100 tons, depending on the specific needs of your plant or yard.

- Double girder design: Provides greater strength and stability for heavy loads and long spans, common in large outdoor yards.

- Outdoor-rated construction: All critical components like motors, controls, and brakes come with anti-corrosion coatings and dust protection to withstand harsh environments.

Choosing the right heavy-duty EOT crane means investing in equipment that lasts longer, works reliably, and handles the toughest jobs without compromise.

Key Features of Heavy-Duty EOT Cranes

Heavy-duty EOT cranes are more than just strong machines—they're engineered carefully to handle tough conditions and meet the specific needs of industrial sites like those in Dhofar. Here's what sets these cranes apart.

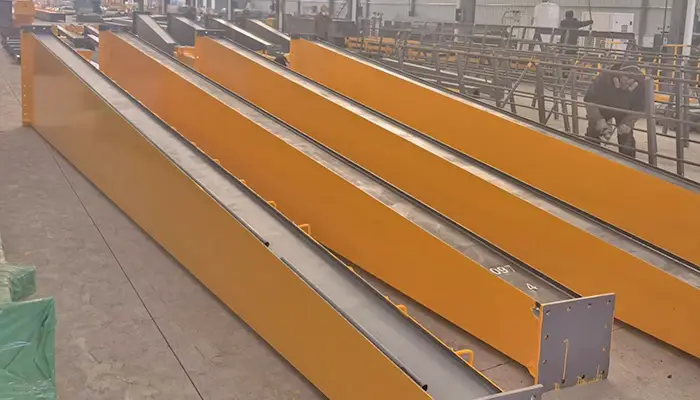

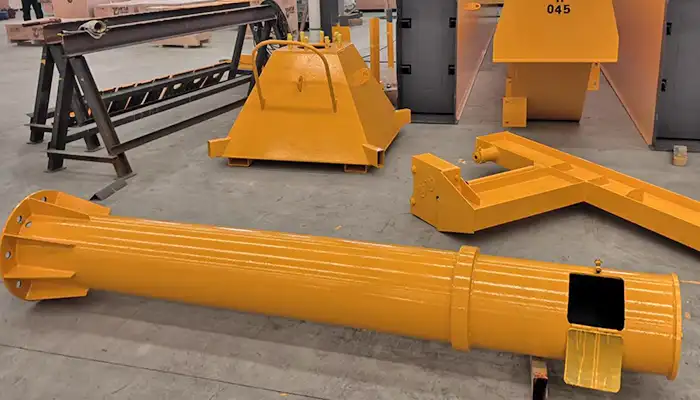

Design Highlights

- Outdoor-grade motors and electricals: Standard motors and controls won't last long outdoors. These cranes use specially sealed motors and electrical components designed to resist moisture, dust, and temperature swings.

- IP55+ protection and anti-rust coatings: The cranes come with at least IP55-rated enclosures, meaning they're protected against dust ingress and water jets. Plus, all steel parts are coated with rust-resistant paint to combat salt corrosion near the coast.

- Remote control and cabin control options: Depending on your operational needs, you can choose between remote pendant controls or operator cabins. Remote control allows safe operation from a distance, while cabins provide full visibility and comfort for operators.

Customization

No two industrial plants are exactly the same. That's why these cranes can be tailored to fit your layout perfectly.

- Tailored span and lifting height: Whether you have a narrow workspace or a wide open yard, the crane's span and hook height can be adjusted to match your site dimensions.

- Add-ons for precision and safety: Features like load weighing systems help you monitor lifting capacity in real time, frequency control smooths out movements for delicate loads, and anti-sway devices reduce load swing for safer handling.

Certifications

Buying a crane isn't just about features—it's also about trust and quality assurance.

- CE and ISO certifications ensure the crane meets international safety and quality standards.

- Third-party inspections provide an extra layer of confidence, verifying that every crane delivered has passed rigorous checks.

- Proven export experience in Gulf countries means these cranes are built to meet local standards and environmental challenges specific to the region.

Crane Installation and Service Support in Dhofar

Buying a heavy-duty EOT crane is just the beginning. Proper installation and ongoing support make all the difference in keeping your crane running smoothly and safely over time. Fortunately, buyers in Dhofar can count on full project support tailored to local conditions.

Project Handling

- On-site installation support: Experienced technicians and engineers can be dispatched to your site to supervise and assist with crane assembly and commissioning. This hands-on approach ensures everything is set up correctly and meets safety standards.

- Structural and civil support guidance: Installing a heavy-duty crane often involves coordinating with your building's structure and foundation. Expert advice is available to help design or verify your runway beams, foundations, and related infrastructure for safe and stable crane operation.

After-Sales Service

- Spare parts availability: Having quick access to genuine spare parts means less downtime if any components wear out or need replacing. Parts can be shipped promptly to Dhofar to keep your crane operational.

- Maintenance training and inspection plans: Proper maintenance is key to crane longevity. Training sessions for your on-site staff help ensure routine checks are done right. Scheduled inspection plans can also be provided to catch potential issues early before they become costly problems.

Logistics Advantage

- Shipping to Salalah Port: Dhofar's main port acts as a logistics hub, making crane shipment and customs clearance efficient. This helps shorten delivery times and reduces transport risks.

- Fast deployment for urgent projects: For critical operations that can't afford delays, quick installation and commissioning support means your crane will be ready to work as soon as possible.

Why Buy from a Certified Chinese Manufacturer

When it comes to heavy-duty EOT cranes, choosing the right manufacturer is just as important as picking the right crane. Certified Chinese manufacturers offer solid advantages, especially for buyers in Dhofar and the Gulf region.

Cost-Effective Large-Capacity Solutions

Chinese manufacturers provide cranes that meet high standards without the high price tag. You get durable, heavy-capacity cranes designed for tough industrial work — but at a cost that fits your budget. This balance of quality and affordability is why many companies turn to China for lifting equipment.

Over 15 Years of Export Experience in the Gulf

With more than a decade and a half exporting cranes to Gulf countries, these manufacturers understand local needs and regulations. Their cranes are proven to work well in coastal, dusty, and high-humidity environments, just like those in Dhofar. This experience means fewer surprises and smoother project execution.

Custom Engineering and Fast Production Turnaround

Certified Chinese manufacturers don't just offer standard cranes. They work closely with clients to design cranes that fit specific plant layouts and lifting requirements. Plus, their production lines are efficient, allowing for quicker delivery times—something crucial when project schedules are tight.

Support for Crane Kits if Local Fabrication is Preferred

Some buyers prefer to handle local fabrication to save on shipping or meet local content rules. Chinese manufacturers can supply crane kits—main components ready for assembly—along with detailed drawings and technical support. This flexibility helps clients balance cost, quality, and local involvement.

Request a Quote or Consultation

If you’re considering a heavy-duty EOT crane for your operations in Dhofar, getting the right solution starts with clear communication. We offer a free technical evaluation to help you find the best crane tailored to your specific needs.

Free Technical Evaluation

By submitting your project details, our engineering team will review your requirements and provide expert advice on the most suitable crane options. This evaluation includes preliminary design suggestions, capacity checks, and recommendations to optimize crane performance and safety in your environment.

What to Include in Your Request

To make sure we understand your needs fully, please provide the following information:

- Required lifting capacity: Specify the maximum weight your crane needs to lift. This is crucial to select the correct hoist and structural design.

- Span and lifting height: The distance your crane must cover horizontally (span) and vertically (lifting height) determines the crane’s dimensions and reach.

- Site conditions: Let us know if the crane will operate indoors or outdoors, and describe environmental factors such as dust levels, humidity, temperature extremes, or exposure to corrosive substances. These details influence material selection and protection measures.

- Power supply type: Information on your available power source (voltage, phase, frequency) helps us design the crane’s electrical system to match your facility’s infrastructure.

Providing these details upfront speeds up the evaluation process and ensures the crane we recommend fits perfectly with your site and operational demands.

If you’re ready, send us your project information today. We’ll work with you closely from initial design to delivery, helping you get a heavy-duty EOT crane that meets your expectations for performance, reliability, and value.

Conclusion

Heavy-duty EOT cranes have proven themselves time and again as reliable workhorses for Dhofar’s cement factories and logistics centers. Their strength, durability, and ability to withstand tough outdoor conditions make them the go-to choice for lifting heavy loads safely and efficiently.

If your operation requires a crane that can handle large capacities while standing up to the challenges of coastal humidity, dust, and continuous use, these cranes are a practical investment that won’t let you down.

Ready to find the right crane for your needs? Get in touch with us for expert engineering advice, custom design solutions, and competitive pricing tailored specifically to your project. We’re here to help make your lifting operations smoother and more efficient from start to finish.

Main Projects

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch