High-Precision Overhead Cranes for Steel Coil & Sheet Handling

Overhead cranes for safe, precise handling of steel coils 5–30 tons, sheets1–10 tons. Learn about eot crane types, features & best practices for buyers.

Category: Steel

Your Trusted Overhead Crane Manufacturer & Supplier

High-Precision Overhead Cranes

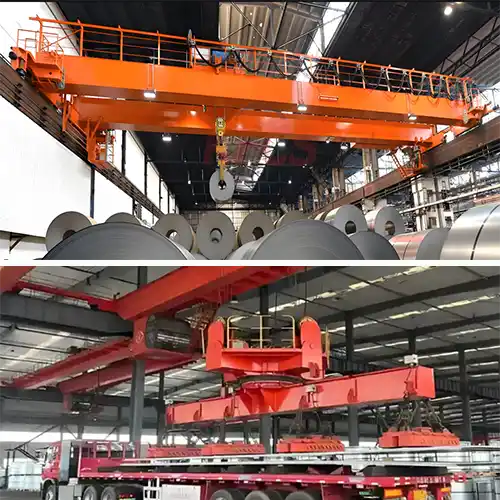

Overhead Bridge Crane for Precise Handling of Steel Coils 5–30 Tons & Sheets 1–10 Tons

Why High-Precision Cranes Are Critical for Steel Handling

Handling steel coils and sheets might sound straightforward, but anyone who’s worked in a steel mill or metal processing plant knows it’s not. These materials are heavy, awkward, and unforgiving. A slight misalignment or uncontrolled movement can cause serious damage, slow down production, or even pose a safety risk. That’s why high-precision cranes are not just nice to have—they’re essential.

Even small errors in positioning a steel coil or sheet can lead to deformation, scratches, or stacking mistakes. Over time, those small damages add up to significant material loss and extra costs. More importantly, precise handling reduces the risk of accidents, keeping operators safe and machinery protected.

Key practical reasons precision matters:

- Prevent Coil Deformation: Steel coils are heavy and can easily lose shape if lifted or set down improperly. A precise crane ensures each coil maintains its integrity.

- Avoid Sheet Damage: Thin steel sheets are prone to bending or scratching. Accurate handling keeps them flat and clean.

- Safe Stacking: Correct positioning prevents leaning stacks, accidental tipping, and related safety hazards.

- Operational Efficiency: Precise cranes reduce re-handling and downtime, keeping production flowing smoothly.

- Cost Savings: Minimizing material damage directly saves money, and fewer accidents reduce maintenance and insurance costs.

In short, if you’re handling steel coils ranging from 5 to 30 tons or sheets up to 10 tons, investing in a precision crane isn’t optional—it’s a practical necessity. It ensures your plant runs efficiently, materials remain intact, and your team stays safe.

Typical Industrial Applications and Load Types

Handling steel coils and sheets is more than just moving heavy loads. It requires planning, the right equipment, and precision operation to maintain material quality, protect equipment, and ensure safety. Each industrial setting presents unique challenges, and knowing these helps buyers select the right crane for their facility.

1. How are cranes used in steel mills?

Steel mills handle massive coils weighing 5–30 tons. Cranes must move these safely from rolling or cooling lines to storage with precision to avoid deformation or unsafe stacking.

- Moving Hot/Cold Coils: Hot coils need heat-resistant handling; cold coils need precise movement to prevent dents or scratches.

- Stacking and Storage: Accurate stacking prevents leaning stacks and hazards. Anti-sway and servo hoists ensure coils are placed correctly.

- Safety Considerations: Load swing control and smooth travel protect operators and nearby equipment.

2. What role do cranes play in metal processing plants?

In processing plants, precision handling of coils and sheets directly affects production quality. Misplacement can disrupt lines and cause downtime.

- Feeding Coils to Lines: Coils must be placed precisely for smooth pickup by feeding equipment.

- Sheet Placement: Thin sheets require delicate handling to prevent bending, scratches, or misalignment.

- Workflow Efficiency: Accurate crane operation reduces delays and keeps production continuous.

3. How are cranes used in warehouses and logistics?

After production, coils and sheets move into storage or shipping. Cranes here must balance lifting power with accuracy to protect materials and optimize space.

- Safe Stacking: Maximize storage capacity without compromising safety.

- Transport: Smooth movements between racks, trucks, and lines prevent shifting or damage.

- Inspection and Sorting: Precise positioning helps with quality checks and inventory control.

4. What are the typical load references for buyers?

Knowing load specifications ensures the crane is properly matched to materials being handled.

- Steel Coils: 5–30 tons per lift; cranes must handle the heaviest coil with a safety margin.

- Steel Sheets: 1–10 tons per lift; consider sheet size, thickness, and whether multiple sheets are lifted together.

Best Crane Types for Safe and Accurate Steel Handling

Selecting the right crane type is critical for handling heavy steel coils and sheets safely and efficiently. The choice affects material protection, workflow, operator safety, and plant productivity. In steel mills and metal processing plants, the two most common options are top-running double girder EOT cranes and gantry cranes. Each has unique advantages depending on application needs.

1. What are the benefits of Top-Running Double Girder EOT Cranes?

Top-running double girder EOT cranes are ideal for indoor production lines where high lifting capacity and precision are essential. Running on overhead rails, they keep the floor area clear for operations.

- High Lifting Capacity: Typically handle 10–50 tons, perfect for heavy steel coils and stacked sheets.

- Stable Performance: Double girder design minimizes deflection, ensuring smooth, precise movements.

- Indoor Applications: Excellent for coil handling, rolling lines, and storage zones requiring accurate placement.

Keywords: top-running EOT crane, double girder crane, precision coil crane

2. Why choose Gantry Cranes for steel handling?

Gantry cranes are freestanding and operate on rails at floor level, making them highly flexible for outdoor storage or transfer areas where overhead runways are not feasible.

- Flexible Installation: Suitable for sites without overhead beams; can be temporary or permanent.

- Multi-Coil Handling: Capable of moving multiple coils or sheets with control and precision.

- Heavy-Duty & Outdoor Use: Best for storage yards, loading docks, and large facilities with variable layouts.

Keywords: gantry crane for steel coils, high-precision gantry crane

3. How to choose between EOT and Gantry Cranes?

The choice depends on facility layout, capacity requirements, and precision needs. Each crane type offers distinct benefits.

- Workspace Constraints: EOT cranes fit indoor lines; gantry cranes excel in outdoor yards.

- Lifting Capacity: Always match capacity to the heaviest expected load, with a safety margin.

- Operational Frequency: Frequent or high-speed lifting favors EOT cranes for smoother travel.

- Precision Requirements: For micro-positioning, use cranes with servo hoists and anti-sway systems.

Essential Customized Features for High-Precision Handling

When handling heavy steel coils and sheets, standard cranes often aren't enough. Without the right features, even a skilled operator can struggle to position loads safely and accurately. Customized options make a huge difference in preventing material damage, improving productivity, and protecting both operators and equipment.

1. How does Anti-Sway & Load Swing Control improve safety?

Moving a 30-ton steel coil is not like lifting a box—any swing or unexpected movement can be dangerous. Anti-sway technology and load swing control stabilize the load during lifting, travel, and placement.

- Reduces coil or sheet movement during transit.

- Minimizes risk of accidents or collisions in tight spaces.

- Protects steel from dents, scratches, and misalignment during stacking.

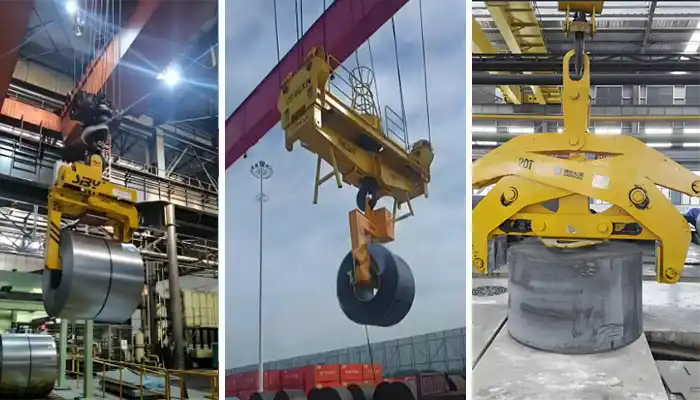

2. Why are Coil Grab Attachments essential for steel handling?

Standard hooks often can't handle the variety of coil diameters, weights, and widths. Coil grab attachments are designed to grip securely while preventing material damage.

- Ensures a secure grip for various coil diameters and weights.

- Reduces handling errors and improves stacking precision.

- Compatible with both EOT and gantry cranes for flexible operation.

3. What advantages does a High-Precision Servo Hoist provide?

A servo-controlled hoist allows operators to maneuver heavy coils or sheets with fine adjustments, critical in tight storage areas or on production lines.

- Provides micro-speed control for precise positioning.

- Ensures smooth acceleration and deceleration to prevent load swing.

- Supports repetitive handling without sacrificing accuracy or safety.

4. How can Automation and Sensors enhance crane operations?

Automation and sensor integration improve consistency, alignment, and tracking—key for high-volume facilities aiming for efficiency.

- Enables automatic positioning for repetitive stacking or feeding tasks.

- Reduces operator fatigue and human error.

- Integrates with anti-sway systems for greater precision.

Best Practices for Safe and Precise Crane Operation

For heavy steel coils and sheets, precision lifting is about more than just equipment—it's about how the crane is used and maintained. Following best practices ensures safer handling, reduces wear on the crane, and keeps operations consistent and reliable over time.

1. Why match crane capacity to the maximum load?

Every coil or sheet has a weight and size specification. A crane should be selected based on the heaviest expected load plus a 10–20% safety margin.

- Ensures the crane can safely lift the heaviest expected coil or sheet.

- Protects structural components and hoists from premature wear.

- Reduces the risk of accidents caused by overloading.

2. Why is avoiding overloading so critical?

Even small overloads reduce precision and put strain on mechanical and electrical systems. Avoiding overloads preserves both safety and performance.

- Prevents unnecessary wear on ropes, hoists, and crane girders.

- Keeps lifting accuracy consistent over time.

- Protects operators and nearby equipment from potential hazards.

3. How important are operator training and inspections?

High-precision cranes require skilled operators and routine inspections. Proper training ensures safe handling, while inspections help detect problems early.

- Ensure operators are trained on precision handling techniques and safety protocols.

- Schedule routine checks for mechanical and electrical components.

- Identify early signs of wear or malfunction to prevent costly downtime.

4. How should anti-sway and servo systems be maintained?

Specialized systems like anti-sway devices and servo-controlled hoists need regular inspection and calibration to maintain accuracy and safety.

- Inspect and calibrate anti-sway systems periodically.

- Verify servo hoists for smooth, accurate movements.

- Replace worn parts before they affect crane performance or safety.

Practical Tips for Crane Buyers and Users

When selecting a high-precision crane for steel handling, it's important to understand exactly what you need to move and where. Typical buyers include steel mills, metal processing plants, and warehouse or logistics operations. Loads usually range from steel coils (5–30 tons) to steel sheets (1–10 tons) per lift. Choosing the right crane ensures safe, efficient, and long-lasting operations.

1. Why confirm load specifications before buying a crane?

Before choosing a crane, verify the weight, dimensions, and number of coils or sheets to be lifted. Requirements vary across steel mills, warehouses, and processing plants.

- Ensures the crane and attachments are sized correctly for coils (5–30 tons) or sheets (1–10 tons).

- Helps determine lifting capacity, span, and hoist specifications.

- Reduces risks of overloading and handling errors.

2. What optional features should buyers consider?

Not all cranes include advanced features, but for heavy coils or delicate sheets, optional systems greatly improve safety and precision.

- Anti-Sway Systems: Stabilize coils and sheets during lifting and travel.

- Servo-Controlled Hoists: Provide micro-speed adjustments for precision placement.

- Coil Grab Attachments: Securely grip coils of varying sizes and weights.

- These features are especially valuable in steel mills and processing lines where accuracy is critical.

3. How does crane layout affect operations?

The placement and layout of a crane directly influence workflow efficiency, safety, and overall productivity.

- Ensure travel paths are free of obstructions.

- Minimize lifting distances between storage, production, and shipping areas.

- Consider operator visibility and smooth workflow for precision handling.

4. Why plan for future expansion when buying a crane?

As production grows, handling needs often increase. Planning ahead ensures cranes remain useful without costly upgrades.

- Account for potential increases in coil weights or sheet bundle sizes.

- Check if the crane can support extra spans or attachments in the future.

- Flexible crane designs adapt better to changing workloads.

5. How important is compliance with safety standards?

Certified cranes protect operators and facilities, while simplifying inspections and legal compliance.

- Look for ISO or CE certifications.

- Ensure electrical and mechanical systems meet local regulations.

- Certified cranes reduce liability and enhance safe operations in steel handling industries.

Conclusion: Invest in Precision for Safety and Efficiency

Handling steel coils and sheets safely and accurately is not optional—it’s critical for maintaining material quality, protecting equipment, and keeping operations efficient. High-precision cranes are designed to meet these challenges, making them an essential investment for steel mills, metal processing plants, and warehouses.

Choosing the right crane goes beyond lifting capacity. Features like anti-sway systems, coil grab attachments, and servo-controlled hoists ensure that coils ranging from 5–30 tons and sheets from 1–10 tons are moved without deformation or damage. Precision handling reduces operational risks, prevents costly mistakes, and allows production to run smoothly.

Key Takeaways for Buyers:

- Protect Materials: High-precision cranes maintain the integrity of steel coils and sheets during handling.

- Enhance Safety: Anti-sway, servo hoists, and secure coil grabs reduce accidents and operator risk.

- Boost Productivity: Accurate placement and smooth handling minimize downtime and increase efficiency.

- Choose Wisely: Evaluate your facility’s layout, load types, and optional features before selecting a crane. Consider future expansion or higher loads to ensure long-term value.

Investing in top-running EOT or gantry cranes with these precision features delivers a reliable, safe, and efficient solution for all steel handling operations.

Related Products

Affordable 10 ton double girder overhead crane with CD/MD hoist trolley, built for U.S. standards, ideal for construction and industrial lifting

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch