Explosion Proof Underhung Crane & Underhung Overhead Crane

Underhung crane & underhung bridge crane with explosion proof design for hazadous application to ensure ceiling bridge crane safety. Check exproof underhung crane now.

Category: Underhung Bridge Crane

Your Trusted Overhead Crane Manufacturer & Supplier

Explosion Proof Underhung Crane & Underhung Overhead Crane

Good Price,High Safety & Low Headroom Design

Underhung crane: what are they? The terms "underhung crane" and "under-running crane" both refer to the same kind of overhead crane. Underhung cranes ride on the bottom flange of the runway beam rather than on top like other types of overhead cranes. The runway beam is frequently suspended from the roof or ceiling structure when using an underhung bridge crane, negating the need for additional floor columns to support the runway. If floor space and the need to remove obstacles are important concerns in the factory or warehouse, this ceiling crane can be useful. The underhung cranes can be mounted on the sloped ceilings or various crane systems.

Underhung cranes come in single- and double-girder designs. Double girder underhung cranes are frequently appropriate for greater capacity or longer spans. However, underhung or under-running cranes are usually only capable of carrying lighter loads (usually about 10 tons maximum).

Which Crane Type Suits My Workshop Best?Based on the application and building dimensions, the suitable overhead crane type for your particular needs is determined (if the overhead travelling crane is to be fitted to an existing building rather than a new building). Consult with your crane manufacturer and installer before deciding on the best piece of equipment to buy in order to decide if an underhung crane is the best option for you.

Overview of Explosion-proof underhung cranes

Explosion-proof underhung cranes are specialized lifting equipment used in environments containing flammable and explosive media, as well as steam and corrosive media. They are classified as either gas or dust explosion-proof. The explosion-proof level is selected based on the specific flammable and explosive media in the workplace. Explosion-proof underhung cranes perform airtight and anti-spark treatment on the electromechanical parts, electrical parts, and running friction parts of the fuselage to avoid explosions caused by electrical sparks or physical movement generated during the operation of the equipment when they come into contact with combustible media. Please call us for detailed explosion-proof underhung crane technical parameters or custom underhung crane designs.

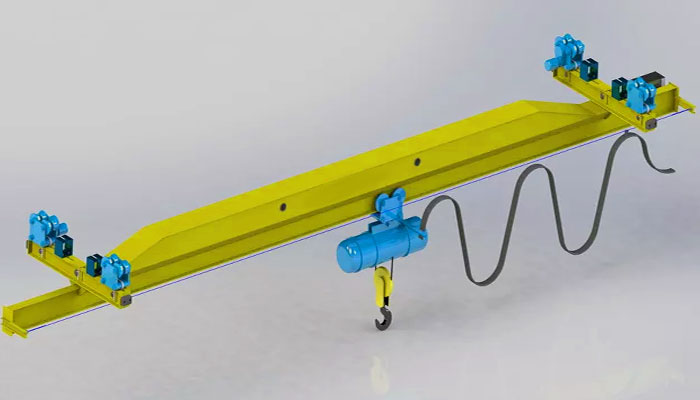

Economical explosion proof underhung crane

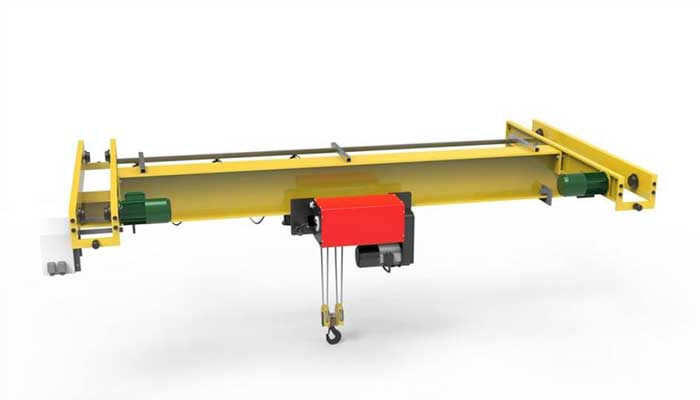

FEM standard explosion proof underhung crane

Overview of explosion underhung crane

LXB type single girder explosion proof underhung crane with capacity of 1 ton, 2 ton, 3 ton, 5 ton, 10 ton are a type of underhung bridge crane, the main technical parameters and explosion-proof grade are provided for your refrence.The one-source crane service including crane installation and maintenance are available. If you have any need of explosion proof single girder crane can be customized based on your lifting requirement and application conditions. Contact us to get construction plan and crane price for your project now.

- Product name: LXB explosion-proof underhung crane & suspension crane

- Explosion-proof grade: DIIBT4

- Use environment: This underhung crane is mostly used in warehouses, caves, coal mines and other places. High dust environment.

- Running track: I-beam.

- Technical Specifications Technical Specifications

- Rated lifting capacity Load: 0.5T, 1T, 2T, 3T, 5T, 10T.

- Limit span Span: S=3m-16m (S=span, the distance from the center of the left track to the center of the right track)

- Effective lifting height Lifting Height: H=3m-12m (H=lifting height, the distance from the ground to the highest point of the hook)

- Lifting structure: electric hoist

- Spreader type: hook

Explosion-Proof Classes & aplications

Class I | Locations: Are those where there are or may be enough flammable gases or vapors in the air to generate explosive or ignitable combinations. | |

Class II | Locations: Are those that pose a risk because flammable dust is present. | |

Class III | Locations: These are ones that are dangerous because they include easily ignitable fibers or flyings, but they are unlikely to exist in sufficient concentrations to generate ignitable mixtures. | |

Division | ||

Division I | Locations where, under typical operating conditions, hazardous air concentrations are present continuously, occasionally, or both. | |

Division II | Locations where hazardous concentrations are handled, processed, or used, but which are typically contained within closed containers or closed systems from which they can only erupt in the event of an accident or system failure. | |

Group | ||

Class I | Group A | Atmospheres containing acetylene |

Group B | Hydrogen-containing atmospheres, as well as gases or vapors that pose a similar risk, including synthetic gas. | |

Group C | Ethylene, cyclopropane, or ethyl ether vapor-containing atmospheres. | |

Group D | Gasoline, hexane, naptha, benzine, butane, alcohol, acetone, benzol, solvent fumes from lacquer products, or natural gas. | |

Class II | Group E | Metal dust-filled environments, such as those containing aluminum, magnesium, and the commercial alloys of these metals, as well as other metals having similarly risky properties. |

Group F | Environments with coal, coke, or carbon black dust. | |

Group G | Atmospheres containing grain dust, starch, or flour. | |

Typical Class I Locations:

- Petroleum refineries, as well as locations for storing and dispensing gasoline.

- Industrial businesses that utilize flammable liquid in dip tanks for operations like cleaning parts.

- Firms that produce chemicals from gas and oil, or petrochemicals.

- Dry cleaning facilities where cleaning fluid vapors may be present.

- Businesses that have spray booths where they paint or plasticize things.

- Aircraft hangars and places for fueling up.

- Utility gas plants and places that store and handle natural gas or liquefied petroleum gas.

Typical Class II Locations:

- Flour and feed mills, grain elevators

- Facilities that produce, use, or store magnesium or aluminum powder.

- Plants that use chemical or metallic processes manufacturers of plastics, pharmaceuticals, and Fireworks,etc.

- manufacturers of candy or starch.

- Coal preparation plants and other carbon-handling or processing regions; cocoa, sugar, and spice factories; sugar mills.

Typical Class III Locations:

- Any establishment that processes wood and generates sawdust or flyings, including textile mills, cotton gins, cotton seed mills, and flax processing facilities.

- Although fibers and flyings are unlikely to be suspended in the air, they can gather near machinery or on light fixtures where heat, a spark, or hot metal might set them ablaze

Explosion proof underhung crane suppliers

As China's leading manufacturer and supplier, we strictly adhere to national management standards. The explosion proof underhung crane can be customized on crane capacity, lifting height and span. If you have any special needs, please feel free to contact our crane engineer. We will custom a special underhung crane and equipment. We spend several decades researching and developing new products and parts to meet the needs of our customers. As a result, we have a wealth of relevant experience. If you have any further questions about the crane equipment, please contact us. Our team can help you and provide professional guidance.

Explosion proof overhead crane for sale

Many flammable and explosive gases, liquids, and dusts can leak or spill out during various processes of production, processing, transportation, and storage in many industrial sectors such as petroleum, chemical, and coal factories. When this type of material is mixed with air, it has the potential to cause serious accidents. As a result, when explosion-proof performance equipment is used in such hazardous environments, it must be certified by a professional organization. Our company's production has the necessary certificates and our explosion proof hoist and crane can help to ensure your material handling efficiency and safety.

Currently, our overhead crane and gantry cranes and jib cranes are exported and installed all over the world, including Algeria, Australia, Egypt, the United States, and Yemen.etc.

Get your custom explosion proof underhung crane good Crane Prices

After many years of development, we are now one of China's leading manufacturers and suppliers of types of overhead cranes. We should increase production of all types of crane equipment to meet market demand. We want to make the best lifting equipment in the world. Furthermore, because of the ease of transportation, most clients prefer to purchase our company's high-quality overhead crane.

Based on your particular application, the customized features such as explosion proof, automatic control, antiswing control, low headroom to meet your requirements. We have become business partners with many old friends since the firm's inception. Furthermore, we welcome new members to our organization. If you need any lifting cranes and hoists, please feel free to contact us. If you order our products, whether small or large, we will give you a fair price. Please contact us if you are interested in our products. Contact us today to check what we can do to save your cost.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch