Single Girder Gantry Crane 20 Ton for Outdoor Use in America

Economical 20-ton single girder gantry crane designed for outdoor use, offering efficient heavy lifting in America.Get your single girder gantry crane!

| Crane Type | MH single girder gantry crane |

| Crane Span | 10 meters |

| Lifting Height | 5 meters |

| Power Supply | 460V, 60Hz, 3-phase |

Category: America

Your Trusted Overhead Gantry Crane Manufacturer & Supplier

Single Girder Gantry Crane for Sale America

Tailored 20 Ton Gantry Crane Single Girder with Single Speed Hoist for Outdoor Use

Reliable 20 Ton Single Girder Gantry Crane for sale. Economical, durable 20-ton single girder gantry crane designed for outdoor use, offering efficient heavy lifting in America.

Introduction: Single Girder Gantry Crane 20 Ton for USA

This case study looks at a single girder gantry crane built for a customer in America. The crane is designed to handle loads up to 20 tons and is intended for outdoor use. It combines practical design with an economical price point, making it a solid choice for many industrial lifting tasks.

Gantry cranes like this one are often used in workshops, yards, and construction sites. They're great when you need a mobile lifting solution that doesn't require permanent infrastructure like overhead cranes. Plus, their open structure means they fit well in outdoor environments, handling heavy loads without needing a full building.

The purpose of this case study is to share how this particular crane was designed and customized to meet the customer's specific needs. It will cover the main specs, design considerations, installation process, and how it performs in the real world. This should give anyone interested a clear idea of what to expect from a similar gantry crane setup.

Customer Requirements and Project Background

The project was based in America, where the customer needed a reliable crane solution for heavy lifting tasks outdoors. They required equipment that could handle loads up to 20 tons safely and consistently.

Because the crane would be used outside, it had to withstand various weather conditions—rain, wind, and temperature changes. This meant the design had to include durable materials and protective coatings to prevent rust and wear over time.

The customer's top priorities were clear:

- Economical Price: They wanted a cost-effective crane without compromising on safety or performance.

- Reliability: The crane needed to work smoothly with minimal downtime, since any halt in operations could slow down their workflow.

- Capacity: The crane had to support a 20-ton load, which is heavy but common in many industrial and construction applications.

These requirements shaped how the gantry crane was customized to fit the specific outdoor working environment and the customer's budget.

Crane Specifications of 20 Ton Single Girder Gantry Cranes

This gantry crane is an MH single girder hoist crane type, chosen mainly for its economical design without sacrificing essential functionality. It's a straightforward model that's widely used in many industries because it balances cost and performance well.

The hoist installed is a single speed wire rope hoist, CD type. This hoist is known for being reliable and easy to maintain. It's well suited for steady lifting tasks where speed control isn't a big concern, which fits this customer's needs perfectly.

Key specs of the crane include:

- Crane Span: 10 meters — wide enough to cover a good working area without being too large or difficult to install.

- Lifting Height: 5 meters — enough vertical clearance for most outdoor loading and unloading operations.

- Power Supply: 460V, 60Hz, 3-phase — standard industrial power in America, ensuring compatibility and stable operation.

These specs reflect a practical, no-nonsense approach to crane design, tailored to the customer's work environment and budget constraints.

Design and Customization Highlights

Since this gantry crane would work outdoors, durability was a top priority during the design phase. The steel structure was treated with weather-resistant paint to protect it from rust and corrosion. This helps the crane hold up well against rain, sun, and temperature swings — common challenges in many American climates.

To handle the 20-ton capacity safely, the crane's frame and supporting legs were reinforced. The design carefully considered load distribution to make sure the crane stays stable while lifting heavy loads. Strong welds and quality materials were used throughout to keep everything sturdy.

For the hoist, a single speed wire rope hoist (CD type) was selected. This hoist matches the 20-ton load requirement and offers smooth, consistent lifting without unnecessary complexity. It's reliable and fits the customer's preference for a straightforward, low-maintenance solution.

On the electrical side, all components were chosen to work seamlessly with the customer's power supply — 460V, 60Hz, 3-phase. This includes motors, controls, and wiring designed to ensure safe and efficient operation without power issues.

Safety was also built into the design:

- Limit switches to prevent over-travel of the hoist

- Emergency stop buttons placed in accessible locations

- Clear labeling and instructions for operators

- Smooth trolley movement to avoid sudden jerks during lifting

These features combine to create a gantry crane that's not only tough and capable but also easy and safe to operate in a demanding outdoor setting.

Performance and Benefits

After installation, the gantry crane performed reliably under the daily demands of outdoor heavy lifting. The single girder design and wire rope hoist worked smoothly, handling loads up to 20 tons without any issues. Operators found the crane easy to use, with precise control during lifts and good stability throughout its range of motion.

From a cost perspective, the customer was pleased with the economical price point. The MH model offered solid performance without unnecessary extras, which helped keep the overall project budget in check. This made it a practical choice for their operation, balancing upfront cost with dependable functionality.

Maintenance has been straightforward as well. The wire rope hoist's simple mechanism means fewer breakdowns and easier servicing. Routine inspections and lubrication can be done quickly, reducing downtime and maintenance expenses. Plus, our team provides ongoing support to address any questions or minor repairs, helping the crane stay in top shape over the long term.

Overall, the crane has helped improve the customer's workflow by speeding up material handling tasks. The ability to lift heavy loads safely and efficiently outdoors has streamlined their operations, saving time and labor. This practical solution fits well into their daily routine, proving that an economical crane can still deliver real, everyday value.

Challenges and Solutions

Outdoor environments bring a set of challenges that can affect the performance and lifespan of a gantry crane. In this project, dealing with weather conditions was a primary concern. Constant exposure to rain, humidity, and temperature changes can accelerate corrosion and wear, which could lead to downtime or safety risks if not properly managed.

To address these environmental challenges:

- The crane's steel structure was coated with industrial-grade, corrosion-resistant paint to prevent rust.

- Electrical components were sealed with weatherproof casings to protect against moisture and dust ingress.

- All exposed wiring was routed through protective conduits to reduce wear and prevent short circuits.

Power supply compatibility was another critical area. The customer's site operates on a 460V, 60Hz, 3-phase power system, which is standard in many American industrial settings but requires precise matching to the crane's electrical components to ensure safety and efficiency.

To ensure electrical safety and smooth operation:

- Motors and control panels were selected specifically for 460V, 60Hz 3-phase power compatibility.

- Grounding systems were installed to prevent electrical shocks or faults.

- Overload and short circuit protection devices were included to safeguard the equipment and operators.

Logistics and installation also posed challenges, especially due to the crane's size and weight. Transporting a 10-meter span crane requires careful coordination to avoid damage and ensure timely delivery.

Key logistical and installation solutions included:

- Breaking down the crane into manageable sections to fit transport vehicles and ease handling.

- Coordinating with local contractors to prepare a level and stable foundation before delivery.

- Providing detailed assembly instructions and technical support to the installation team.

- Conducting on-site adjustments, such as leg leveling and hoist alignment, to ensure precise operation after assembly.

Conclusion

The tailored 20-ton single girder gantry crane was successfully designed, built, and installed for outdoor use in America, meeting all the customer's key requirements for durability, reliability, and cost-effectiveness.

Customer feedback has been positive, highlighting:

- Smooth and consistent lifting performance under daily heavy load operations.

- Ease of operation and maintenance, minimizing downtime and repair costs.

- Durable construction that withstands outdoor weather conditions without degradation.

This project demonstrates how a practical, well-engineered gantry crane can improve workflow efficiency by reducing manual labor and speeding up material handling tasks.

Looking forward, there is strong potential for additional customized crane projects based on the customer's expanding needs.

We invite interested parties to contact us for:

- Detailed consultations to understand your specific lifting and site requirements.

- Personalized quotations tailored to your budget and operational demands.

- Technical support and after-sales service to ensure your crane runs smoothly for years to come.

Related Products

Affordable 10 ton double girder overhead crane with CD/MD hoist trolley, built for U.S. standards, ideal for construction and industrial lifting

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

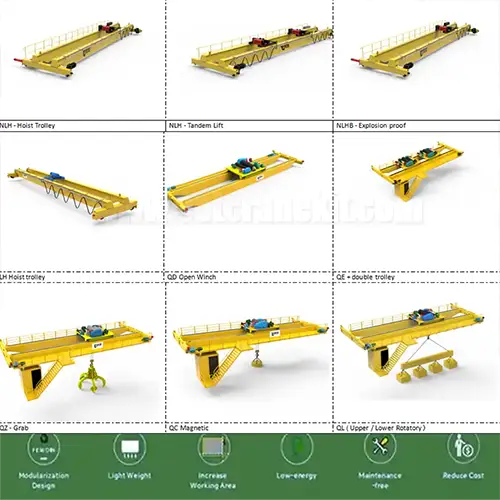

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch