Looking for Best Steel Mill Crane Price? Fill Specs & Get Price!

Get accurate quotes & fast delivery by providing overhead crane specifications tailored to your steel mill needs.Fill out eot crane specs & get price now!

Category: Featured

Your Trusted Overhead Crane Manufacturer & Supplier

Looking for the Best Steel Mill Crane Price?

Fill Out Required Overhead Crane Specifications & Get Your Steel Mill Crane Price Now

Introduction: Steel Mill Crane Specifications & Prices

Why Just Asking for a Price Isn't Enough

If you're searching for the best price on a steel mill overhead crane, a simple "How much does it cost?" won't get you far.Without clear details, suppliers can only guess what you need. That guesswork often means prices that are too high or quotes that don't match your real requirements.

The Importance of Detailed Crane Specifications

Steel mill cranes vary a lot depending on how and where they're used. Your mill might handle slabs, coils, or billets. The size of your workspace, the lifting capacity needed, and even your power supply all affect the right crane design.

Giving detailed specifications upfront helps manufacturers build exactly what you need. You get a price that fits your budget and a crane that works efficiently.

What You'll Get from This Guide

This article is your roadmap to preparing the right overhead crane specifications before requesting a quote.

By filling in the key details, you'll:

- Get faster, more accurate pricing

- Avoid misunderstandings

- Make sure the crane matches your steel mill's unique needs

Steel Mill Overhead Crane Basics

Common Types of Steel Mill Cranes

Steel mills use different kinds of cranes, each designed for specific tasks. Knowing the common types helps you pick the right one for your mill:

- Overhead Crane: Runs on rails fixed above the workspace, ideal for moving heavy steel products like slabs and coils across large areas inside the mill.

- Gantry Crane: Similar to overhead cranes but supported by legs that run on the ground, perfect for outdoor use or where overhead rails aren't feasible.

- Ladle Crane: Specialized cranes built to handle ladles carrying molten metal, requiring heat resistance and extra safety features.

- Semi-Gantry Crane: Combines features of overhead and gantry cranes, with one side running on a rail and the other supported by a leg.

Each crane type has its pros and cons based on the mill's layout and handling needs.

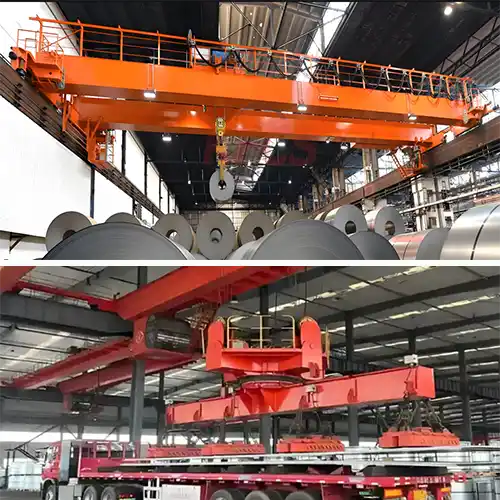

double girder gantry crane for steel coil plant

Why Matching Crane Type to Your Mill Matters

Not all cranes fit every steel mill operation. Choosing the right crane type matters because:

- It affects how efficiently you move steel products.

- It determines how much space the crane needs.

- It influences safety, especially in handling hot or heavy loads.

- It impacts the overall cost, both in purchase and operation.

For example, if your mill deals mostly with heavy billets indoors, an overhead crane might be best. But if you have outdoor slab handling, a gantry crane could be the way to go.

How Specifications Shape Crane Design and Pricing

The specs you provide—like lifting capacity, span, and working environment—directly influence how the crane is built and priced.

- Higher lifting capacities require stronger, more expensive components.

- Longer spans need bigger girders and more powerful motors.

- Harsh environments may need special coatings or explosion-proof parts.

Giving clear specs helps manufacturers tailor the crane design to your needs. This prevents paying extra for features you don't need and ensures the crane performs well in your steel mill's conditions.

Your Trusted Steel Mill Overhead Crane Manufacturer & Supplier

Essential Overhead Crane Specifications to Provide

Crane Type and Usage

Getting the right price for a steel mill overhead crane starts with clearly defining the crane type and how you plan to use it. This information shapes the entire design and helps suppliers give you an accurate, tailored quote.

Types of Cranes and Their Roles

Steel mills use different crane types depending on the layout and tasks involved. Here are the main types:

- Overhead Crane: The classic choice for indoor steel mills. It runs along rails fixed high above the floor, moving heavy steel products horizontally across long distances. It's great for handling slabs, coils, and billets inside the workshop.

- Gantry Crane: Unlike overhead cranes, gantry cranes have legs that run on the ground. They're perfect for outdoor areas or places where installing overhead rails isn't practical. If your mill has open yards or outdoor slab storage, a gantry crane might be best.

- Semi-Gantry Crane: A hybrid design with one side running on an overhead rail and the other supported by a leg on the ground. This offers flexibility in workshops with limited space or specific structural constraints.

- Ladle Crane: A specialized crane built to handle molten steel ladles. These cranes need heat-resistant materials and precise control systems to safely move extremely hot loads. Ladle cranes often require additional safety features and certifications.

Clearly stating the crane type you need helps manufacturers recommend the right components, controls, and materials to match your mill's conditions.

Specifying Your Primary Application

Your mill's main steel handling task greatly affects the crane's design and price. Common steel mill applications include:

- Ladle Handling: Moving molten steel safely is critical. Ladle cranes or cranes with heat protection and shock-absorbing controls are used here.

- Slab Handling: Slabs are large and heavy. Cranes for slab handling usually need high lifting capacities and special attachments like electromagnets or slab clamps designed to grip the steel securely without damage.

- Coil Lifting: Coils are delicate and require specialized clamps or hooks to avoid deformation. Coil cranes often have features like adjustable gripping force and smooth control to handle coils safely.

- Billet Transport: Billets are smaller, dense steel bars. Cranes used for billets often need more precise movement and sometimes multiple hoists for efficient batch handling.

When you tell the supplier exactly what the crane will handle — for example, a "slab handling crane" or "coil handling crane" — they can provide solutions tailored to your material handling challenges.

Frequency of Use: How Often Will the Crane Work?

How often you use the crane impacts the choice of components and durability requirements:

- Continuous or Daily Use: If your steel mill runs 24/7 or has multiple shifts, the crane must be robust and reliable. Heavy-duty motors, industrial-grade parts, and possibly automation features help reduce downtime and maintenance costs.

- Occasional Use: For mills or workshops where the crane operates only a few times a day or week, simpler designs and manual controls might be enough. This can save money upfront but may not suit high-demand environments.

Be upfront about your expected usage. Over-specifying might raise costs unnecessarily, while under-specifying can lead to early wear or breakdowns.

Indoor or Outdoor Operation Environment

The crane's operating environment directly affects the design and pricing:

- Indoor Cranes: These usually have standard electrical components and basic weather protection. Temperature and humidity tend to be controlled, reducing the need for special coatings or heavy-duty parts.

- Outdoor Cranes: Must withstand rain, dust, wind, and temperature swings. This means corrosion-resistant materials, waterproof electrical enclosures, and sometimes stronger structures to handle wind loads. If your steel mill crane will work outside — like in slab yards or storage yards — specify this clearly.

Knowing if the crane will be indoors or outdoors helps avoid costly retrofits or premature failures caused by unsuitable components.

Taking the time to clearly specify the crane type, application, frequency, and environment is the first step to getting a price that fits your steel mill's real needs. This clarity saves you time, money, and frustration down the road.

Lifting Capacity and Mechanism

Getting the lifting capacity and mechanism right is crucial for steel mill overhead cranes. It determines how much weight the crane can safely lift, how it handles different steel products, and how well it fits your operation's needs.

Rated Load Capacity

Start by specifying the maximum load your crane needs to lift. This is usually given in tons, such as 10 tons, 25 tons, or even 50 tons and above for heavy steel mill operations.

- The rated load capacity is not just about the heaviest piece of steel you'll lift but also includes a safety margin.

- Overloading a crane risks accidents, costly downtime, and damage to equipment.

- Manufacturers design cranes around this rated capacity to ensure safety and durability.

Make sure you know the heaviest load your mill will require the crane to lift regularly.

Number of Hoists or Trolleys

Some steel mill cranes have more than one hoist or trolley, depending on the tasks:

- Single Hoist: Suitable for straightforward lifting and moving of steel slabs, coils, or billets one at a time.

- Multiple Hoists: Used for handling very long loads or lifting several items simultaneously. For example, a billet crane might need two hoists to lift a heavy bundle evenly.

Specifying the number of hoists helps suppliers design the crane's control systems and structural supports correctly.

Lifting Height or Hook Travel Distance

Lifting height is the vertical distance the crane's hook or lifting device travels from the lowest to the highest point.

- It depends on your workshop's ceiling height and how high you need to stack or move steel products.

- Taller lifting height often means a longer hoist wire rope, which can affect the crane's overall design and price.

- If your mill stacks slabs or coils at various heights, be sure to specify the maximum lifting height required.

Type of Lifting Attachments

Different steel products need different attachments for safe and efficient handling:

- Magnet: Commonly used for lifting slabs or plates. Magnets can be electromagnets (powered) or permanent magnets. They offer quick loading and unloading but require power and maintenance.

- Clamp: Used for coils, billets, or slabs. Clamps grip the steel firmly without damaging the surface.

- Grab: A bucket-like attachment for loose materials or scrap steel.

- Hook: Basic but versatile, hooks are used when lifting with slings or chains.

Specify the lifting attachment you need or plan to use, as it impacts crane design and cost.

Be as precise as possible about your crane's lifting capacity, hoist setup, lifting height, and attachment type. This helps manufacturers create a steel mill overhead crane that fits your handling needs perfectly, ensuring safety, efficiency, and a fair price.

Crane Dimensions and Working Area

To design the right steel mill overhead crane, manufacturers need precise information about the crane's physical space and operating environment. This helps avoid fitting problems and ensures smooth operation.

Span Between Runway Rails

The span is the width across which the crane will travel. Knowing this exact measurement helps determine the crane's bridge size and structural strength.

- The span is the distance between the two runway rails supporting the crane.

- It usually matches the width of the workshop or bay.

- Accurate measurement is key to avoid clearance or installation issues.

Length of the Working Bay or Workshop

The total length where the crane will move affects the runway design and the crane's travel system.

- The working bay length is the distance along the runway rails.

- This determines how far the crane's bridge and trolley can travel.

- It helps choose the right motors and controls for smooth operation.

Number of Cranes Operating in the Same Area

If multiple cranes work side by side, safety and coordination become top priorities.

- Specify if more than one crane will operate in the same bay.

- This ensures proper spacing and anti-collision systems can be planned.

- It reduces risks of accidents or downtime caused by crane collisions.

Travel Requirements

How far and how fast your steel mill crane moves affects the design and price. Clear info here helps balance performance and cost.

Runway Length and Travel Distance

The travel distance is how far the crane can move on the rails, which may or may not cover the entire bay length.

- Runway length usually equals the bay length but can be shorter if limited travel is needed.

- This information guides motor power and braking system choices.

Desired Lifting and Travel Speeds

Speed preferences impact the crane's motor and control systems and the overall cost.

- If your operation needs faster lifting or movement, say so.

- Faster speeds improve productivity but require better components.

- Slower speeds may be safer or needed for precise handling.

Control Type

How you want to operate the crane makes a big difference in design and cost.

- Manual control means an operator directly controls the crane, often with a pendant or cabin.

- Semi-automated control automates some functions for easier operation and better precision.

- Fully automated cranes work with minimal human input, ideal for large, busy steel mills.

Giving clear, detailed info about your crane's dimensions and travel needs helps manufacturers design a perfect fit. This reduces delays, avoids costly mistakes, and ensures you get a competitive price for your steel mill overhead crane.

Power Supply Details

Before you request a quote for a steel mill overhead crane, it's important to give full details about your power supply. This helps ensure the crane's electrical system will work safely and reliably in your mill's environment.

Voltage and Frequency

Start by specifying the voltage and frequency of your power supply. This is a basic but critical detail.

- Common voltages include 380V at 50Hz or 415V at 60Hz, depending on your country or facility.

- Using the wrong voltage can cause equipment failure or safety hazards.

- Providing this info upfront helps the manufacturer design the crane's electrical system to fit perfectly.

Power Feeding Method

How the crane receives electrical power matters for installation and operation.

- Power can be fed from above (top feed) or from the side of the crane runway (side feed).

- The feeding method influences cable management and safety.

- Knowing this early helps avoid last-minute changes during installation.

Electrical Components for Indoor or Outdoor Use

Your crane may operate inside a workshop or outdoors, which affects the choice of electrical parts.

- Indoor cranes use standard electrical components that work well in controlled environments.

- Outdoor cranes need weatherproof and corrosion-resistant electrical parts to withstand rain, dust, or temperature swings.

- Informing the supplier about this ensures long-lasting, trouble-free crane operation.

Environmental and Safety Conditions

Steel mills can have tough working environments. Sharing details about temperature, dust, and safety zones helps design a crane that performs well and meets all safety regulations.

Temperature Range and Working Environment

Explain the typical temperature range and conditions where the crane will work.

- Is it a hot mill with temperatures above 40°C? Or a cooler workshop environment?

- Is there a lot of dust, moisture, or corrosive gases present?

- This info affects the choice of materials, paints, and protective coatings on the crane.

Hazardous or Explosion-Proof Zones

If your steel mill has areas with flammable gases, dust, or explosive materials, this is critical.

- Mention if the crane needs to be explosion-proof or meet special safety standards.

- Explosion-proof cranes have special electrical enclosures and design features to prevent sparks.

- These cranes cost more but are essential for safe operation in hazardous zones.

Providing detailed power supply and environmental info upfront saves time and money. It ensures your steel mill overhead crane is designed to run smoothly and safely, no matter where or how you use it.

Special Features or Customizations

Sometimes, standard overhead cranes aren't enough for your steel mill's specific needs. Sharing any special features or customization requests early on helps manufacturers tailor the crane perfectly for your operation.

Remote or Cabin Control

How you want to control the crane makes a big difference in safety and efficiency.

- Remote control lets operators work at a safe distance, improving visibility and safety.

- Cabin control places the operator inside a protective cabin on the crane, giving full control and a direct view of the load.

- Specify your preferred control style so the manufacturer can include the right controls and safety features.

Anti-Sway and Anti-Collision Systems

If your steel mill handles heavy or delicate loads, special safety systems can be a big help.

- Anti-sway systems reduce load swinging, making handling safer and more precise.

- Anti-collision systems help avoid accidents when multiple cranes operate nearby.

- These features improve safety and can boost productivity, especially in busy or tight spaces.

Heat Protection, Special Coatings, or Covers

Steel mills often have harsh conditions that can damage cranes if not protected properly.

- Heat protection shields the crane from high temperatures typical in hot mills.

- Special coatings protect against corrosion, dust, and moisture.

- Additional covers or weatherproofing may be needed for outdoor cranes or harsh environments.

- Letting your supplier know these needs upfront ensures a durable, long-lasting crane.

Compliance Certifications

Meeting industry standards and certifications is often required for steel mill equipment.

- Certifications like CE, ISO, or third-party inspections prove the crane meets safety and quality standards.

- Some mills or countries require specific certifications for compliance.

- Inform your supplier about these to get a crane that passes all required tests and audits.

Sharing your special feature requirements early helps you get a crane that fits your mill's exact needs — safer, more efficient, and fully compliant. This also helps avoid costly changes or delays later.

Optional But Useful Information to Share

While not always required, providing extra details about your project can help your steel mill overhead crane supplier give you a better quote and a smoother buying experience. These additional points help with planning, customization, and cost optimization.

Project Timeline and Delivery Expectations

Letting your supplier know when you need the crane helps with scheduling production and shipping.

- If you have a strict deadline, mention it upfront so they can prioritize your order.

- Early communication about timing helps avoid delays and ensures on-time delivery.

- This is especially important if your mill has a planned shutdown or expansion schedule.

Budget Range for Crane Configurations

Sharing your budget range helps suppliers suggest options that fit your financial plan.

- Knowing your budget helps the supplier tailor the crane's features and specs accordingly.

- It allows for recommendations on where to focus investment—whether on heavier lifting capacity, automation, or special coatings.

- This prevents surprises and helps you get the best value for your money.

Country of Installation for Shipping and Compliance Considerations

Your crane's final destination affects shipping costs and compliance requirements.

- Different countries have varying electrical standards, certifications, and import rules.

- Shipping costs can vary greatly depending on location, so providing your country upfront helps in accurate cost estimation.

- Compliance requirements may also influence crane design and documentation.

Types of Steel Products Handled

Knowing what products the crane will move helps choose the right lifting attachments and safety features.

- Common steel mill products include slabs, billets, coils, and ingots.

- Each product type has specific handling needs—for example, coils require special hooks or magnets, while billets might need clamps or grabs.

- Sharing this info ensures the crane and attachments are optimized for your mill's operations.

While these details might seem extra, they play a big role in getting you a more accurate, cost-effective, and timely steel mill overhead crane solution. Providing them early benefits both you and the supplier.

Your Trusted Overhead Crane Manufacturer & Supplier

Steel Mill Overhead Crane Specification Sheet

A. Crane Configuration

| No. | Item | Your Input / Description |

|---|---|---|

| 1 | Crane Type | Overhead / Gantry / Semi-Gantry / Ladle / Other: ______ |

| 2 | Lifting Capacity | ______ tons (e.g., 10T, 20T, 50T, etc.) |

| 3 | Number of Hoists or Trolleys | One / Two / Other: ______ |

| 4 | Lifting Mechanism | Wire Rope Hoist / Winch / Other: ______ |

| 5 | Lifting Attachment | Hook / Magnet / Clamp / Grab / Other: ______ |

B. Performance Requirements

| No. | Item | Your Input / Description |

|---|---|---|

| 6 | Lifting Height (Hook Travel) | ______ meters |

| 7 | Crane Span (Runway Rail Distance) | ______ meters |

| 8 | Crane Travel Length (Runway Length) | ______ meters |

| 9 | Lifting & Traveling Speed | Standard / Specify: ______ m/min |

| 10 | Operation Mode | Remote / Pendant / Cabin / Auto / Other: ______ |

| 11 | Duty Cycle (Usage Frequency) | Occasional / Daily / Continuous |

C. Site Conditions

| No. | Item | Your Input / Description |

|---|---|---|

| 12 | Installation Location | Indoor / Outdoor |

| 13 | Temperature Range | From ______ °C to ______ °C |

| 14 | Environmental Conditions | Dust / High Heat / Corrosive / Humid / Hazardous |

| 15 | Number of Cranes in Same Bay | ______ cranes |

| 16 | Country and City of Installation | ______ (for shipping and compliance) |

D. Special Options & Compliance

| No. | Item | Your Input / Description |

|---|---|---|

| 17 | Power Supply Voltage/Frequency | ______ V / ______ Hz |

| 18 | Power Feeding Method | Top Feed / Side Feed |

| 19 | Special Features | Anti-sway / Anti-collision / Heat Shields / Other: ______ |

| 20 | Certification Requirements | CE / ISO / Third-party Inspection / Other: ______ |

Your Trusted Overhead Crane Manufacturer & Supplier

How Providing Detailed Specs Helps You Get the Best Price

Giving your steel mill overhead crane supplier complete and precise specifications isn't just about getting a quote—it directly impacts the price you'll pay and the quality of the final crane.

Avoids Vague or Inflated Quotations

When you send incomplete or unclear info, suppliers have to guess your needs.

- This often leads to higher prices to cover unknown risks or worst-case scenarios.

- Vague quotes may include unnecessary features or oversized components, driving up costs.

- Detailed specs help avoid this guesswork, so you get a fair and realistic price from the start.

Enables Suppliers to Tailor Design and Materials

Every steel mill has unique needs. When you provide detailed specs, the supplier can customize the crane accordingly.

- They can choose materials that are strong enough but not overbuilt, saving money.

- Design can be optimized for your mill's layout, workflow, and lifting tasks.

- Tailored cranes perform better, last longer, and fit your budget perfectly.

Speeds Up Proposal and Delivery Time

Clear, thorough information allows suppliers to prepare accurate proposals faster.

- It reduces time spent on follow-up questions and clarifications.

- Faster design approval leads to quicker production and delivery.

- This means you get your steel mill overhead crane ready to work sooner, minimizing downtime.

Minimizes Back-and-Forth and Ensures Clarity

Good specs reduce misunderstandings between you and the supplier.

- It prevents costly changes or delays caused by missing or wrong info.

- Both parties stay on the same page, making the whole process smoother.

- Clear communication upfront means your crane will meet expectations the first time.

Taking the time to provide complete overhead crane specifications pays off. You get a better price, a crane tailored to your needs, and a faster, hassle-free buying experience.

How Our Team Supports Your Inquiry Process

At our factory, we know that preparing accurate overhead crane specifications can feel overwhelming. That's why we're here to make the process smooth and hassle-free. From the first inquiry to final delivery, our team provides hands-on support every step of the way.

Offering Downloadable Inquiry Forms and Checklists

To help you get started quickly, we provide ready-made inquiry forms and detailed checklists.

- These tools guide you through all the key details to fill out, so you don't miss anything important.

- You can download and complete them at your convenience, ensuring your request is clear and complete.

- This saves you time and speeds up the quotation process, helping you get the best steel mill overhead crane price.

Technical Support for Specification Guidance

If you're unsure about certain specs or how to describe your mill's requirements, our technical team is ready to help.

- We offer expert advice to clarify which details matter most for your application.

- Our engineers can assist with calculations, choosing the right crane type, or specifying lifting capacities and accessories.

- This support reduces guesswork and ensures your inquiry is accurate and tailored to your mill's unique needs.

Customization Services Based on Your Steel Mill's Needs

No two steel mills are exactly alike. That's why we specialize in customizing cranes to fit your facility perfectly.

- Whether you need special lifting attachments, heat protection, or automation features, we work closely with you to design the ideal solution.

- Our customization also considers your mill's layout, ceiling height, and production flow for maximum efficiency.

- This approach guarantees you get a crane that not only fits your budget but also enhances your mill's operations.

Our team is committed to supporting you throughout your crane inquiry and purchase journey. With our downloadable forms, expert technical guidance, and tailored customization services, you're set up to receive the best possible steel mill overhead crane quote with minimal hassle.

Conclusion: Send Your Required Crane Specifications and Get Your Crane Price

To wrap it up, the key to getting the best price on your steel mill overhead crane is all in the details you provide upfront.

When you take the time to fill out your crane specifications thoroughly and accurately, you help suppliers offer you a fair, competitive quote tailored exactly to your needs. This not only leads to better pricing but also speeds up the entire process—from design and approval to manufacturing and delivery.

By avoiding guesswork and back-and-forth, you get a crane that fits your steel mill perfectly, arrives on time, and works efficiently for years to come. Don't wait — the sooner you provide your detailed specs, the faster we can deliver your ideal overhead crane at the best possible price.

Related Products

Affordable 10 ton double girder overhead crane with CD/MD hoist trolley, built for U.S. standards, ideal for construction and industrial lifting

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch