Libya Case Study: Mobile Jib Crane & Chain Hoist Benefits

Case Study Outline: Mobile Jib Crane with Chain Hoist in Libya

Project Overview

This project took place in Libya, where the client needed a reliable solution for moving and lifting light materials in a small workshop environment. The goal was simple: make everyday lifting tasks easier, safer, and faster without requiring heavy installation or permanent structures.

The client opted for a combination of a mobile BZ crane and a chain hoist, designed to fit compact spaces and provide flexible operation. This setup is particularly useful for workshops, small factories, or industrial sites where materials need to be moved frequently but loads are not extremely heavy.

Equipment Supplied

Mobile BZ Crane

- Capacity: 1 ton

- Designed for mobility within small industrial areas

- Quick setup and minimal structural requirements

Electric Chain Hoist

- Span: 2.5 meters

- Lifting Height: 3 meters

- Suitable for light-duty lifting

- Simple operation and maintenance

Power Supply:Voltage: 380V, Frequency: 50Hz, Phase: 3-phase

- Fully compatible with standard industrial power in Libya

Project Purpose

The main purpose of this installation was to support efficient small-scale material handling. With this setup:

- Operators can move and lift parts without strain or risk of injury.

- Materials can be transported quickly between workstations.

- The mobile crane allows flexibility, meaning it can serve multiple production areas.

- Maintenance is straightforward, keeping downtime to a minimum.

Overall, this project demonstrates how a well-planned, small-scale lifting solution can improve workshop efficiency without complicated infrastructure.

Client Requirements

Before choosing the portable jib crane , the client had a clear set of requirements. The project was not about lifting heavy steel beams or huge machinery—it was about everyday, practical handling of light materials in a small workshop environment. Meeting these needs meant focusing on flexibility, safety, and ease of use.

Key Requirements

- Mobility for Workshop or Site Flexibility

The client needed a crane that could move easily across different areas of the workshop. Fixed cranes were not practical because materials were not always in the same location. A mobile setup meant operators could reposition the crane quickly without extra installation work or downtime. - Safe and Reliable Lifting of Lightweight Loads

While the loads were light, safety could not be compromised. The crane and chain hoist had to lift reliably every time, with built-in safeguards to prevent accidents, like overload protection and stable movement under load. - Easy Installation and Operation with Minimal Technical Support

The workshop team didn’t have specialized rigging or crane technicians. The system had to be simple enough for ordinary staff to set up, operate, and maintain without needing extra support or complex procedures. - Compliance with Local Power Standards

Electrical compatibility was essential. The equipment had to work with 380V, 50Hz, 3-phase power, which is standard in Libya. This ensured smooth operation and avoided extra costs for transformers or adapters.

Equipment Selection & Features

For this project, the client needed a solution that was compact, flexible, and reliable. After reviewing the site conditions and operational needs, the combination of a mobile BZ crane and a BZ chain hoist was chosen. Both pieces of equipment are designed for light-duty lifting but with practical features that make everyday use easier for operators.

Mobile BZ Crane

The mobile BZ crane was selected for its flexibility and ease of deployment. It is small enough to fit in tight workshop spaces but strong enough to handle a full 1-ton load safely.

- Capacity: 1 ton, ideal for light materials such as parts, tools, or small assemblies.

- Span: 2.5 meters, giving enough reach for common workshop layouts.

- Lifting Height: 3 meters, suitable for stacking or moving items at bench or shelf level.

- Mobility: Wheeled or movable design allows operators to reposition the crane without disassembly.

Advantages:

- Quick setup and redeployment anywhere in the workspace.

- Minimal structural support required, no permanent installation needed.

- Reduces manual labor and increases workflow efficiency.

Chain Hoist

Paired with the mobile crane, the BZ chain hoist provides precise and safe lifting of light-duty items. Depending on the workshop needs, it can be manual or electric.

- Type: Manual or electric BZ chain hoist, adaptable to different operator preferences.

- Load Handling: Accurate lifting for items where control is important, minimizing load swinging.

- Safety Features: Overload protection to prevent accidents. Durable chain construction for long-term reliability.

- Ease of Maintenance: Simple inspection routines. Chain replacement is straightforward, saving downtime.

Together, this combination of mobile crane and chain hoist offers a practical, low-maintenance lifting solution that fits small industrial sites or workshops. Operators can move materials safely and efficiently, without complicated installation or heavy infrastructure.

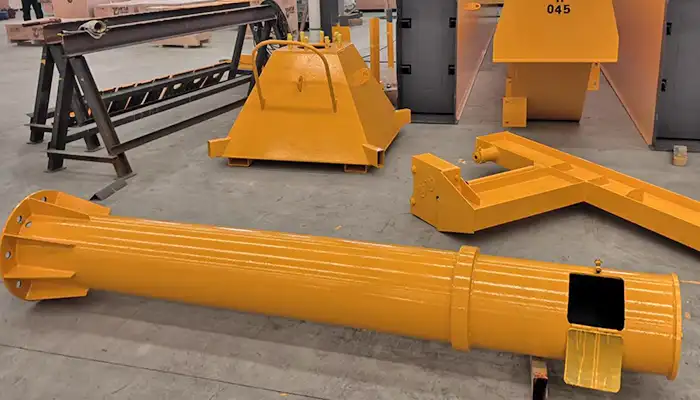

Jib cantilever of 1 ton portable jib crane

1 ton electric chain hoist

1 ton portable jib crane column

mobile jib crane colomn foundation

Installation & Commissioning

Proper installation and commissioning were key to ensuring the crane and hoist operated safely and efficiently from day one. Even for a mobile, small-scale setup, attention to detail makes a big difference in performance and longevity.

Site Preparation

Before bringing in the crane, the site needed to be carefully prepared:

- Ensure a level and stable surface to prevent tipping or uneven load movement.

- Clear any obstacles in the operation area so the mobile crane can move freely.

- Check that there is sufficient overhead clearance for the 3-meter lifting height of the crane.

Power Connection

Electrical setup is simple but critical:

- Verify 380V, 50Hz, 3-phase power supply to match equipment requirements.

- Check all wiring and connections for safety and stability.

- Install proper circuit protection to prevent short circuits or overload issues.

Safety Measures

Even with light loads, safety cannot be overlooked:

- Ensure the crane is properly grounded to prevent electrical hazards.

- Keep the load path clear of personnel and obstructions at all times.

- Provide operator training on safe crane handling, proper use of the hoist, and emergency procedures.

Testing

Before full operation:

- Conduct load testing at full 1-ton capacity to confirm the crane and hoist perform reliably.

- Inspect the chain, trolley, and crane structure for smooth operation.

- Adjust any components as needed to ensure consistent and safe lifting.

Operational Benefits

Once installed, the mobile BZ crane and chain hoist setup provided the client with a practical and efficient lifting solution. The combination of mobility, simplicity, and reliability brought immediate improvements to the workshop workflow.

Flexible Positioning

- The mobile crane can be moved easily between workstations, allowing operators to handle materials wherever needed.

- This flexibility supports multiple workflow arrangements, which is especially useful in small workshops or changing production layouts.

- Operators no longer need to drag heavy items manually, reducing fatigue and risk of injury.

Compact Design

- The crane's small footprint makes it ideal for tight spaces where fixed overhead cranes or larger equipment wouldn't fit.

- Even with limited room, the crane can handle daily lifting tasks without obstructing other work processes.

Low-Maintenance, Long-Lasting Chain Hoist

- The BZ chain hoist is easy to inspect and maintain, with simple chain replacement procedures.

- Durable construction ensures the hoist remains reliable even with frequent daily use.

- Minimal maintenance translates to less downtime and more consistent workflow.

Cost-Effective Solution

- This setup provides an efficient way to handle light materials without investing in heavy, permanent lifting systems.

- Reduces manual labor and increases productivity without large infrastructure costs.

- Ideal for workshops, small factories, or industrial sites where lifting needs are frequent but loads are moderate.

Overall, the mobile BZ crane and chain hoist offered a practical, reliable, and cost-efficient lifting solution, making everyday workshop operations safer and easier.

Lessons Learned / Buyer Insights

From this project in Libya, several key insights emerged that can help other buyers make better decisions when selecting small mobile cranes and hoists. Even with light-duty applications, proper planning upfront saves time, effort, and costs later.

Consider Mobility Requirements Early

- Think carefully about where the crane will be used.

- Mobile cranes are only effective if they can move freely without obstruction.

- Planning mobility early avoids reinstallation hassles or last-minute site modifications.

Verify Lifting Height and Span

- Confirm that the crane's span and lifting height meet all operational needs.

- Even small miscalculations can cause workflow inefficiencies or the need for additional equipment.

- Measure the tallest loads and furthest reach points to ensure the crane covers them safely.

Ensure Power Supply Compatibility

- Always check the voltage, frequency, and phase before procurement.

- In this project, matching 380V, 50Hz, 3-phase power ensured smooth operation without extra adapters or transformers.

- Incorrect power planning can delay commissioning and increase costs.

Opt for a Robust but Simple Hoist

- For light-duty lifting, a simple, reliable chain hoist is often better than complex or over-engineered options.

- Easy-to-maintain hoists reduce downtime and require minimal operator training.

- Focus on durability and safety features, not unnecessary extras.

Conclusion

This project in Libya shows that mobile BZ cranes paired with chain hoists are a practical solution for lightweight, flexible lifting tasks in small workshops and industrial sites. The combination of mobility, simple installation, and reliable operation makes them well-suited for everyday material handling without the need for permanent infrastructure.

Key factors that contributed to the project’s success included:

- Careful equipment selection to match lifting capacity, span, and height requirements.

- Proper site preparation and installation, ensuring stability and safety from day one.

- Operator training, which allowed staff to use the equipment efficiently and safely.

By focusing on these essentials, small industrial sites can improve workflow, reduce manual labor, and maintain consistent productivity. This case serves as a practical example for buyers looking for cost-effective, low-maintenance lifting solutions that fit compact spaces and handle light loads reliably.