European Open Winch Explosion Proof Overhead Crane for Heavy Lift

Heavy-duty overhead crane designed for safe, reliable lifting in hazardous environment, featuring modular open winch systems & explosion-proof compliance.

| Crane type | Explosion proof overhead crane with Euroepan style Open winch |

| Crane capacity | 5 ton to 75 ton and more |

| Crane span | As custom requirement |

| Lifting height | As your request |

| Power supply | Customized |

Category: Explosion Proof Cranes

Your Trusted Explosion Proof Crane Manufacturer & Supplier

Open Winch Explosion Proof Overhead Cranes 5 Ton to 75+ Ton

Explosion Proof Double Girder Overhead Crane Design with European Style Open Winch Trolley for Heavy Lifting

Introduction: Exploison Proof Overhead Crane with Open Winch Trolley European Style

What Is an Explosion Proof Overhead Crane?

An explosion proof overhead crane is a type of lifting equipment designed to work in hazardous areas. These are places where explosive gases, vapors, or dust may be present. A normal crane might create sparks, but this one won't. Its motor, wiring, and control box are all sealed or specially protected.

You'll often find these cranes in: Oil and gas plants,Chemical factories,Paint shops,Fuel storage areas,etc. They're built to keep both people and property safe.

In explosive environments, one small mistake can cause a fire or worse. That's why using the right equipment matters.

Explosion proof cranes are not just about safety. They also need to perform well. These cranes usually carry heavy loads and work every day. So, they have to be Reliable,Easy to control,Strong enough for 24/7 use, etc. You don't want to stop production because of a crane breakdown. And you definitely don't want to risk a fire.

What's Special About European-Style Open Winch Cranes?

This type of crane looks different—and works better for heavy-duty jobs.

The "open winch" means the hoisting parts are placed openly and separately. That makes it easier to inspect, cool, and maintain. It's designed for long-term, tough use.

Here's why buyers prefer this design:

- Separate motor and gearbox – Easy to maintain and cool

- Modular structure – Easier to upgrade or replace parts

- Precision lifting – Less sway, smooth travel, and exact positioning

- Quieter operation – Less noise in the plant

This design also supports higher duty cycles. That means it can run more often, with less wear and tear.

Lifting Up to 75 Tons—And More If Needed

These cranes can lift up to 75 tons with ease. And yes, if your project needs more, they can be customized for higher capacity. That's the beauty of a tailored solution.

Some projects require double trolley systems. These allow two trolleys to work together to lift a long or awkward load. It's not just about lifting heavy—it's about lifting smart.

Double trolley options offer:

- Better balance and load distribution

- Safer lifting for long or bulky items

- Flexible control—move one or both trolleys as needed

If your job site has complex lifting needs, this setup could be a perfect match.

What is a European Style Open Winch Explosion Proof Overhead Crane?

A European style open winch explosion proof overhead crane is designed for safe and powerful lifting in hazardous environments. It uses a modern open winch system and is built to meet strict explosion-proof standards.

Key things to know:

- Open winch trolley: Allows for high lifting speeds and smooth operation under load.

- Explosion-proof motors and controls: Specially sealed to prevent sparks in explosive zones.

- Heavy-duty performance: Built to handle frequent and tough lifting jobs.

- Strong steel frame: Designed for stability, even with large and uneven loads.

How It Differs from Traditional Explosion Proof Cranes

Traditional cranes with explosion-proof features often have compact or closed designs. These are limited in performance and harder to maintain.

How the European style stands out:

- Higher lifting capacity: Can handle up to 75 tons or more—ideal for heavy-duty industries.

- More durable construction: Designed for continuous or high-frequency operation.

- Better access to parts: Open design makes repairs and inspections much easier.

- Precise movement control: Uses VFD systems for smoother starts, stops, and speed control.

European style double girder explosion proof overhead crane with open winch trolley

What Is the Open Winch Design?

The open winch design separates all the main lifting components. That means they're not packed inside a hoist body. Instead, they are easy to see, reach, and work on.

Modular Structure

Each part is independent and replaceable.

- Makes upgrades or changes simple without needing to redesign the whole crane.

- Useful when different lifting tasks need custom setups.

Separate Motor and Gear Units

Cooling and servicing are easier.

- Parts don't overheat as quickly because they're spaced out.

- Easier to maintain each part, which saves downtime and cost.

Easy Maintenance and Inspection

No need to disassemble everything.

- Technicians can quickly check or repair components.

- Helpful for industries where regular safety checks are required.

Built to European Standards (EN, ATEX, IECEx)

These cranes aren't just safe—they're certified. That gives buyers peace of mind, especially when working in high-risk areas.

Complies with major safety systems:

- EN standards: Covers the structure, operation, and safety of cranes in Europe.

- ATEX certification: Required in the EU for equipment used in explosive zones.

- IECEx certification: A global system for explosion-proof product approval—useful for export and multinational projects.

Explosion Proof Features and Protection Classes

Explosion-proof overhead cranes are designed to operate safely in dangerous environments where flammable gas, vapor, or dust may be present. To avoid the risk of ignition, all key components are built with certified protection. Below is a detailed breakdown of where and how these safety features are applied.

Hazard Zones and Classifications

Before choosing an explosion-proof crane, it's important to understand where and how often hazardous materials appear in your workspace. These zones determine the level of protection needed.

- Zone 1: Explosive gas is likely to appear during normal operations. Requires full explosion-proof protection.

- Zone 2: Explosive gas may occur only occasionally and for a short time. Still needs certified explosion protection.

- Zone 21: Explosive dust is likely to appear during daily operation. Protection focuses on dust-tight enclosures.

- Zone 22: Explosive dust may occur infrequently. Protection is less strict but still critical.

Crane specifications should always match the zone classification to ensure compliance and safety.

Explosion-Proof Crane Components

Each main part of the crane must be adapted or enclosed to prevent sparks or heat from escaping and causing an explosion. Below is a detailed look at what needs to be protected and how.

Explosion Proof Control Panels – The Brain of the Exproof Crane, Fully Protected

Control systems must work without creating risk, even in risky environments.

- Sealed housings prevent flammable substances from entering.

- Built using components rated for gas or dust zones.

- Wiring and terminals use explosion-proof materials and layout.

Motors – The Power Source Must Be Sealed and Safe

Motors in hazardous zones must be sealed and explosion-proof.

- Enclosed flameproof construction (usually Ex d type).

- Designed to keep heat and sparks inside.

- Often include thermal sensors and insulation to avoid overheating.

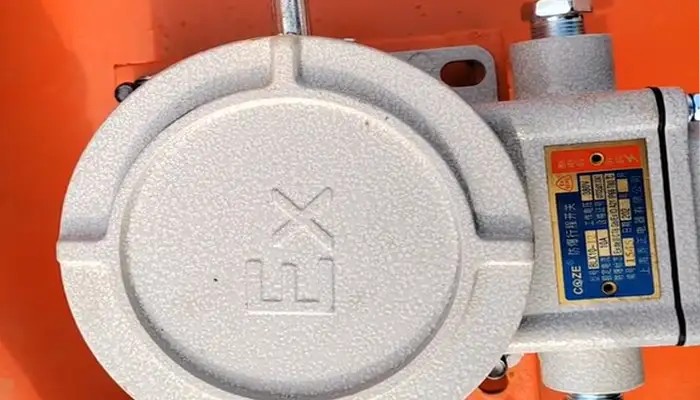

Explosion Limit Switches – Safety Stops with Spark-Free Operation

Limit switches must operate reliably without risk of igniting gas or dust.

- Housed in spark-resistant enclosures.

- Designed to break circuits safely at end positions.

- Certified for use in gas and dust zones.

Brakes – Spark-Free and Heat-Controlled for Lifting Safety

Braking systems must hold and stop heavy loads without generating sparks.

- Made with non-sparking, explosion-resistant materials.

- Often electromagnetic and designed to fail safely.

- Fully enclosed to isolate heat and prevent friction exposure.

Lighting and Cabling – Reliable Power and Visibility Without Risk

Lighting and electrical cabling must also follow explosion-proof standards.

- Low-heat, sealed light fixtures rated for gas or dust zones.

- Armored or shielded cables placed inside sealed conduits.

- All junction boxes and connectors are explosion-protected.

Explosion Protection Types

Different types of explosion protection are used depending on the component's function and the level of hazard. Each has its own method of keeping the environment safe.

| Protection Type | Code Example | What It Does |

|---|---|---|

| Flameproof Enclosure | Ex d | Contains any explosion inside the housing so it doesn't spread. |

| Increased Safety | Ex e | Avoids arcs, sparks, or overheating in the design itself. |

| Intrinsic Safety | Ex i | Limits the energy in circuits so ignition is impossible—even in failure. |

| Pressurization | Ex p | Keeps flammable gases out by maintaining higher pressure inside the enclosure. |

Each type has its use, and proper selection depends on where and how the crane will operate.

Double Trolley and Custom Configurations for 75 Ton and More

When lifting ultra-heavy or long materials, a single trolley might not be enough. That's where a double trolley system comes in. It offers better load control, safer lifting, and flexible operation.

Advantages of a Double Trolley System

Double trolley Overhead Cranes setups are designed for loads that need to be lifted from more than one point. This section explains why that matters and how it improves your operations.

Improved Load Distribution

Lifting from two points spreads the load more evenly.

- Reduces the strain on the crane structure and runway beams.

- Lowers the risk of equipment damage caused by uneven lifting.

- Makes heavy lifts more stable and secure.

Tandem Operation for Large Items

When loads are bulky or awkward, both trolleys work together.

- Synchronization keeps the load balanced during lifting and travel.

- Perfect for things like pressure vessels, long machinery, or coils.

- Reduces the chance of tilting or swaying during movement.

Greater Flexibility for Long or Uneven Loads

Not every lift is the same—double trolleys adapt to each task.

- Each trolley can operate together or independently.

- Useful for materials that have irregular shapes or shifting centers of gravity.

- Ideal for industries like shipbuilding, steel manufacturing, and energy.

Examples of Custom Configurations

Not every crane fits the same mold. This section shows how double trolleys can be configured to match specific tasks or lifting goals.

2×37.5 Ton Trolleys for 75 Ton Lifting

Two equal trolleys work in harmony to share the load.

- Allows a combined lifting capacity of 75 tons.

- Each 37.5-ton open winch trolley can also be used on its own.

- Offers maximum flexibility when not every lift requires full capacity.

Independent Operation Options

Each trolley doesn't have to do the same job every time.

- Operators can control them separately for dual lifting in different zones.

- Increases efficiency by handling two smaller lifts at once.

- Good for workshops with mixed-size materials.

Customized Lifting Specifications

Every crane setup is tailored to the actual working conditions. These design options make sure the crane fits your space and use.

Custom Spans

Beam width is matched to your building or gantry layout.

- Fits both narrow and wide bays.

- Avoids costly structural modifications.

Lifting Heights

Hook height is adjusted to your tallest load or clearance needs.

- Works well in tall workshops or when lifting tall machinery.

- Prevents collisions with the ceiling or obstacles.

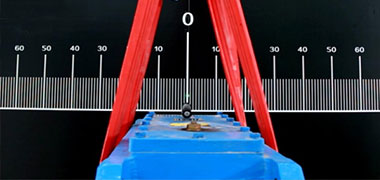

Variable Lifting Speeds

Speed control makes lifting smoother and safer.

- Open winch design allows fine-tuning for different loads.

- Slower speeds for precision work, faster speeds for high volume handling.

Applications in Hazardous Industries

Explosion-proof overhead cranes with European-style open winch trolleys are built for tough and hazardouse environments where safety is not optional. These exproof cranes are widely used in industries where flammable gases, vapors, dust, or chemicals are part of daily operations. Below are key areas where these cranes prove essential.

These sites often involve flammable gases and pressurized systems.

- Used for lifting pumps, valves, compressors, and pipeline parts.

- Suitable for both offshore platforms and onshore refineries.

- Cranes must meet strict ATEX or IECEx explosion-proof standards.

Chemical processing often creates vapors and heat—risk factors for ignition.

- Cranes handle tanks, chemical containers, and large machinery.

- Common in areas where solvents, fuels, or high-pressure gases are processed.

- Equipment needs certified enclosures and spark-free components.

Paint Shops and Chemical Handling Areas

Even routine operations like coating or surface treatment can be dangerous.

- Ideal for spray booths, paint-curing zones, and chemical mixing rooms.

- Explosion-proof lighting and motors help prevent ignition.

- Helps transport drums, barrels, and fixtures during production.

Explosive Material Storage Areas

Some zones are designed specifically to store flammable or explosive materials.

- Cranes used for moving crates, containers, or raw materials.

- Safe lifting helps prevent accidental impacts or sparks.

- Enclosures and control systems are sealed and grounded properly.

Mining and Heavy Manufacturing Zones

Dust, gas, and heavy loads often go hand-in-hand in mining or metallurgy.

- Used in coal handling, ore lifting, and smelting shops.

- Must handle rough conditions like dust clouds or extreme temperatures.

- Durable explosion-proof design ensures reliability in high-risk zones.

Benefits of European Style Open Winch Design

The European-style open winch design stands out for its precision, durability, and safety—especially in demanding industrial environments.

Enhanced Safety and Efficiency

Open winch designs are built to handle heavy loads with safety in mind.

- Components are mounted openly for easier inspection and heat dissipation.

- Explosion-proof housing is used only where needed, reducing complexity.

- Minimizes downtime with faster access for checks and service.

Smooth and Precise Load Handling

Precision matters—especially in hazardous zones where one wrong move can be risky.

- Fine load control thanks to advanced gearboxes and frequency converters.

- Soft start and stop functions reduce load swing and mechanical stress.

- Ideal for handling fragile, flammable, or sensitive equipment.

Low Maintenance and Extended Lifespan

Designed for long service life and reduced wear—even in harsh conditions.

- Separate motor, gearbox, and drum units allow for quick part replacement.

- Reduced friction and vibration increase working efficiency and component life.

- Lower total cost of ownership over time.

Intelligent Controls and Monitoring

Modern cranes go beyond lifting—they think ahead.

- Equipped with VFD (Variable Frequency Drive) for smooth speed control.

- Load monitoring prevents overloading and ensures safety margins.

- Built-in diagnostic tools help detect issues early and avoid failures.

Easy Integration with Automation and Safety Systems

Many plants today are semi or fully automated—these automatic cranes are ready.

- Supports remote control, programmable lifting cycles, and automated stops.

- Can connect with plant-wide systems like SCADA or PLCs.

- Explosion-proof versions of sensors and controls keep it safe and smart.

Key Considerations When Selecting an Explosion Proof Overhead Crane

Choosing the right explosion-proof crane is critical to both safety and productivity. If you have any need of explosion proof overhead crane or have any doubts or questins, please feel free to contact us.

Lifting Capacity and Duty Cycle

Understand the weight and frequency your crane needs to handle.

- Select a crane that can safely lift your heaviest loads, with some margin.

- Duty cycle ratings (A3 to A5) indicate how often and hard the crane can work without overheating or wearing out too quickly.

- Matching capacity and duty cycle helps avoid premature failures and downtime.

Type of Hazardous Zone and Compliance Needs

Different sites have different explosion risks and rules.

- Identify if the crane will work in Zone 1, Zone 2, or other classified hazardous areas.

- Make sure the crane meets necessary certifications (ATEX, IECEx) for your zone.

- Choose explosion-proof components suitable for the exact risk level.

Single vs. Double Trolley Configuration

Decide based on load type and handling requirements.

- Single trolley cranes are simpler and great for most standard lifts.

- Double trolley systems are better for long, heavy, or awkward loads needing balanced lifting.

- Consider your workflow and flexibility needs when choosing.

Space Constraints and Structural Design

Your facility layout impacts crane design choices.

- Measure clearances, ceiling height, and available runway span carefully.

- Open winch designs are good for low headroom and tight spaces.

- Structural strength of beams and supports must handle crane loads plus safety factors.

Control Method

How operators will safely and efficiently run the crane.

- Pendant control offers direct and simple operation close to the load.

- Radio remote control allows freedom of movement and better visibility.

- Cabin control is ideal for large facilities or precise control in complex operations.

Customization Needs and Future Scalability

Plan for today's and tomorrow's demands.

- Can the crane be customized for your specific lifting heights, spans, or speeds?

- Think about possible future expansions or changes in production needs.

- Modular open winch designs often make upgrades and maintenance easier.

Conclusion: Send Us An Inquiry on Heavy Lifting Explosion Proof Overhead Cranes

To sum up, our European style open winch explosion proof overhead cranes offer:

- Reliable heavy lifting — up to 75 tons and beyond with customized options

- Top-notch safety features designed for hazardous environments

- Flexible configurations, including double trolley systems for complex loads

- Full compliance with European and international explosion-proof standards

Safety, customization, and strict compliance aren't just checkboxes — they're the foundation of every crane we deliver. Our cranes are built to keep your workplace safe while maximizing your lifting efficiency.

If you're working in oil & gas, petrochemical, mining, or any hazardous industry, now is the time to upgrade to a crane solution tailored for your toughest demands.

Ready to improve your lifting operations with a safe, powerful, and compliant explosion-proof crane?

Send us an inquiry today. Let's discuss your specific needs and find the perfect crane solution for your facility.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch