20 Ton Overhead Crane Buyer’s Guide: Types, Specs & PurchaseTips

Learn how to choose, configure, and purchase the right 20-ton overhead crane for your plant. Expert tips for efficiency, safety, and long-term ROI.

Category: 20 Ton Overhead Crane

Your Trusted Overhead Crane Manufacturer & Supplier

20 Ton Overhead Crane Buyer's Guide — Selection & Purchase Tips

How to Choose, Configure, and Purchase the Right Crane for Your Plant

Why So Many Buyers Choose the 20 Ton Overhead Crane

If you're running a steel fabrication workshop, machinery plant, or maintenance bay, you've probably come across the 20-ton overhead crane more than once. It's not the biggest crane out there, but it hits a practical balance that makes it one of the most common capacities ordered worldwide.

The "Middle Ground" Capacity — Why 20 Tons Makes Sense

In most industrial environments, lifting needs fall somewhere between 10 and 25 tons. That's where the 20-ton crane fits perfectly — heavy enough to handle large assemblies, yet compact enough to suit standard workshop layouts without major building modifications.

- 10-ton overhead cranes often reach their limit when you deal with oversized molds, machine frames, or bundled steel.

- 25-ton overhead crane or 30-ton overhead cranes can handle more but require stronger building structures and come with higher purchase and installation costs.

- 20 ton overhead cranes, on the other hand, deliver just the right balance of strength, size, and cost-efficiency for everyday heavy lifting.

So, in many cases, it's not about getting the biggest crane possible — it's about choosing the one that fits your real workload and budget.

Who Usually Buys a 20 Ton Overhead Crane

Buyers come from a wide mix of industries, but they tend to share similar operational needs:

- Factory owners looking to improve in-house lifting efficiency instead of outsourcing heavy tasks.

- Plant maintenance managers who need a reliable crane for regular equipment repair and replacement.

- Workshop engineers planning production lines for handling steel materials, molds, or machine parts safely and efficiently.

Each buyer may have different floor layouts or workflows, but the goal is usually the same — a crane that lifts safely, runs smoothly, and fits into existing infrastructure.

What 20 Ton Cranes Are Commonly Used For

You'll see 20-ton cranes doing all sorts of tough jobs, including:

- Steel handling: lifting coils, plates, beams, or fabricated frames.

- Machinery assembly: aligning engines, gearboxes, or other large mechanical parts.

- Mold handling: moving injection molds or casting molds between stations.

- Maintenance work: lifting turbines, generators, or other large components for repair.

These are all tasks where a 10-ton crane might struggle — but anything heavier would be unnecessary or uneconomical.

How This Guide Helps You Decide

If you're in the process of selecting a 20-ton overhead crane, this guide will help you make practical, informed decisions. It covers:

- Crane type and structure: single vs. double girder, top-running vs. under-running.

- Configuration: lifting height, span, control mode, and power supply.

- Cost factors: what really affects the total price and long-term cost.

- Supplier selection: what to check before placing an order or signing a contract.

Buying a 20-ton crane isn't just about capacity — it's about fitting the right equipment into your working environment and long-term production plans.

Knowing What You're Buying — Basic Technical Understanding

Before you start collecting quotations, it's important to understand what those technical terms in crane specifications really mean. Many buyers skip this part and later find that what they ordered doesn't quite fit their workshop or production line. This section helps you read specs with confidence — so when you talk to suppliers, you know exactly what you're asking for.

| Parameter | What It Means | Typical Range / Option | Notes |

|---|---|---|---|

| Capacity | Max load the crane can lift | 20 tons | Confirm single or dual hook |

| Span | Distance between runway beams | 10–30 m | Match workshop width |

| Lifting Height | Hook travel distance | 6–18 m | Depends on roof clearance |

| Working Class | Duty frequency | A3–A6 | Choose per operation load |

| Lifting Speed | Load movement rate | 3–8 m/min | Variable speed recommended |

| Control Mode | How the operator controls | Pendant / Remote / Cabin | Based on safety & layout |

| Power Supply | Voltage & frequency | 380V–440V, 50/60Hz | Match local standard |

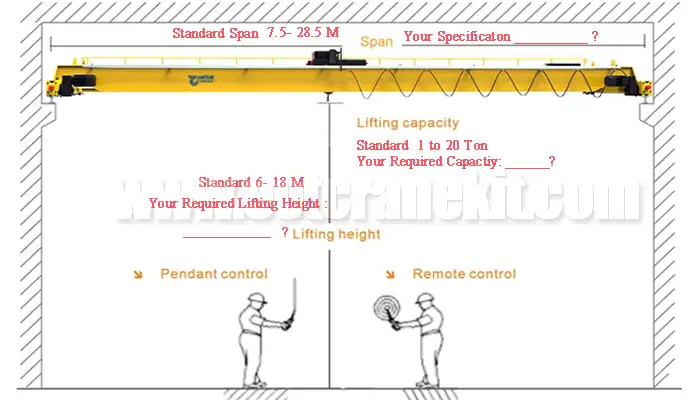

20 Ton Overhead Crane Video & 3D 20 Ton Overhead Crane Drawing of Main Specification Required for Inquiry

20 Ton Double Girder Overhead Crane with Electric Hoist Trolley for Sale

20 ton overhead crane main specificaitons requried to get tailored solution and specific crane price

Core Parameters to Confirm Before You Ask for a Quote

When it comes to a 20-ton overhead crane, several basic parameters decide how well it will work in your plant. These are the details suppliers need to prepare an accurate solution and price.

Capacity

A "20-ton" crane means it's rated to safely lift a maximum of 20 tons. But here's the catch — some cranes use two hooks or two trolleys, especially for long or uneven loads. If you're lifting molds, large frames, or spread-out objects, confirm whether you need a single 20-ton hook or two 10-ton hooks working together.

Span

This is the distance between the two runway beams that support the crane. Common spans range from 10 to 30 meters, depending on your building width. The right span ensures the crane travels smoothly without structural stress or misalignment.

Lifting Height

Lifting height refers to how far the hook can travel up and down. Always check your building height and clearance under the roof truss. If the hook can't reach high enough, or if the hoist hits the beam too early, operations will be limited.

Working Class

This defines how frequently and intensively the crane can operate.

- A3–A4: For light to moderate use — ideal for maintenance or low-duty applications.

- A5–A6: For daily, continuous operations in workshops or production lines.

Choosing the right class helps extend the crane's lifespan and reduces maintenance issues.

Lifting Speed

Lifting speed affects how quickly loads move — and how precisely they stop.

- Single-speed hoists are fine for general lifting.

- Variable-speed (inverter-controlled) systems allow smoother starts and stops, reducing swing and improving accuracy, especially for assembly or mold positioning work.

Control Mode

You can choose how the operator controls the crane:

- Pendant control: Simple and low-cost, ideal for short spans.

- Remote control: Improves safety and convenience; allows the operator to stand at a safe distance.

- Cabin control: For large cranes or long spans where visibility and comfort matter.

Power Supply

Always match the crane's electrical system to your local standard:

- 380V / 50Hz: Common in most Asian and European regions.

- 415V / 50Hz: Common in the Middle East and Australia.

- 440V / 60Hz: Often used in the Americas and some industrial zones.

Confirm this early — it affects motor selection and control components.

What Each Term Means for You in Practice

Knowing the technical terms is one thing — understanding how they affect your actual operations is another. Here's what these specifications really mean on the shop floor.

Working Class (A3–A6)

If you see "A5" in a specification, it means the crane is designed for continuous daily use, handling heavy loads frequently. This isn't a light-duty crane for occasional lifts — it's built to work hard every day without wearing out prematurely. Choosing the correct working class ensures reliability and longer service life.

Lifting Height

This is the distance your hook can move up and down. Make sure your building has enough headroom so the hook doesn't hit the roof, trusses, or trolley. If you're lifting tall molds, equipment, or assembled machines, miscalculating the lifting height can cause delays or even unsafe conditions.

Span

The distance between runway beams affects more than just the crane's coverage. A longer span can increase the crane's overall cost, require heavier girders, and increase wheel load on your building structure. On the other hand, a shorter span may limit your working area. Choosing the right span balances operational flexibility and structural feasibility.

Practical Tip:

A 20-ton crane with a longer span or higher duty class will generally cost more because the main girders, end trucks, and supporting structure must be reinforced to safely handle the load. Planning these details early saves money and avoids surprises during installation.

Choosing Single or Double Girder — Which Fits Your Workshop

When it comes to 20-ton overhead cranes, one of the first decisions you'll face is single vs. double girder. This choice impacts cost, installation, and how efficiently you can lift loads in your workshop.

Top Running Single Girder Overhead Crane

- Lower cost — requires less steel and simpler structure.

- Lighter weight — easier to install and maintain.

- Compact design — ideal if your building height is limited or headroom is low.

- Best for: Light-to-moderate lifting frequency, smaller spans, and workshops where budget is a priority.

Top Running Double Girder Overhead Crane

- Higher lifting height — hook can travel higher since the hoist sits on top of the girders.

- Longer span capability — suitable for wider buildings.

- More stable and durable — ideal for frequent, heavy-duty lifting.

- Best for: Busy production lines, steel fabrication plants, or large maintenance shops.

Key Decision Points:

- Building height and headroom

- Load handling frequency and duty class

- Budget and installation constraints

Tip: If your operation is heavy and continuous, double girder cranes usually provide better long-term value despite higher upfront costs.

Power Supply & Control Type

How your crane is powered and controlled is just as important as its structure. This affects safety, convenience, and operational efficiency.

| Control Type | Pros | Cons | Best Use |

|---|---|---|---|

| Pendant | Low cost, simple | Operator near load | Small spans, light-duty |

| Remote | Safer, flexible | Slightly higher cost | Medium spans, frequent lifting |

| Cabin | Full visibility, comfortable | Expensive, requires space | Large spans, outdoor or long-run operations |

Practical note: Choosing the right control and power combination ensures safe, smooth, and efficient operation without surprises during installation.

Control Types

- Pendant control: Simple, cost-effective, operator stands near the load. Good for short spans.

- Remote control: Allows the operator to stay clear of the load, improving safety.

- Cabin control: For large spans or outdoor cranes, offering full visibility and comfort for the operator.

Power Supply Considerations

- Check your voltage and frequency: 380V, 415V, or 440V; 50Hz or 60Hz.

- Power supply compatibility is critical to avoid rewiring or motor replacements.

Indoor vs. Outdoor Installation

- Indoor: Standard protection is usually sufficient.

- Outdoor: Needs weatherproof motors, anti-corrosion paint, and possibly wind-resistance reinforcement.

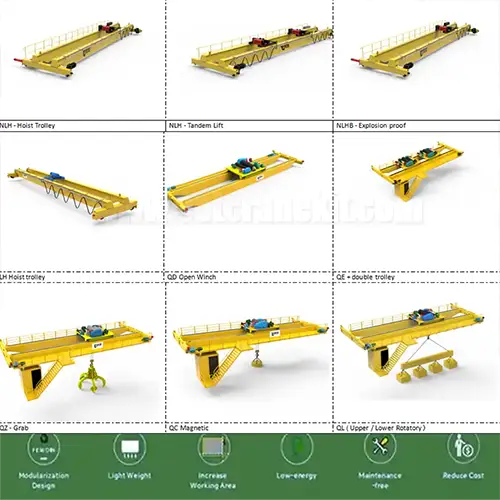

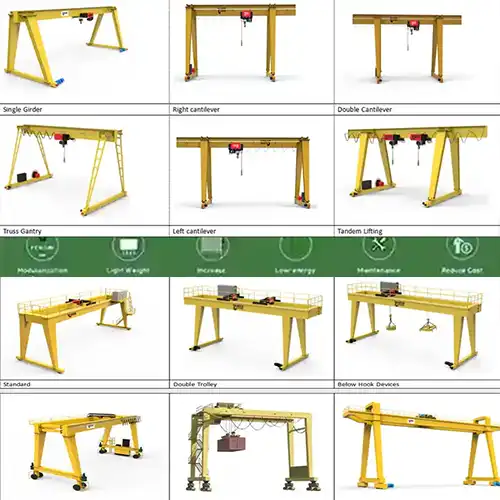

Main Types of 20 Ton Overhead Cranes

When selecting a 20-ton overhead crane, understanding the different types, features, and ideal operating conditions helps you make a practical choice. Each model is designed for specific tasks, working environments, and lifting frequencies.

| 20 Ton Overhead Crane Type | Best For | Key Features | Environment |

|---|---|---|---|

| Single Girder | Light-to-medium duty | Economical, easy installation | Indoor, low headroom |

| Double Girder | Heavy-duty, frequent use | High lifting height, stable, cabin/auxiliary hoist | Workshops, production lines |

| European Standard | Smooth & efficient lifting | Inverter hoist, compact, energy-saving | Modern workshops |

| Explosion-Proof | Hazardous areas | Ex motors/wiring, spark-proof | Chemical, paint, gas plants |

| Foundry / Metallurgical/ Ladle Crane | Molten metal handling | Heat-resistant, robust structure | Steel mills, foundries |

| Outdoor | Weather-exposed operation | Rainproof, windproof, anti-corrosion | Ports, open yards |

Single Girder Overhead Crane (20 Ton)

Overview: Economical, simple design with a lower structure.

Max Span: Typically up to 25 meters.

Best For: Light-to-medium duty operations, workshops with limited headroom.

Special Features: Easy installation and maintenance, lower initial cost, compact design.

Double Girder Overhead Crane (20 Ton)

Overview: Built for heavy-duty, high-frequency lifting.

Span & Height: Supports long spans and higher lifting heights.

Best For: Production lines, steel fabrication, and maintenance facilities with frequent or continuous lifting.

Special Features: Can integrate maintenance platforms, operator cabins, and auxiliary hoists; provides superior stability and durability.

European Standard Overhead Crane (20 Ton)

Overview: Modern design focusing on efficiency and smooth operation.

Best For: Workshops seeking energy efficiency and precise load control.

Special Features: Compact structure, inverter-controlled hoist for smooth lifting, reduced energy consumption, lighter overall weight.

Explosion-Proof Crane (1–20 Ton)

Overview: Designed for hazardous environments like chemical plants, paint workshops, or gas-handling areas.

Standards: Conforms to Ex safety standards.

Special Features: Special motors, wiring, and control protection against sparks or ignition; suitable for environments with flammable gases or dust.

Foundry / Metallurgical Crane (20 Ton)

Overview: Specialized for high-temperature operations in steel mills or foundries.

Best For: Handling molten metal, heavy ingots, or steel billets.

Special Features: Heat-resistant components, reinforced structure, and robust safety features for extreme environments.

Outdoor 20 Ton Crane

Overview: Built to withstand weather conditions while maintaining safe operation.

Best For: Ports, yards, or open workshops.

Special Features: Rainproof and windproof design, anti-corrosion coating, and optional weather protection covers for motors and electronics.

Buying Tip: Don't choose a crane based solely on tonnage. Consider operation frequency, working environment, lifting height, and span requirements to ensure long-term efficiency and safety.

Customization Options — Tailoring the 20 Ton Overhead Travelling Crane to Fit Your Site

A 20-ton overhead travelling crane is highly adaptable. With the right customization, it can perfectly match your workshop layout, load requirements, and operational needs. Here's how buyers typically tailor their cranes for maximum efficiency and safety.

Double Girder Design for Longer Crane Span

- A double girder configuration allows longer spans and higher lifting heights, ideal for wide workshops or large production areas.

- Offers greater stability and reduces deflection under heavy loads.

- Supports auxiliary hoists, cabins, or maintenance platforms, making it suitable for frequent or continuous operation.

Duty Class (A3–A6)

Determines the frequency and intensity of crane operation:

- A3–A4: Light to moderate use, suitable for occasional lifting.

- A5–A6: Heavy-duty, continuous use in busy production lines.

Selecting the correct duty class ensures durability and reduces maintenance costs over the crane's lifetime.

Control Systems

- Pendant control: Simple and cost-effective, operator stays near the load.

- Remote control: Enhances safety and flexibility; operator can control the crane from a safe distance.

- Cabin control: Recommended for long spans or high-frequency operations; provides excellent visibility and comfort.

- Control choice can be customized to match workflow and operator preferences.

Power Supply

- Cranes can be adapted to local voltage and frequency standards (e.g., 380V, 400V, 415V; 50Hz or 60Hz).

- Ensures reliable operation and avoids costly electrical modifications during installation.

Special Lifting Devices

Depending on your materials and workflow, additional attachments can be installed:

- Magnet: For steel plate or billet handling.

- Grab: For bulk material lifting.

- C-hook: For lifting coils or rolls.

- Spreader beam: For oversized or irregular loads.

Environmental Protection

- Outdoor coating: Guards against rain, sun, and dust exposure.

- Heat-resistant design: Suitable for foundries and high-temperature operations.

- Explosion-proof features: For chemical plants, paint shops, or flammable environments.

Automation Options

- Anti-sway systems: Reduce load swing for safer handling.

- Position memory: Ensures precise, repeatable lifts.

- Semi-automatic operation: Improves efficiency in repetitive or continuous lifting tasks.

Practical Note: Providing workshop drawings, building dimensions, lifting requirements, and environmental conditions is essential for precise customization. Accurate details help design a crane that fits your site safely, efficiently, and reliably.

Customizing a 20-ton overhead travelling crane ensures it isn't just a standard piece of equipment — it becomes a site-specific, high-performance lifting solution for your workshop.

Typical Industrial Applications — Where 20 Ton Overhead Cranes Work Best

A 20-ton overhead crane is highly versatile and widely adopted because it hits a sweet spot between capacity, cost, and practicality. It can handle typical loads from 5 to 20 tons, making it suitable for many industrial lifting tasks. Let's break down why 20-ton cranes are often chosen, the loads they handle, and any special features that make them ideal for each application.

Overview of 20 Ton Pverhead Crane for Different Indusrial Sectors

| Industry | Typical Loads | Recommended Crane Type | Special Features |

|---|---|---|---|

| Steel & Metal Fabrication | 5–20 tons | Double girder / Magnet | High duty class, inverter hoist, smooth trolley |

| Machinery Manufacturing | 5–18 tons | European-style double girder | Precise positioning, low vibration |

| Construction / Precast | 8–20 tons | Double girder / Top-running | Adjustable height, remote control |

| Maintenance Workshops | 5–20 tons | Single or Double girder | Compact design, moderate duty class |

| Energy & Power Plants | 10–20 tons | Heavy-duty double girder | Anti-sway, semi-auto, inverter-controlled |

Steel and Metal Fabrication

In steel workshops, 20-ton cranes are frequently used to lift steel plates (5–15 tons), beams (10–20 tons), and bundled sections (12–18 tons).

- Why 20 tons is chosen: It covers the majority of heavy steel handling tasks without overloading building structures or requiring oversized cranes.

- Recommended crane type: Double girder cranes with magnet lifting attachments.

- Special features: Strong main girders, high duty class (A5–A6), smooth trolley movement, and optional inverter-controlled hoists for precise positioning.

Machinery Manufacturing

For machinery assembly and component movement, a 20-ton crane handles machine frames (8–15 tons), engines (10–18 tons), and large gearboxes (5–12 tons).

- Why 20 tons is chosen: Most industrial machines fall under this weight range, making it efficient without oversizing the crane.

- Recommended crane type: European-style double girder cranes with inverter-controlled hoists.

- Special features: Smooth lifting, precise positioning, low vibration — essential when assembling delicate or heavy machinery parts.

Construction and Precast Plants

Moving molds, formwork, or reinforced concrete products often involves loads of 8–20 tons per unit, including large molds and concrete panels.

- Why 20 tons is chosen: Provides enough capacity for heavy precast elements while fitting standard workshop or yard layouts.

- Recommended crane type: Double girder or top-running cranes.

- Special features: Adjustable lifting height, higher span capacity, optional remote control for outdoor or large-area operation.

Maintenance Workshops

Maintenance tasks require lifting pumps, motors, turbines, and spare equipment ranging from 5–20 tons.

- Why 20 tons is chosen: Covers most maintenance tasks in a single crane without needing multiple smaller cranes.

- Recommended crane type: Single or double girder depending on space and load frequency.

- Special features: Compact design for smaller workshops, easy installation, moderate duty class (A3–A5) for intermittent heavy lifts.

Energy and Power Plants

Handling turbines, generators, and transformers can involve loads from 10 up to 20 tons for smaller units; larger equipment may require multiple cranes or higher capacity.

- Why 20 tons is chosen: Suitable for medium-sized components, repairs, and routine maintenance without oversizing the crane system.

- Recommended crane type: Heavy-duty double girder or European-standard cranes with high duty class (A5–A6).

- Special features: Precision positioning, semi-automatic operation, inverter control for smooth lifting, and optional anti-sway systems.

Buyer Tip: The 20-ton overhead crane is adopted widely because it balances lifting capacity, building compatibility, and cost efficiency. Typical loads in most workshops and plants fall within this range, making it the practical choice for steel, machinery, maintenance, and precast operations. Consider the operating environment, load frequency, and special features like magnet hooks, inverter speed control, or anti-sway systems to match your exact needs.

Buying and Installation Preparation — What to Prepare Before Ordering

Before ordering a 20-ton overhead crane, proper preparation can prevent design errors, reduce installation problems, and save time and cost. Here's a practical guide to get ready.

Verify Runway Beam and Building Structure

- Ensure that your runway beams and supporting structures can safely handle the crane's weight and full load.

- Include dynamic load considerations — cranes in frequent operation exert forces beyond static load.

- A structural engineer's confirmation is highly recommended for safety and compliance.

Ensure Clearance for Trolley Movement and Hook Height

- Measure available headroom to ensure the hook can travel the full lifting height without obstruction.

- Check lateral clearance so the crane can move freely across the span.

- Take into account overhead piping, lighting, or other equipment that may interfere with crane operation.

Confirm Power Supply Compatibility

- Verify your facility's voltage and frequency (380V, 400V, 415V, 50Hz, 60Hz).

- Correct voltage avoids motor issues, ensures smooth operation, and prevents costly electrical modifications.

Decide Installation Method

- Self-installation with guidance: Suitable if your team has experience and tools; supplier can provide technical support and manuals.

- On-site professional installation: Recommended for complex setups or high-duty cranes to ensure safety, proper alignment, and commissioning.

Prepare Layout Drawings or Workshop Photos

- Provide accurate building layouts, runway beam positions, and lifting points.

- Include photos of the installation area to highlight potential obstacles.

- Detailed documentation helps suppliers provide precise design, quotation, and customization options.

Quick Buyer Checklist

☑ Confirm lifting requirements (load weight, frequency, and special attachments)

☑ Provide workshop drawings or clear photos

☑ Describe the working environment (indoor, outdoor, high temperature, hazardous)

☑ Mention any special lifting attachments needed (magnet, grab, C-hook, spreader beam)

Practical Note: Preparing these details before requesting a quotation ensures your 20-ton crane fits your workshop perfectly, operates safely, and avoids costly changes during installation. This preparation step is critical — it saves headaches, ensures accurate pricing, and guarantees a smooth installation process.

Cost and Pricing Factors — What Really Affects the 20 Ton Crane Price

Understanding how a 20-ton overhead crane is priced helps buyers make informed decisions and avoid unexpected costs. Prices reflect not just the crane itself, but optional features, site conditions, logistics, and long-term operational value. Here's a breakdown of the key factors to plan your budget effectively.

Base Cost Components

The foundation of any crane price comes from essential components required for safe and reliable operation:

- Crane structure: Main girders, end trucks, runway wheels.

- Trolley and hoist: Core lifting mechanism and hooks.

- Control cabinet and wiring: Pendant, remote, or cabin system.

These are the essentials — without them, the crane cannot function.

Optional Features

Many buyers add features to improve efficiency, safety, or versatility. These optional upgrades will affect overall cost:

- Inverter for smooth speed control

- Automation systems (anti-sway, positioning memory, semi-auto operation)

- Special lifting attachments (magnet, grab, C-hook, spreader beam)

- Safety devices (overload protection, limit switches, warning alarms)

Choosing the right optional features ensures efficiency and long-term reliability.

Logistics and Shipping

- Transport cost depends on crane span, weight, and container requirements.

- Long-span cranes may require flat-rack shipping or special handling.

- For local delivery, consider crane lifting and placement at site.

Site Condition Impact

- Building height and span: Higher or wider spans require more steel and stronger structures.

- Installation complexity: Tight spaces, uneven floors, or special foundations can increase cost.

- Outdoor vs indoor: Weatherproofing or environmental protection adds to the price.

Long-Term Value

- Maintenance costs: More durable components reduce frequent repairs.

- Spare part durability: Ensures the crane can operate without unexpected downtime.

- Operational efficiency: Smooth, precise, and energy-efficient cranes save money over time.

Buyer Tip: The lowest quote is often incomplete — it may not include optional features, shipping, installation, or environmental protection. Always confirm the full configuration and after-sales support before comparing prices.

Choosing the Right Overhead Crane Supplier — What Professional Buyers Evaluate

Selecting the right supplier can make or break your crane investment. Beyond price, professional buyers focus on reliability, technical expertise, and long-term support. The right partner ensures your overhead crane performs safely and efficiently throughout its service life.

Key Evaluation Points:

- Certifications: Look for ISO, CE, and third-party inspection reports to ensure quality and compliance.

- Relevant Experience: Suppliers with export history or project experience in industries similar to yours can anticipate challenges and provide tailored solutions.

- Technical Support: Check whether the supplier can provide drawings, consultation, and installation guidance — essential for smooth project execution.

- Spare Parts & Service: Availability of replacement parts and responsive service is critical to minimize downtime.

- Delivery & Documentation: Reliable shipment schedules, clear packing lists, and complete documentation reduce installation delays and errors.

- Client Feedback: References and past project reviews give insight into supplier reliability, professionalism, and after-sales support.

Professional Tip: A qualified supplier does more than deliver equipment — they guide design, assist installation, provide ongoing maintenance, and ensure your crane operates safely and efficiently.

Maintenance and Operation — What Every Owner Should Know

Keeping your overhead crane in top condition ensures safety, efficiency, and protects your investment. Daily attention and regular maintenance prevent costly repairs and unplanned downtime. Here's what every crane owner should focus on.

Daily Inspection Checklist

Inspect the crane before each workday to prevent accidents or hidden damage:

- Brakes: Ensure smooth engagement and secure load holding; listen for unusual noises indicating wear.

- Hooks: Check for deformation, cracks, or overloading; safety latches should move freely.

- Wire Ropes: Look for frayed strands, kinks, corrosion, or broken wires; replace immediately if damaged.

- Limit Switches: Test upper and lower travel limits to prevent over-travel and potential damage.

Lubrication & Gear Care

Proper lubrication reduces wear and keeps moving parts running smoothly:

- Follow the manufacturer's lubrication schedule for hoists, bearings, and gears.

- Use specified grease or oil; avoid generic alternatives that may cause premature wear.

- High-temperature or dusty conditions may require more frequent lubrication.

Electrical System Checks

- Inspect contactors, fuses, and wiring for wear, corrosion, or overheating.

- Check insulation and ensure all electrical connections are tight and secure.

- Confirm proper grounding to prevent electrical faults and equipment damage.

Periodic Professional Inspection

- Monthly: Trained technician performs basic inspection of mechanical and electrical components.

- Yearly: Full inspection including load testing, rope replacement, and brake adjustment to comply with safety regulations.

Spare Parts Planning

- Stock essential items such as wire ropes, contactors, fuses, and brake components.

- Monitor usage and plan replacements based on manufacturer guidelines and actual crane workload.

- Keep fast-moving spares on-site, especially for remote or high-demand operations.

Common Buyer Questions — FAQ Section

Buying an overhead crane raises many questions, especially for first-time buyers. Here are the most common questions and practical answers.

How long is production and delivery time?

Production depends on crane type, capacity, and customization. A typical 20-ton overhead crane takes 30–45 days to manufacture. Delivery time depends on shipping distance and logistics. Discuss schedules with your supplier in advance for accurate planning.

Can a 20-ton crane be used outdoors?

Yes. Outdoor cranes require weather protection, such as waterproof motors, corrosion-resistant paint, and enclosures for electronics. Consider wind, rain, and temperature conditions at your site for safe operation.

How do I confirm building load capacity?

A structural engineer should verify that your building or workshop can support the crane, trolley, and maximum load. Proper runway beams and foundation support are essential for safety.

What's the warranty period?

Most suppliers provide a standard 12-month warranty after commissioning. Some may extend coverage for major components like motors or hoists. Always check the contract for details.

Is training or installation service included?

Professional suppliers often provide installation guidance, on-site commissioning, and operator training. Clarify what is included, especially if your staff is inexperienced with overhead crane operation.

What documentation will I receive?

Suppliers should provide comprehensive documentation:

- Operation and maintenance manuals

- Test and load certification reports

- Safety and compliance certificates (ISO, CE, or third-party inspection)

Having these documents ensures compliance and supports long-term maintenance planning.

Free Consultation — How to Begin Your 20 Ton Overhead Crane Project

Taking the first step toward installing a 20-ton overhead crane can feel overwhelming. But it doesn't have to be. With a little preparation, you can move from research to a concrete plan confidently.

What You Should Prepare

- Workshop Details: Share key information such as building span, lifting height, environmental conditions (indoor/outdoor, temperature, dust), and power supply voltage.

- Operational Requirements: Specify lifting frequency, typical load types, and any attachments or clamps needed for your material handling.

- Quotation Request: Ask for a basic layout-based quotation. Even a preliminary plan helps you visualize your crane setup and understand costs.

Send Us An Inquiry Now

Once your information is shared, the process usually follows these stages:

- Design Confirmation: Engineers review your workshop and load details, then propose the optimal crane configuration.

- Manufacturing: Your crane is fabricated according to confirmed specifications.

- Delivery: Transport is arranged with clear documentation to your site.

- Installation & Commissioning: Your crane is installed, tested, and handed over ready for operation.

Ready to plan your 20-ton crane? Share your workshop details today — our engineers can provide a matching solution within a day. It's fast, practical, and the first step toward smoother, safer lifting operations in your facility.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch