15T & 4T Gantry Cranes for Sale Ethiopia | Reliable & Efficient

Gantry cranes are a cornerstone of industrial operations, and in Ethiopia, they're becoming increasingly essential for workshops, steel fabrication, warehouses, and construction yards. They offer a practical solution when heavy materials need to be moved safely, quickly, and with precision. Unlike simple hoists or forklifts, gantry cranes can handle repeated lifts of both heavy and awkward loads without wearing down the floor or risking operator safety. In many Ethiopian industrial zones, production and storage areas can be compact, and material handling often involves irregularly shaped steel plates, machinery, or construction components. Gantry cranes bridge the gap between mobility and lifting strength, providing a flexible solution for operators. The cranes are designed for reliability in demanding conditions, making them practical investments for facilities that handle heavy loads daily. Gantry cranes are not just "nice to have" – they're integral to efficient operations across several industries in Ethiopia: With their ability to cover large areas and reach higher lifting points, gantry cranes help keep operations flowing smoothly without the constant need for extra manpower. Selecting the right crane starts with understanding each model's capabilities and how they fit your workspace. For this Ethiopia setup, two gantry cranes were supplied to cover different lifting needs, ensuring efficiency and flexibility across the facility. The 15-ton gantry crane is designed for heavier loads and broad coverage. It handles bulky materials like steel plates or machinery components while maintaining smooth and precise operation. Its span and lifting height make it ideal for larger workshops or fabrication areas. Specifications and Key Features: The 4-ton crane complements the heavier model by focusing on taller lifts and narrower spaces. It is perfect for reaching higher storage racks or moving lighter components without crowding the workspace. Its compact design allows flexible operation in tighter areas. Specifications and Key Features:Introduction

Overview of Gantry Cranes for Industrial Use in Ethiopia

Practical Applications

Crane Models and Specifications

15-Ton Gantry Crane

4-Ton Gantry Crane

Practical Applications

Gantry cranes are designed to make heavy lifting safer and more efficient, and their value is most obvious in day-to-day operations. In Ethiopian workshops and industrial facilities, these cranes handle a variety of materials while keeping workflows smooth and reliable.

Operators can use the cranes to lift and move steel plates, machinery parts, or construction components with ease, reducing manual labor and minimizing the risk of accidents. Their flexibility allows them to operate in different zones without interfering with other equipment or staff.

Key Applications:

- Handling steel plates, machinery parts, or construction materials: Safely move heavy or bulky items without strain on workers.

- Loading/unloading in warehouses and industrial workshops: Streamline material transfer from trucks or storage racks.

- Material positioning for assembly or fabrication: Precisely place components for welding, cutting, or assembly tasks.

- Efficient operation in mixed-load environments: Operate multiple cranes or hoists together for varying weights and heights.

With these practical uses, gantry cranes improve productivity, reduce downtime, and make material handling operations safer and more predictable.

Buyer Considerations

When buying gantry cranes, it’s easy to focus only on lifting capacity. In reality, several practical factors affect how well a crane performs in daily operations. Considering these points early can save time, reduce costs, and prevent operational headaches down the line.

Every facility has unique requirements, so buyers should assess their actual lifting needs. Choosing a crane that is either underpowered or excessively large can create inefficiencies. The layout of your workspace also plays a critical role—spans, travel paths, and clearance must align with the crane’s specifications to avoid collisions or bottlenecks.

Electrical compatibility is another crucial factor. These cranes run on 380V, 50Hz, 3-phase power, so ensuring stable voltage and proper grounding is essential for reliable operation. Finally, maintenance planning and long-term operational efficiency should be considered. Easy access to hoists, availability of spare parts, and a clear maintenance schedule help keep the crane running smoothly for years.

Key Buyer Considerations:

- Matching crane capacity to actual lifting needs: Avoid under- or over-specifying capacity; plan for peak loads.

- Workspace layout and crane span compatibility: Ensure the crane fits the available floor space and doesn’t interfere with workflow.

- Power supply and voltage stability (380V50HZ3P): Confirm local electrical compatibility to prevent downtime or equipment damage.

- Maintenance and long-term operational efficiency: Plan for easy inspection, regular servicing, and access to spare parts.

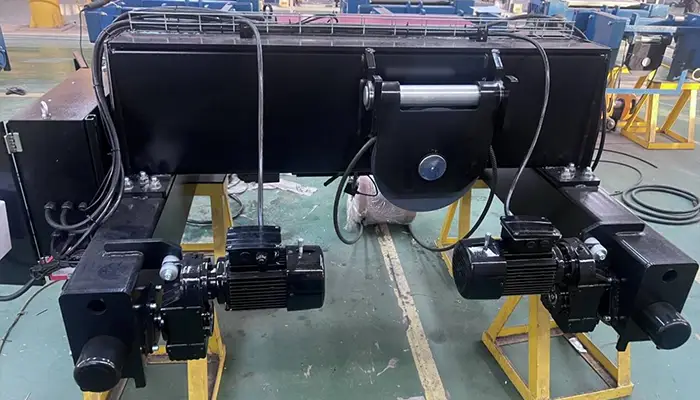

15 ton ton electric hoist trolley for double girder gantry crane

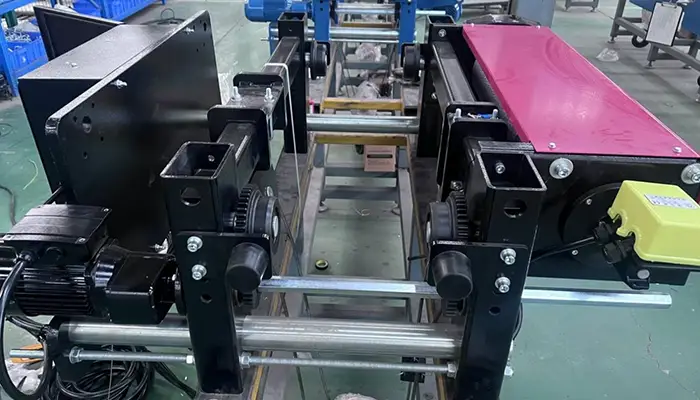

4 ton electric hoist for single girder gantry crane

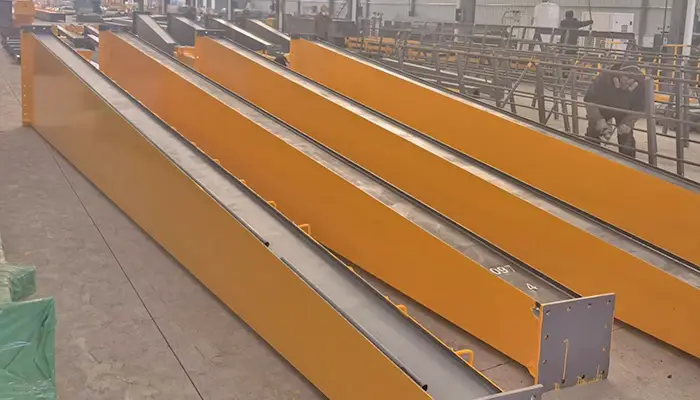

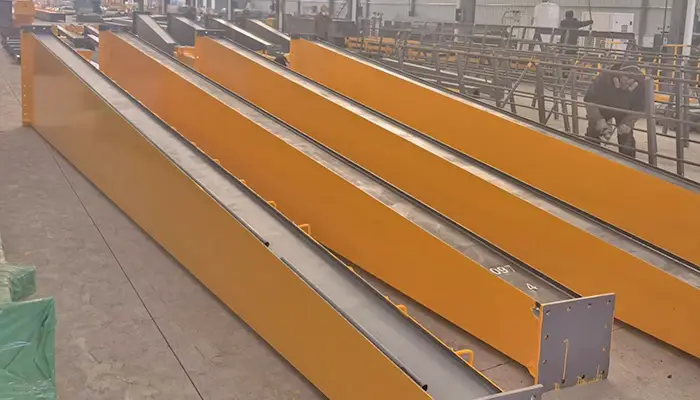

steel structure of gantry cranes

Supporting gantry legs of gantry cranes

Benefits for Buyers

Investing in the right gantry cranes can have a direct impact on daily operations. For buyers in Ethiopia, the combination of 15-ton and 4-ton cranes with European-style hoists provides tangible advantages that go beyond just lifting heavy loads.

One of the biggest benefits is mobility and flexibility. These cranes can cover multiple zones in a workshop or warehouse, allowing operators to move materials without having to reposition heavy machinery constantly. They adapt to changing workflows, which is especially useful in busy industrial spaces.

Key Benefits:

- Mobility & flexibility across different zones: Easily move loads from storage to production areas or between workstations without disrupting other operations.

- Precision lifting with European-style hoists: Smooth operation and accurate placement reduce the risk of material damage and improve workflow efficiency.

- Reduced labor costs and faster material handling: Minimize manual lifting, streamline loading/unloading, and speed up assembly or fabrication processes.

- Reliable and durable for continuous industrial use: Designed for daily heavy-duty operation, these cranes maintain performance over long periods with proper maintenance.

These benefits translate into practical savings and improved productivity, making the cranes a reliable solution for any facility handling heavy or awkward materials.

Technical Insights

Understanding the technical details behind these gantry cranes helps buyers make informed decisions and plan operations more efficiently. Proper planning ensures the cranes deliver maximum performance while remaining safe and easy to maintain.

Span and Lifting Height

Choosing the right span ensures the crane covers the required work area without obstructing other equipment or workflow. Similarly, the lifting height must match the tallest loads or storage racks, avoiding unnecessary repositioning and improving efficiency.

Hoist and Control Options

European-style electric hoists provide smooth, precise lifting. Buyers can choose between pendant control for close-up operation or remote control for wider coverage, allowing flexible operation based on workflow needs.

Safety Features

- Overload protection to prevent lifting beyond capacity

- Upper and lower limit switches to avoid collisions or over-lifting

- Emergency stop buttons for instant shutdown in case of hazards

Maintenance Considerations

These cranes use standard spare parts and are designed for easy access to hoists and mechanical components, reducing downtime and simplifying routine inspections.

- Optimal span and lifting height planning to maximize coverage without obstruction

- Hoist and control options for precise and flexible operation

- Safety features including overload protection, limit switches, and emergency stop

- Easy maintenance using standard parts and accessible components

Ethiopia Project

Real-world examples help buyers see how cranes perform in actual industrial settings. In this Ethiopia project, both the MGO 15-ton and MHO 4-ton gantry cranes were installed in a busy workshop to handle steel plates, machinery parts, and other heavy components. The goal was to improve material handling efficiency while keeping operations safe and reliable.

During the project, several practical lessons emerged. Careful installation planning was crucial to align crane spans, lifting heights, and runway placement with the workshop layout. Coordinating multiple cranes in the same facility required attention to workflow planning, ensuring that operators could use both cranes simultaneously without collisions or downtime. Finally, proper crane integration with European-style hoists allowed precise lifting, smooth material positioning, and easy maintenance access.

Key Takeaways from the Ethiopia Project:

- Installation planning: Align spans, lifting heights, and runway beams with the workshop layout for smooth operations

- Workflow coordination: Schedule crane movements and tasks to avoid interference and maximize efficiency

- Crane integration: Combine heavy and lighter cranes with precision hoists for flexible operation across multiple zones

- Operational results: Demonstrated improved efficiency, safer handling of materials, and reliable performance in daily industrial use

This case shows that a well-planned combination of MGO and MHO cranes can handle a variety of loads and tasks efficiently, while keeping safety and operational flexibility front and center.

Buyer Takeaways

Choosing the right gantry crane requires more than just checking the lifting capacity. The Ethiopia project demonstrates how practical planning ensures safety, efficiency, and long-term value.

Assess Lifting Needs

Match the crane's capacity and span to the loads you handle regularly. Overestimating or underestimating can cause inefficiency, wasted budget, or downtime.

- Identify the heaviest load you'll lift daily

- Consider the frequency of lifts and workflow requirements

- Include a safety margin for peak operations

Select European-Style Hoists

European-style hoists offer precise control and long-term durability. They reduce material damage and maintenance costs while ensuring smooth operation.

- Smooth, accurate lifting and positioning

- Long service life with minimal wear

- Compatible with different crane types and tasks

Plan for Power and Installation

Electrical and structural planning is key. Confirm that your site's power supply matches the crane requirements and that the crane layout fits the workspace.

- Voltage compatibility (380V, 50Hz, 3-phase)

- Runway placement and clearance

- Floor stability and access for maintenance

Maintain and Train Operators

Regular maintenance and operator training keep the crane reliable and safe. Proper planning reduces downtime and extends equipment life.

- Schedule inspections and lubrication regularly

- Use accessible spare parts for quick repairs

- Train operators on coordinated crane operation and safety

Bottom Line

By focusing on lifting needs, hoist quality, site planning, and maintenance, buyers ensure their gantry cranes operate efficiently, safely, and provide long-term value.