High-Precision Overhead Cranes | Accuracy, Safety & Efficiency

High precision overhead crane for sale. Tailored overhead crane designed for heavy industrial lifting. Maximize accuracy, safety, efficiency.

Category: Featured

Your Trusted Overhead Crane Manufacturer & Supplier

High-Precision Overhead Cranes

Maximize Accuracy, Safety, and Efficiency for Heavy Industrial Lifting

Introduction – Why High-Precision Cranes Matter for Buyers

1. What are the consequences of inaccurate crane operation?

Even small misplacements can create major problems. A swinging or off-target coil can damage materials, harm equipment, or endanger workers. Inaccurate operation leads to downtime, repair costs, and quality issues.

- Material damage: Scratches, dents, or deformation of steel, aluminum, or delicate machinery parts

- Safety hazards: Collisions, dropped loads, or tipping risks

- Production delays: Misaligned parts or repeated lifts slow workflow

- Quality issues: Poor positioning impacts assembly and final product accuracy

Precision ensures loads are placed exactly where needed, every time.

2. When are high-precision cranes essential?

Not every workshop needs ultra-precise cranes, but in specific cases, standard cranes aren't enough. High-precision cranes are essential when handling:

- Heavy, long, or fragile loads: Steel plates, machinery components, wind turbine blades, or aerospace panels. These loads require precise control to prevent swinging, bending, or damage.

- Limited lifting space: Tight workshops or lines where precision ensures safe placement without collisions.

- Precision assembly or multi-crane coordination: Assembling molds, ship panels, or large machinery often requires synchronized multi-crane or multi-hook movements to avoid tilting or misalignment.

In short, precision cranes are about safe, reliable, and efficient placement—not just lifting.

3. How do high-precision cranes improve workflow and protect materials?

Precision cranes directly improve productivity and material safety by minimizing errors and ensuring smooth operations.

- Reduce downtime: Less rework and fewer adjustments keep workflows moving

- Protect high-value loads: Expensive or delicate materials are safeguarded from damage

- Streamline workflows: Precise placement keeps assembly and storage running smoothly

- Lower maintenance costs: Controlled lifting reduces stress on hoists, hooks, and structures

4. What crane types and features are available for precision lifting?

High-precision cranes come in standard types with customizable features:

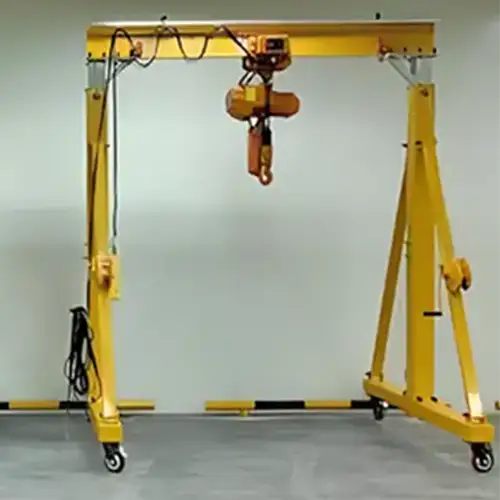

- Crane Types: Single girder overhead crane, double girder overhead crane , gantry crane, or double hook crane, double hoist bridge cranes

- Lifting Capacity: From small loads of a few hundred kilograms to over 100 tons

- Custom Features: Anti-sway systems, micro-speed/inching mode, zero-speed hovering, multi-crane synchronization, load rotation devices

Industries That Require High-Precision Material Handling

1. Why is precision critical in steel and metal processing?

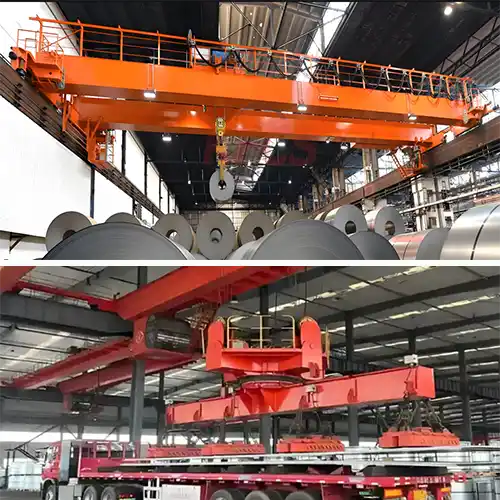

High precision overhead crane for steel coil and steel plate handling. Steel mills and workshops handle coils, slabs, and sheets that are heavy and high-value. Even small misalignments can cause stacking errors, surface damage, or safety risks.

- Typical Loads: Steel coils (5–30 tons), sheets, slabs

- Precision Requirement: Prevent damage, stacking errors, and ensure safe handling

- Crane Types & Capacity: Top-running double girder bridge crane, gantry crane, 10–50 tons

Configurations & Features:

- Dual trolley for balanced lifting

- Coil grab attachments

- Servo-controlled hoist for accuracy

- Anti-sway stabilization

- Micro-speed mode for precision placement

2. How do high-precision cranes support heavy machinery manufacturing?

Large components such as molds or machine tools must be positioned exactly during assembly. Precision cranes prevent errors that cause downtime or part damage.

- Typical Loads: Machine tools, molds, large components (1–20 tons)

- Precision Requirement: Accurate placement for assembly quality

- Crane Types & Capacity: Single/double girder bridge crane, 2–20 tons

Configurations & Features:

- Compact design for limited workshop space

- Micro-speed/inching mode

- Zero-speed hovering

- Positioning sensors for repeatable accuracy

3. Why is precision essential in shipbuilding and offshore fabrication?

Shipyards handle extremely heavy sections like hull panels. Precision ensures multi-crane operations stay synchronized, preventing tilting, misalignment, or costly delays.

- Typical Loads: Hull panels, deck modules, sections (20–150 tons)

- Precision Requirement: Multi-crane coordination, alignment accuracy

- Crane Types & Capacity: Twin bridge cranes, multi-hook overhead cranes, long-span

Configurations & Features:

- Multi-crane synchronized operation

- Laser alignment systems

- Anti-sway devices for flexible loads

- Spreader bars for weight distribution

4. How do cranes improve handling in wind energy and renewable equipment?

Wind turbine blades and tower segments are long and fragile. Precision cranes prevent bending or cracking while ensuring safe, efficient positioning.

- Typical Loads: Turbine blades, tower segments, generator parts (5–30 tons)

- Precision Requirement: Avoid bending and misalignment

- Crane Types & Capacity: Long-span double girder, gantry cranes

Configurations & Features:

- Anti-sway stabilization

- Load tilt and rotation adjustment

- Servo motor drives for controlled motion

5. Why is precision critical in aerospace and aviation manufacturing?

Aerospace components are delicate and high-value. Even millimeter misalignments affect assembly safety. Precision cranes guarantee exact positioning.

- Typical Loads: Fuselage sections, engines, wings (0.5–5 tons)

- Precision Requirement: Millimeter-level positioning

- Crane Types & Capacity: Light-load double girder, cranes with vacuum/frame attachments

Configurations & Features:

- Laser-guided positioning

- Zero-speed hovering

- Anti-sway systems

- Micro-speed/inching control

6. How do high-precision cranes serve semiconductor, electronics, and medical sectors?

These industries move small but sensitive loads where vibration or mishandling causes defects. Precision cranes ensure controlled, smooth, and clean operations.

- Typical Loads: Wafers, PCB stacks, medical devices (50 kg–2 tons)

- Precision Requirement: Vibration-free, ultra-accurate handling

- Crane Types & Capacity: Compact bridge cranes, small single/double girder

Configurations & Features:

- Vibration-damping hoists

- Micro-speed/inching mode

- Cleanroom-compatible designs

7. Why are precision cranes vital in power generation and heavy industry?

Power plants lift ultra-heavy equipment like turbines and generators. Precision ensures accurate, safe placement—avoiding failures, delays, and costly downtime.

- Typical Loads: Turbines, generators, boilers (20–100 tons)

- Precision Requirement: Correct placement to avoid operational failure

- Crane Types & Capacity: Top-running double girder, large gantry cranes

Configurations & Features:

- Dual hoist trolley

- Load sensors for real-time monitoring

- Anti-sway stability

- Long hook travel

- Multi-speed control

Typical High-Precision Handling Scenarios

High-precision cranes are designed to handle loads safely and accurately. Different types of loads and operations call for specific crane features. Below are the main scenarios commonly found in industrial settings.

1. Long or Irregular Loads

Long materials—such as steel beams, ship panels, or turbine blades—tend to swing or bend if not controlled properly. Precision handling prevents collisions and ensures stability.

- Common Challenges: Load sway, uneven weight distribution, limited maneuvering space

- Crane Features Needed: Anti-sway systems, micro-speed control, dual trolley or spreader bars

- Recommended Crane Types: Long-span double girder cranes, gantry cranes

- Practical Advice: Use servo-controlled hoists with anti-sway to keep long loads steady during lifting and placement.

2. Heavy or High-Value Loads

Steel coils, machinery parts, or precision molds are both heavy and costly. Mishandling may cause severe damage or financial loss.

- Common Challenges: Material damage, accidental collisions, uneven lifting

- Crane Features Needed: Load monitoring sensors, anti-collision systems, multi-speed control

- Recommended Crane Types: Top-running double girder cranes, heavy-duty gantry cranes

- Practical Advice: Equip cranes with micro-speed drives and servo hoists to ensure safe, precise lifting of expensive loads.

3. Precision Assembly or Alignment

For assembling molds, aerospace parts, or machinery components, millimeter-level accuracy is required to guarantee assembly quality and prevent rework.

- Common Challenges: Tight tolerances, stability of suspended loads, costly errors from misalignment

- Crane Features Needed: Zero-speed hovering, laser-guided positioning, micro-speed/inching mode

- Recommended Crane Types: Light-load double girder cranes, cranes with frame or vacuum attachments

- Practical Advice: Combine with vision-assisted or sensor-based guidance to achieve repeatable, precise placement in assemblies.

4. Multi-Crane Coordination

Certain oversized loads—like ship hull sections or ultra-long steel beams—cannot be handled by a single crane. Coordinated operation of multiple cranes is required for safety.

- Common Challenges: Synchronizing lifts, maintaining load balance, avoiding collisions

- Crane Features Needed: Multi-crane synchronization, real-time communication, anti-sway control

- Recommended Crane Types: Twin bridge cranes, multi-hook overhead cranes

- Practical Advice: Use synchronized motion control systems to achieve balanced, safe handling of long or heavy loads.

High-Precision Control Technologies for Overhead Cranes

High-precision cranes rely on specialized technologies to lift safely, position accurately, and handle heavy or delicate loads efficiently. The choice of technology should match your load type, workshop setup, and precision needs.

1. Servo Motors with Closed-Loop Feedback

Scenario: Lifting heavy steel coils or precision machinery components where exact positioning is critical.

Technology Function: Continuously monitors hook/load position and adjusts movements in real time.

Key Features & Benefits:

- Continuous position feedback

- Automatic correction for positional errors

- Millimeter-level placement accuracy

- Reduced material damage and operational mistakes

- Consistent performance for repeated lifts

2. Variable Frequency Drives (VFD) with Inertia Compensation

Scenario: Moving long or flexible loads like turbine blades or steel beams. Sudden starts/stops can cause sway.

Technology Function: Smooths acceleration and deceleration while compensating for load inertia.

Key Features & Benefits:

- Adjustable motor speed

- Reduced mechanical shock

- Safer handling of heavy/irregular loads

- Less wear on crane and hoist

- Controlled, predictable movement

3. Micro-Speed / Inching Mode

Scenario: Placing molds, aerospace components, or delicate equipment in tight spaces.

Technology Function: Allows the operator to move the load in very small increments.

Key Features & Benefits:

- Millimeter-level incremental movement

- Fine speed adjustment

- Accurate load placement

- Reduced risk of collisions

- Improved assembly quality

4. Zero-Speed Hovering

Scenario: Aligning high-value components or coordinating multiple cranes.

Technology Function: Keeps the hook/load completely stationary until operator command.

Key Features & Benefits:

- Stabilizes load mid-air

- Works with precise positioning sensors

- Eliminates hook drift

- Enhances operator and material safety

- Perfect for precision assembly

Scenario: Lifting long, flexible, or heavy loads prone to oscillation.

Technology Function: Actively stabilizes the load using software or mechanical damping.

Key Features & Benefits:

- Automatic sway correction

- Real-time load stabilization

- Prevents collisions

- Protects load integrity

- Improves operator confidence

6. Vision and Laser-Assisted Positioning

Scenario: Ultra-precise placement for aerospace, electronics, or medical equipment.

Technology Function: Guides crane to exact location with sub-millimeter accuracy.

Key Features & Benefits:

- Laser or camera-based positioning

- Integration with crane control systems

- Fast, accurate placement

- Reduces material handling errors

- Enhances workflow efficiency

7. Multi-Crane Synchronization

Scenario: Lifting long ship panels, structural steel beams, or oversized equipment.

Technology Function: Coordinates multiple cranes to move a single load in perfect unison.

Key Features & Benefits:

- Real-time communication between cranes

- Synchronized motion control

- Safe lifting of oversized loads

- Maintains load balance and stability

- Prevents tilt, sway, or collisions

Key Benefits for Buyers

Investing in high-precision overhead cranes isn't just about lifting heavier loads—it's about improving safety, protecting materials, and optimizing operations. When cranes are equipped with advanced control technologies and configured correctly for your facility, the impact is felt across every stage of material handling. From preventing costly mistakes to increasing operator confidence, these benefits directly affect productivity and long-term ROI.

- Enhanced Safety: Reduced accidents and collisions by controlling load swing, drift, and multi-crane coordination. Operators can work confidently even with heavy, long, or fragile loads.

- Material Protection: Minimized damage to steel, machinery, molds, or delicate components thanks to precise positioning, anti-sway systems, and smooth motion control.

- Optimized Productivity: Faster, predictable handling reduces downtime, streamlines workflows, and enables multiple tasks to be completed safely in less time.

- Lower Maintenance Costs: Smooth, controlled operations extend the lifespan of cranes, hoists, and other components, reducing repair frequency and operational interruptions.

- Flexibility: High-precision cranes can handle a wide range of load types, adapt to different industrial scenarios, and accommodate future expansion, including automation upgrades or multi-crane operations.

How to Choose the Right High-Precision Overhead Crane

Selecting a high-precision overhead crane is about more than picking the biggest or most advanced model. It's about matching the crane to your loads, workshop layout, and operational goals. Understanding your material types, precision needs, and future growth plans ensures you make the right investment that delivers long-term value.

- Match Crane Type to Load & Workshop: Choose between single girder, double girder, gantry, or custom long-span designs depending on your load size, lifting height, and workspace constraints. The right configuration ensures stability and operational efficiency.

- Select Control Technology: Consider servo-controlled hoists, variable frequency drives (VFD), anti-sway systems, or laser-assisted positioning. Aligning technology with your load type and precision requirements ensures safe and accurate handling.

- Consider Load Type & Weight: Always verify that the crane's lifting capacity exceeds your maximum load, including a safety margin. This prevents overloading, reduces wear, and increases operational safety.

- Plan Multi-Crane / Multi-Hook Operations: For long, heavy, or irregular loads, plan for synchronized crane setups. Proper coordination avoids tilting, load sway, and collisions.

- Factor in Custom Features: Evaluate whether you need spreaders, vacuum lifting, rotation mechanisms, vibration damping, or other specialized attachments. These features improve precision, efficiency, and adaptability for your specific material handling needs.

- Check Future Expansion Needs: Consider potential increases in load size, automation integration, or higher precision requirements. Choosing a flexible crane design allows your facility to grow without costly equipment upgrades.

Conclusion – Smart Choices for High-Precision Cranes

High-precision overhead cranes are critical for industries handling heavy, long, fragile, or high-value materials. From steel mills and shipyards to wind energy, aerospace, and precision manufacturing, the right crane ensures safety, accuracy, and efficient operations.

Key Takeaways for Buyers

- Safety First: Advanced control technologies reduce accidents, load sway, and collisions.

- Material Protection: Precision handling prevents damage to steel, machinery, or delicate components.

- Operational Efficiency: Smooth, predictable lifts save time, reduce downtime, and improve workflow.

- Long-Term Value: High-precision cranes lower maintenance costs and extend equipment life.

- Adaptability: Customizable features allow handling of varied load types and future expansion.

Next Steps for Crane Buyers

- Assess your facility: Identify load types, weights, and handling scenarios.

- Define precision needs: Determine the level of accuracy required for your operations.

- Choose the right crane: Match crane type, capacity, and control technology to your requirements.

- Plan for custom features: Consider spreaders, anti-sway, multi-crane synchronization, or vacuum lifting if needed.

- Think ahead: Factor in potential growth, automation integration, or higher precision needs.

Related Products

Affordable 10 ton double girder overhead crane with CD/MD hoist trolley, built for U.S. standards, ideal for construction and industrial lifting

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch