Overhead Cranes in Lithium Battery Plants: Explosion-Proof Guide

Learn when to use standard or explosion-proof overhead cranes in lithium battery production to ensure safety, compliance, and cost-efficiency.

Category: Featured

Your Trusted Explosion Proof Overhead Crane Manufacturer & Supplier

Overhead Cranes in Lithium Battery Plants: Explosion-Proof Guide

Overhead Cranes in Lithium Battery Plants: When Is Explosion-Proof Required?

General vs. Explosion-Proof Cranes: A Practical Guide for Lithium Battery Manufacturers

Lithium battery manufacturers often wonder when they truly need explosion-proof overhead cranes and when regular cranes will work just fine. This guide aims to help clear up that question. Knowing the difference can save money without sacrificing safety.Explosion-proof cranes are more expensive and complex, so it’s important to use them only where necessary.

The demand for lithium batteries is booming worldwide—thanks to electric vehicles, energy storage, and electronics.In these plants, overhead cranes are essential. They handle raw materials, assist with equipment maintenance, and move parts along the production line. Without cranes, the plant wouldn’t run efficiently.Because battery manufacturing involves flammable chemicals, safety is critical. Some areas require special explosion-proof cranes to prevent accidents. But not every part of the plant has this risk.

Do all areas in a lithium battery plant need explosion-proof overhead cranes?The short answer is no. Some zones handle volatile chemicals and need explosion-proof cranes, while others deal with non-flammable materials or have good safety controls.Knowing which areas require explosion-proof cranes helps manufacturers keep costs down and maintain a safe workplace.

Typical Crane Applications in Lithium Battery Plants

Common Types of Overhead Cranes Used

Lithium battery manufacturing involves various processes and materials that require different overhead crane solutions. Understanding the common crane types helps choose the right equipment for each task:

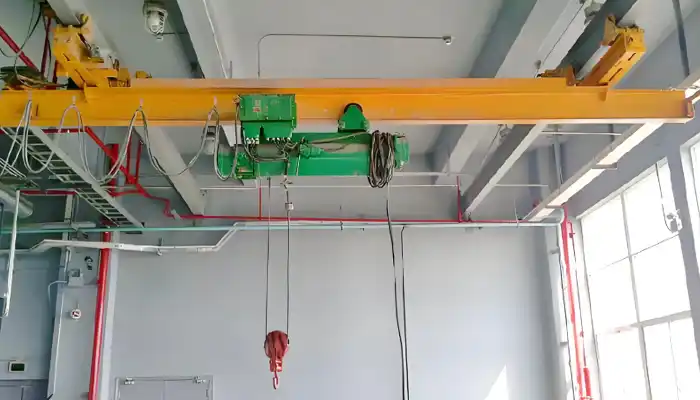

- Single Girder Cranes: These cranes use one main beam with the hoist running along it. They are generally lighter, simpler, and more economical. Single girder cranes are commonly used in areas where loads are moderate—typically up to 10 tons—and spans are relatively short. They work well in workshops, raw material handling zones, and assembly lines where heavy lifting isn’t the primary concern.

- Double Girder Cranes: Featuring two parallel beams, double girder cranes are built for heavier loads, often from 10 tons up to 30 tons or more. They provide higher lifting capacity, better stability, and allow for longer spans and heavier equipment movement. These cranes are ideal in battery plants for handling bulky machinery, heavy molds, or large battery modules that require robust support.

- Low-Headroom Cranes: Lithium battery plants often include cleanrooms or dry rooms with limited vertical space. Low-headroom cranes have a compact design that minimizes the crane’s height, maximizing the lifting height within tight ceilings. These cranes ensure smooth handling of sensitive materials in confined spaces without compromising safety or efficiency.

- Underrunning Cranes: These cranes run underneath the runway beams, saving space above the crane. They are especially suitable where ceiling heights are very low or where overhead space is restricted by other equipment or utilities. Underrunning cranes are flexible for small workshops or areas with structural constraints.

Typical Crane Functions in the Plant

Overhead cranes perform several critical roles throughout the lithium battery manufacturing process:

- Raw Material Handling: Moving raw materials such as aluminum and copper foils, separator films, and steel trays between storage and production areas. Efficient crane operation helps prevent damage to delicate materials and speeds up production.

- Equipment Installation and Maintenance: Cranes assist in installing or servicing machinery like coating machines, calendering equipment, winding machines, and laser welding units. They help lift and position heavy molds or tooling parts during changeovers.

- Material Transfer in Production Lines: Cranes handle semi-finished components, molds, and assemblies along the production flow, ensuring smooth transitions between processes.

- Battery Module and Pack Handling: Transferring finished battery cells, modules, or packs from assembly lines to warehouses or loading docks. This requires careful handling to avoid damage.

Factors Influencing Crane Choice

When selecting cranes for a lithium battery plant, manufacturers consider:

- Load Weight and Size: The weight and dimensions of materials and equipment directly affect crane capacity and type. For example, heavy molds require double girder cranes, while lighter materials can be handled with single girder models.

- Space Constraints: Areas with low ceilings or tight spaces need low-headroom or underrunning cranes to maximize available lifting height without structural modifications.

- Operational Frequency and Speed: How often the crane will be used and the required lifting speed impact the choice of motor, controls, and durability.

- Environmental Conditions: Cleanroom or dry room environments may require corrosion-resistant materials, smooth finishes, or special coatings to prevent contamination.

Typical Crane Capacities in Lithium Battery Plants

Different plant areas require cranes with varying lifting capacities. Choosing the right capacity ensures safe and efficient handling of materials and equipment:

- Raw Material Warehouse: 5 to 10 Tons: This area stores aluminum foil, copper foil, separator films, and steel pallets. Cranes here typically handle medium to heavy loads, such as bundled raw materials or palletized goods. A capacity of 5 to 10 tons meets most handling needs without oversizing equipment.

- Coating and Calendering Areas: 5 to 10 Tons: These sections involve heavy machinery and tooling. Cranes must lift parts, molds, or equipment for maintenance or replacement. The 5-10 ton range supports smooth handling while ensuring crane durability.

- Dry Rooms (Pre-Assembly): 1 to 3 Tons (Low-Headroom Cranes): Dry rooms require low-headroom cranes because of ceiling height limits. The materials here, often battery components or delicate assemblies, are lighter. Cranes with 1 to 3 tons capacity fit these precise and clean handling needs.

- Electrolyte Filling and Storage: 1 to 5 Tons (Explosion-Proof Required): These zones involve flammable liquids and solvents. Cranes handle drums or tanks carefully and require explosion-proof features. Capacities vary but usually fall between 1 and 5 tons for safe lifting of containers.

- Module and PACK Assembly: 3 to 5 Tons: Modules and battery packs need careful handling to avoid damage. Cranes with 3 to 5 tons capacity offer enough strength for moving semi-finished or assembled battery units during production.

- Finished Product Warehouse: 5 to 10 Tons: Final battery products are stored and shipped here. Cranes with 5 to 10 tons capacity manage palletized loads and packaging with ease.

Where General Overhead Cranes Are Suitable (No Explosion-Proof Required)

Many areas in lithium battery plants do not pose explosion risks because they lack flammable vapors or gases. In these zones, general overhead cranes provide safe, reliable, and cost-effective material handling. Below is a detailed overview of these typical areas and why standard cranes are sufficient.

Raw Material Warehouse

This area stores base materials needed for battery manufacturing. These materials are mostly solid and non-volatile, so the environment is relatively safe. The absence of flammable chemicals means standard cranes are suitable here.

- Materials: Aluminum foil, copper foil, separator films, steel pallets

- Environment: No volatile or flammable chemicals are stored or processed.

- Safety: Adequate ventilation and handling procedures prevent dust or static buildup.

- Crane Needs: Typical overhead cranes with capacities of 5–10 tons efficiently move and stack these materials without explosion-proof requirements.

Coating, Calendering, Electrode Preparation Areas

This section involves mechanical processes where raw materials are treated and shaped. Equipment is usually enclosed, reducing the chance of vapor or gas leaks.

- Processes: Fully enclosed machinery performing coating, pressing, and shaping.

- Risk Level: Low risk of hazardous vapor or gas emissions due to sealed machines and ventilation systems.

- Crane Role: General overhead cranes assist with feeding materials, equipment maintenance, and moving intermediate products.

- Capacity: Cranes typically range from 5 to 10 tons, adequate for most tasks here.

- Safety Measures: The controlled environment and process design minimize ignition risks, so explosion-proof cranes are unnecessary.

Dry Rooms (Pre-Assembly)

Dry rooms are highly controlled environments with very low humidity to protect sensitive battery components during assembly preparation. Space is limited, and special cranes are needed to fit the compact layout.

- Conditions: Ultra-low humidity (<1% RH), strict cleanliness, and contamination control.

- Materials: Battery components and materials are sealed and free from flammable chemicals.

- Hazards: Static electricity is the primary concern, managed by grounding and anti-static measures.

- Crane Specs: Low-headroom cranes with capacities of 1–3 tons are used to operate in tight ceiling spaces.

- Explosion Risk: No flammable vapors or gases are present; therefore, explosion-proof cranes are not required.

Module and PACK Assembly Lines

This area handles the assembly of battery modules and PACKs, where the battery cells are already stable and chemically inert.

- Materials: Assembled cells and modules, fully stabilized and enclosed.

- Environment: No ongoing chemical reactions or exposure to flammable solvents.

- Crane Function: Overhead cranes assist with precise handling, alignment, and transfer of modules during assembly.

- Typical Capacity: Cranes with 3–5 tons capacity efficiently cover most handling needs here.

- Safety: Stable materials and clean environments mean no explosion-proof certification is needed.

Finished Product Warehouse

The final stage involves storing completed batteries, ready for shipment. The environment here is low risk due to sealed battery units and controlled storage conditions.

- Purpose: Storage, inventory management, and logistics for finished battery products.

- Safety: Fully sealed batteries minimize risks of leakage or vapors.

- Crane Use: Standard cranes with capacities of 5–10 tons manage pallet handling and product movement.

- Risk Level: Minimal hazard; explosion-proof cranes are not necessary.

| Area | Materials & Conditions | Typical Crane Type, Capacity & Why Standard Cranes Work |

|---|---|---|

| Raw Material Warehouse | Aluminum foil, copper foil, separator films, steel palletsNon-flammable materials stored in ventilated warehouse | Crane Type: Single girder or light double girder cranesCapacity: 5–10 tonsWhy Standard: No flammable vapors, well-ventilated, materials are non-combustible |

| Coating & Electrode Prep Areas | Enclosed mechanical equipment, coated foils and filmsMinimal gas or vapor emissions | Crane Type: Single or double girder cranes, sometimes low-headroom cranes for tight spacesCapacity: 5–10 tonsWhy Standard: Processes are enclosed, low risk of flammable gases |

| Dry Rooms (Pre-Assembly) | Sealed battery parts, ultra-low humidity (<1% RH)Strict static control, very clean environment | Crane Type: Low-headroom single girder cranes, often with stainless steel or aluminum components to reduce contaminationCapacity: 1–3 tonsWhy Standard: No flammable substances, main hazard is static which is controlled by grounding and materials |

| Module/PACK Assembly Lines | Assembled battery cells, modules, and PACKsMaterials are stable and non-volatile | Crane Type: Single or double girder cranes, standard headroomCapacity: 3–5 tonsWhy Standard: No volatile materials, safe environment for general cranes |

| Finished Product Warehouse | Fully sealed, finished batteriesStorage and logistics area | Crane Type: Single or double girder cranes, sometimes overhead traveling cranes for large warehousesCapacity: 5–10 tonsWhy Standard: Batteries sealed and safe, low risk of fire or explosion |

Standard overhead cranes are ideal for lithium battery plant zones where there is:

- No presence of flammable or explosive atmospheres

- Non-volatile or sealed materials being handled

- Fully enclosed or well-ventilated processes

- Controlled static and electrical safety protocols

Using general cranes in these areas ensures operational efficiency while keeping costs reasonable and safety intact.

Where Explosion-Proof Cranes Are Required

Certain areas in lithium battery plants involve handling or exposure to flammable liquids, vapors, and gases. These environments present a real risk of fire or explosion if electrical equipment, including cranes, is not properly designed. Explosion-proof cranes are specifically built to operate safely under these hazardous conditions, preventing sparks or electrical faults that could ignite combustible atmospheres.

Electrolyte Filling Rooms

The electrolyte filling process involves using highly flammable solvents critical to battery performance. The confined environment of a dry room can cause vapors to build up, increasing explosion risk.

- Hazard: Solvents such as ethylene carbonate (EC), dimethyl carbonate (DMC), and diethyl carbonate (DEC) are volatile and emit flammable vapors during filling.

- Risk: Vapors can accumulate, especially in enclosed, low-ventilation spaces, creating a potentially explosive atmosphere.

- Requirement: Explosion-proof cranes are mandatory here. This means all crane components — motors, brakes, control panels, wiring — must comply with recognized explosion-proof standards to eliminate ignition sources.

Electrolyte Storage & Mixing Areas

Flammable liquids are stored and mixed in large quantities, often in drums and tanks. The nature of these materials demands strict safety controls.

- Hazard: Even minor leaks or spills can release flammable vapors into the air.

- Zone Classification: These zones are typically classified as Zone 1 or Zone 2, indicating a frequent or occasional presence of explosive gases.

- Requirement: Cranes in these zones must be fitted with explosion-proof motors, brakes, electrical enclosures, and control systems. All parts must be sealed and certified to prevent any spark or electrical discharge.

Cell Aging & Formation Rooms

This phase involves charging and stabilizing cells, which can sometimes lead to gas release due to defects or thermal events.

- Hazard: Thermal runaway or defective cells may leak flammable gases during formation or aging.

- Risk: Without adequate ventilation or gas detection, these gases can accumulate and create hazardous conditions.

- Requirement: Whether explosion-proof cranes are needed depends on the effectiveness of ventilation and gas monitoring systems. If ventilation is strong and gas leaks are promptly detected, standard cranes may be acceptable. Otherwise, explosion-proof cranes are required to ensure safety.

Explosion-proof cranes are engineered to meet strict safety certifications and standards (such as ATEX, IECEx, or CNEX). They use special materials, sealed enclosures, and spark-proof components to ensure zero ignition risk in hazardous areas.

Explosion-Proof Area Assessment Table

In a lithium battery plant, different factory areas have varying risks related to flammable materials and vapors. This table helps identify where explosion-proof overhead cranes are necessary and where standard cranes are safe to use. Understanding these distinctions helps manufacturers optimize safety without overspending on unnecessary explosion-proof equipment.

| Factory Area | Overhead Crane Use | Explosion-Proof Needed? | Reason |

|---|---|---|---|

| Raw Material Warehouse | Yes | No | Handles aluminum foil, copper foil, separator films, and steel pallets. No flammable vapors or gases present. |

| Coating/Calendering | Yes | No | Processes are enclosed mechanical operations with very low risk of vapor or gas emission. |

| Dry Room (Pre-Assembly) | Yes (Low-headroom cranes) | No | Materials are sealed and humidity is ultra-low. No flammable substances, though static control is important. |

| Electrolyte Filling Room | Yes | Yes (Mandatory) | Flammable solvents (EC, DMC, DEC) create vapor risk. Explosion-proof cranes are required to prevent ignition. |

| Electrolyte Storage Room | Yes | Yes | Flammable liquids stored in drums and tanks may leak vapors. Classified as hazardous Zone 1 or 2 areas. |

| Aging & Formation Room | Optional | Case-by-case | Potential release of flammable gases from cells. Explosion-proof cranes needed if ventilation or gas detection is insufficient. |

| Module/PACK Assembly | Yes | No | Handles stable battery modules with no volatile chemicals or vapors present. |

| Finished Product Warehouse | Yes | No | Batteries are fully sealed and stable. Risk of explosion is negligible. |

This table simplifies the decision-making process for crane selection based on the hazard level in each area. Explosion-proof cranes should be prioritized in areas with flammable vapors or liquids, while general cranes suffice in safer zones, ensuring cost-effective and safe plant operation.

Technical Requirements for Explosion-Proof Overhead Cranes

When working in hazardous environments like lithium battery plants, cranes must meet strict safety standards to prevent sparks or electrical faults that could ignite flammable vapors. Explosion-proof cranes are designed with special components and certifications to ensure safe operation in these risky zones.

Certification Standards

Explosion-proof cranes must comply with recognized international safety certifications. These certifications verify that the crane’s electrical and mechanical parts meet stringent rules for use in hazardous areas:

- CNEX (China): China’s national certification for explosion-proof equipment, ensuring compliance with local safety regulations.

- ATEX (European Union): Certification required for equipment used in potentially explosive atmospheres within the EU.

- IECEx (International): Global standard verifying compliance with IEC standards for explosion protection.

- NEC (National Electrical Code, US): Defines hazardous locations and safety requirements for electrical equipment in the US.

Explosion-Proof Components

Each critical part of the explosion proof crane is specially designed to prevent sparks, overheating, or ignition sources:

- Motors (Ex d, Ex e):Ex d (Flameproof enclosure): The motor housing can contain any internal explosion without igniting the surrounding atmosphere.Ex e (Increased safety): Electrical connections and components are built to prevent sparks or arcs.

- Brakes: Designed to avoid sparks during operation, often enclosed or made of non-sparking materials.

- Electrical Control Panels: Sealed and ruggedized to prevent ignition of explosive gases; often made with corrosion-resistant materials.

- Limit Switches: Explosion-proof limit switches are used to control crane movement safely without causing sparks.

- Cable Junction Boxes: Fully sealed boxes that prevent any flammable gas ingress and protect electrical connections.

- Grounding Protection: Effective grounding prevents static electricity buildup, a common ignition source in explosive environments.

Explosion-proof cranes combine these features to ensure safe and reliable operation in hazardous zones. Regular inspections and certifications must be maintained to comply with safety standards and keep the working environment secure.

Material Construction

The materials used in explosion-proof overhead cranes are carefully selected to ensure safety, durability, and resistance to harsh environments. Proper material choices help prevent sparks, corrosion, and failures that could lead to accidents in hazardous zones.

Stainless Steel Enclosures

Why Stainless Steel?: Stainless steel is widely used for crane enclosures and control panels because it is highly resistant to corrosion, rust, and chemical damage.

Benefits:

- Protects sensitive electrical and mechanical components from moisture and chemical exposure common in battery plants.

- Smooth surface reduces dust and particle buildup, helping maintain a clean and safe environment.

- Durable against physical impacts, extending equipment life and reducing maintenance.

Safety Role: Stainless steel enclosures can be sealed tightly to prevent explosive vapors from entering electrical compartments, reducing the risk of ignition.

Non-Sparking Trolleys and Wheels

Importance of Non-Sparking Materials: Sparks caused by metal-on-metal contact are a major ignition risk in explosive atmospheres.

Materials Used:

- Trolleys and wheels are often made from special alloys like bronze or engineered plastics designed to be non-sparking.

- Some wheels have polyurethane coatings to further reduce noise, wear, and spark risk.

Operational Benefits:

- Smooth, quiet operation with minimal friction.

- Reduces wear on runway beams and crane structures.

Safety Benefits:

- Prevents accidental ignition caused by mechanical impact or friction during crane movement.

- Essential for cranes operating in Zone 1 or Zone 2 hazardous areas.

Corrosion-Resistant Sealed Control Boxes

Purpose: Control boxes house critical electrical components like contactors, relays, and wiring junctions. Protecting them from corrosion and gas ingress is vital.

Features:

- Made from corrosion-resistant materials such as aluminum alloys or stainless steel.

- Fully sealed with gaskets or o-rings to prevent moisture, dust, and explosive gases from entering.

- Designed to withstand harsh chemical exposure typical in lithium battery plants.

Safety Contribution:

- Prevents sparks and electrical faults inside the control box from igniting external flammable atmospheres.

- Extends the service life of electrical components, reducing downtime and maintenance costs.

Using high-quality materials in explosion-proof crane construction ensures reliable performance and safety in the demanding environments of lithium battery manufacturing.

Optional Add-Ons for Explosion-Proof Overhead Cranes

In addition to core explosion-proof features, many lithium battery plants install extra safety and operational aids to boost crane performance and ensure even higher safety levels.

Gas Detectors and Alarms

- Purpose: Detects flammable or toxic gases in real-time near crane operation zones.

- Why Important: Early warning allows operators to stop work and evacuate before gas concentrations reach dangerous levels.

Features:

- Integrated into the crane control system for automatic alerts.

- Can trigger emergency shutdowns or ventilation systems.

- Benefit: Provides an added layer of protection, especially in areas like electrolyte filling or storage rooms where vapors can accumulate.

Anti-Collision and Positioning Systems

- Purpose: Prevents collisions between cranes, crane components, or obstacles in tight workspaces.

How It Works:

- Sensors and software monitor crane position and speed.

- Automatically slow down or stop cranes to avoid accidents.

Benefits:

- Improves workplace safety by reducing human error.

- Protects expensive equipment and materials from damage.

- Enhances operational efficiency with precise crane movement control.

Flame-Proof Lights and Signal Devices

- Purpose: Provides illumination and clear visual/audible signals in hazardous zones without ignition risk.

Characteristics:

- Designed to contain any sparks or flames within their housing.

- Certified explosion-proof lighting fixtures and alarms.

Benefits:

- Ensures safe visibility during crane operations, especially in dim or enclosed spaces.

- Alerts workers clearly to crane movements or emergencies.

- Complies with strict safety regulations for hazardous environments.

Adding these optional systems can greatly improve both the safety and efficiency of overhead cranes in lithium battery plants, ensuring compliance with stringent industry standards.

Common Mistakes and Misunderstandings About Explosion-Proof Cranes

Even experienced lithium battery manufacturers sometimes fall into certain misconceptions about explosion-proof crane requirements. These myths can lead to unsafe conditions or unnecessary costs. Let’s clear them up.

Myth 1: Sealed Barrels Remove All Explosion Risks

- Why people think this: If chemicals are stored in sealed containers, many assume vapors can’t escape, so no explosion hazard exists.

- The reality: Vapors can still leak during filling, transfer, or from imperfect seals.

Even small leaks in enclosed spaces can cause explosive atmospheres over time. - Takeaway: Explosion-proof cranes are still needed in electrolyte storage and filling areas to prevent ignition from leaked vapors.

Myth 2: Forklifts Are Always Safer Than Cranes in Explosive Areas

- Why people think this: Forklifts are mobile and seem less complex, so some assume they are inherently safer.

- The reality: Standard forklifts are not explosion-proof and can generate sparks or heat, igniting flammable gases.

Only explosion-proof forklifts designed to strict standards should be used in hazardous zones. - Takeaway: Don’t assume forklifts are a safe alternative to explosion-proof cranes without proper certification.

Myth 3: Partial Explosion-Proofing Is Enough

- Why people think this: Some believe that only certain crane components need explosion-proof protection, or only part of the crane should be certified.

- The reality: Safety standards require full compliance for all electrical, mechanical, and control parts in hazardous zones.

Partial protection leaves gaps where sparks or faults could cause explosions. - Takeaway: Full explosion-proof certification and installation are mandatory to ensure true safety.

Myth 4: Over-Specifying Explosion-Proof Equipment Is Safer

- Why people think this: Some assume more robust or higher-rated explosion-proof cranes provide extra safety.

- The reality: Overdesigning beyond actual hazard requirements adds unnecessary cost, complexity, and maintenance without improving safety.

It can also delay projects and reduce operational efficiency. - Takeaway: Correctly classifying hazardous zones and matching crane specs avoids wasted investment while ensuring compliance.

Crane Selection Considerations by Zone

Selecting the right overhead crane for each zone in a lithium battery plant is critical. The environment, materials handled, and safety requirements all impact what type of crane is appropriate.

Dry Rooms

Dry rooms have strict environmental controls with ultra-low humidity to protect sensitive battery components.

- Crane Type: Use low-headroom electric overhead cranes to fit within tight ceiling spaces without compromising lifting capacity.

- Materials & Construction: Components made from aluminum alloy or stainless steel are preferred. These materials resist corrosion and minimize contamination risks.

Special Features:

- Smooth, sealed surfaces help maintain ultra-clean conditions.

- Avoid lubricants or paints that could off-gas particles or chemicals.

- Bearings should be sealed to prevent dust or moisture ingress.

Why it matters: Dry rooms need cranes that don’t compromise the controlled atmosphere or introduce contaminants.

Hazardous Areas (Electrolyte Filling, Storage, Aging Rooms)

These zones have flammable vapors or gases, requiring strict explosion-proof standards.

- Crane Type: Only use fully certified explosion-proof cranes designed for hazardous environments.

- Certifications to Check: Must comply with local and international standards like CNEX, ATEX, IECEx, or NEC.

Technical Considerations:

- Motors, brakes, electrical panels, and controls must be explosion-proof rated.

- Verify the crane's gas group classification (e.g., IIB) matches the expected gases.

- Confirm the temperature class (e.g., T4) to ensure components won't ignite gases at operating temperatures.

Additional Features:

- Enclosed cable systems and sealed control boxes prevent spark generation.

- Optional gas detection alarms can be integrated for added safety.

- Why it matters: Using the wrong crane here risks catastrophic fire or explosion.

Clean Areas (Assembly Lines, Warehouses, General Workshops)

These zones handle stable materials and finished products, often requiring hygienic conditions.

- Crane Type: Use standard overhead cranes but with hygienic finishes to avoid dust and dirt buildup.

Materials & Components:

- Sealed bearings reduce maintenance and contamination risk.

- Surfaces should be smooth and easy to clean.

- Avoid paints, lubricants, or greases that can release harmful fumes or particles.

Operational Considerations:

- Consider noise reduction features if workers are nearby.

- Use energy-efficient motors for sustainability.

Why it matters: Maintaining cleanliness and worker safety is important without the cost or complexity of explosion-proof cranes.

The best crane choice depends heavily on the zone’s specific hazards and operational needs. Choosing the right materials, certifications, and design features ensures safe, efficient, and compliant handling throughout the plant.

| Zone | Crane Type & Features | Key Considerations |

|---|---|---|

| Dry Rooms | - Low-headroom electric overhead cranes- Aluminum or stainless steel parts- Sealed bearings | - Fits tight ceiling space- Resists corrosion and contamination- Avoid off-gassing paints and lubricants |

| Hazardous Areas | - Fully certified explosion-proof cranes (CNEX, ATEX, IECEx, NEC)- Explosion-proof motors, brakes, controls | - Match gas group and temperature class to environment- Enclosed cables and sealed control boxes- Optional gas detectors |

| Clean Areas | - Standard overhead cranes with hygienic finishes- Sealed bearings | - Smooth, easy-to-clean surfaces- Avoid off-gassing paints and greases- Noise reduction and energy-efficient motors possible |

This table gives a quick overview of the appropriate crane type, materials, and technical requirements for each zone in a lithium battery plant. Let me know if you want it expanded with examples or checklist items!

Manufacturer’s Service Recommendations

Choosing the right crane manufacturer is critical for lithium battery plants because of the strict safety standards and operational demands. A professional supplier provides tailored solutions and expert support to meet your plant’s unique requirements.

Low-Headroom Cranes for Dry Rooms and Low-Ceiling Areas

Dry rooms and cleanrooms often have tight vertical space. A good manufacturer offers:

- Custom-designed cranes that maximize lifting capacity while fitting into limited headroom.

- Use of lightweight, corrosion-resistant materials like aluminum and stainless steel to maintain cleanroom standards.

- Smooth and precise crane movements to protect delicate battery components during handling.

- Designs that minimize dust generation and simplify cleaning for hygiene compliance.

Complete Explosion-Proof Overhead Cranes for Electrolyte Filling and Mixing Zones

These areas handle flammable solvents and vapors, requiring strict safety measures:

- Cranes fully certified to major international explosion-proof standards, including CNEX, ATEX, IECEx, and NEC.

- Explosion-proof motors, brakes, control panels, and limit switches designed to prevent any ignition source.

- Construction with corrosion-resistant materials to withstand exposure to chemicals.

- Built-in safety features like flame-proof lighting and emergency stop systems for immediate response.

- Optional remote control operation to minimize worker exposure in hazardous zones.

Custom Lifting Clamps and Handling Tools for Electrolyte Drums

Handling electrolyte drums safely and efficiently requires specialized tools:

- Custom lifting clamps engineered for secure, stable gripping of electrolyte containers.

- Compatibility with explosion-proof cranes to ensure safety compliance.

- Ergonomic designs that improve handling speed and reduce worker fatigue during loading/unloading.

Certified Explosion-Proof Control Panels and Electrical Enclosures

Electrical components in hazardous zones must be fully protected:

- Control panels and enclosures built to resist corrosive environments and prevent sparks or arcs.

- Designs that ensure zero ignition risk in explosive atmospheres.

- Easy access for routine inspection and maintenance to keep downtime low.

- Provided with comprehensive compliance documentation and third-party certifications for peace of mind.

Comprehensive Support Services

A trusted manufacturer goes beyond supplying cranes to support your entire project lifecycle:

- Hazard zoning consultation to accurately classify plant areas and define crane requirements.

- Expert guidance on product selection tailored to your plant’s specific applications.

- Complete documentation support for regulatory approvals and safety audits.

- Skilled installation and commissioning teams to ensure safe and efficient setup.

- Operator training and ongoing maintenance programs to maximize crane safety and longevity.

- Responsive after-sales service, including spare parts supply and troubleshooting assistance.

Conclusion

Not every area in a lithium battery plant needs explosion-proof cranes. Understanding the specific hazards in each zone helps save costs and improve safety.

Proper hazard assessment ensures explosion-proof cranes are used only where flammable vapors or chemicals exist. In cleaner areas like raw material storage, coating, dry rooms, and assembly, standard cranes work well and are more cost-effective.For high-risk zones such as electrolyte filling and storage, explosion-proof cranes with certified components are essential to prevent ignition and meet safety standards.Partnering with an experienced crane supplier ensures you get the right cranes for each area, with support for installation, compliance, and maintenance.This smart, zone-based approach boosts safety, controls costs, and keeps your plant running efficiently in a growing industry.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch