Under Running Crane, Underhung Bridge Crane & Underhung Crane

Underhung bridge crane / underhung overhead crane, light &small cranes of 500kg to 10 ton with double / single girder. Get under running overhead crane!

| Underhung Overhead Crane | Overhead crane with under hung crane design |

| Crane Capacity | 0.5 ton up to 1o ton |

| Lifting Height | Customized |

| Crane Span | Customized |

Category: Overhead Crane

Your Trusted Overhead Travelling Crane Manufacturer & Supplier

Under Running Crane, Underhung Bridge Crane & Underhung Crane

500KG to 10 Ton Underslung EOT Crane Single Girder & Double Girder Design

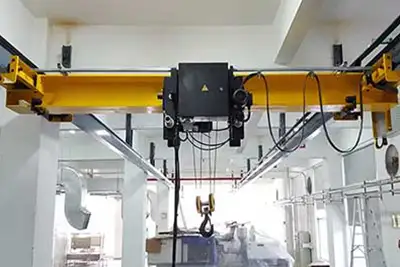

With underhung bridge cranes design, the end trucks / end carriages move on the bottom flange of the runway beam unlike the top running overhead cranes. The underslung overhead cranes are usually supported and mounted to the ceiling structure or roof structure which are ideal solution for workshops or warehouses with low clearance or low headroom space.

What is an under running overhead crane?-An underhung bridge crane are also named underhung crane or underslung crane whose end carriages/ end trucks travelling on the bottom flange of the runway beam, which enables the crane bridge girder running under the crane runway, Under running overhead cranes can be designed into verious types such as single girder underhung crane& double girder underhung crane, monoral underrunning crane, kbk underhung bridge crane, etc.

Overview of Under Running Overhead Cranes

What is an underhung bridge crane? Underhung bridge cranes, also known as underslung bridge cranes or underrunning bridge cranes, are built for versatility and utility, with an ergonomic design. Underhung overhead cranes are often used for capacities of less than 10 tons.

Under-running overhead cranes are designed with flexibility and practicality in mind, featuring a user-friendly design that gives optimal versatility for meeting all of your production needs. Because the bottom flange of the runway beam provides support for the wheels that drive the bridge over the facility, these cranes are also known as underhung overhead cranes.

An under-running overhead crane's trolley and hoist move across the bottom flange of the bridge beam, lowering the crane's hook and lift height.

Because a double girder design is frequently more expensive and not suitable for the application, under-running overhead cranes are normally built up as single girder cranes.

The following are some of the advantages of using under-running overhead cranes:

- They work well in wide bays. Multiple runways can be served by underhung overhead cranes, lowering the girder's depth.

- Overall design standards are less stringent.

- Because under-running overhead cranes are substantially lighter, they don't require any additional supporting columns, which saves valuable floor space. Instead, the crane is supported by the existing overhead building structure.

- Costs are lower. Low equipment costs derive from the lightweight design and usage of existing ceiling trusses or roof structure.

- Multiple crane setups are possible.

For greater production efficiency, under-running cranes can be installed next to each other and operated simultaneously.

- Typical lifting capacity of under running overhead crane :0.25 ton to 10-tons

- Typical service duty:Light to medium duty

- Lifting system of under running overhead crane : motorized monorail hoists, wire rope hoists, chain hoists

- Common applications of under running overhead crane : Assembly, fabrication shops, maintenance buildings, and manufacturing facilities

- Maximizes floor space if attached or supported by existing ceiling structures or roof structure

- Lower material costs if there is no requirement for runway support columns.

- Attached to ceiling structure, higher lifting height, suitable for low headroom application.

Single Girder & Double Girder Under Running Bridge Crane

Under running overhead crane also can be designed in to single girder crane and double girder crane designs, equpped with various types of crane hoists, hoist winch and hoist trolley, etc.

Under running overhead cranes are most commonly designed in a single girder overhead crane configuration with monorail trolley hoists for lighter loads handling with small capacity of 10 tons or less.Underslung cranes are also can be designed with double girder overhead crane configuration for higher capacities and supportive column can be added if necessary.which would be very expensive.

An under running single girder overhead crane can adopt a suspension hoist and trolley which move across the bottom flange of the bridge beam. A double girder under running bridge crane can run the hoist trolley on the top or on the bottom of the bridge beams. Click to learn more on underhung bridge cranes and underhung overhead bridge crane projects or send us an inquiry to get your customized under running overhead crane solution by contact at + 86 151 3871 1597 by phone or by whatsapp.

Ceiling Mounted & Freestanding Underhung Overhead Crane with KBK Crane Design

underhung bridge cranes can be designed in a free-standing overhead crane configuration with the requirements of additional support or mounting columns if the existing support structure of the workshop can not support the weight of crane and loads .

Rigid free standing suspension kbk crane with underhung crane design

Free standing single girder kbk crane with underhung crane design

Advantages of Under Running Overhead Cranes

Ceiling mounted crane system, free your floor space

The ceiling mounted underhung types of cranes enable you to maximize the floor space in your workshops for production and storage to make the best utilization of your floor space..

Compact crane design, best workshop space utilization

With ceiling roof mounted design, the underhung bridge cranes provide excellent side approach and make the best use of the width and height of your workshops. The underhung bridge crane are the ideal solutions for workshops and warehouse with low headroom clearance and space where a top running overhead crane system is impractical. Hook height and lift height is less than top running overhead cranes because the main crane girder and monorail hoist are suspended right underneath the crane runways.

Complex installation and maintenance

The installation and maintenance of an under running overhead crane system is more complex and taking longer downtime because of the underhung bridge crane design. Even though it takes long time to check the alignment or crane wheel, it is easier to maintain the alignment and there are fewer tracking problems because the movement of crane I-beam is limited, fastened and secured to building structure.

Top running bridge crane & Under running bridge craneUnlike top-running overhead cranes, the end trucks / end carriages of underhung bridge cranes move on the bottom flange of the runway beam. Underslung overhead cranes are supported and mounted to the ceiling or roof structure, making them an excellent choice for workshops or warehouses with limited clearance or headroom.

What is an overhead crane that runs by its own power? -An underrunning crane, also known as an underhung overhead crane or an underslung crane, is one in which the end carriages/end trucks drive on the bottom flange of the runway beam, allowing the crane bridge girder to run beneath the crane runway. Single girder underhung overhead cranes and double girder underhung overhead cranes, monoral underrunning cranes, kbk underrunning cranes, and so on are all examples of under running overhead cranes.

Please contact the underslung crane manufacturer for additional information or click to check top running crane vs underhung crane.

Applications of underhung bridge crane

The installation of underhung overhead crane rails and underhung single-girder crane is the most rational method of equipping the production with lifting mechanisms (if there is no crane rail).

The height required for the construction of underhung overhead-traveling cranes is small. The presence of consoles on the longitudinal girder allows the supported cranes to be bypassed in the area of the crane's working area.

Light (A3) and medium (A5) loading modes are suited for underhung overhead-travelling cranes. Single-girder underrunning cranes with manual driving mechanisms are feasible with a low working load and a small load-carrying capacity (up to 5 tons). Our underhung overhead cranes have design elements that allow cargo to be transported from one span to another using a docking mechanism for underhung overhead cranes on neighboring spans, or a crane and single rail. Underhung multi-span overhead cranes are a popular and practical solution. If necessary, this particular variant of the underhung overhead crane is utilized to disperse the load on the trusses bearing the load.If necessary, this unique form of the underhung overhead crane is utilized to distribute the load as evenly as possible on the trusses carrying the crane rail. In addition, the multi-span variant allows for the use of just one crane rather than two or three.

Common Applications of Underhung Overhead Crane

- Equipment Assembly

- Die Handling

- Production

- Loading and Unloading

- Metal Grinding Cells

- Maintenance

- I-beams, W-flanged beams, and proprietary track runways are all viable options.

- With the use of a third runway, it can be used in spans of up to 100 feet.

An underslung crane can be the best option if you need a lifting mechanism but only have a restricted amount of headroom. In most overhead cranes, the end carriages that hold the horizontal beam or girder run on top of the gantry rails, while in underslung cranes, they travel beneath the gantry rails.

Which Type is Right for You, Top Running Crane or Underhung Crane ?

Top running overhead crane and underhung bridge crane, which type of crane is right for your application? Confront the various crane designs and optional crane configurations, careful and thoroughly consideration are required to select a top running crane or underhung bridge crane. The following factors can help you to select a top running or underhung bridge crane system for your application:

- Is the existing support structure capable of supporting the weight of crane and loads?

- Any additional support structure are required?

- Are there existing runways which can accommodate the crane?

- What is the capacity of the loads required to be lifted?

- What is the condition of the available overhead room ? High, unobstructed ceilings, or limited headroom?

- What is the lifting height required?

- How much of the bridge will the hoist trolley need?

- Does your loads need to be handled near the edges or walls of the building?

- How is the condition of floor space?

The above questions help you to understand your application conditions and help you to select from the top running and underhung overhead cranes. The top-running crane systems are widely adopted for handling heavy loads while under-hung bridge cranes are widely used for flexibility and functionality with an ergonomic design providing versatility and usability. Any problem or doubt on top running overhead crane and under hung bridge crane, please feel free to contact us. Free consultation and process crane design for your underhung overhead crane are available for all honest clients or customers. Send us your inquiry on overhead crane today.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch