Single Girder Underlung Crane for Sale, 7.5 Ton Overhead Crane

7.5 ton bridge crane for sale. Custom single girder underslung crane for sale, economical ceiling mounted bridge crane , remote control overhed crane 7.5 ton.

| Crane type | Single girder underslung crane |

| Crane specifications | 7.5 ton, 6m span, 20 m lifting height |

| Power supply | 380V/50Hz/3 Phase |

| Project location | Egypt |

Category: Underhung Bridge Crane

Your Trusted Overhead Crane Manufacturer & Supplier

Single Girder Underlung Crane for Sale, 7.5 Ton Overhead Crane

7.5 ton bridge crane for sale. Custom single girder underslung crane for sale, economical ceiling mounted bridge crane , remote control overhed crane 7.5 ton.

Compared to top running systems, single girder underhung crane runways are significantly lighter, which enhances their versatility and usability. Since they are much lighter, they can be mounted on the ceiling. Additionally, they can operate alongside each other without causing any interference. Another mechanical benefit of underhung crane systems is the ability to interlock them together. By locking two cranes' adjacent ends, an operator can transfer loads from one system to another. Moreover, these systems can interlock with monorails to transfer materials along a fixed path.

The LX underhung single girder overhead crane is a type of lightduty crane that runs beneath an H steel rail. It is constructed with a reasonable structure and highstrength steel for durability. It is used in conjunction with the CD1 model MD1 model electric hoist or Europeans style electric wire rope hoist to form a complete set, with a capacity ranging from 0.5 ton to 10 tons. The span is between 5-40m, and the working duty is between M3-M5, with a working temperature range of 25-40℃.

The LX under running single girder overhead crane finds extensive application in warehouses, steel plants, steel yards, material stocks, etc., for lifting goods. It can be classified into two types based on the main girder and hoist type: LX single girder underslung crane with Universal Design and NLX single girder underslung crane with European style.

Specification of single girder underslung cranes

Lifting Capacity (ton) | 0.5 ton, 1 ton, 2 ton, 3 ton, 5 ton, 10 ton | |||

Span (meter) | 316 | |||

Crane Travelling Mechanism | Travelling Speed (m/min) | 20/30 | ||

Motor | 0.5 3 ton | ZDY124; N = 2x0.4kw | ||

5 10 ton | ZDY214; N= 2x0.8kw | |||

Lifting Mechanism | Electric Hoist | Lifting Speed (m/min) | 8; 0.8/8 | |

Lifting height (meter) | 6 30m | |||

Trolley Device | Trolley Traverse speed (m/min) | 20/30 | ||

Motor | Taper Brake Rotor Motor | |||

Working Duty | M3/A3 ( 25% ) | |||

Power Supply | 3 Phase; 380V/50HZ | |||

Wheel Diameter | 0.5 3 ton | 134 mm | ||

5 10 ton | 154 mm | |||

Recommend Travel I beam | 0.5 2 ton | 20a 45c | ||

3 5 ton | 32a 45c | |||

10 ton | 40b 63c | |||

Application of single girder underslung crane

The LX model single girder underslung crane is primarily utilized in manufacturing and maintenance operations, and can be extensively employed in various industries, including Pre Engineered Steel Building, Steel Plant, Steel Product Maker, Oil Industry, Plastic Plant, Cement Plant, Power Plant, Mine Industry, Food Industry, Chemical Industry, Cable Plant, Machine Tools, Car/Truck Industry, Transport Company, Construction Company, Electrical Company, Shipyard, Stone Yard, Installation and Maintenance.

Single girder underslung crane runway

Underhung crane runways can be ceiling mounted because of being dramatically lighter. Also they have the ability to run sidebyside without interfering with one another. Another mechanical advantage that under hung crane systems have is that they can be interlocked together. By locking the adjacent ends of two cranes together an operator can transfer the load from one system to another. They can also interlock with monorails to allow for the transferring of material along a fixed path.

Usually suspended from roof trusses, these cranes are mainly used for maintenance purposes inside small areas, such as pumping stations and small workshops. They are compact in design and construction, making them ideal for low buildings that require maximum hook height.

single girder underslung overhead crane installed on the concrete building factory

Single girder underslung bridge crane installed for steel factory

Top Running Crane vs. Under Running Crane

- Support structure: Under running cranes can be suspended directly from the roof structure or other overhead beam. Top running cranes need independent columns to support the end trucks and the bridge beam.

- Capacity: As underslung cranes are suspended from the roof structure, they are available only on lighter capacities, usually less than 10 tons. The capacities of top running overhead cranes are much larger. The safe working load of top running cranes can even up to 550 t.

- Configuration: Because of the light capacity, underslung cranes usually adopt the single girder configuration, although double girder under running crane is also available in some special cases. But the top running overhead crane equipped with double girder is more frequent.

- Utilization of space. Something unique to under running cranes is their ability to make full use of the available height and the tight space. They can ensure efficient material handling even in plant where very little space is available.

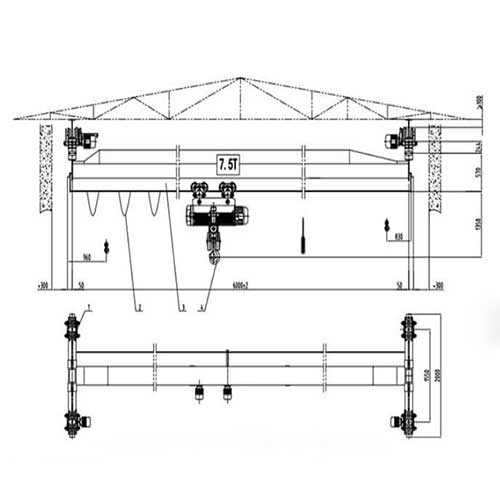

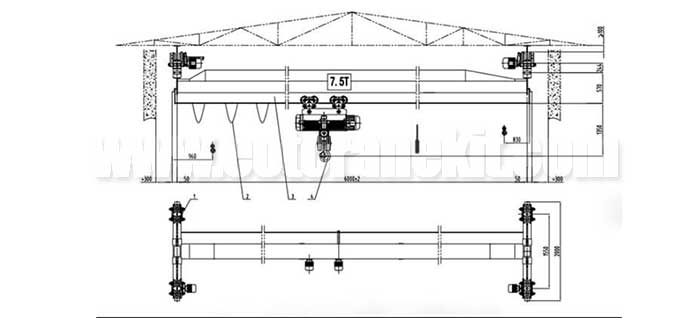

7.5 Ton single girder underslung crane for sale to Egypt

Our company recently sold a 7.5-ton single girder underslung crane to a client in Egypt. The client operates a large manufacturing plant that produces a wide range of products. They required a crane that could handle heavy loads and operate in a limited amount of space.

The main challenge was to design and install a crane that could meet the client's requirements while working within the limited space available. Additionally, the client had a tight budget and required a cost-effective solution.

Main specification of single girder crane for sale to Egypt

- Type: LX type single girder underslung crane

- Load capacity: 7.5 ton

- Lifting height: 20m

- Travel Speed: 20 m/min

- Crane Span: 6 m

- Hoist type: CD wire rope electric hoist

- Lifting speed: 7 m/min

- Working duty: A3

- Power supply: 380V/50Hz/3 Phase

- Control Mode: Remote control

Our team worked closely with the client to develop a customized solution that met their needs and budget. We recommended a 7.5-ton single girder underslung crane that was ideal for their manufacturing plant. This crane has a tight structure and good rigidity, which allowed it to operate in the limited space available. Furthermore, the crane produces low noise and no pollution during operation, which was an important consideration for the client.

Our team designed and installed the crane according to the client's specifications, ensuring that it met all safety standards and regulations. We also provided training to the client's staff on how to operate and maintain the crane.

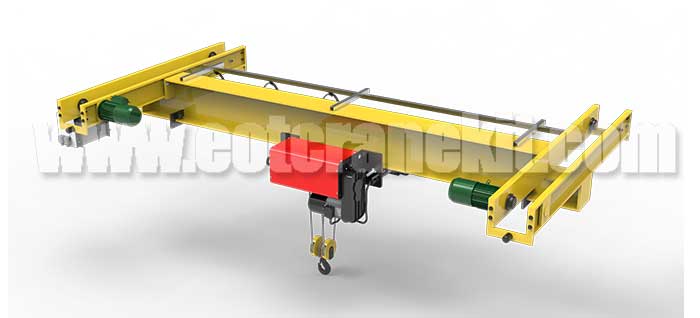

Main girder of single girder underslung crane

Single girder underslung overhead crane hoist

Custom features of 7.5 ton single girder underslung cranes

- The single girder underslung crane is a lightweight overhead crane also known as under running or underhung crane.

- It is commonly used in production and assembly lines, as well as warehouses, to lift and transport heavy loads.

- The crane requires minimal space and runs on the bottom flange of the crane runway, which is mounted on roof beams or directly on the ceiling.

- The singlebeam underslung crane consists of standard components, can be easily and reliably installed at a lower cost, and allows for efficient material handling and precise positioning of various components in specific areas.

- It can be mounted directly under an existing roof structure, with no need to install support rail beams, making it an ideal solution for making the most of available space in your plant.

The 7.5-ton single girder underslung crane has been operating smoothly since its installation. The client has reported that it has improved their manufacturing processes and increased their productivity. They are also pleased with the cost-effectiveness of the solution, which has helped them to save money while still meeting their requirements.

Our company was able to provide a customized solution that met the client's needs and budget. The 7.5-ton single girder underslung crane has proven to be a reliable and cost-effective solution for the client's manufacturing plant in Egypt.

Packages of Single Girder Underslung Crane 7.5 ton

The proper packages of single girder underslung crane is used for safe transport of all components.

- Electric parts are packed in highquality plywood crates to prevent distortion during conveying.

- Main and end beams are wrapped in plastic woven cloth to reduce abrasion during transport.

- The entire set of overhead crane will be shipped in a container or by bulk, depending on your preference.

- The package ensures that your crane arrives at its destination in excellent condition and ready for installation.

Packages of overhead crane for delivery to Egypt

Packages of overhead crane for delivery to EgyptFAQ on single girder underslung cranes

1. Q: What is a single girder underslung crane?

A: A single girder underslung crane is a type of overhead crane where the crane's bridge is supported by end trucks that run on the bottom flange of runway beams.

2. Q:What are the advantages of using a single girder underslung crane?

A: Single girder underslung cranes offer several advantages, including:

- Costeffective: These cranes are generally less expensive than other types of overhead cranes, making them a costeffective solution for lifting and moving loads.

- Spacesaving: The underslung design of the crane means that it hangs from the ceiling, freeing up floor space and allowing for more efficient use of the workspace.

- Easy to install: Single girder underslung cranes are relatively easy to install and can be customized to fit the specific needs of the workspace.

- Versatile: These cranes can handle a wide range of load capacities and can be used in a variety of industries, including manufacturing, construction, and warehousing.

- Low maintenance: Single girder underslung cranes require minimal maintenance, reducing downtime and increasing productivity.

Overall, single girder underslung cranes provide a costeffective, spacesaving, and versatile solution for lifting and moving loads in a variety of industries.

3. Q:What industries commonly use single girder underslung cranes?

A: Single girder underslung cranes are commonly used in industries that require the lifting and moving of lighter loads, such as manufacturing, assembly, and maintenance applications. These cranes are particularly useful when there is limited headroom available, as the underslung design allows for greater vertical clearance. Additionally, they are often used in facilities with limited floor space, as they can be mounted to the ceiling or roof structure. Some specific industries that commonly use single girder underslung cranes include automotive, aerospace, electronics, and general manufacturing.

4. Q:What safety features should be considered when operating a single girder underslung crane?

A: When operating a single girder underslung crane, safety should always be the top priority. Some important safety features to consider include:

- Overload Protection: The crane should be equipped with overload protection to prevent it from lifting more weight than it is designed to handle.

- Emergency Stop Button: An emergency stop button should be easily accessible to the operator in case of an emergency.

- Limit Switches: Limit switches should be installed to prevent the crane from travelling too far in any direction.

- Warning Devices: Warning devices such as lights and alarms should be installed to alert workers when the crane is in operation.

- Regular Maintenance: Regular maintenance and inspections should be conducted to ensure that the crane is in good working condition.

With the safety features, the risk of accidents and injuries can be greatly reduced when operating a single girder underslung crane.

5. Q:Why to select our single girder underslung crane?

- A: Our suspension single girder crane offers high safety and reliability due to its tight structure and good rigidity.

- The operation of the single girder underslung crane is flexible and requires low maintenance.

- The crane produces low noise and no pollution during operation.

- We offer a variety of types of single girder underslung cranes that are widely used and feature smooth movement, effective braking, and long service life.

- Our single girder underslung cranes are of high quality and costeffective.

Double girder unerslung cranes

If you are interested in a double girder underslung crane, our factory manufactures and supplies a range of options with different configurations to meet your specific requirements. We offer double girder underslung cranes with chain hoists and wire rope hoists. The entire component, including the hoist and end carriages, is lightweight, which saves on construction costs. All three motions of the crane come with double speed motors, allowing for precise picking and placing of components or loads.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch