Explosion-Proof Open Winch Trolley for Double Girder Cranes

Explosion proof open winch for sale. Safe, durable crane trolley with sealed explosion-proof motor, brake & controls for hazardous gas & dust environments.

Category: Explosion Proof Cranes

Your Trusted Overhead Explosion Proof Crane Kit Manufacturer & Supplier

Explosion-Proof Open Winch Trolley for Double Girder Cranes

Designed for Overhead Cranes & Gantry Crane in Hazardous Environments | ATEX & IECEx Compliant

Overview of Explosion-proof Open Winch Trolley

The explosion-proof open winch trolley is the main lifting unit used in QB-type double girder explosion-proof overhead cranes. It handles the lifting and lowering of heavy loads in areas where safety is a major concern due to fire or explosion risks.

This trolley is not like a standard hoist. It's specially built for hazardous work areas, where flammable gases, vapors, or dust are present. These conditions are common in industries like oil refining, chemical processing, and some water treatment facilities.

Designed for Dangerous Work Zones

This open winch trolley is made to run safely in explosive environments.

- It's suitable for Zone 1 and Zone 2, which are areas where explosive gas might appear during normal operation.

- It can also be used in Zone 21 and Zone 22, where explosive dust or particles may be in the air.

If you work in a place where one small spark can cause a disaster, this is the type of trolley you need.

Heavy-Duty and Reliable

This trolley is built for long-term, heavy-duty use.

- It lifts and moves loads from 5 tons up to 75 tons or more.

- It runs smoothly and can handle frequent lifting cycles.

- It's open-structure means easy maintenance and cooling, which helps in tough environments.

Whether you're moving tanks, barrels, or machinery, this trolley is up to the task—and it does it without risking safety.

Technical Specifications

Our explosion-proof open winch trolley comes with flexible specs to meet different industrial needs. Here's what you can expect:

- Rated Load Capacity:

From 5 tons up to 75 tons or more. We can customize based on your specific lifting requirements. - Lifting Height:

Standard models support up to 30 meters, with options for even higher lifts if needed. - Lifting Speed:

Choose between single speed or dual speed motors. For smoother control, we also offer optional Variable Frequency Drive (VFD) systems. - Travel Speed:

Typical speed ranges from 5 to 20 meters per minute. Custom speeds can be arranged to fit your operation. - Power Supply:

Designed for common industrial power — 380V or 415V, 3-phase, and supports both 50Hz and 60Hz frequencies. - IP Rating:

Components come with protection levels between IP55 and IP65, ensuring good resistance to dust and water.

Key Features

Our explosion-proof open winch trolley is designed to keep your operation safe, efficient, and reliable in hazardous environments. Here's what makes it stand out:

Flameproof Motor, Brake, and Control Systems

- All critical components are fully enclosed to prevent sparks or flames from escaping.

- The motor and brake are built to handle heavy loads without risking fire hazards.

- Control boxes feature flameproof housings to protect electrical parts.

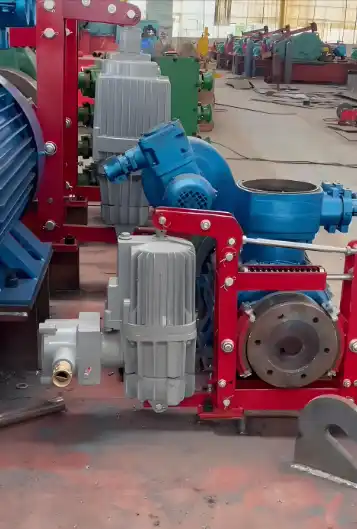

Modular Open Winch Design

- Open layout allows quick and easy access to internal parts.

- Modular design means repairs or replacements can be done by swapping individual parts, saving time and cost.

- Improved airflow helps cool components, boosting reliability.

High Lifting Capacity (5t to 75t+)

- Supports heavy industrial lifting, from 5 tons up to 75 tons or more.

- Suitable for large, bulky loads like tanks, heavy machinery, or metal products.

Robust Steel Structure with Anti-Corrosion Finish

- Heavy-duty steel frame resists vibration and heavy use.

- Corrosion-resistant coatings protect against moisture, chemicals, and salt air — ideal for harsh environments.

Sealed Junction Boxes and Spark-Proof Wiring

- Fully sealed junction boxes prevent any sparks or arcs from escaping.

- Wiring is protected with spark-proof materials and routed through secure conduits.

Precise Speed Control Options

- Dual-speed motors let operators choose between fast lifting or slow, precise movements.

- Variable Frequency Drives (VFD) provide smooth speed adjustment for delicate tasks.

Explosion-Proof Classification

Our QB-type open winch trolley meets strict safety standards to ensure reliable operation in hazardous areas.

Certified Compliance

This trolley fully complies with major explosion-proof regulations, including:

- GB3836 (China's national explosion-proof standard)

- ATEX Directive 2014/34/EU (Europe)

- IECEx Standard (International)

Protection Types

The trolley is designed with advanced explosion-proof protections such as:

- Ex d IIB T4 and Ex d IIC T4 — flameproof enclosures suitable for gas groups IIB and IIC

- Ex tD A21 IP65 — explosion protection for dust environments with high ingress protection (IP65)

Certified for Hazardous Zones

This equipment is safe to use in areas with different types of explosive atmospheres:

- Gas Groups: IIA, IIB, and IIC — covering a wide range of flammable gases and vapors

- Temperature Classes: T1 to T4 — ensuring the surface temperature of equipment stays below ignition points of various gases

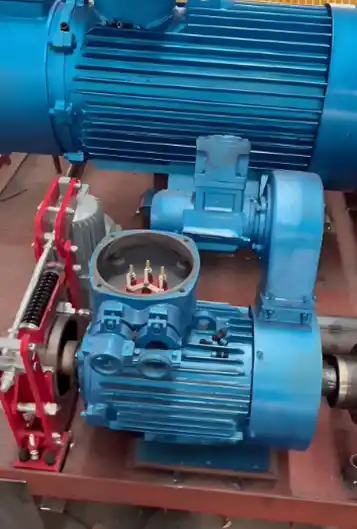

Main Explosion Proof Components of Open Winch Trolley for Heavy Duty Crane

Each part of the explosion-proof open winch trolley is designed for safety, durability, and smooth operation.

Explosion proof open winch for sale

Wheel

Explosion proof motor underconstruction

Explosion proof brake

Explosion proof electrical box

Explosion proof pendant control

Explosion-Proof Motor

- The motor is fully enclosed in a flameproof casing to prevent any sparks from escaping.

- It has thermal protection to avoid overheating during heavy use.

- Built to resist sparks and operate safely even in explosive gas or dust environments.

Explosion-Proof Brake

- This is an electromagnetic brake designed to stop the load quickly and safely.

- It acts fast and is fail-safe, meaning it will hold the load even if power is lost.

- Its sealed design prevents sparks from escaping during braking.

Explosion-Proof Electrical Box

- All electrical connections are housed inside a sealed enclosure that blocks sparks and dust.

- The wiring inside uses durable, spark-proof insulation to withstand tough industrial conditions.

- Designed for easy inspection and maintenance without compromising safety.

Drum & Wire Rope Assembly

- The drum holds a hardened steel wire rope that resists twisting and kinking.

- The wire rope is specially treated to handle heavy loads and last longer.

- The assembly ensures smooth winding and unwinding during lifting and lowering.

Gearbox

- Uses a heavy-duty helical gear reducer for quiet and efficient power transmission.

- Designed for low noise and minimal vibration, making operation smoother.

- Built tough to withstand heavy loads and constant use in hazardous environments.

Applications

The explosion-proof open winch trolley is built for tough jobs in hazardous environments. It's trusted in industries where safety and reliability are critical. Here are some typical places where it works best:

- Oil & Gas Refineries

Handling heavy equipment and materials in areas with flammable gases. - Petrochemical Plants

Lifting and moving loads where explosive vapors are common. - Paint and Coating Workshops

Working safely in environments with volatile, flammable chemicals. - Wastewater Treatment Facilities

Operating in places where methane and other explosive gases may be present. - Explosives and Ammunition Plants

Where absolute spark prevention is mandatory. - LNG and Chemical Terminals

Handling hazardous liquids and gases with strict safety requirements.

This trolley is made to keep your operation safe and efficient in these high-risk zones.

Options & Customization

We know every job is different. That's why our open winch trolley comes with flexible options to fit your exact needs.

- Variable Frequency Drive (VFD) Control

Allows smooth, precise speed adjustments for safer and more efficient lifting. - Explosion-Proof Remote or Cabin Control

Choose remote controls or operator cabins that meet strict explosion-proof standards for safer operation. - Maintenance Platform and Access Ladders

Optional built-in platforms and ladders make routine checks and repairs easier and safer. - Corrosion-Resistant Materials

Special coatings and materials are available for harsh marine environments or aggressive chemical exposure. - Custom Lifting Heights, Speeds, and Power Supply

We tailor the trolley's lifting height, speed settings, and electrical requirements to match your exact application.

With these options, you get a solution that fits your site, your safety needs, and your workflow perfectly.

Get a Quote / Inquiry Form

Ready to find the perfect explosion-proof open winch trolley for your project? Our inquiry form makes it simple to get an accurate quote tailored to your needs.

What We Need From You

To provide the best solution, please share some key details:

- Load Capacity: What's the maximum weight you need to lift?

- Lifting Height: How high does the trolley need to lift your loads?

- Hazardous Zone Classification: Which explosion-proof zone will the trolley operate in (e.g., Zone 1, Zone 2)?

- Voltage and Power Supply: What's your site's electrical setup (e.g., 380V, 415V, 3-phase)?

- Application Site: Describe your work environment—oil refinery, chemical plant, or other hazardous locations.

Send Us Your Documents

If you have:

- Layout drawings

- Project specifications

- Or any other technical documents

Feel free to upload them directly with your inquiry. This helps us understand your site better and provide a solution that fits perfectly.Contact us today to get your explosion proof open for your double girder crane. Explosion proof crane kit for your need!

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch