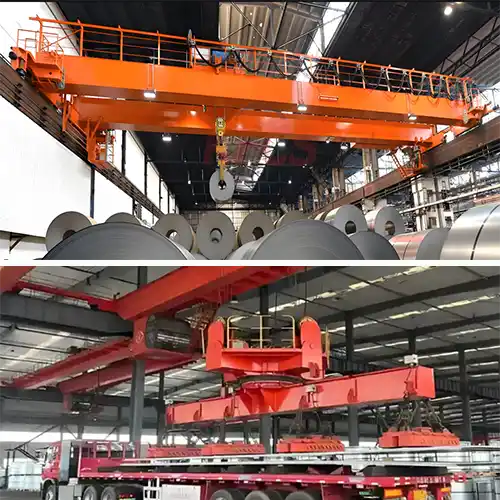

Steel Mill Cranes As Per Your Overhead Crane Specifications

Get customized steel mill cranes based on your overhead crane specs—capacity, span, load type, and operating conditions included. Filled your specs now!

Category: Featured

Your Trusted Overhead Crane Manufacturer & Supplier

Steel Mill Cranes As Per Your Overhead Crane Specifications

Get customized steel mill cranes based on your overhead crane specs—capacity, span, load type, and operating conditions included. Filled your specs now!

Fill the Steel Mill Crane Specifications Sheet and Get Your Customized Overhead Crane

Looking for the right overhead crane for your steel mill? Simply fill out the specifications sheet with your lifting needs—capacity, span, material type, and operating environment. Our team will design a tailor-made crane solution to match your production demands and ensure safe, efficient handling in your plant.

General Specificaiton Table for You to Get Tailored Steel Mill Overhead Cranes

main specifications requried to get your customized single girder overhead cranes for steel mill plants check European style single girder overhead crane specificaitons

main specifications required to get tailored single girder overhead crane tailored for steel mill plants , chek European style double girder overhead crane specifications

A. Crane Configuration

| No. | Item | Your Input / Description |

|---|---|---|

| 1 | Crane Type | Overhead / Gantry / Semi-Gantry / Ladle / Other: ______ |

| 2 | Lifting Capacity | ______ tons (e.g., 10T, 20T, 50T, etc.) |

| 3 | Number of Hoists or Trolleys | One / Two / Other: ______ |

| 4 | Lifting Mechanism | Wire Rope Hoist / Winch / Other: ______ |

| 5 | Lifting Attachment | Hook / Magnet / Clamp / Grab / Other: ______ |

B. Performance Requirements

| No. | Item | Your Input / Description |

|---|---|---|

| 6 | Lifting Height (Hook Travel) | ______ meters |

| 7 | Crane Span (Runway Rail Distance) | ______ meters |

| 8 | Crane Travel Length (Runway Length) | ______ meters |

| 9 | Lifting & Traveling Speed | Standard / Specify: ______ m/min |

| 10 | Operation Mode | Remote / Pendant / Cabin / Auto / Other: ______ |

| 11 | Duty Cycle (Usage Frequency) | Occasional / Daily / Continuous |

C. Site Conditions

| No. | Item | Your Input / Description |

|---|---|---|

| 12 | Installation Location | Indoor / Outdoor |

| 13 | Temperature Range | From ______ °C to ______ °C |

| 14 | Environmental Conditions | Dust / High Heat / Corrosive / Humid / Hazardous |

| 15 | Number of Cranes in Same Bay | ______ cranes |

| 16 | Country and City of Installation | ______ (for shipping and compliance) |

D. Special Options & Compliance

| No. | Item | Your Input / Description |

|---|---|---|

| 17 | Power Supply Voltage/Frequency | ______ V / ______ Hz |

| 18 | Power Feeding Method | Top Feed / Side Feed |

| 19 | Special Features | Anti-sway / Anti-collision / Heat Shields / Other: ______ |

| 20 | Certification Requirements | CE / ISO / Third-party Inspection / Other: ______ |

Slab Handling Crane — Quick Reference

Slabs are large, flat semi-finished steel products typically produced after the casting process. They serve as raw material for rolling mills to create plates, sheets, and coils. Due to their heavy weight and size, slabs require specialized handling equipment like overhead cranes with proper lifting devices to ensure safe and efficient movement in steel plants.

Common Sizes:

- Length: 4–8 meters

- Width: 1.5–2.5 meters

- Thickness: 0.15–0.30 meters

- Typical Weight: 8 to 25 tons per slab (depending on size and steel grade)

Handling Notes:

- Clarify whether slabs are uniform size or mixed sizes to adjust clamp or grab design.

- Surface condition (hot, scaled, or cold) affects gripping method and crane setup.

- Quantity per lift varies; ensure crane capacity includes a 20–30% safety margin.

Practical Tip: Confirm if slabs will be lifted individually or in bundles. Bundles can significantly increase total lift weight.

Slab Handling Crane — Specification Checklist

| Specification | Description | Your Input (Fill In or Select) |

| Types of Slabs Handled | Are slabs uniform size or mixed sizes? | ☐ Same size ☐ Mixed sizes _________________________ |

| Slab Weight (tons) | Weight of one slab | ______ ton (e.g., 12 ton) |

| Length (m) | Longest side of slab | ______ m (e.g., 6.5 m) |

| Width (m) | Shorter side of slab | ______ m (e.g., 2.2 m) |

| Thickness (m) | Height or thickness | ______ m (e.g., 0.22 m) |

| Surface Condition | Surface temperature/finish | ☐ Hot ☐ Cold ☐ Scaled _________________________ |

| Quantity per Lift | Number of slabs lifted at once | ______ (e.g., 1 slab) |

| Handling Method | Type of lifting attachment | ☐ Clamp ☐ Magnet ☐ Sling ☐ Other: _____________ |

| Operating Environment | Conditions of operation | ☐ Indoor ☐ Outdoor ☐ Heat ☐ Dust ☐ Moisture |

| Industrial Applications | End-use industry or production line | ___________________________ (e.g., Steel Rolling Mill) |

| Country/Region | Location of installation or use | ___________________________ (e.g., Argentina) |

Note: Please provide the following details to receive a free, customized quotation for your slab handling crane requirements.

Need a crane for slab handling?

Send your filled-in checklist to request a free quotation tailored to your application.

Billet Handling Crane — Quick Reference

Billets are semi-finished steel products with a smaller cross-section than slabs, usually square or rectangular. They are used as raw materials in rolling mills for producing bars, rods, and wire. Because billets are dense and heavy, they require precise handling with overhead cranes.

Common Sizes:

- Length: 3–6 meters

- Cross-section: Square (typically 0.1–0.15 m) or rectangular

- Typical Weight: 1 to 3 tons per billet

Handling Notes:

- Billets may be handled individually or in bundles—know the lift configuration.

- For square billets, magnet or clamp attachments are common.

- High-temperature billets require special insulation or heat-resistant gear.

Practical Tip: If billets are bundled, confirm bundle size and total weight. Mixed bundle lengths may require adjustable clamps or guided spreaders.

Billet Handling Crane — Specification Checklist

| Specification | Description | Your Input (Fill In or Select) |

|---|---|---|

| Types of Billets Handled | Same size or mixed lengths/cross-sections? | ☐ Same size ☐ Mixed sizes _____________________________ |

| Billet Weight (tons) | Weight of a single billet | Billet weight: ______ ton (e.g., 2.5 ton) |

| Length (m) | Length of each billet | Length: ______ m (e.g., 5 m) |

| Cross-Section (m) | Square/rectangular side dimension(s) | Side: ______ m × ______ m (e.g., 0.12 m × 0.12 m) |

| Quantity per Lift | Number of billets lifted at once | Quantity: ______ (e.g., 4 billets) |

| Handling Method | Lifting equipment used | ☐ Clamp ☐ Magnet ☐ Sling ☐ Other: _______________________ |

| Surface Condition | Temperature or surface type | ☐ Hot ☐ Cold ☐ Scaled _________________________________ |

| Operating Environment | Indoor/outdoor, heat, dust, etc. | ☐ Indoor ☐ Outdoor ☐ Heat ☐ Dust ☐ Moisture __________ |

| Industrial Applications | Where the billets are used | ____________________________ (e.g., Forging Plant) |

| Country/Region | Project location | ____________________________ (e.g., Vietnam, UAE) |

| Safety Margin (%) | Extra load margin for safety | Safety margin: ______% (e.g., 25%) |

Looking for a reliable billet handling crane?

Send this checklist to get a free, customized price quotation from our technical team.

Bloom Handling Crane

Blooms are semi-finished steel products, larger than billets but smaller than slabs. Typically square or rectangular, they are used for structural shapes like beams, rails, and bars. Handling requires overhead cranes with suitable lifting attachments.

Common Sizes:

- Length: 4–6 meters

- Cross-section: 0.15–0.3 meters (square or rectangular)

- Typical Weight: 2 to 6 tons per bloom

Handling Notes:

- Requires higher capacity cranes than billets.

- Surface condition (hot or cold) affects clamp/magnet choice.

- Lifting devices must match bloom shape.

Practical Tip: For mixed sizes, use adjustable grippers. Clarify whether blooms are lifted one by one or in groups.

| Specification | Description | Your Input |

|---|---|---|

| Types of Blooms Handled | Same size or mixed sizes? | ☐ Same size ☐ Mixed sizes ___________________ |

| Bloom Weight (tons) | Weight of one bloom | ______ ton (e.g., 4 ton) |

| Length (m) | Longest dimension | ______ m (e.g., 5.5 m) |

| Cross-Section (m) | Side dimensions | ______ m × ______ m (e.g., 0.2 × 0.25) |

| Quantity per Lift | How many at once | ______ (e.g., 2 blooms) |

| Handling Method | Lifting attachment | ☐ Clamp ☐ Magnet ☐ Sling ☐ Other: __________ |

| Surface Condition | Affects lifting method | ☐ Hot ☐ Cold ☐ Scaled ____________________ |

| Operating Environment | Location & conditions | ☐ Indoor ☐ Outdoor ☐ Heat ☐ Dust ☐ Moisture |

| Industrial Applications | Where used | ____________________ (e.g., Rolling Mill) |

| Country/Region | Project location | ____________________ (e.g., India, Saudi Arabia) |

| Safety Margin (%) | Extra load allowance | ______% (e.g., 20%) |

Need a bloom handling solution?

Send us your checklist and receive a free crane price quotation customized to your needs.

Steel Pipes

Steel Pipes are hollow cylindrical tubes used for transporting fluids or as structural components in construction and industry. They come in various diameters, lengths, and wall thicknesses. Due to their shape and weight, handling steel pipes requires overhead cranes with specific lifting devices like pipe clamps or slings to ensure safe and stable movement.

Common Sizes:

- Outer Diameter: 21 mm to 1,220 mm

- Length: 3 to 12 meters

- Wall Thickness: 2 to 20 mm

- Typical Weight: Varies widely (e.g., 100 kg to 5 tons per pipe depending on size and material)

Handling Notes:

- Pipes may be seamless or welded; both types affect handling stability.

- Long pipes require multi-point lifting or spreader bars to prevent bending.

- Pipe bundles are often lifted together — confirm weight and strapping details.

Practical Tip: For bundle handling, specify whether pipes are tied, strapped, or loose to ensure safe lifting gear selection.

Steel Pipe Handling Crane — Specification Checklist

| Specification | Description | Your Input (Fill In or Select) |

|---|---|---|

| Types of Pipes Handled | Seamless, welded, galvanized, etc. | Type: ____________________ (e.g., Welded steel pipes) |

| Pipe Weight (tons) | Max weight per pipe or bundle | Pipe weight: ______ ton (e.g., 3 ton) |

| Outer Diameter Range (mm) | Pipe diameter range | ______ mm to ______ mm (e.g., 50 mm to 800 mm) |

| Length (m) | Pipe or bundle length | ______ m (e.g., 6 m) |

| Wall Thickness (mm) | Pipe wall thickness | ______ mm (e.g., 6 mm) |

| Quantity per Lift | Number of pipes or bundles lifted together | Quantity: ______ (e.g., 1 bundle = 12 pipes) |

| Handling Method | Type of lifting gear | ☐ Pipe clamp ☐ Slings ☐ Magnet ☐ Spreader beam ☐ Other: _____ |

| Bundle Condition | Tied, strapped, or loose? | ☐ Tied ☐ Strapped ☐ Loose |

| Operating Environment | Storage or work area conditions | ☐ Indoor ☐ Outdoor ☐ Humid ☐ Dusty ☐ Corrosive ______ |

| Industrial Applications | Project/industry using the pipes | ____________________________ (e.g., Oil & gas service) |

| Country/Region | Project location | ____________________________ (e.g., Philippines, India) |

| Safety Margin (%) | Extra load allowance | Safety margin: ______% (e.g., 20%) |

Need a crane for steel pipe handling?

Send us this completed checklist and receive a free quotation with a solution tailored to your pipe handling needs.

Steel Beams

Beams are long, heavy structural steel elements, often with I-shaped or H-shaped cross-sections, used in building frameworks and infrastructure projects. Their size and weight require overhead cranes with appropriate lifting clamps or spreader beams to safely handle and position them during manufacturing and construction processes.

Common Sizes:

- Length: 6–12 meters

- Height: 100–600 mm (depending on I-beam, H-beam, or custom profile)

- Flange Width: 50–300 mm

- Typical Weight: 0.2 to 3 tons per beam

Handling Notes:

- Beams may be lifted individually or in bundles. Confirm whether bundles are strapped or loose.

- Asymmetrical or wide flange beams may need custom clamps or spreader beams.

- Surface may be rusty, galvanized, or painted — affects grip type and safety.

Practical Tip: Always provide the beam type (I-beam, H-beam, U-beam, etc.) and loading orientation (horizontal/vertical) to select the correct lifting device.

Steel Beam Handling Crane — Specification Checklist

| Specification | Description | Your Input (Fill In or Select) |

|---|---|---|

| Types of Beams Handled | I-beam, H-beam, U-beam, etc. | Type: __________________ (e.g., H-beam) |

| Beam Weight (tons) | Weight of each beam or bundle | Beam weight: ______ ton (e.g., 1.2 ton) |

| Length (m) | Beam or bundle length | ______ m (e.g., 9 m) |

| Flange Width (mm) | Width of the top/bottom flanges | ______ mm (e.g., 150 mm) |

| Beam Height (mm) | Total height of the beam section | ______ mm (e.g., 300 mm) |

| Quantity per Lift | Number of beams lifted at once | Quantity: ______ (e.g., 1 beam or 4-beam bundle) |

| Handling Method | Lifting gear type | ☐ Clamp ☐ Magnet ☐ Sling ☐ Spreader Beam ☐ Other: ______ |

| Bundle Condition | Tied, strapped, or loose | ☐ Tied ☐ Strapped ☐ Loose |

| Operating Environment | Worksite environment | ☐ Indoor ☐ Outdoor ☐ Corrosive ☐ Dusty ☐ Other: ______ |

| Industrial Applications | What project or industry uses the beams? | __________________________ (e.g., Civil construction) |

| Country/Region | Final project location | __________________________ (e.g., Malaysia, UAE) |

| Safety Margin (%) | Extra capacity over beam weight | Safety margin: ______% (e.g., 25%) |

Looking for a beam-handling crane system?

Submit your checklist to get a free quote tailored to your project.

Steel Profiles

Steel Profiles are steel sections shaped into various standardized forms like angles, channels, T-sections, and U-sections. They are widely used in construction, machinery, and frameworks. Due to their varied shapes and sizes, handling steel profiles requires overhead cranes with customized clamps or grabs designed for secure lifting and precise placement.

Common Sizes:

- Length: 6–12 meters

- Cross-section Types: Angles (L), Channels (C, U), T-profiles, Z-profiles

- Typical Weight: 0.1 to 2 tons per profile or bundle

Handling Notes:

- Profiles may come in a wide range of shapes and sizes; specify exact types and loading method.

- Often transported in bundles; clarify if bundles are tied or loose.

- Uneven or thin profiles may require soft slings or adjustable clamps.

Practical Tip: Include clear details on the shape, number per lift, and whether mixed profiles will be handled together — this ensures the lifting gear is properly designed.

Steel Profile Handling Crane — Specification Checklist

| Specification | Description | Your Input (Fill In or Select) |

|---|---|---|

| Types of Profiles Handled | L, C, U, Z, T, or other shapes | Profile type: ____________________ (e.g., C-channel) |

| Profile Weight (tons) | Single profile or bundle weight | Profile weight: ______ ton (e.g., 1.5 ton) |

| Length (m) | Length of profile or bundle | ______ m (e.g., 6 m) |

| Quantity per Lift | Number of profiles lifted at once | Quantity: ______ (e.g., 1 or 5 tied) |

| Handling Method | Lifting device or gear type | ☐ Sling ☐ Clamp ☐ Magnet ☐ Spreader Beam ☐ Other: ______ |

| Bundle Condition | Are profiles strapped, tied, or loose? | ☐ Strapped ☐ Tied ☐ Loose |

| Operating Environment | Environment type | ☐ Indoor ☐ Outdoor ☐ Corrosive ☐ Dusty ☐ Other: ______ |

| Industrial Applications | Projects or uses for profiles | __________________________ (e.g., Warehouse framing) |

| Country/Region | Project location or delivery country | __________________________ (e.g., Indonesia, Egypt) |

| Safety Margin (%) | Extra crane capacity recommended | Safety margin: ______% (e.g., 25%) |

Looking for a customized crane solution to handle steel profiles?

Submit your filled checklist now to receive a free quotation.

Plates & Sheets

Plates & Sheets are flat steel products where plates are thicker and sheets are thinner. They are commonly used in shipbuilding, machinery, automotive, and fabrication industries. Handling plates and sheets safely requires overhead cranes equipped with magnets, vacuum lifters, or clamps designed to prevent damage and ensure secure lifting.

Common Sizes:

- Length: 2–12 meters

- Width: 1–3 meters

- Thickness: Sheets: 0.5–6 mm, Plates: 6–100 mm

Typical Weight:

- Sheets: 100–800 kg each,

- Plates: 1–10 tons each

Handling Notes:

- Sheets are typically thin and flexible; plates are heavy and rigid.

- May be lifted singly or in stacks; note edge sharpness and risk of bending.

- Stacked lifting requires even weight distribution; magnets or plate clamps are commonly used.

Practical Tip: Confirm whether you lift single sheets/plates or bundles. Hot-rolled vs. cold-rolled surfaces may affect grip and safety requirements.

Plate & Sheet Handling Crane — Specification Checklist

| Specification | Description | Your Input (Fill In or Select) |

|---|---|---|

| Types of Items Handled | Plate, sheet, or both | ☐ Sheet ☐ Plate ☐ Both |

| Single Item Weight (tons) | Weight of one plate or sheet | Weight: ______ ton (e.g., 2 ton) |

| Length (m) | Length of individual item | Length: ______ m (e.g., 8 m) |

| Width (m) | Width of individual item | Width: ______ m (e.g., 2 m) |

| Thickness (mm) | Thickness of item | Thickness: ______ mm (e.g., 20 mm) |

| Quantity per Lift | Number of sheets or plates lifted at once | Quantity: ______ (e.g., 5 sheets or 1 plate) |

| Handling Method | Lifting device or gear type | ☐ Clamp ☐ Magnet ☐ Sling ☐ Other: ___________________ |

| Surface Condition | Hot, cold, or with scale | ☐ Hot ☐ Cold ☐ Scaled ☐ Oiled ☐ Other: ___________ |

| Operating Environment | Environment type | ☐ Indoor ☐ Outdoor ☐ Corrosive ☐ Dusty ☐ Other: ______ |

| Industrial Applications | Project or usage (e.g., shipbuilding, fabrication) | __________________________ |

| Country/Region | Project location or delivery country | __________________________ (e.g., Vietnam, Saudi Arabia) |

| Safety Margin (%) | Extra crane capacity recommended | Safety margin: ______% (e.g., 25%) |

Want a custom quote for handling plates and sheets?

Send us your checklist today to receive a free, expert quotation.

Steel Wire Rod

Steel Wire Rod is a semi-finished steel product, typically hot-rolled into coils. It's the raw material used to produce a variety of downstream wire products, such as wire ropes, reinforcement wire, welding electrodes, nails, springs, and mesh. It is commonly used in construction, automotive, agriculture, and manufacturing.

Common Sizes:

- Diameter: 5.5 mm to 16 mm (sometimes up to 28 mm)

- Coil Weight: 1 to 3 tons per coil

- Coil Outer Diameter: ~1.0 to 1.2 meters

- Coil Inner Diameter: ~0.8 meters

- Coil Height: ~1.0 meter

Handling Notes:

- Usually delivered in tightly wound coils, banded with steel straps.

- Coils may be hot or cold depending on process.

- Handling is often done by coil grabs or C-hooks through the center bore.

- Coils are often stacked; lifting multiple coils requires strict attention to weight and stability.

Practical Tip: Always confirm coil bore size and whether vertical or horizontal storage/handling is used — this affects lifting equipment type.

Steel Wire Rod Coil Handling Crane — Specification Checklist

| Specification | Description | Your Input (Fill In or Select) |

|---|---|---|

| Coil Type & Condition | Hot-rolled or cold-drawn, plain or ribbed | ☐ Hot-rolled ☐ Cold-drawn ☐ Other: ___________ |

| Coil Weight (tons) | Weight per coil | Coil weight: ______ ton (e.g., 2 ton) |

| Diameter (mm) | Wire diameter inside the coil | Diameter: ______ mm (e.g., 8 mm) |

| Coil Outer Diameter (m) | Approximate outer size | OD: ______ m (e.g., 1.1 m) |

| Coil Inner Diameter (m) | Required for selecting grab or hook type | ID: ______ m (e.g., 0.8 m) |

| Coil Height (m) | Total height of coil stack | Height: ______ m (e.g., 1.0 m) |

| Quantity per Lift | Number of coils lifted at once | Quantity: ______ (e.g., 1 coil) |

| Handling Method | Lifting device type | ☐ C-Hook ☐ Coil Grab ☐ Sling ☐ Magnet ☐ Other: _________ |

| Coil Orientation | Position of coils during handling | ☐ Eye Horizontal ☐ Eye Vertical |

| Operating Environment | Indoor, outdoor, dusty, corrosive, etc. | ☐ Indoor ☐ Outdoor ☐ Corrosive ☐ Dusty ☐ Other: ________ |

| Industrial Applications | Usage (e.g., rebar production, welding, cables) | __________________________ |

| Country/Region | Delivery or use location | __________________________ (e.g., UAE, Thailand) |

| Safety Margin (%) | Extra crane capacity for safety | Safety margin: ______% (e.g., 25%) |

Want a tailored quotation for a steel wire rod coil handling crane?

Send us your checklist today and get a free expert quotation!

Steel Bars

Steel bars are long, solid metal sections widely used in construction, machining, fabrication, and reinforcement applications. They come in a variety of shapes—round, square, flat, or hexagonal—and are typically handled in bundles. The lifting and handling of steel bars require cranes with the right attachment and support method to ensure safety and efficiency, especially for long or heavy bundles.

Common Sizes:

- Length: 6 to 12 meters

- Diameter (round bar): 10 mm to 100 mm

- Cross-section: Round, square, flat, or hexagonal

- Typical Weight: 50 kg to 2 tons per bundle (varies by diameter and number of bars per bundle)

Handling Notes:

- Bars are typically bundled together for easier lifting.

- Bundle integrity is critical; broken ties can lead to load instability.

- Handling may be done with slings, spreader beams, or specialized clamps.

- Long bar lengths require spreader beams to prevent bending.

Practical Tip: Confirm bar type and bundle weight. For long or thin bars, anti-sway and soft-handling features help prevent damage and enhance safety.

Steel Bar Handling Crane — Specification Checklist

| Specification | Description | Your Input (Fill In or Select) |

|---|---|---|

| Bar Type | Shape and category of bar | ☐ Round ☐ Square ☐ Flat ☐ Hex ☐ Other: ____________ |

| Bundle Weight (tons) | Weight per bundle | Bundle weight: ______ ton (e.g., 1.5 ton) |

| Bar Length (m) | Total length of individual bars | Length: ______ m (e.g., 12 m) |

| Diameter or Size (mm) | Diameter or thickness, depending on bar type | Diameter: ______ mm (e.g., 25 mm) |

| Quantity per Lift | Number of bundles lifted at once | Quantity: ______ (e.g., 1 bundle) |

| Handling Method | Lifting device used | ☐ Sling ☐ Clamp ☐ Magnet ☐ Fork ☐ Other: ____________ |

| Orientation During Lift | Direction and support required | ☐ Horizontal ☐ Vertical |

| Operating Environment | Indoor, outdoor, corrosive, dusty, high-temperature, etc. | ☐ Indoor ☐ Outdoor ☐ Corrosive ☐ Dusty ☐ Other: ________ |

| Industrial Applications | Use case (e.g., rebar fabrication, machining, forging stock) | ___________________________ |

| Country/Region | Intended usage/delivery location | ___________________________ (e.g., Indonesia, Mexico) |

| Safety Margin (%) | Extra crane capacity added for safety | Safety margin: ______% (e.g., 25%) |

Castings

Steel castings are irregularly shaped components formed by pouring molten steel into molds. They are widely used in industries such as heavy equipment, mining, energy, and shipbuilding. Castings are often asymmetrical and vary greatly in size and weight, making lifting more complex.

Common Sizes:

- Length: 0.5 to 5 meters

- Width / Height: Varies with design

- Typical Weight: 0.5 to 20 tons per casting

Handling Notes:

- May be single or grouped lifts; clarify if bundling is used.

- Gripping must account for uneven weight distribution and delicate surfaces.

- Lifting gear may include adjustable slings, hooks, or custom clamps.

Practical Tip: Provide drawings or photos if possible. Irregular geometry and center of gravity affect lifting safety and method.

Castings Handling Crane — Specification Checklist

| Specification | Description | Example (Fill in your details) |

|---|---|---|

| Types of Castings Handled | Shape & consistency of castings | ☐ Uniform shape ☐ Irregular shape ______________________ |

| Casting Weight (tons) | Typical weight per casting | Casting weight: ______ ton (e.g., 5 ton) |

| Dimensions (L × W × H in m) | Max size to determine crane reach | Dimensions: ______ m × ______ m × ______ m |

| Quantity per Lift | Number of castings lifted at once | Quantity: ______ (e.g., 1) |

| Surface Condition | Surface finish or coating (rough, oiled, etc.) | Surface: ______ (e.g., rough as-cast) |

| Handling Method | How it will be lifted | ☐ Slings ☐ Clamps ☐ Hooks ☐ Other: _______________________ |

| Operating Environment | Temperature, location, and dust/moisture level | Environment: ______ (e.g., Indoor, hot foundry) |

| Industrial Applications | Usage scenario | Application: ______ (e.g., Turbine casting) |

| Country | Where the crane will be installed | Country: ______ |

| Safety Margin (%) | Extra capacity above load weight | Safety margin: ______ % (e.g., 25%) |

Want a tailored crane for handling steel castings?

Request your free quotation now.

Forgings

Steel forgings are compressed metal parts known for high strength and reliability, used in automotive, aerospace, marine, and machinery applications. They are generally symmetrical but dense and heavy, requiring precise and safe handling by overhead cranes.

Common Sizes:

- Length: 0.3 to 4 meters

- Cross-Section: Round, square, flat, or custom

- Typical Weight: 100 kg to 15 tons per forging

Handling Notes:

- May be handled hot or cold; specify temperature conditions.

- Balanced lifting is critical—especially for long or thick pieces.

- Slings and hooks are commonly used; C-hooks for ring-shaped forgings.

Practical Tip: Clarify if forgings will be lifted hot. Heat-resistant slings or clamps may be necessary.

Forgings Parts Handling Crane — Specification Checklist

| Specification | Description | Example (Fill in your details) |

|---|---|---|

| Types of Forgings Handled | Shape of items | ☐ Round bar ☐ Flat ☐ Ring ☐ Custom: ______________________ |

| Forging Weight (tons) | Typical weight per piece | Forging weight: ______ ton (e.g., 2 ton) |

| Dimensions (L × W × H in m) | Max length and cross-section | Dimensions: ______ m × ______ m × ______ m |

| Quantity per Lift | Number of items lifted per cycle | Quantity: ______ (e.g., 1 or 2) |

| Surface Condition | Hot, cold, or scale-coated | Surface: ______ (e.g., Hot forged) |

| Handling Method | Lifting tools required | ☐ Slings ☐ C-hook ☐ Clamp ☐ Other: _______________________ |

| Operating Environment | Indoor/outdoor, heat, or corrosive conditions | Environment: ______ (e.g., Outdoor, hot zone) |

| Industrial Applications | End-use sector | Application: ______ (e.g., Marine shaft) |

| Country | Destination for the crane system | Country: ______ |

| Safety Margin (%) | Additional buffer for weight and safety | Safety margin: ______ % (e.g., 20%) |

Need a customized crane solution for handling steel forgings?

Contact us now for a free quote.

Related Products

Affordable 10 ton double girder overhead crane with CD/MD hoist trolley, built for U.S. standards, ideal for construction and industrial lifting

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch