Calculating ROI for 20 Ton Gantry Cranes | Cost & Payback Guide

Learn how to calculate ROI for your 20 ton gantry crane. Compare purchase cost, energy savings, labor efficiency, & payback period for smarter investment.

Category: 20 Ton Gantry Crane

Your Trusted 20 Ton Gantry Crane Manufacturer & Supplier

Calculating ROI for Your 20-Ton Gantry Crane Investment

Cost, Savings & Payback Guide

Learn how to calculate ROI for your 20-ton gantry crane investment. Explore cost breakdowns, real industry examples, and tips to justify your crane purchase with clear payback and productivity data.

Investing in a 20-ton gantry crane is a big decision for any company. These cranes are not cheap, and they often represent one of the largest single investments in a workshop or outdoor handling area. That’s why calculating the return on investment (ROI) before making a purchase is not just a good idea—it’s essential. ROI helps you understand how long it will take for the crane to pay for itself through increased efficiency and reduced costs.

When calculating ROI, it’s easy to focus only on the purchase price. But the total cost of owning a crane goes far beyond the initial investment. Installation, operation, and ongoing maintenance all add up. Skipping these details can lead to surprises down the line, like unexpected downtime or higher-than-expected energy costs.

Understanding ROI also helps you evaluate the real value a crane brings to your operation. It’s about more than just moving heavy loads. A well-chosen crane can improve workflow, reduce strain on workers, and even make your production schedule more reliable.

Key points to consider when calculating ROI:

- Total Costs: Include the crane price, installation, operation, and maintenance expenses.

- Operational Efficiency: How much faster and safer can materials be moved with this crane?

- Productivity Gains: Will the crane reduce bottlenecks and allow your team to handle more work in the same time?

Taking the time to calculate ROI ensures that the investment you make in a 20-ton gantry crane is practical, well-planned, and aligned with your company’s goals. It’s not just about buying equipment—it’s about making sure the crane truly works for you.

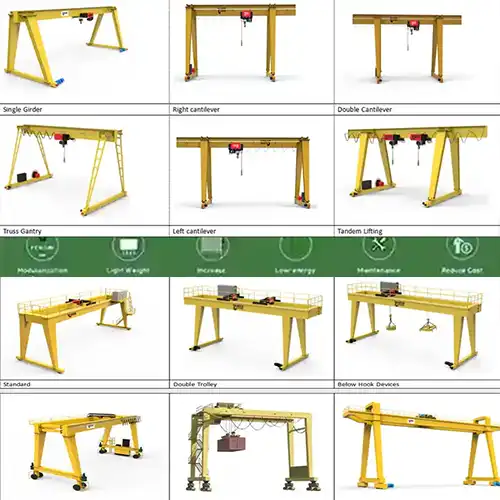

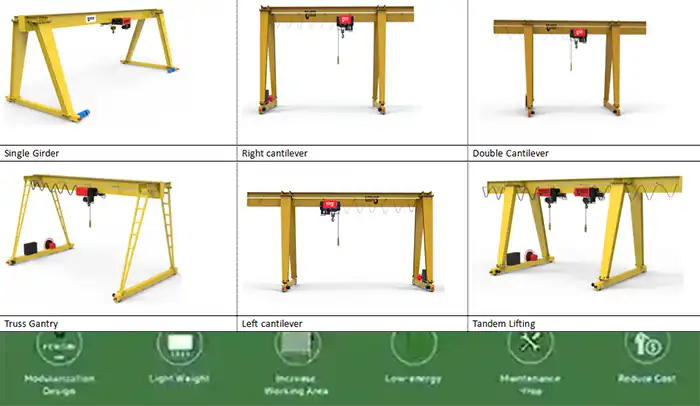

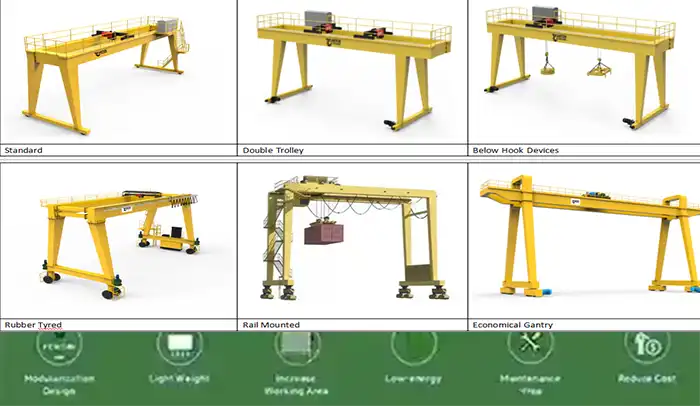

20 ton gantry crane single girder, customized solutaions provided, optional features, low headroom , cantilevered gantry cranes, tandem lifting 2 hooks gantry cranes, truss girder gantry cranes, etc.

20 ton gantry crane double girder design, check 20 ton gantry crane single girder vs double girder to get your required cost-effective solution , WhatsApp: + 86 151 3871 1597

Cost Breakdown

When planning to invest in a 20-ton gantry crane, it's crucial to look beyond the sticker price. Understanding the full range of costs helps you avoid surprises and plan your budget accurately. Let's break it down step by step.

Purchase Costs

- Single vs Double Girder: Single girder cranes are generally more affordable and suitable for lighter, less frequent lifting. Double girder cranes cost more but can handle heavier loads, longer spans, and provide better stability.

- Customization: Factors like span length, lifting height, and outdoor or indoor use affect the price. Customized cranes are more expensive, but they better match your operational needs.

- Optional Accessories: Additional features like remote controls, anti-sway devices, overload sensors, and weatherproofing for outdoor use add to the cost but can improve safety, performance, and lifespan.

Practical Tip: Always request a detailed quotation showing base crane price and optional features separately. This makes it easier to see which upgrades are necessary and which are optional.

Installation Costs

- Foundation or Rail Preparation: For gantry cranes that travel on rails or require a stable foundation, preparation work can include concrete pads, anchoring, and leveling.

- Labor, Crane Erection, and Testing: Skilled technicians are needed to assemble the crane, test all mechanisms, and ensure safety compliance.

Practical Tip: Include installation costs in your ROI calculation. Sometimes installation can be 10–20% of the purchase price, depending on site conditions.

Operational Costs

- Energy Consumption: Electric motors consume power based on load and operating hours. Planning for electricity costs is important, especially in high-use operations.

- Operator Wages: Trained operators are required for safe and efficient crane operation. Labor costs should be included in operational budgeting.

- Auxiliary Equipment: Items like trolleys, slings, and spreader beams used with the crane can have minor costs but are necessary for certain lifts.

Practical Tip: Track energy use per shift and compare it to crane usage to identify efficiency improvements.

Maintenance Costs

- Scheduled Maintenance: Regular lubrication, inspections, and replacement of worn parts prevent unexpected breakdowns.

- Unscheduled Repairs and Downtime: Unplanned failures can cost significantly in both repairs and lost productivity.

- Long-Term Service Contracts or OEM Support: Some buyers opt for maintenance contracts or extended OEM support to simplify service planning and avoid surprises.

Practical Tip: Maintenance costs typically range from 2–5% of the crane's purchase price annually, depending on usage intensity and environmental conditions.

Sample ROI Calculations by Industry

The return on investment (ROI) for a 20-ton gantry crane depends heavily on how often it's used and what kind of materials it handles. Different industries have different lifting frequencies, work environments, and operating costs. Below are some simple examples to help visualize how ROI can vary across sectors.

Steel Industry

In steel mills and metal processing plants, 20-ton gantry cranes often run for long hours every day. They handle slabs, billets, coils, and heavy molds — sometimes in high-temperature or dusty conditions.

- Operating Frequency: 10–16 hours per day, often 300+ days a year.

- Primary Costs: Higher energy use, wear-resistant components, and regular maintenance.

Example ROI:

- Suppose a crane moves 200 tons of billets per day.

- If the crane improves handling efficiency by 20%, it saves roughly 40 tons worth of handling time daily.

- Over a year, that translates into thousands of saved labor hours and reduced equipment downtime, often covering the purchase cost in 2–3 years.

Practical Note: For steel applications, reliability and durability matter more than just the purchase price. Frequent operation means faster payback through productivity gains.

Construction & Fabrication

In construction yards and fabrication workshops, 20-ton gantry cranes handle beams, columns, and prefabricated assemblies. These cranes might not run as continuously as those in steel mills, but they play a big role in improving project efficiency.

- Operating Frequency: 6–8 hours per day, depending on project load.

- Primary Costs: Moderate energy use, moderate maintenance.

Example ROI:

- A single crane can replace two or three forklifts and several workers needed for manual lifting.

- If the crane reduces handling time by even 30 minutes per load, across dozens of lifts per day, that's a clear cost saving.

- In most fabrication plants, ROI is achieved within 3–4 years, especially when factoring reduced labor and faster project completion.

Practical Tip: Consider project turnaround speed as part of ROI. Faster handling means faster delivery—and more contracts won.

Warehouse & Logistics

In storage yards and logistics centers, gantry cranes may not run continuously, but they handle valuable goods with precision and safety.

- Operating Frequency: 4–6 hours per day or as needed.

- Primary Costs: Low energy use, light maintenance, but higher emphasis on safety and precision.

Example ROI:

- Suppose the crane handles oversized cargo that used to require external lifting services.

- By owning a 20-ton gantry crane, the company saves service rental fees—often $500–$1,000 per lift.

- Over a year, these savings can reach tens of thousands of dollars, achieving ROI in 4–5 years.

Practical Tip: For warehouses, the value comes not just from speed but from avoiding external lifting costs and improving in-house flexibility.

Notes on Assumptions

ROI calculations are only as accurate as the assumptions behind them. To keep your estimates realistic, always consider:

- Crane Lifespan: Typically 15–20 years with proper maintenance.

- Working Hours: Average daily use varies by industry (4–16 hours).

- Average Load Ratio: Cranes rarely operate at full 20-ton capacity; use 60–80% for realistic estimates.

- Downtime: Factor in 2–5% downtime for regular maintenance and inspections.

Practical Tip: A well-maintained 20-ton gantry crane can outlast its projected service life, improving ROI even further over time.

Justifying the Investment to Management

When it's time to present your 20-ton gantry crane proposal to management, numbers alone might not tell the whole story. Decision-makers want to see how the investment will improve performance, reduce costs, and strengthen long-term operations. The goal is to turn technical details into clear business value.

Productivity Gains

A 20-ton gantry crane can dramatically improve how materials move through your plant or yard. Instead of relying on multiple smaller lifting tools or manual handling, one crane can streamline the entire process.

- Reduced Load Handling Time: Lifts that once took 15–20 minutes can now be completed in just a few. Over hundreds of lifts, those time savings add up fast.

- Minimized Bottlenecks: Smooth material flow means production lines or assembly areas don't need to wait for handling equipment to become available.

Practical Tip: Record the time savings during a trial operation or test lift. Showing real numbers from your own facility is the best way to demonstrate productivity gains.

Safety Improvements

Improved safety is one of the easiest benefits to explain to management—and one of the hardest to put a price on. A well-designed 20-ton gantry crane helps eliminate risky manual lifting and reduces the need for forklifts in tight spaces.

- Fewer Workplace Accidents: Mechanical lifting reduces strain injuries and minimizes risks of dropped loads.

- Compliance with Safety Regulations: Modern cranes come equipped with overload limiters, emergency stops, and warning systems that help you meet workplace safety standards.

Practical Tip: Mention that fewer accidents not only protect workers but also lower insurance premiums and prevent costly downtime.

Cost Savings

Cost savings can be both direct and indirect. While the upfront investment in a 20-ton gantry crane may seem high, the long-term reductions in operating and labor expenses often outweigh it.

- Lower Labor Costs: A single crane can replace several manual handlers or forklifts, reducing daily labor needs.

- Reduced Equipment Wear: Because the crane handles most of the heavy lifting, other machines like loaders or transport carts last longer.

- Operational Efficiency: Less time wasted waiting for lifting equipment means higher overall productivity.

Practical Tip: Include examples of cost reduction per month or per year. This helps management visualize savings beyond the initial expense.

Payback Period & ROI

Once you've outlined all benefits, tie them together with simple financial projections. Management will want to know when the investment starts paying for itself.

- Clear Presentation: Use tables or charts to compare total costs (purchase, installation, operation, and maintenance) against savings and productivity gains.

- Highlight Long-Term Value: Show how, over a 10–15 year service life, the crane's total benefit can far exceed its initial cost.

- Payback Example: In many operations, a 20-ton gantry crane can achieve full payback in 2–4 years, depending on usage frequency and labor cost savings.

Practical Tip: Always present ROI and payback alongside tangible outcomes—such as faster order fulfillment, reduced downtime, or improved safety performance.

Conclusion

Investing in a 20-ton gantry crane is more than just a purchase — it’s a long-term decision that affects productivity, safety, and cost efficiency across your entire operation. By understanding the full cost breakdown—from purchase and installation to operation and maintenance—you get a clear picture of what the crane truly costs to own and run.

When compared to these expenses, the benefits often outweigh them by a wide margin. A properly selected and maintained 20-ton gantry crane can save countless labor hours, reduce handling time, and keep your material flow consistent and reliable. These gains directly improve profitability and operational stability, especially in industries like steel processing, construction, and logistics.

In short:

- The initial cost covers more than the crane itself—it includes long-term performance and reliability.

- The operational and maintenance efficiency directly affects your ROI timeline.

- The measurable benefits—higher productivity, safer workplaces, and reduced downtime—translate into real financial returns.

Practical Takeaway: When presenting your case for investment, focus on clear ROI data and real-world improvements, not just the price tag. A well-planned 20-ton gantry crane investment pays for itself and continues adding value year after year.

Our 20-Ton Gantry Crane Project Reference

Explore how our 20-ton gantry cranes perform across indoor and outdoor projects. Each case demonstrates tailored solutions for different operational needs.

I. Indoor Use Projects

Steel Fabrication Workshop – UAE

- Type: Single Girder 20 Ton Gantry Crane

- Application: Handling steel beams and frames during fabrication and assembly.

- Key Features: Compact design for limited headroom; remote control system for precision lifting.

- Result: Improved workflow efficiency by 35% and reduced manual material handling.

Machinery Manufacturing Plant – Vietnam

- Type: Double Girder 20 Ton Gantry Crane

- Application: Loading/unloading heavy mechanical components for machining and assembly lines.

- Key Features: Frequency inverter for smooth motion, low noise motor, and safety overload limiter.

- Result: Enhanced operational reliability with reduced downtime and easier load positioning.

Mold Handling Workshop – Thailand

- Type: Single Girder 20 Ton Gantry Crane

- Application: Handling injection molds between storage and molding machines.

- Key Features: Compact lifting structure with soft-start hoist and precise positioning control.

- Result: Reduced mold changeover time by 40%, improving production flexibility.

Outdoor Use Projects

Steel Stockyard – Saudi Arabia

- Type: Double Girder 20 Ton Rail-Mounted Gantry Crane

- Application: Outdoor lifting and stacking of steel plates and bars.

- Key Features: Anti-corrosion paint, IP55 protection motors, full canopy weatherproof hoist.

- Result: Ensured continuous operation under high temperature and dusty conditions.

Concrete Prefab Yard – Malaysia

- Type: Single Girder 20 Ton L-Type Gantry Crane

- Application: Lifting precast concrete panels and columns.

- Key Features: Cantilever design for side loading; equipped with safety limit switches and emergency stop system.

- Result: Reduced loading cycle time and improved yard logistics efficiency.

Shipyard Maintenance Zone – Indonesia

- Type: Double Girder 20 Ton Outdoor Gantry Crane

- Application: Handling marine components and ship parts during repair works.

- Key Features: Rust-resistant coating, rainproof covers, dual-speed hoisting.

- Result: Increased productivity and safety for heavy-duty outdoor lifting.

20 Ton Gantry Crane Price — Key Cost Factors

Estimating 20-ton gantry crane prices depends on working conditions, crane configuration, and environmental factors. Key variables include:

- Crane span and lifting height – Larger dimensions require more steel and structural strength.

- Working class and duty cycle – Continuous heavy-duty operation costs more than light indoor usage.

- Control mode – Pendant, remote, or cabin operation affects cost and usability.

- Environmental protection – Outdoor cranes require anti-corrosion coatings, weatherproof covers, or IP-rated electrical systems.

- Optional functions – Anti-sway control, frequency conversion, or explosion-proof design enhance safety/performance but increase price.

Practical Tip: Always request itemized quotations showing base crane price and optional accessories to clearly see the value of each upgrade.

20 Ton Gantry Crane Price Reference Table

| Product Name | Capacity (t) | Span (m) | Work Duty | Lifting Height (m) | Operation Mode | Price (USD) |

|---|---|---|---|---|---|---|

| 20 Ton L Type Single Girder Gantry Crane | 20 | 26 | A6 | 8+32 | Cabin | $94,864 |

| 20/5 Ton L Type Single Girder Gantry Crane | 20/5 | 27 | A5 | 12 | Cabin | $74,340 |

| 20/5 Ton L Type Single Girder Gantry Crane | 20/5 | 40 | A5 | 16 | Cabin | $93,660 |

| 20 Ton Single Girder Gantry Crane | 20 | 27 | A3 | 9 | Cabin | $44,800 |

| 20/5 Ton FEM Single Girder Gantry Crane | 20/5 | 24 | A5 | 9 | Cabin + Remote | $77,910 |

| 20/5 Ton Double Girder Gantry Crane (MG Type, Double Hook) | 20/5 | 28 | A5 | 10 | Cabin + Remote | $102,410 |

- Prices are for reference only and may vary with steel market trends, motor brands, imported components, or regional labor costs.

- Provide crane span, lifting height, working environment, and usage frequency for a precise quotation.

- Our engineering team can design the most cost-effective 20-ton gantry crane solution for your project.

Related Products

Affordable 10 ton double girder overhead crane with CD/MD hoist trolley, built for U.S. standards, ideal for construction and industrial lifting

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch