2 Ton Stage Hoists for safe, efficient lifting in Philippine

Case Study: 2T Stage Hoists for Sale in the Philippines

Project Overview

This project focused on supplying stage hoists for a performance venue in the Philippines. The client needed equipment that could safely and efficiently lift stage elements such as lighting rigs, speakers, curtains, and other heavy components used in events. The main goal was to improve stage operations, reduce manual labor, and ensure safety for operators and performers.

Equipment Supplied:

- Quantity: 4 stage hoists

- Lifting Capacity: 2 tons per unit

- Maximum Lifting Height: 18 meters

- Power Supply: 220V, 60Hz, single-phase

The hoists were specifically chosen to match the local power supply. Single-phase 220V systems are common in many venues across the Philippines, making it easier to integrate these hoists without requiring special electrical upgrades.

These hoists are compact and easy to handle, which is crucial in stage environments where space is often tight. The 18-meter lifting height allows for flexible rigging, making it possible to lift equipment high enough to clear stage scenery while still maintaining full control over the load.

Key Points for Buyers and Operators:

- Ensure the lifting height meets the full clearance needs of your stage setup.

- Check local power supply compatibility—single-phase 220V is standard in many locations, but always confirm.

- Consider operator access and space around the stage to safely install and operate the hoists.

With these hoists, the venue could move heavy stage equipment quickly and safely, keeping event schedules on track. Operators appreciated that the units were straightforward to install, with intuitive controls that did not require specialized training.

Project Background

The client for this project was a mid-sized event production company operating several performance venues in the Philippines. Their main challenge was handling heavy stage equipment during setup and teardown, which often involved lighting rigs, sound systems, and curtains. Before this project, lifting and moving these items relied heavily on manual labor, which was slow and posed safety risks.

Project Goals

- Enable Safe and Efficient Lifting: The client needed hoists that could reliably lift stage equipment without risking operator injury or equipment damage. Safety features like limit switches and overload protection were critical.

- Improve Speed and Reliability of Stage Setup: Faster lifting meant shorter setup times, fewer delays, and smoother event transitions. The hoists needed to operate consistently for multiple events in a row without performance drops.

- Ensure Power Supply Compatibility: The venues used standard 220V single-phase, 60Hz electrical systems. The hoists had to integrate directly with this power supply without requiring costly electrical upgrades.

By clearly defining these goals, the project ensured that the equipment supplied would not only meet lifting requirements but also improve the overall workflow for stage crews. This practical approach helped the client save time and reduce the risk of accidents during event setups.

Key Considerations for Buyers

- Assess the weight and type of equipment you need to lift. This ensures the hoist capacity matches your needs.

- Look at the frequency of use—venues with daily events need robust hoists that can handle repeated lifting without overheating.

- Check electrical compatibility before purchase to avoid extra costs or installation delays.

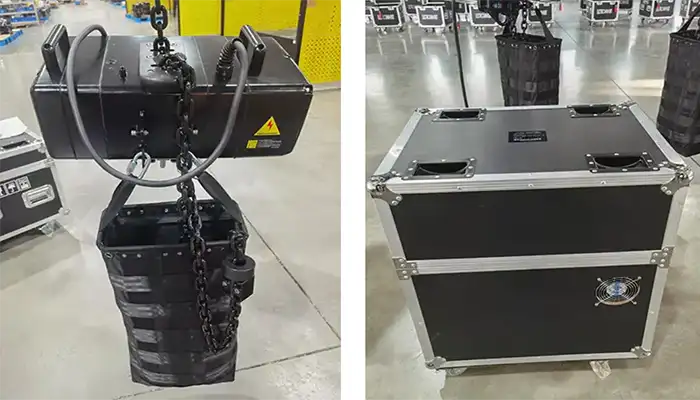

2 ton stage electric chain hoist - stage hoist for sale

2 ton stage electric chain hoist

Equipment Details

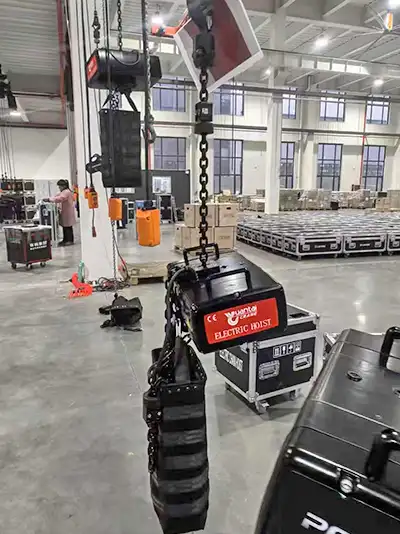

For this project, four electric stage hoists were supplied, specifically selected to meet the client's operational needs. These hoists are designed for stage environments, where space can be limited and equipment must be both reliable and easy to operate.

Hoist Model & Features

- Capacity: 2 tons, enough to handle heavy lighting rigs, speakers, and stage curtains.

- Lifting Height: 18 meters, providing plenty of clearance for high-stage setups.

- Power Supply: Single-phase 220V, 60Hz, which fits standard electrical systems in many Philippine venues.

- Design: Compact and built for stage use, making it easier to maneuver and mount even in tight spaces.

The compact size does not compromise lifting performance. In fact, the hoists can be installed in areas where larger cranes or hoists would simply not fit. Their design also ensures that weight is distributed safely, preventing undue stress on stage structures.

Safety Features

- Overload Protection: Prevents lifting beyond capacity, reducing risk of accidents or damage to the hoist.

- Emergency Stop: Allows operators to immediately halt operations in case of any unexpected issues.

- Limit Switches: Automatically stop the hoist at maximum or minimum lifting heights, protecting both the equipment and the load.

Safety is not just about the machine—it's about the operators too. These features give stage crews peace of mind while moving heavy or awkwardly shaped equipment.

Ease of Use

- Simple Controls: Operators can easily raise or lower loads without extensive training.

- Lightweight and Portable: The hoists are easy to relocate or adjust, which is critical when dealing with different stage layouts or multiple venues.

Practical Tips for Buyers

- Check if your stage area has any height restrictions or obstacles—an 18-meter lifting height is ideal, but clearance above the hoist should be confirmed.

- Ensure the power supply matches the hoist voltage and phase to avoid installation delays.

- Confirm the weight of your typical loads and verify the hoist's capacity allows for a safety margin.

Summary

These hoists were chosen for their combination of reliability, safety, and practicality—making them well-suited for venues that need frequent, flexible lifting without compromising crew safety.

Installation & Commissioning

Proper installation and commissioning are essential to ensure that stage hoists operate safely and reliably. Even the best equipment can run into problems if the mounting or electrical setup isn't correct. For this project in the Philippines, careful planning and on-site checks were a key part of the process.

Installation Requirements

- Mounting Structure: The hoists require a structure capable of supporting 2-ton loads. This could be a steel truss, overhead beam, or reinforced stage rigging. The structure must be stable and properly aligned to prevent swaying or uneven lifting.

- Rigging and Anchoring: Correct rigging ensures the hoist is securely attached and evenly balanced. Anchoring points must be inspected to avoid any movement during lifting operations. This step is critical for both operator safety and protecting the stage equipment.

- Space Considerations: The hoists need enough clearance around them for safe operation and easy access by operators. Planning for movement paths and cable management prevents accidents during setup or live events.

Commissioning Steps

- Electrical Connection Verification: Before operation, technicians confirmed the 220V, single-phase connections were stable and compatible with the hoist. Proper grounding and circuit protection were also checked to avoid electrical hazards.

- Functional Testing: Each hoist was tested for lifting and lowering loads to ensure smooth operation. This included checking the limit switches, motor performance, and speed controls. Any irregularities were addressed immediately.

- Safety Inspection and Staff Training: A final inspection ensured all safety features, including overload protection and emergency stops, were working properly. Operators received hands-on training to familiarize them with controls, emergency procedures, and routine checks.

Practical Tips for Buyers and Venue Managers

- Always inspect the mounting structure for signs of wear or weak points before installing heavy hoists.

- Test the hoist without load first, then gradually increase weight to the operational maximum.

- Train staff on both normal operation and emergency shutdown procedures—this avoids costly mistakes during live events.

- Document installation steps and electrical checks for future maintenance and safety audits.

Operational Benefits

Once installed and commissioned, the stage hoists brought immediate improvements to daily operations. For venues that handle frequent events, every minute saved in setup or teardown counts. These hoists were designed to make lifting tasks easier, faster, and safer.

2 ton stage hoist for sale

2 ton stage hoist box

Key Operational Benefits:

- Increased Efficiency in Stage Setup and Teardown: With the 2-ton hoists, crews could lift heavy lighting rigs, curtains, and sound equipment in a fraction of the time it would take manually. Tasks that previously required multiple people could now be handled with fewer operators, speeding up the entire workflow.

- Reduced Manual Labor and Operator Fatigue: Moving heavy equipment by hand is physically demanding and increases the risk of injury. These hoists removed much of that strain, allowing operators to focus on precise placement rather than raw lifting. This also improved morale, as staff could work longer without fatigue.

- Reliable Lifting for Repeated Event Use: The hoists are built for frequent operation, making them ideal for venues hosting multiple events per week. Their robust design ensures consistent performance, even with repeated lifting cycles. This reliability reduces downtime and maintenance interruptions.

- Enhanced Safety for Performers and Crew: By automating heavy lifts and providing safety features like limit switches, overload protection, and emergency stops, the hoists significantly reduced the risk of accidents. Performers and crew could move under rigging safely, knowing the hoists were secure and reliable.

Practical Takeaways for Venue Operators:

- Plan lifting sequences in advance to maximize efficiency—these hoists perform best when used consistently and systematically.

- Regularly inspect hoist components to maintain reliability for frequent events.

- Train staff to use safety features correctly, especially emergency stops and limit switches.

Overall, these hoists improved not just speed, but also operational consistency and workplace safety, making them a practical investment for any performance venue.

Challenges & Solutions

Every project comes with its own set of challenges, and the stage hoist installation in the Philippines was no exception. Careful planning and practical solutions were essential to ensure the hoists worked efficiently and safely in the venue environment.

Challenges

- Single-Phase Power Limitation: Many venues in the Philippines rely on 220V single-phase electricity, which can limit the options for heavy-duty stage hoists. Using equipment designed for three-phase power could require costly electrical upgrades.

- Space Constraints on Stage: Stages often have limited overhead and floor space, with lighting rigs, speakers, and other equipment already in place. Fitting large hoists without interfering with existing stage setups can be tricky.

- Coordination with Existing Rigging Systems: Many venues already have rigging in place for lights, curtains, or props. Introducing new hoists requires careful coordination to avoid conflicts and ensure smooth operations.

Solutions

- Customization of Hoist Controls for 220V Single-Phase: The hoists were adapted to work reliably with the existing single-phase power supply, eliminating the need for costly electrical upgrades and making installation faster and more straightforward.

- Compact Hoist Design for Tight Stage Areas: These hoists are smaller and lighter than traditional models, allowing them to fit into limited spaces without obstructing other equipment. The compact design also makes them easier to move or reposition if the stage layout changes.

- On-Site Training for Smooth Integration: Staff received practical, hands-on training to operate the hoists safely alongside existing rigging. This included proper lifting sequences, emergency procedures, and load balancing to avoid collisions or accidents.

Practical Tips for Buyers

- Assess your venue's power supply before selecting hoists—customization may save both time and money.

- Measure available stage space and overhead clearance carefully to ensure the hoists fit without blocking other equipment.

- Plan installation with existing rigging in mind to prevent operational conflicts.

Client Feedback

The client reported a high level of satisfaction with the stage hoists supplied for their venues in the Philippines. Feedback highlighted several key points that demonstrate the practical value of the equipment:

- Reliability of Lifting Operations: Operators noted that the hoists consistently handled loads without interruptions or mechanical issues, even during repeated events. The smooth and controlled lifting provided confidence when moving heavy stage equipment.

- Ease of Installation and Operation: The compact design and simple controls made installation straightforward. Staff could quickly understand how to operate the hoists, reducing the need for extensive training.

- Safety and Performance Satisfaction: Safety features such as limit switches, emergency stops, and overload protection reassured the crew. Operators felt secure handling heavy equipment, and the performance of the hoists met the demands of the venue's event schedule.

Overall, the client emphasized that the hoists had made a noticeable difference in both operational efficiency and crew confidence during events.

Conclusion & Takeaways

This project demonstrates that carefully selected stage hoists can greatly improve operational efficiency in theaters and event venues. When planning such installations, several practical factors are critical:

- Proper Planning and Specification: Confirm the lifting capacity, lifting height, and power supply compatibility before purchase. These steps prevent costly mistakes and ensure smooth integration into existing systems.

- Practical Design Considerations: Compact and user-friendly hoists make installation and daily operation easier, especially in venues with limited space or multiple rigging systems.

- Operational Benefits: Reliable lifting, reduced labor, and enhanced safety are the main advantages, making stage operations faster, safer, and less physically demanding for staff.

For venue managers or event production companies, the key takeaway is clear: selecting hoists that match your operational needs, stage layout, and power supply results in a more efficient and safer workflow. Careful specification and planning make the difference between a hoist that works and one that creates delays or risks.