10 Ton & 3 Ton Underhung Bridge Crane for Sale South Africa

10 ton & 3 ton underhung bridge cranes for sale Durban, South Africa. Single girder underhung bridge crane, remote control, 400V 50Hz 3P for sale, good price.

Category: Underhung Bridge Crane

Your Trusted Underhung Overhead Crane Manufacturer & Supplier

10 Ton & 3 Ton Underhung Bridge Crane for Sale South Africa

10 ton & 3 ton Underhung Bridge Cranes for Sale South Africa

10 ton & 3 ton underhung bridge cranes for sale Durban, South Africa. Single girder underhung bridge crane, remote control, 400V 50Hz 3P for sale, good price.

Basics of underhung bridge crane for Uzbekistan

- Crane Type:underhung bridge cranes

- Date of Placing Oder:2022.7.15

- Date of Delivery :2022.08.15

- Way of Transportation: By shipping, containers

- Way of Payment:48% TT prepaid.

- Destination country: South Africa

- Destination port:CFR Durban

- First Contact:2021.06.08

10 ton & 3 ton underhung bridge crane main specifications & general requirements

Crane type | Model | Working Class | Tonnage(T) | Span m) | Left/ right Cantilever (m) | Lifting Height(M) | Crane control | Voltage | Indoor /Outdoor use | Crane Rail | Quality |

Electric under hung crane | M3 | 10 | 13 | 1/1 | 9 | Remote control | 400V 50Hz 3P | Indoor use | / | 1 | |

Electric underhung crane | LX | M3 | 5 | 13.5 | 0.75/ | 6 | Remote control | 400V 50Hz 3P | Indoor use | / | 1 |

Custom features of underhung bridge crane components

- The galvanized steel wire rope with a diameter of 28mm is 100m, and the tensile strength is 1870N/mm². The steel wire rope is divided into four sections, namely 60m+20m+10m+10m.

- It is equipped with four single-piece pulleys and 10 ton hooks, which are used by customers to drag tractors stuck in mud with wire ropes.

Gallary of 20 ton & 5 ton electric hoist crab trolley for sale Sounth Africa

Main girder of 20 ton single girder electric hoist crab trolley for sale Sounth Africa

Main girder of underhung bridge crane for sale Sounth Africa

Main girder of 10 ton and 3 ton underslung bridge crane for sale Sounth Africa

End carriages and end trucks of single girder under running bridge crane for sale Sounth Africa

Wires conneciton of electric overhead travelling cranes Sounth Africa

Underhung bridge cranes

The electric underhung crane is a light duty overhead crane with a lifting mechanism consisting of a CD1, MD1 type electric wire rope hoist. The underhung bridge crane is suspended beneath the I-beam. The light underhung crane has a standard lifting capacity of 0.5 to 5 tons. It can be tailored to your specific applications and lifting needs. This electric underhung bridge crane is suitable for use in the fields of machinery, assembly lines, warehouses, and so on.

Underhung overhead crane with Chinese style girder and cd/md electric wire rope hoist

Features and Advantages

- Save space; the upper portion of the H-shaped steel can be finished since the height of the hoist will not be greater than that of the H-shaped steel.

- Products and equipment are not damaged by power off and braking, and the buffering device is safe and stable.

- For reliable performance, reduced noise, copper wire longevity, and low power consumption, use a three-in-one motor.

- Superior hardened gears that are reliable and durable.

- The span is extended, and the available space is effectively utilized.

- A C-shaped steel slide is safer and more durable, as well as harder to wear.

- It is possible to build with external suspension.

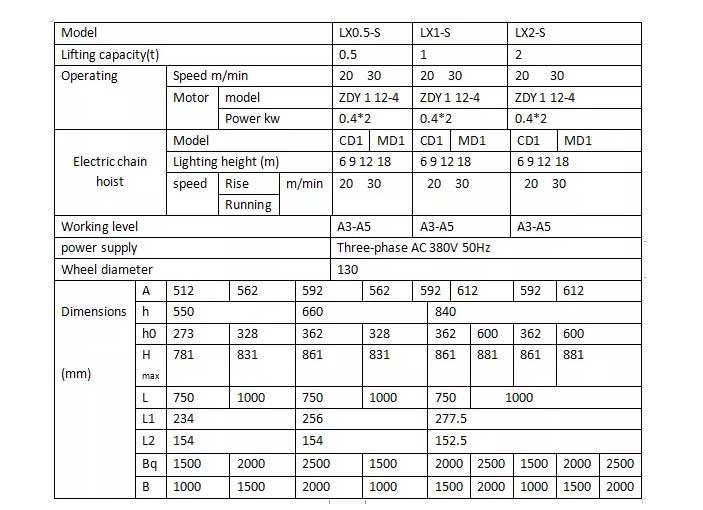

Main specifications of single girder underhung cranes

Application of single girder underhung bridge cranes

- This electric underhung bridge crane can be used in a variety of industries, including machinery, assembly lines, and warehouses.

- Control method: Pendant control or remote control, depending on your needs.

- Working temperature range: -25 to 40°C

- It is not permitted to work in an environment containing flammable, explosive, or corrosive media.

Operations of underhung bridge cranes

Before Use:

- The operator must inspect the hooks, wire ropes, and safety devices to ensure that they are in good working order before proceeding.

- Before turning on the power, the operator must ensure that no one is under the crane or on the track.

- When hoisting a heavy object for the first time in each shift (or when the load reaches the maximum weight), the weight must be lowered to the ground after lifting 0.5m, and the brake performance must be checked.

After Use:

- Raise the crane's hook to a certain height, halt it there, and set the controlling pendant to the zero position before shutting off the electricity.

- Routine maintenance of cranes.

- Handover of the shift.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch